What tools are used when laying bricks.

1) is used for evaporation from the tank of the solution, followed by its application on brick masonry and preliminary distribution over the entire surface.

Basic tools for brick masonry.

A-Quelma; b - extension for convex seams; in - extending

for concave seams; g - mortar shovel; d - hammer-korchak.

2) Trowel. It is used for a more accurate leveling of the solution on the surface of the brick, as well as it is convenient for it to fill the vertical seams with a mortar mixture and trim the excess solution from the seams.

3) tool used for cutting bricks In order to legend him the desired size or form.

4) Share. It is used to legend the seam of aesthetic species, while the size of the width of the width must correspond to the width of the seam being processed.

5) Mop. Mostly applied to finalizing the seams when laying ventilation channels. In particular, to clean the excessive solution protruding from the seams or, in the event of a shortage, for more complete filling of the seams, as well as to smooth the solution in the seams.

Tools for checking masonry quality (measuring)

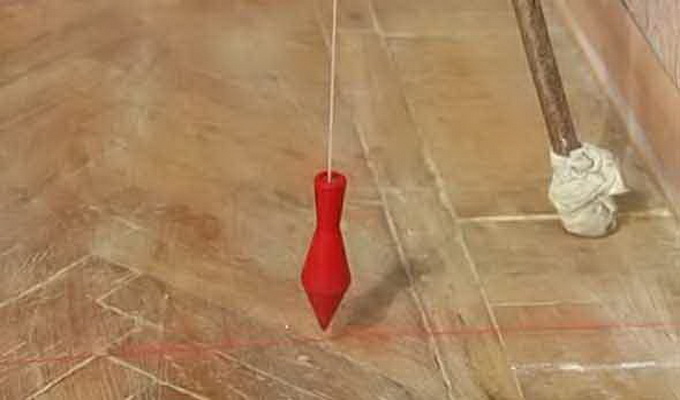

1) Plumb.It will be applied to recall the verticality of the brick masonry of all kinds. The plumbs are distributed to those that determine the verticality of the tier or within one floor, the weight of such plumbs from 200 to 400 grams. The following type of plumbing is used when determining verticality within a few floors, the weight of such plumbs varies from 600 to 1000 grams.

Measuring tools.

A - plumb; b - square; in - roulette; M - folding meter.

2) Building level. Industry produces, mainly in three sizes of three hundred, five hundred and seven hundred millimeters. The building level is designed to control the verticality and horizontal of brickwork. The design of the level includes glass capsules with divisions filled with non-freezing liquid and a small amount of air. One capsule is responsible for horizontality, the other verticality. Capsules have a slightly curved shape, due to which the air bubble shows the laying deviations in one direction or another.

3) Rule. Used to test the facial side of the masonry. It is made of wood or duralumin. The wooden rule has preferably 30x80 mm in cross section and a length of one and a half - two meters, duraluminum - has a H-shaped design and a height of 1.2 meters.

4) Wooden square. Used to determine the rectangles of the erected angles. It has a triangle shape with a straight angle, where one of the parties converging in a straight corner has a size of 700 mm, and the other is 500 mm.

5) Swarf cord. It is used where it is necessary to observe the accuracy of horizontal seams, as well as their thickness. The cord has in diameter of 3 mm, stretches between the coaches and the beacons during the masonry of the miles.

6) It is used to exhibit the rows of masonry, fixing the marks of the upper and lower edge of window and doorways, runs, jumpers plates of floors, etc. is made predominantly from the tree, has a view of a 50-to-50 and 70 bar for 50 millimeters and about 1.8 millimeters. - 2 meters, on which every 77 mm are marked with a serif. There are also metallic orders that have the same serifs. The laying is carried out in accordance with these serifs.

The order is attached to the wall with special fasteners, having a letter of the letter P and is crossed by special wedges. Mounts are placed every six or eight rows. The cozer-moor is attached to the order, which is rearranged as masonry. In the picture on the right

Inventory wooden order.

| See on site | |||

| Homemade | Simple greenhouse | Furnace Swedk | Greenhouses |

Masonry process. The masonry process consists of working operations performed in such a sequence: setting apartments; pulling the stiffness to ensure the correctness of the laying of bricks and rows; Feed and layout of bricks on the wall; shocking solution in the drawer; supply of the solution on the wall and allocation of it under the outer mile; laying outdoor verst; Distribution of the solution under the inner vest; Laying internal versts; Distribution of the solution under the eating; Laying chairs; Check the correctness of the laying row. The sequence of laying the mile can be different and depends on the dressing system and the labor organization method. In addition to these operations, bricklayers have to chop the brick, as well as to break the seams.

Tools and fixtures. Each operating operation in the masonry process is performed by certain tools.

The main of them are Kelma, mortar shovel, extending, hammer-korchak.

Trowel - steel blade with a wooden handle with a wooden handle on both sides - is designed for reclamation of the masonry solution, filling with a solution of vertical seams and trimming in extension seams.

Massive blade - It serves to feed and dismantling the solution on the wall, mixing it in the drawer.

Expands - Treat seams, i.e. give them a certain form. The cross-section profile and the size of the frames are selected in accordance with the specified shape and the thickness of the seams.

Hammer-Korfact - The mason uses the whole brick when cabing for incomplete and with brick tester.

Mop. - Designed to clean the ventilation and smoke channels from the solution protruding from the seams, as well as for a more complete filling with the solution and smooth the seams in the channels. On the steel knob, the rubber plate is fixed between the flanges with a size of 140x x140xu (12) mm, which is a worker.

The quality of the masonry is tested by control and measuring instruments: a plumb, level, rule, coal, cord-moor.

Plumbers consisting of a steel cone-shaped case, a twisted cord and an aluminum plank, serve to check the verticality of walls, simpleness, pillars and corners of masonry, i.e., to dry the masonry. Plunders weighing 200 ... 400 g are designed to verify the correctness of masonry on tiers and within the height of the floor, 600 ... 1000 g - to test the outer corners of the building in the limits of a height of several floors.

Building level Apply to check the horizontal and vertical of the masonry. Level length 300, 500 or 700 mm. The level of the level is from an aluminum alloy, two glass tubes-ampoules are strengthened on the housing, curved by a large radius curve filled with non-freezing liquid so that they remain a small air bubble. With the horizontal position of the bubble level, lifting up, stops in the middle between the divisions of the ampoule. The bubble offset left or right on this position shows that the surface on which the level is installed is not horizontal, and the more its slope to the horizon, the larger the bubble from the middle position is shifted. Due to the fact that the tubes are located in two directions, the level can not be checked not only horizontal, but also the vertical planes.

Rule It is a te -genged wooden rail with a cross section of 30x80 mm, a length of 1.5 ... 2 m or a duralumin of a special profile of a special profile with a length of 1.2 m, intended for checks facial surface masonry.

Wooden square 500x 700 are used to check the rectangles of the fixed angles. Metal squares from the corner profile are also used for stone works.

Roulette and folding meter - The measurement tools that place the axles and positions of the structures make control measurements of the masonry.

To ensure the qualitative implementation of stone masonry and improving the productivity of bricklayers use small-sized hand tools.

Vegetable brackets To secure the rush cord. The p-shaped brackets from the rod steel profile with pointed ends or from sheet steel (23, b) are fixed in masonry seams, and brackets from sheet metal They put on a brick, laid by plafhmy.

Intermediate lighthouses - Temporary linings that are installed under the steering cord so that it does not resist, in the form of a rectangular box or a welded frame. The beacons installed on the masonry through 4 ... 6 m, fix the position of the stretched fiber cord in the vertical and horizontal plane.

Templates in the form of wooden or metal lines intended for windows markup and door openings, marking of flue and ventilation channels and other parts of the masonry.

Cord - Packerel - Twisted cord with a thickness of 3 mm, which is stretching when laying the verst between their friends and lighthouses as a benchmark for ensuring the rectinity and horizontal of the rows of masonry, as well as the same thickness of horizontal seams. With the help of cord, the bricklayer determines which position should have each stacked brick in the mile.

Orders - devices from corners, pipes or wooden plates with divisions applied on them, respectively, the thickness of horizontal rows of masonry (77 mm - for single, 100 mm - for thickened brick). Spitches are designed to attach to them when laying a moisture cord and providing vertical and horizontal masonry rows. Metal orders up to 1.8 m long (for one "masonry tier) are used as angular, and wooden up to 3 m long (on the floor) as intermediate.

Corner metal orders serve as a template (for rows of masonry), which proper installation (on a plumb) and hard consolidation provides vertical masonry. Correct the brackets with the screw clamps, or hooks inserted into the holes for fastening the gentle cord to the order, and the other end in the laying seams. The orders are installed before the laying on the corners of the building in the places of the walls of the walls, and on the extended areas - every 10 ... 12 m.

When installing a metal friend, one bracket-clamp 2 is fixed in the vertical seam of the masonry, and after 3 ... 4 rows of masonry - another. Then, between installed brackets-clamps and masonry insert the order and adjusting screws pressed it to the masonry and adjust the vertical position. The correct installation is checked with a plumb. After reconciling, the orders are tightened by the steering cord. Remove the order of the rule, mounted at the rifle of the screw clamping clamp. Rotation, the groove weakens the bracket and remove from the seam.

Intermediate wooden orders - It is wooden rails with a cross section of 50 x 50 or 70 x 50 mm, up to 3 m long, on which divisions (serifs) are applied every 77 or 100 mm, respectively, the thickness of the masonry row. In size 77 (100) mm enters the height of the brick and the seam thickness of 12 mm. Intermediate spitches are used to mark the rows of masonry, fixing the nose marks and top of the window and doorways, jumpers, runs, plates of overlaps and other elements of masonry.

To the surface of the walls, the coaches are attached so that the parties on which the rows of masonry are placed inside the buildings (in the direction of the bricklayer). The order is fixed in masonry P-shaped steel holders 10 in the form of a bracket with a transverse bar. Do it as follows. In the horizontal seams along the masonry every 6 ... 8 rows in height, bracket holders are introduced, having their one over the other. Staples should enter the wall with their ends and a transverse bar. Setting over the second holder, one or two rows of bricks, insert the order in the brackets and fasten it with wooden wedges. The cozer cords are fixed with a double bracket cord, which is held on the rail of coaches by tensioning the moorings and as a result of friction between the bracket and spoke. The order is removed along with the holders, without removing the wedges. To do this, it is gently swing in the plane perpendicular to the wall surface. Holders overcoming the resistance of the solution come out of the horizontal seams of the masonry, and the coach lift up along with them.

Fig. 31. Tools for brickwork:

a - combined Kelma; b - mortar blade; in - bouts for convex and concave seams; Molotok-Korchka; d - mop; E is a pneumatic jackhammer; Well - jumper; W - Skarpel

Measuring Tools for determining the quality of masonry: plumb, meter, square, level, rule. Set of a mason tool, see Table. four.

Table 4. Mason Tool Set

|

Tool |

Four |

||||

|

Massive shovel |

|||||

|

Hammer-Korchka. |

|||||

|

Plumb 400 and 600 g |

|||||

|

Extending |

|||||

|

Meter folding |

|||||

|

Wooden square |

|||||

|

Merchant twisted cord |

|||||

Fig. 32. Measuring tools for masonry:

A - plumb; b - folding meter; in - roulette; g - square; d - wooden rule

The use of the basic tool in full tool significantly improves the quality of its work and reduces its execution. The mop is used to clean the ventilation channels from the solution protruding from the seams or to fully fill the seams with a solution (Fig. 31, e). Level (Fig. 33, a) is used to check the horizontal of masonry, it can be wooden and metallic. The level is the non-freezing fluid, and the horizontal and vertical planes are checked on the position of the bubble. Level length is about 50 cm. When working with such a level, it is necessary to install it on the bar, the length of which is 1-1.5 m. In soviet times A set of tools with the most necessary for the bricklayer devices was produced in a special bag (Fig. 33, b).

Fig. 33. Fixtures for the construction of masonry:

A - level; b - bricklayer bag; B is a co-order and fastening of the coaches to the masonry (1 - rail; 2 - holder; 3 - wedge); G - Brick Pallet

Stone masonry is not a simple, so to keep the constant thickness, the correctness of masonry in the rows, to withstand the exact direction requires a number of devices: cord-moor, spit, and much more. The order is the usual rack with a length of 3 m (Fig. 33, c). The order is the labels every 77 cm (why it is 77-cm - here the height of the brick row is 65 mm and the thickness of the horizontal suture of the solution is 12 mm). In addition to wooden regions, metallic deacions are used. The whar is tensioning between the coaches and will be from the wall, taking into account the lining of the brick (Fig. 34, a). The vegetarian is performed from a twisted cord with a thickness of 3 mm and its purpose to ensure the rectinence of rows of masonry. Sometimes there is a need to disassemble stone walls, punching the furrows for the required communications. For these purposes, pneumatic jackhammers, scarpels, jumpers, pixels with solid metal tips are used (Fig. 31, e, z, s).

Fig. 35. Template for masonry Arch, Arches:

1 - cord; 2 - the pattern - the square; 3 - Wedges

3.

Preface

The bricklayer tool in many determines the labor productivity of the worker. From what devices and tools will use a worker, the quality of the masonry and the speed of the process depends largely.

The bricklayer tool in many determines the labor productivity of the worker. From what devices and tools will use a worker, the quality of the masonry and the speed of the process depends largely. All tools for stone work are divided into instrumentation and manufacturing equipment. In addition, it is worth taking care of an individual aid kit and devices for cleaning the construction trash.

The bricklayer tool in many determines the labor productivity of the worker. From what devices and tools will use a worker, the quality of the masonry and the speed of the process depends largely. All tools for stone work are divided into instrumentation and manufacturing equipment. In addition, it is worth taking care of an individual aid kit and devices for cleaning the construction trash.

For simple work With a stone, just twelve tools are just enough.

1. Kelma for concrete and stone works (trustees); 2. Shawnya Poland; 3. Safety glasses; 4. plumb (forge); 5. Sinky; 6. Roulette; 7. Construction level half-meter; 8. Water level; 9. Coil with twine; 10. Flat metal brush; 11. Fluster brush (or brush); 12. Hammer (scolf, twovet, or hammer-cam).

Often the released tool needs to bend, so each of them will be described whenever possible with advice on its modernization, refinement or correction.

What is Kelm and photo tool

What it is - Kelma - asks an unfair man in the street, and a lot will surprise that this word bricklayers call ordinary trowel. Kelma for concrete and stone works, first of all, should be with the metal end of the handle. Next, the Kelmma acquired should be slightly folded in the leg of its handle. The plane of the Kelma blade should not be parallel to the knob of the Kelma. The direction of the Kelma handle should go to a sharp corner with the plane of the blade (blades) of the Kelma. That is, somewhere in the imaginary thirty-bentimeter space from Kelma, both of these planes or directions must cross under an acute angle. After such an improvement, the solution remaining on the Kelma when hesitating the stone of the Kelma will slide or splash down, bypassing the arm of the bricklayer. Further, if necessary, you can subjected to the canvas (blade) of the cells in order for the solution better from it better.

Photo what kind of Kelma is presented below:

Tools for masonry: sledgehammer, goggles, plumb

Shawood is sharply desirable to have such a weight so that Mason can make it the fastest hit. Therefore, this manual tool is a bricklayer needs to choose forces as a male or a tern in ancient. The center of gravity directly the most metal dwellers must coincide with the axis of the sledgehafts, where the handle is inserted. Many sold sledgehammers do not meet this requirement, which in turn sometimes leads to the breaking of a sledgehammer from the hand with a stone.

It is necessary to work with the eye sledgehammers additionally: it is so that the hole of the eyes in the upper part of the blanks is wider than at the bottom. This improvement is very significant, as it makes it possible to do without a wedge in the handle of the sledgehammer. The role of a wedge will perform the wood of the handle - expanding in the upper part and repeating the shape of the spreading eye.

The handle of the sledgehammer is better made from the wood of elm, kizyl, acacia, cherries or cherries, or from olive solid rock. The tree must be two-three-year drying. It is worth noting in advance that end of the wood blank, which is closer to the ground (in a living tree). This end of the workpiece must then be at the top of the pens of the sledgehammer - where the handle leaves the busty holes of the eye. This is then done to subsequently - with some drying of the wood of the handle - it was possible to restore its dense position in the eye by soaking in the water. The fact is that at the top of the handle of the sledgehammer there will be wider capillaries of wood, so they will stronger water and swell. The billet for the handle itself, first of all, should be a banal meter segment of the logs, cracking from drying in a thermal place. Then the log disperse on its large cracks, which will give their "lamps" to future handles.

As can be seen in the photo of the tool of the bricklayer, the length of the handle is selected individually, so that the sledgehammer does not touch the Earth when the bricklayer is lowered by a sledgehammer. The lower end of the handle is desirable to round up, and under the fingers you can make small recesses. The cut-off handle is sandpaper, lacquered and subsequently passed through the eye from top to bottom. The end of the eye is screamed, so that one or two centimeters remain.

Steel for sledgehammer is desirable to have the so-called instrumental, brand U-8 or close to it.

When the sliced \u200b\u200bsledge hammer should be made by building mittens to mitigate the impact on hand.

Protective glasses would be good to have with regulated rubber straps. If such straps are splitted in the nape region, they increase the degree of fixation of the glasses on the headwear of the wizard. Glass glasses should be made of glass - plastic glass tend to lose their transparency due to acquired scratches. Glasses must be worn every time with a bar of stone, is one of the rules of the stone of the stone. On average, during the summer season, one stone fragment flies directly directly into the eye.

The plumb is desirable to have a two-chagramic, centered. Such plumbings can be stocking in the amount of four - five pieces. One of the plumbing can be equipped with antennae from a thin fishing line (0.3 mm), which is done and fixed in a thin hole, drilled across the plumb - in the middle of its length.

Three centimeters leaving a plumb to three centimeters will stop the unwanted rotation of the plumb, which is due to the twisted fibers of some cords.

Stone Tools: Sink, Roulette, Level

The culprit is called a device intended for performing seams with a form of one or another type. In more detail about all types of exfoliations, the head of the "Switching or Types of Longs" will introduce more details.

Roulette is desirable to have with such a metal web, on which divisions are found, and not applied paint. For small volumes of work, a five-meter roulette is sufficient.

The level of construction semi-meter must be purchased reliable, with a duralumin village. The tubes in which oil with an air bubble (level pointers) must be made of glass and have parallel walls. In this regard, it is impossible to trust the levels of Polish or Turkish production. After purchasing the level you need to check and, if necessary, to independently set. First you need to check and set the horizon level pointer. To do this, on some wall with a water level, you need to mark the two horizon points at a fortycantimeter distance from each other. After that, to drive into them one by one identical carnation, which then need to put the level of the workpiece and look at its central pointer (glass tube). If the air bubble is in the middle of the tube, then the horizon of this level is set correctly. At the same time, the level must be checked again by turning it into 180 degrees. If the air bubble deviates from the center of the tube, then the level must be adjusted. To do this, you need to twist the bubbles in this middle pointer. Powder will not be strictly in the middle of the tube (after that you need to double the horizontal, turning it into 180 degrees).

The plugger of the plumb is checked in the same way, only cloves are driven along the plumb line (Western), hung on a nail higher. The plugger of the plumb is in one of the end of the level. At the opposite, the end is an angle pointer with a characteristic degree scale around it. This pointer is used when the masonry is made at a given angle, of course, while the tilter is set according to the template or on the corner wall.

Water level. This is a hose with glass or plastic transparent tubes at the ends. The water level is intended only for one - the definition of the horizon line in a particular place of construction, on a particular height of the specified height. Often, as a water level, use a transparent hose, for which no longer needed tubes, although the transparency of such a hose leaves much to be desired, especially when it is not new. It is better when the water-level glass or plastic tubes have a diameter of at least two centimeters, since in narrow tubes water due to the surface tension creates meniscus - curvature of its surface. This little circumstance should be considered when using such a level. Tubes with a diameter of two centimeters have a small meniscus, located only at the edges of the water surface. Of course, you can use water levels with narrow tubes, but in this case you will have to set the horizon line marks either by the lower level of meniscus, or at the top level of meniscus - by agreement with the partner. Good vision in this matter is a very unable factor. When applying the desired levels of the horizon level, the wizard's view should have perpendicular to the wall plane.

Water level, if it is homemade, it is desirable to provide another piece of the same hose that can be blurred with a glass tube, which will save the level in the "charged" state during its storage.

The coil with a twine can be replaced with a coil with a fishing line.

More tool bricklayer: brush, brush, hammer

Flat metal brush can be slightly rounded. It is needed to clean the stone masonry from the excess solution protruding from the seams of masonry. Such a brush can be sued with a regular soldering iron in the locations of the wire from the clamp. This will increase the service life of the brush before its full abrasion.

A stone masonry tool is used to remove dust or particles of a dried solution from the surface of the stones and from the seams of masonry after processing them with a flat metal brush.

Hammer (scolf, twovet, hammer-cam). An ordinary hammer can be the last of the most required tools For works with a butte stone. Even better than the hammer from the tool steel U-8. The hammer is needed for a vaccine and plausing of butte and other stone. If there are more special tools - a scaller or twovet, as well as a hammer-cam produce all work with a stone will be faster and more convenient. Folding the hammer can be made similar to the bridge of sledgehammers. In addition, the hammer itself, like a dweller of the sledge hammer, can be accumulated from the bottom with thick copper wire, the ends of which you need to drive into the pen. This will not crawl with a hammer with the handle down.

In addition to the listed, the bricklayer needs the most common building tools to mix the solution or working with wood. Not least it is worth thinking about a personal first-first aid kit, consisting of green, bandage and patches.

The difference between the wizard from the Shabashnik begins with his relationship to his tool. About all sorts of special tools information should be sought in a more narrow-profile literature.

In order to ensure the laying of the brick was a good one, the following tools will rise in work:

Korkie. It is used to burst the frozen cement. In return, it is allowed to use Kirko-Moth. It is distinguished by the fact that both of its end are driving like a hammer. And in the blades, one of them remains sharp. And it is formed in the form of a slightly curved "beak". Weigh construction kirk 3.4 kg. The material from which it is made is high-strength iron.

Shovel. It will be necessary to calculate concrete to the huge area, preparation cement mortar, garbage cleaning with construction site. Forms shovel: Pointed (bayonet), Soviet. For the device of the walls and partitions from the brick, any of them will be used.

Spade. This tool is allowed to apply for the preparation of cement-sandy solution. The length of its blades is up to 300 mm, and the width is 250 mm. In order to the intercession, it was comfortable to work, the cross section of a wooden or plastic handle should be no more than 1.5 cm.

Trowel. Builders often call it in a special way: a trowel. This tool is used to calculate the "bed" from the cement-sand solution and leveling the raw surfaces. It consists of 2 parts: the handles and the metal triangular plate, combined with a curved rod. The shoulder blade has a length of 100 mm and is made of good steel, and the handle is wooden, length, up to 8 cm. The average weight of this tool is 0.3-0.4 kg.

Fishing. It is necessary in order to lack the laying had a distinct and positive drawing. It seal masonry seams. With the support of this hand tool, it is allowed to give every form: convex either with deepening. The form is given at that time until the cement-sandy solution is dry. Before starting work, the work surface should be cleaned from small splashes of brick masonry solution. Make it is allowed by any suitable rag or brush. Initially, the seams located vertically, after that - along the line of masonry rows. This tool is filled from 2 parts: a handle, a length of 70 mm and a curved metal plate with a length of 100 mm. If this is a tool to moisten with water, it easily moves on the surface of the brick masonry.

Hammer-Kirchka. It will be necessary for the ring of bricks and its cutting.

Rule. They use when it is necessary to distribute a smooth layer on the surface of the wall of brickwork applied to it. The rule is permitted independently made from a polished wooden plank. The most comfortable size for work is 0.2 / 1.1 m.

Iron brush. It will be necessary in order to make the walls and the working surface clean. She is cleaned lumps of frozen cement mortar.

Buchard. Necessary in order to make notches. Executed in the form of a heavy hammer, at both ends of which there are iron teeth.

Halfury. We are necessary for leveling cement mortar. This tool is allowed to make self-smooth smooth boards. The best size: 70/15 cm.

Mason tool:

- Massive shovel

- Trowel

- Hammer-Korchka.

- Opening

- Mop.

- Plumb

- Building level

- Rule

- Wooden square

- Swarf cord

- Wooden order

Massive shovel

Designed to feed and dismantling the solution on the wall. The shovel also stirred the solution in the box and smash it between the versts under the taught.

Trowel

It is a steel blade with a wooden handle, polished on both sides. It is intended for recreaking the solution on a masonry, filling with a solution of vertical seams and trimming in the seams of an excess solution.

Hammer-Korchka.

It is used to cut a whole brick on halves, quantity, etc., and also for chipping bricks.

Opening

Serve for the processing of seams - with their help, the seams give a certain form. The cross-section profile and the size of the exfoliations must correspond to the specified form and thickness of the seams.

Mop.

Designed to clean the ventilation channels from the solution of the sutures of the solution, as well as to fully fill the seams with a solution and burn them. On the steel knob's steel handle, a rubber plate is fixed between the flanges with a size of 140 x 140 x 10 mm, with which the process of stripping and smoking is carried out.

The following tools are used to verify the quality of masonry and are called instrumentation:

Plumb

With it, the verticality of the walls, simpleness, pillars and the corners of the masonry are evaporated. Weighing 200-400 g, we check the correctness of the masonry on tiers and within the height of the floor; Weight plumbing 600-1000 g are served to check the outer corners of the building within a few floors.

Building level

Produced with a length of 300, 500 and 700 mm. Used to check the horizontal and vertical of masonry. On the level of the level, two glass tubes-ampoules are fixed, curved by a large radius curve filled with non-freezing fluid so that they remain a small air bubble. If the level is in a horizontal position, the bubble, lifting up, stops in the middle between the divisions of the ampoule.

The bubble offset left or right on this position shows that the surface on which the level is installed is not horizontal, and the more its slope to the horizon, the larger the bubble from the middle position is shifted.

Due to the fact that the tubes are located in two directions, the level can not be checked not only horizontal, but also the vertical planes.

Rule

The separated wooden rail with a cross section of 30 x 80 mm, length 1, 5-2 m. It is also made of duralumin in the form of a n-shaped profile with a length of 1, 2 m. This rail is checked with the facial surface of the masonry.

Wooden square

It has a length of the parties 500x700 mm and is used to check the rectangles of the fixed angles.

Swarf cord

A twisted cord with a thickness of 3 mm, which is stretched with a masonry of the verst between their friends and lighthouses. The fiber cord is used when laying as a guideline to ensure straightness and horizontal rows of masonry, as well as the same thickness of horizontal seams. Using the cord, determine which position should have each stacked brick in the verset.

Wooden order

It is a cross section with a cross section of 50 x 50 or 70 x 50 mm and a length of up to 1, 8-2m, on which divisions (serifs) are applied every 77 mm, respectively, the thickness of the masonry row. Size 77 mm is composed of brick height (65mm) and seam thickness (12 mm). The apartments are used to mark up the rows of masonry, fixing the nose marks and the top of the window and doorways, jumpers, runs, plates of overlaps and other elements of the building. It is set to the outer surface of the walls of the walls in such a way that the parties on which the masonry rows are placed inside the building, where the masonry is carried out. The order is fixed to the laying by steel holders in the P-shaped form. This is done like this:

In the horizontal seams along the masonry every 6-8 rows, the heights are introduced by solutions, having them one over the other. Staples should enter the wall with their ends and a transverse bar. Setting over the second holder, one or two rows of bricks, insert the order in the brackets and fasten it with wooden wedges. The cozers are fascinated to the coaches, which lead masonry. The pitch cord is installed and rearranged by a double bracket, which is held on the rail of the coaching coil tensioning and as a result of friction between the bracket and spoke.

The order is removed along with the holders without removing the wedges, for which it is gently swing in the plane perpendicular to the wall surface.

Holders, overcoming the resistance of the solution, come out of the horizontal seams of the masonry and the coach raise up along with them. Inventory orders are also made from a metal corner profile of 60 x 60 x 5 mm. On the rebax corner of the spitches are sliced \u200b\u200bin the division of a depth of 3 mm every 77 mm or drilled holes for fastening the pierce cord.