We were lucky to be born and live in a country in which excess exists water resources. Waters, indeed, grabs, and not all appreciate this most important resource for humans. It would seem that the crane opened and use. But in our cities the quality of tap water is far from perfect. Another thing in the village to try well water. It is quite complete taste, such water can be easily quenched thirst. And what crispy cucumbers are suitable for the winter, if the well water is used!

In our villages you can meet two are not so far from each other well. In one take water only for watering, and then the inhabitants of the nearest homes. The whole village goes to the second well on the water. You start asking why it happened, and it turns out that in one place they simply drunken a well where the aquifer should be. There is water in the well, but no one is happy with her. And elsewhere I was looking for water "Dedovsky" method - and in the morning to the well, a small queue is going. Between the wells in direct from the power of 300 meters, one aquifer, and the quality of water is completely different. So where and how to look for a place under the well? And how to build a well in the country with your own hands?

Folk references to the proximity of groundwater. How to search and not mistaken?

Folk signs can suggest whether aquifer seals the surface:

- Water in basements after melting snow.

- Thick fog in places where there are no reservoirs.

- Moss on earth.

- Abundance of midge after sunset.

- The hot dry summer grass remains green.

- Reservoir nearby.

You can not believe in signs, and then will help you decide on the choice of place to dig a well two. famous method. The first is drilling. There are geological maps of water reserves. If your site is located on the estimated area of \u200b\u200bthe aquifer, the drillers will reach the water. Only guarantees that it can be used for drinking and cooking, no one will give you. It will be necessary to give a test for analysis. However, even the positive conclusion of the SES does not mean that you will have "delicious" water on the site from the well.

Another way to find a place for the well - biolocation. Previously, they were looking for water with two ventilation twigs. Now we use brass wire with a diameter of 2 mm. Take two half-meter slices of wire, measured 10 cm for handle and bend at right angles. With such "devices" in each hand bypass the site. The frames can not be clamped in the hands tightly, they should spin freely. When they themselves begin to move, then water is close. As in the children's playing "hot - cold." Burned and crossed both frames - the place for the well was found. With all the seeming simplicity of this method, it is better that the water in the method of biolocation is looking for an experienced person who has found a place for one well. In any case, the cost of a biolocation method is much cheaper drilling.

Important! No need to confuse the well equipped on the site of a bored well, with a well, which is naturally filled with water. In the old days, the wells were equipped only in such places. In the first case it is a well well, in the second - water well.

Classic water well well doodle

You are lucky, and the site found for the "right" well - water intake. Burning the well does not have to, the water itself will fill the waterball.

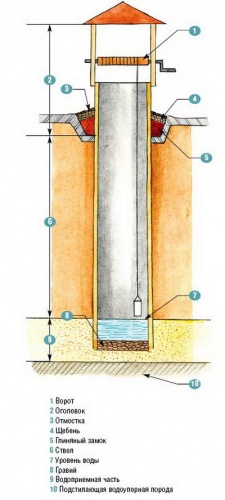

A wells made up of three main parts: waterborg, barrel and headband. In the catchment collector (it is also called the reservoir) water is going and is located. The barrel protects the water from the sprinkling soil. Now the trunks are made from concrete rings and in shape they are round, and before the squares were made of logs. Appointment of the head - protection of water from dirt and precipitation (which is not a place in one water collector with well water), as well as from freezing.

Get ready for the fact that digging a pit will have to hand, as hundreds of years ago. We are preparing the tool: a bayonet shovel with a short cutter (in a hole with such a cut-out to dig more conveniently), a small lomik, buckets, a solid rope, with which these buckets your helper will pull out the staircase to the depth of the pit and a flashlight. Choose a flashlight that can be fixed on your head.

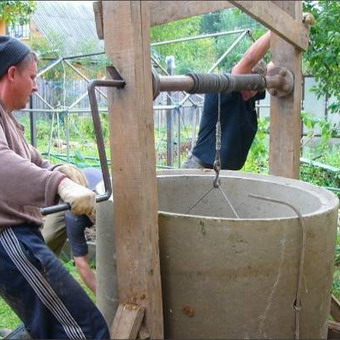

Important! Concrete rings for the trunk of the well buy and bring after the pit is dug. Pay for a simple manipulator for the time you need to excavation, assured, and lower manually rings in the ground will not work. Rings are better to buy from the chamfer, such a design is more expensive, but it easily adjacent when installed. The first ring is desirable to buy a cone-shaped form or with a metal knife - this form will simplify further blockage. When installing the rings, constantly check the vertical of the walls using a plumb.

We begin to dig a hole under the well centimeter size by 30 larger ring diameter. Delete, exporting the ground immediately to the side. Carefully follow the shredding of the walls. If the walls of the pit "hold" - everything is in order, we continue to work until water appears.

Lower the ring and continue to dig. Rings under his weight will be seen in the ground. After installing the first rings, it is necessary to shout at the height of two.

With severe sweeping of the soil, this method is dangerous. ROOM meter in depth of the pit and omit the first ring. We continue to remove the soil and deepen the pit. Then we put the second ring and again continue to dig. And so until the desired depth of the trunk is achieved. Water and dirt from the pit must be pulled off with a mud pump or pull out buckets. After the appearance of water (it was then that the most difficult stage of work begins) to dig, it is necessary to dig up on a couple of meters deep into a pair. Try to choose the soil from these last meters as soon as possible.

So we came to the bottom. It remains to lean the dirt and close the seams between the rings. Seams are made clay mortar Or make a hemp (as an option - the scenar sawn rope) and shrink the cement composition. The walls of the rings are fixed with the brackets and paint oil paint. A layer of gravel of centimeters 10 is added to the bottom - it will serve as a natural filter.

Types of scene for well

The queue of the device around the well has come. Associate a piece of concrete, clay or make the so-called soft gentle. Remember that the breakfast must be done necessarily, otherwise, in the spring, when the soil is frozen, the dirt will fall into the wellblock.

Traditionally, the scene is made of clay (clay castle). A grip to 2 meters fall around the rings around the rings, and clay falls back in its place. Clay is required to thoroughly tamper. From above, the clay castle is protected by a layer of gravel or sand. Three years will occur sedimentation of the rings (shrinkage), and the clay layer will have to the spring. The quality of the scene is checked by the purity of water in the well.

The soft gentle is suitable from sand and waterproofing film. To the depth of a little more depth of the fruit of the soil, the Earth is selected and the sand is falling asleep. The sand is rambling, then covered with a film. The edge of the waterproofing film is started on the top ring of the well barrel, carefully pressed and fixed with a metal ribbon. The sand layer is covered with gravel, decorative stone, plant grass planted.

![]()

Device headband

The most pleasant and creative stage of work is the device of the head. Of course, you can restrict ourselves to a knocked outboard from the board, which can protect the water from dirt and precipitation. But it is unlikely that such a "house" will decorate your plot. Yes, and your works should be rewarded with a worthy of beautiful completion. In stores you can buy cute ready-made "houses" for adopts of wood, metal, plastics. As they say, for every taste and wallet. However, what can be compared with the process of creativity? Mother himself original design And to realize. This is not dirt to pull out of the deep pit!

Wells in Russian villages are traditionally drawn up in the form of a church. But after all, you can come up with another solution for the decoration of the head. Such a well will decorate your summer cottage and will reward after work with delicious and cold well water.

Today, the overwhelming majority of human settlements of our country are associated with the system of communications that best satisfy any needs of the population. The provision of freshwater inhabitants is carried out by means of centralized water pipes, whose pipes extend to thousands of kilometers. However, in some cases, access to water supply systems may be partially or fully limited. But even if your home is connected to the water pipeline, interruptions may occur in its work due to accidents at the substation. And the quality of the water supplied through the centralized system often does not comply with the requirements of the consumer. An alternative source of clean fresh water for owners of private houses and cottages can be a well. This construction for many centuries was one of the most important strategic objects providing our ancestors to the lively moisture. To date, the wells are not so relevant, but many daches simply cannot present their site without this autonomous water source.

In order to build a well in the country with your own hands, you need to have certain knowledge and construction skills. Like any other type of work, the procedure for the construction of the well has its own specifics that we will try to tell in this article.

Some information about groundwater

Through the wells, access to groundwater, which are formed by penetrating atmospheric precipitation and surface water in the soil. The source of groundwater protrudes from the surface of the Earth the aquifer, which is maintained from below the waterproof layer. Such a reservoir does not have pressure, so non-permanent earthwounds given to them. Thus, the water level installed in the wellhold shaft usually corresponds to the upper boundary of the aquifer.

There is also a so-called rigor - groundwater, located very close to the surface of the earth on the waterproof layer. As a rule, it is formed in a period of abundant precipitation and disappears during drought. The ripper is not suitable for water supply, since the water forming it has not yet had time to filter the soil and therefore too dirty. The mold of the well needs to be isolated from the rigor.

Wheel selection

Before proceeding with the construction of a well with their own hands, exploration should be held in order to determine the presence and depth of the occurrence of the aquifer. In this case, water level in the neighborhood of well mines will be the most indicative in this case. With a large probability of the characteristics of the soil and aquifers on your site will be identical. If there are no wells and wells nearby, then, most likely, you will have to turn to the hydrologist. To give an unequivocal answer to the presence of groundwater in a particular place will help the drilling of an exploration well, but this is a fairly costly operation, and not everyone agrees to it.

Of course, there is a lot of indirect signs that testify that there is an underground source at a small depth. With a high probability, no problems will occur during the construction of the well not far from natural reservoirs. An explicit sign of groundwater presence can also be frequent subtopers of the cellar or basement during the melting period of the snow. However, all these signs do not give a 100% guarantee, and therefore there are certain risks.

When choosing a place for a well in the country, it is necessary to be guided and common sense. Such sources of groundwater pollution, like interrupted pits, livestock yards, restrooms must be at least 25-meter removal from the future buildings. It is not recommended to build a well on the shores of water bodies and slopes of ravines.

Do I need permission to build a well in the country?

According to Article 19 of the Law of the Russian Federation "On Subsoil", the owner of the land plot has the right to build a well to the first aquifer without coordination with any instances. However, in some regions, local laws governing this sphere can be used, so before the start of work does not interfere with the regional legislation. In any case, the owner of the country area should ensure the safety of work, as well as compliance with environmental protection requirements.

Safety technique

Work on the construction of the well with their own hands are conjugate with the risk of injury. In this regard, you should not neglect the following simple precautionary measures:

- employees descending into the Mine Well, must necessarily wear protective helmets;

- the device for lifting buckets with the soil should be reliable - ropes must have the necessary strength, fasteners should be periodically check.

Device of the well

Any mine well consists of the following main parts:

- headband - element of a well, towering over the ground;

- the trunk is directly the very mine of the well from the ledge to the static water level;

- the water treatment part is a part of the well filled with water.

The following types of wells are distinguished: incomplete, complete and complete with ZUMPF. Incomplete, or imperfect design assumes that the bottom of the well is located above the upper boundary of the waterproof layer, and it means that the mine is filling with water occurs both through the bottom opening and through the side walls. Full, or the perfect well relies with its bottom to the underlying reservoir, and the water in the mine comes only through the side walls. Well with ZUMPF provides for the deepening of the mine in the aqueous reservoir in order to obtain an additional reservoir for water.

One way to increase the volume of the underwater part of the well is the expansion of the mine section below the static water level. As a result, the so-called tent is formed. It is usually made at the height of the aquifer of more than 2-3 meters.

For individual use, the imperfect structure of the well is most often choosing, as it is most simple in manufacturing and completely covers the daily need. At the same time, the mold of the well is not very deepened into the aquifer, since the underlying water is practically not involved in the fueling of the well. The cross-sectional area of \u200b\u200bthe mine is also trying to make minimal, because the gain from its increase is insignificant, and labor costs and consumption of materials may increase at times.

The bottom of the imperfect well, as a rule, lay the three layers of gravel or rubble forming a bottom filter. For the lowest layer, the thickness of which is usually no more than 100 mm, use the smallest stones. Each subsequent layer is formed from larger grains, rather than apply in the previous one (size 6-8 times more). Sometimes the boards with holes are placed on the bottom of the well, and the filtering layer of gravel is poured on top. A similar design makes sense if the aquifer is highly dissolved and water comes abundantly.

What material to make a well in the country

Most often, a wooden log house or concrete is used to form a well barrel. Less frequently used brick and natural stone. Each of these materials has its advantages and disadvantages.

Tree - widespread material, easy to handle. It is used to build a well from time immemorial. Made by technology Wooden log house can serve several decades, and even a century. From wood you can build a well mine of any shape and sizes. Wooden well can become not only a source of drinking water, but also decorative elementwho will complement landscape design Plot, giving him the charm of the old days. We will take their high cost and complexity of installation to disadvantages from wood.

Concrete wells have good strength characteristics and are also rather durable. The disadvantages of the use of concrete rings should include a high probability of tightness in the place of the joints, as a result of which the soil from the upper layers of the soil can fall into the mine. Laying the solution between rings does not always help in solving this problem. Another minus is a large mass of the rings, almost eliminating the possibility of their installation without using a special crane. Way out - monolithic concreting Barrel using formwork.

Tool for building a well

Despite the rapid development of technologies, currently there are not so many devices that could significantly facilitate the construction of a classic well. In most cases, the main work will be performed by the old Dedovo way. We give a list of that tool that will be useful:

- shovel (preferably spernaya);

- ladder for descent to the mine;

- buckets for garbage removal;

- device for lifting buckets;

- carrying with extension to lighting the mine;

- pump for pumping water.

In addition to the above items, depending on the type of well, the mass of other tools may be needed. For example, assembly wooden sruba It is difficult to imagine without an ax, hammer, hacksaws, electric drills, a special drill under holes for brazening, electrourub. For wells made of concrete, brick or stone will have to cook cement mortar, Therefore, it is not necessary to do without a special container and spatula. The list of tools is likely to expand at times when you proceed directly to the procedure for making a well with your own hands.

Construction of a wooden well in the country

So, you decided to build a well on the cottage from the tree. Where to begin? First of all, it is necessary to decide on the wood of wood. The most sought-after material is still oak - it has the necessary strength and durability. Oak logged in water can maintain its integrity over several decades, the surface part will begin to collapse no earlier than in 20-25 years.

A little less often for the construction of the Mine of the Well, an HRB, larch, alder, Osin, Elm. Other breeds either do not differ in durability, or give water an unpleasant smell or bitter flavor.

Wooden logs (or bars) for the future well must be carefully selected and is defined in a certain way. It is not allowed to use rotary forests, as well as the infected wood or mold of wood. Before assembling the workpiece, it is recommended to dry thoroughly. You should not leave them for a long time on the street, since under the influence of sunlight and atmospheric precipitation they can crack.

The well log house can be collected from solid logs, timber or plates (dried in half logs). As a rule, the cross section of the shaft is a square with a side of 700-1400 mm. To build it, it is advisable to use logs with a diameter of 150-200 mm, a ram 150x150 or a plate of a log with a diameter of 200-220 mm. The log house is first assembled at the top, the crowns are placed. Then there is a disassembly and installation directly in place.

The crown crowns must be carefully adjusted to ensure the tightness of the structure. The side of the billets facing inside the cut should not have burrs, cracks, cleavings. To eliminate all defects, it is recommended to be treated with electroveank. In the corners, the crowns are conjugated in the paw without a rest with a native thorn or without it. The conjunction of the crowns between itself is carried out by force.

Installation of a wooden sruba

Installation of the conductive log in the mine can be carried out in three ways:

- construction of the design from the bottom;

- build up from above with gradual lowering of a church;

- building from below.

The first method is used in the case when the depth of the mine is small (up to 6 m), its walls are quite strong and the risk of their collapse is minimal. Works begin with digging pits to the entire depth of the future well. Then the base is installed on the bottom and the entire subsequent crowns are mounted on it. To avoid the likely collapse of the shaft walls during the work, they can be temporarily strengthened.

The descendant method will be applied with great depth of the well. Initially, the mine is digging a depth of 3 meters or a little more, then the log house is collected in it by the method of increasing from the bottom until it is higher than the level of the Earth on 3 crowns. Next, the sedimentation of a log is carried out by dug up under it soil. First, the soil is removed in the middle of the sides of the cut, and the lining is installed in the vacant space. Next, the angles and lining are knocked out. Thus, there is a gradual deposition of a church. If suddenly the design is stuck in the mine, then it is possible to deposit it using shocks applied on the upper crown. In the event that it does not help, a heavy load falls on the log cabin, for which it is pre-flooring from the boards. If the actions undertaken were not crowned with success, the log house is increasing from below.

The method of increasing the cut from below is that along the entire length of the well every 4-5 the crowns are made by the crown in the "fingers", which are laid in special horizontal grooves in the soil. Speakers for the dimensions of the chub "Fingers" in the excavations are pressed up and then we are twisted. Thanks to them, the cabin is securely fixed in the trunk of the well mine, giving the opportunity to continue building the structure down. A similar way to install a church is not always applicable. For example, in a loose ground, it is impossible to make enough durable lads for "fingers".

The real misfortune for the builders of the well can be floating. They are constantly embossed in the place of the new weight of the breed, thereby significantly reducing the speed of work. It is possible to isolate the mold of the well from the swimming pool with the help of a sheet - the walls from the boards bonded with each other with the help of the corners. Depending on the intensity of floors, the design of the tongue design may be the most different. In each case, you will have to look for your recipe.

In general, during the construction of the well, freelance situations often arise, requiring non-standard solutions. And if you have already decided to build a well at your own hands, then during the work, be prepared to apply all your knowledge and smelting.

The well made of concrete can be constructed in three ways: monolithic casting with the installation of the outer and inner formwork, laying on top of each other ready-made concrete rings, assembling construction from concrete plates.

Monolithic casting is not used so often due to the large labor complexity. At the same time flooded concrete mix It should be prepared using high-quality cement and gravel a certain fraction. Usually for the preparation of concrete cement, sand, gravel mixed in the ratio of 1: 2: 3. For reinforcement, reinforcement steel is used.

The concrete frame obtained as a result of the pouring is cozed by a lowered method, gradually removing the soil from under it until it reaches the aquifer. To facilitate the landing of the lower part of the trunk, the cone shape is attached, or equip it with a special shoe with knives.

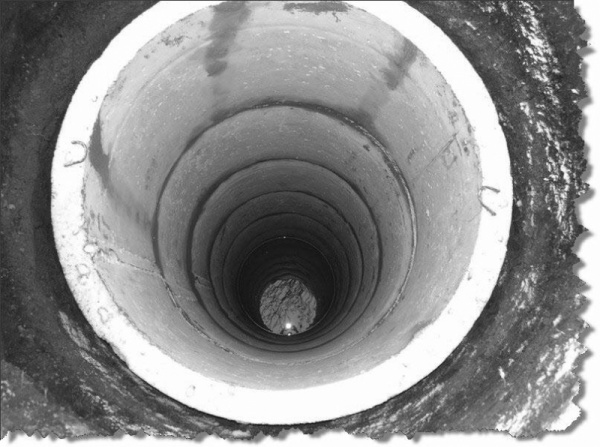

The well made of concrete rings is perhaps the most sought-after construction. As a rule, ready-made factory rings are used for its construction, but if the ring is desired, it can be done independently. The extension of the well trunk occurs in two ways that are familiar to us on the installation of a wooden log. In the first case, the rings are laid out from the bottom of the finished mine by laying on each other, in the second - the design gradually besieged as the soil is excavated from under it.

Regardless of the selected method of installing the joints between concrete rings, you need to close. Typically, the seams are paved with hemp, and then carefully embarrassed by cement mortar. To give the structure of greater strength, concrete rings are additionally sealed with steel brackets or lining. They will not be allowed to dispay the frame if, during deposition, one of the rings suddenly turns out to be squeezed.

Stage Running a portion of the well in aquifer is almost the most difficult during the construction, since water can arrive very quickly, and the air temperature at a depth is significantly lower than on the surface. To pump the liquid mass from the Copme zone, you can use a drainage pump.

When building a well in the country from concrete plates, the same technique is used as when mounting a wooden log cabin. The plates are put on the solution and fasten the corners.

Brick or Stone Well

For the construction of wells, natural stone and red brick are often used. The barrel of the mine at the same time is most often made round with a diameter of 0.7-1 m.

The most suitable natural materials for the stone well are sandstone, tight limestone and slate. Before proceeding with the construction, it is necessary to select suitable stones - they must be approximately the same size. This will allow the laying of smooth horizontal rows with small seams. The wall thickness of the bead stone should be at least 350 mm. To protect the design from rupture it should be reinforced. The inner and outer side of the stone well is recommended to be placed in cement mortar prepared in proportion 1: 2. Outside it is allowed to use instead of a fatty clay solution.

The masonry of the brick well is performed by a pumping way along the radius with the mandatory dressing of the seams. Wall thickness - 250-370 mm. Since the outer seams are wider than the internal, you must carefully monitor their filling. So that the well gets the right round shape, the template should be used during the work. The vertical structure of the design must be checked with the help of a plumbing - this, by the way, concerns other types of wells. To make the laying of greater strength, it is reinforced with steel wire, which is stacked every 3-5 rows. If you plan to fill the mine with water through the side walls, then you need to make windows to install the filters at the bottom of the masonry.

When performing a laying "Bottom", the outer surface of the mine will have to be plastering as it extensions. A qualitatively performed outer plaster will significantly reduce the damage from the effects of groundwater, and, it means that the durability of the well will increase significantly. For the convenience of subsequent cleaning of the well, the mine can be immediately layered in the design metal staples forming the staircase. The inner surface of the brick well is usually plastered after it is completely laid out.

Creating a shower for a well

The scene is an important element of the well design. She is designed to protect the mine from the flow of surface waters. Often around the well make a clay castle, which is sewn from above with concrete or reinforced concrete. A similar disposal has a number of shortcomings that make it use undesirable. First, the concrete surface, despite all its strength, is subject to the formation of chips and cracks, through which dirty water from the surface can penetrate the well. Secondly, in the formation of a concrete break between it and the shaft well, a rigid connection is formed, which in winter, as a result of the soil intake, can lead to a tip of the upper ring from the lower (in the case of a well laid down by concrete rings). As a result, the gap is formed between them, through which the surface waters will fall inside the well.

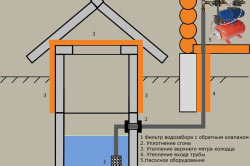

Alternative to hard speakers soft slutdevoid of all the above disadvantages. Consider its structure on the example of the same well made of concrete rings. For the formation of the scene along the perimeter of the well make a rejection of a width of up to 1.2 meters. Next, the pit falls asleep with sand and tamper. From above laid waterproofing, booding it on the top ring and securely fixing. The fastening of waterproofing is carried out by means of a metal tape, which is pressed to the ring with a dowel. The optimal waterproofing material is the film used for the insulation of the foundation of buildings. The resulting cesspost is covered with a layer of gravel or laid tiles.

It is worth paying attention to the fact that the deficiency around the well is better to do after the total deposition of the soil, which usually comes no earlier than one year after the end of the construction of the mine.

How to make a headguard

The creation of the head is the final stage of the construction of the well in the country. The upper part can be issued the most different ways. In most cases, a wooden house with a roof is erected, which will protect the well from pollution. An integral element of such a structure is a gate intended for manually lifting water from a well with a bucket. Of course, if the water is supplied to the house using a pump, you can do without a gate, however, in case of malfunction, you risk to eliminate it should be left without melting.

Below are several options for the top of the well. In each particular case, this option is selected, which provides maximum convenience of mounting based on the type of the well mine. It is also important how the chosen design fits into the landscape design of the country area.

Concrete well at the dacha with their hands video

Well at the dacha, made by your own hands, is the pride of each owner. Often, the wells will be ascended even if there is a plumbing in the house - just to decorate the site. Of course, the construction of the well is possible not far from each territory, sometimes the aquifer is too deep, and then you have to drill a well. Find out how to make a well with your own hands, see the photo of all stages of construction and get the advice of specialists you can by reading this article.

Previously, with the landscaping of the country area, the well was simply a necessity. Currently, in addition to the main function, the well built with his own hands has become an integral part of the landscape design.

Construction is better to start in the fall, when the water horizon has the lowest level. Of course, before making a well on cottage plotIt is necessary to make a small study of the territory of the site and determine the depth of the waterproof layer. If there are current wells nearby, the task is simplified.

The most reliable way to search for water is exploratory drilling. If, as a result of research, it turns out that the aquifer is located at a depth of no more than 20m, you can safely begin construction.

Construction of a well with your own hands: laying rings

So how to make a well with your own hands, so that not only to ensure the household with clean water, but also decorate the plot? The most common design is a well made of reinforced concrete rings.

![]()

Look at the photo, how to make a well: the first ring is placed in the dug hole, follow-up on the downstream ring. From under the lower ring, the soil is selected - and the rings under their own weight are lowered. Thus, the column is increasing up to the aquifer. The approach of the aquifer is determined by a noticeable cooling - the air temperature in the well drops by 1-2 degrees, mini-spring people appear on the walls of the mine.

During the construction of the well, it is quite often possible to face the so-called rigor - underground water, located at a relatively small depth of the waterproof reservoir. For water supply, the rigor is usually not used, as it does not have time, leaking through the ground, to be cleaned of contamination.

When the mine istes, it is isolated: one or two lower junctions between the rings from the inside are closed with mortar. Water intake occurs from below. After the solution is grabbed, the penetration of the well continues. In the aquifer, as a rule, they are installed from one to two rings.

After that, all the remaining joints from the inside are closed with a solution with the addition of liquid glass, the bottom of the well will be rested with a layer of gravel with a height of 20-30 cm (fraction 5-25 cm), which will serve as a filter for the incoming water. The burglar space is falling asleep with gravel and sand, the clay is tight above to prevent the rain and melt water from entering the well.

The upper ring is located above the ground level to protect against snow and dirt. Waterproofing the joint between the upper ring and the entire column is performed especially carefully.

After the water level in the well becomes sufficient for the dive of the "baby" pump, it is necessary to pump water several times to "dig" the well.

How to make a well in the country with your own hands (with photos): Construction of the head

The next stage of how to make a well in the country - the construction of the ledge. Wells look most effectively, top part (headpoint) which are framed in the form.

Pay attention to the photo of the well with your own hands: the log cabin can be assembled around the upper concrete ring. As a result, such a well will be not only a functional, but also a decorative element in your site.

![]()

For the construction of the head of the well in the form of a wooden log cabin, you will need a board with a thickness of 30-40 mm, a forest-round timber or a ring diameter of 180-220 mm. Instead of logs, you can also use a timing of about 150x150 mm.

Prepare the material. If you are dealing with a forest-round, then in this case it should be cleaned from the crust, to open, remove the bitch and process the antiseptic. Then the logs must be sorted by increasing the diameter, because the larger diameter forest will fall on the lower crowns than on the top. If you choose on rounded logs or timber, they are also better to handle the antiseptic. This is desirable even if you are convinced that it has already been done in production.

To make a well on the plot, mark the position and size of the log cabin on the ground. Over the entire area of \u200b\u200bthe future design, remove the ground to a depth of at least 150 mm. Put a layer of rubble, gravel or pebbles into the resulting pit, and dream it. On top of the stone "pillows" it is desirable to pour concrete and after it solidified to arrange waterproofing from several layers of rubberoid.

Cut the log or timber on the workpiece of the required length. It should be borne in mind that the headband usually has dimensions from 1000 x 1000 mm to 1500? 1500 mm. The number of billets depends on the diameter (thickness) of the material you use - the ledge should rise above the surface of the Earth by about 750 mm.

When assembling a log, it should be borne in mind that among numerous types of cutting angles in practice, 2 methods are most often used - "in the bowl" and "in the paw". When cabing "In the bowl", the ends (residues) logs protrude beyond the walls of the church. Therefore, this species is sometimes called the cut "with the residue". The ends of the logs most often protrude beyond the borders of the car angle of approximately 200-300mm.

The technology of cutting walls "in the paw" (sometimes this type of logging is also called "into the angle") is characterized by the fact that the logs do not protrude beyond the corners of the cut. The ends of the logs in the corners are connected by a secret toe (paw).

The method of connecting a bar "In Polterev" is that at the corners of the top or lower Crown Remove half of their thickness.

When building a well, with your own hands on the waterproofing layer throughout the perimeter of the prepared platform, put the antiseptic or spotted boards. The assembly of the wellhead is starting with the laying of the first (bustling) crown of the thickest logs, left below. Then they consistently perform the final assembly of the crowns.

So that the log house was more stable, the logs of each crown to bind with each other with special round or rectangular spikes - molecules. Before they are installed in the log, a through vertical hole with partial gripping logs of the underlying crown is drilled. Begroen clogged into the holes before the failure. The remaining unburned section of the brazen is cut off with a plane of a bar with a chisel.

Now that you know how to make a well, cover all the wooden parts by several layers of colorless or tinting varnish.

Over the well set a wooden gate with a metal handle. The chain or cable is fixed to the collar and tie a bucket.

|

|

|

|

|

|

|

|

|

As can be seen in the photo, the wells in the country, erected by their own hands, are not only functional, but also very beautiful structures!

Borehole drilling in the country

Often, wells do not allow watering water from deep aquifers with high-quality water, so many today give preference to the well. The wells are built at a depth of 30 m or more. With their help, you can take not only groundwater, but also running more deeply, which makes it possible to get high quality drinking water. The process of the well construction includes drilling of the wellbore, its equipment with pipes and filter, pumping and pump installation. Depending on the depth of the waterproofing layer, its structure and the nature of the threaded wells of the well may have a different design and differ by the device of the water treatment part. There are many methods of manual drilling wells, but they all require special snap, tools and devices, so it is best to invite specialists to perform these works.

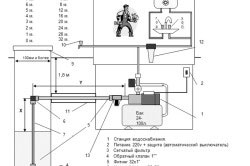

- Device of the well

- The main stages of work

- Manufacturing of the head and castle

For any owner of a private house, including a dacket, great importance for the economy has the presence of a particular water source. If there is a plumbing in apartments and comfortable houses, then in ordinary small buildings everything is much more complicated. The main source of drinking water supply in this case is surface and underground water. The first are mainly used for economic needs and are not suitable for drinking, as they require special cleaning methods. The most commonly used groundwater.

In order for them to be used, it is necessary or covered. The first option is the easiest. It is necessary to do it according to Sanpin 2.1.544-96 (requirements for the quality of water of non-centralized sources of water supply). From how the well is equipped, the water quality and its design depends largely. And water is a factor of transmission of pathogens of infectious and not infectious diseases, such as hepatitis, enterovirus and intestinal infections, helminthoses and others. It is of great importance, especially if a well enjoys several houses and families at once. It is possible to develop outbreaks of infectious diseases. Consider in more detail how to make a well in the country with your own hands, as well as the technique of manufacture and possible design.

Choosing the location of the future well

In order to make your well, the first thing you need to position it correctly. At the same time, it is important to know which types of groundwater and at what depth they are locuded. So, there are three main types of groundwater: the ridder (non-variable layer), pressure and artesian water (inter-plastic). The ripper is not protected from superficial pollution, and its composition is largely determined by precipitation, and the volume depends on the permeability of the soil. The second layer is protected by a waterproof layer, so in epidemiological, chemical and radiation ratio it is practically safe, because it is very widely used. And the most profoundly located layer is the so-called artesian water.

These waters are the cleanest. The most aquifers are the layers of sandstone and clay. The main source of groundwater is atmospheric precipitation, to a lesser extent - filtered soil water from local sources. Do well the easiest next to other water sources. The most reliable way to determine the presence of water is drilling well. There are also indirect signs of the presence of aquifer: frequent fogs in a given area in the absence of surface reservoirs, flooding of basements in springtime, the location of the nearby rivers and lakes, the presence of moshcars and mosquitoes, moss on the surface of the soil, good grass growth in the dry period of the year. A method of biolocation can be applied: a wire frame from a brass long 50 cm is made, a diameter of 2-3 mm, bend at a right angle so that 1 part is 10 cm. Then take them into hand and go through the site. They crossed in places of the closest insertion of the aquifer.

Back to the category

Basic rules when building a well

Virtually any owner of private ownership will be able to make a well. It can be built from different materials: Brick, tree, concrete. All this is done with your own hands or with the help of the work brigade. The design is selected any. At the same time, the following requirements must be followed.

First, the well in the country area is built at a distance of at least 25 m from sources of possible pollution: seats of walking and livestock, washing, bath, restrooms and cesspools.

This is especially important for preventing water pollution by organic substances.

It is impractical on the banks of the river or the slopes of ravines, as water in such places is well drained in such places. You need to build, observing the current sanitary rules and norms. Before it is erected, the resolution of sanitary-anti-epidemic, hydrogeological services will be required. Otherwise, such activities will be illegal.

Back to the category

Device of the well

As mentioned above, it is possible to design a well from a tree, but most optimally from concrete (internal part). The headband can be made wooden as a roof. First of all, you need to decide what kind of well you want to do with your own hands. It may be shaft and tubular. In the first case, it breaks down with the help of a shovel, that is, manually, and in the second it makes its way. No need to dig it manually if the water lies too deeply, it will be long and hard. What kind of drive is needed for water, manual or by the pump.

It is quite difficult to make a tubular well with your own hands, it will take special equipment for this. In addition to determining the height of the groundwater, it will be necessary to determine the nature of the soil, namely the presence of solid stones between the aquifers. All this can complicate work or make them impossible. That is why it is important to know the hydrogeological features of this site.

Back to the category

List of materials and tools

It is possible to create a similar building with your own hands, only having the necessary equipment and raw materials. To work, you will need: Sapper shovel, several buckets, staircase, device for lifting and lowering buckets, flashlight (for need), pump, jackhammer, wooden blanks for devices for formwork and headband, concrete (cement solution), clay, gravel (crushed stone) , sand. Any owner and the builder should know from which components to consist of any well or cape. The main parts of it is the headband, the main trunk and the waterborg (reservoir).

Each component performs a specific function. The head assists water and the structure itself from contamination, including garbage and atmospheric precipitation, freezing. The trunk is necessary to ensure that the walls of the well do not appear, that is, the design was hermetic.

The reservoir serves as a place of cluster of groundwater. The design of the trunk can be rectangular or cylindrical. Most optimal time For this type of work is autumn, since during this period the level of groundwater level is the smallest, it largely facilitates work. If it is important to comply with the safety regulations: to wear a helmet, check the strength of the rope (cable), because otherwise the raised buckets can fall the worker on the head. There should be a flashlight in stock.