The electric water heater of the accumulative type, or, in a simple, boiler, has long and firmly entered our life, providing additional comfort and allowing not to depend on the utility systems of hot water supply. This simple device in automatic mode supports the necessary water temperature, while having its definite reserve. The instruments manufactured by industry have a variety of shape, sizes and external design. Despite the seeming differences, at its base, all water heaters have a similar design and a single principle of operation. However, making the choice between a model of the boiler, it should not only understand how it is arranged, but also to understand the features of the execution of some of its components.

Boiler design

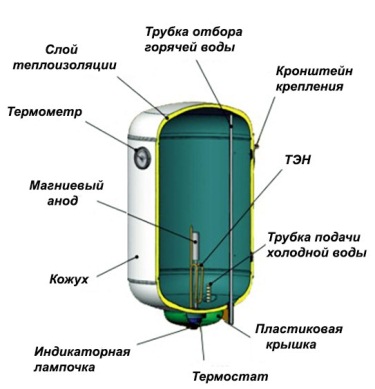

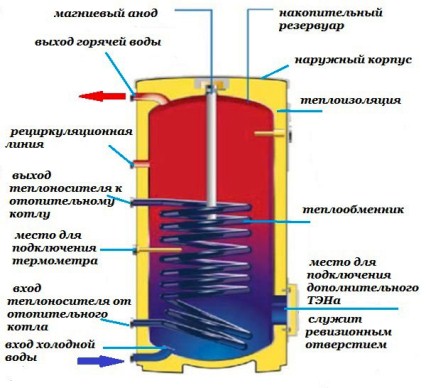

In fact, any water heater of this type is a large thermos having an inside tubular electric heater (TEN), so the design of all boilers has such items:

- external case with details allowing you to secure the device on the wall or floor;

- inner tank;

- heat-insulating layer between the inner capacity and the case;

- tubular electric heater;

- thermostat with the possibility of adjusting the heating temperature;

- safety valve;

- protective magnesium anode;

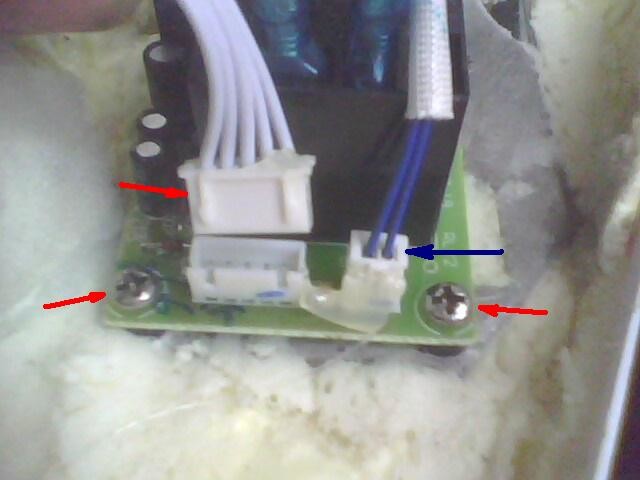

- control and indication scheme.

When choosing a boiler, it is impossible not to notice a big difference in price even between different models of one manufacturer. It is primarily due to the technology and material of the manufacture of the indoor tank, as well as the presence of an electronic control unit and indication.

These parameters set the convenience of using the device as well as the duration of its service.

Housing

Water heater housings have both strictly cylindrical and oval and even rectangular shape, a variety of coloring and design design. Often on the outside of the casing, the thermometer is mounted for monitoring the operation of the device, as well as regulators or control elements. The material of the manufacture of housings is steel sheet or plastic.

To install the boiler, in the design of the housing there are fasteners, depending on the type of placement (wall or outdoor installation scheme). The space between the water heater housing and the inner tank is filled with thermal insulation material - most often in its role is dense polyurethane.

Inner Buck

The design of the inner container of the boiler must comply with the criterion of increased corrosion resistance and at the same time to withstand constant temperature differences, so the manufacturers pay a lot of attention to this element, developing new tank coatings and applying methods for its protection.

Steel coated pots from glass email or glass foam

Such a coating is obtained by spraying the protective layer, followed by its firing at high temperature (up to 850 ° C). The glass is not capable of oxidation, so absolutely not corrodes. In addition, her smooth surface opposes the formation of scale.

Paradoxically, but the main disadvantage of such a coating stems from its dignity - the high hardness of the layer is low and over time, the constant water temperature drops lead to the formation of microcracks in its layer, which in the end contribute to the destruction of the tank.

Manufacturers are constantly looking for new compositions for covers of this type. For example, the addition of titanium powder equalized the temperature coefficients of the expansion of glass fluorofore and steel, slightly improving the resistance of the layer to cracking. Slightly reduce bad influence The temperature effects can be by setting the water temperature in the boiler not higher than 70 o C, although still at least once a month will have to warm up the device to comply with the sanitary rules. An increased weight of the boiler can be considered another disadvantage of the glass fluorforum coating of the tank. Companies producing water heaters with tanks of this type provide a guarantee for their products not more than 3 years.

Steel tanks with titanium spraying

Spraying titanium powder on the inside of the tank is achieved excellent corrosion resistance. In this case, this type of coating has high strength and mechanical resistance, having weak points only on welding joints. A guarantee for a device with such a tank is up to 10 years, which is a huge advantage, even if it takes into account its fairly high cost.

Stainless inner tanks

Such capacities are deprived of the disadvantages of the two previous elements. Stainless steel, like titanium, is able to withstand the influence of impurities in water, as well as corrosion. It is believed that stainless steel gives water a peculiar smell and taste appearing during its heating, but these are only speculation, absolutely not confirmed by scientific research. It is known that "stainless steel" does not enter into chemical reaction with water. Manufacturers also give up to 10 years warranty, but they are the most expensive. Stainless steel tanks, as well as with titanium spraying, are more susceptible to the formation of scale, rather than glass refractory, but it does not diminish their advantages. In the inner tank, the cutting tubes of cold water and removal of hot, as well as an electronic heating unit and protection.

Heating and protection unit

Elements that are responsible for heating water to a certain temperature, as well as protective from the destruction of the inner tank metal, are installed on a metal flange, connected by a seal to the inner tank of the device.

Water heating uses in various power. Depending on the heating principle, distinguish:

- "Wet" tans, which are directly in contact with water, so inevitably covered with a scale, which must be removed periodically, otherwise due to overheating, the TEN fails;

- heaters "dry" type. It is devoid of this disadvantage, since installed in a metal tube, which also makes contact with the liquid. Such a scheme allows you to get rid of the scale not only on the heater, but also on the tube coated with a layer of glass fluorofore.

Some boilers are equipped with several heaters. This design allows stepped heating adjustment, and also reduces the number of inclusion cycles for each of them (voltage jumps during the inclusion of instruments affect their durability).

Together with the Tanes on the flange there is a thermostat and a magnesium rod (anode). The thermostat is responsible for the inclusion of the heating element while reducing the water temperature below the consumer installed. The thermoregulators are used both mechanical type and electronic devices working together with the electronic control unit. Often, the thermostat device includes a protective shutdown scheme in the absence of water in the tank. The magnesium electrode is designed to reduce the exchange of metal components inside the boiler, giving up its particles. Such a scheme reduces the effect of flushing electrons from structural elements and they are corroded to a significantly lower. The magnesium rod itself is quite quickly destroyed and requires periodic replacement (when thinning to 10 mm or a decrease in length to 200mm). The control and indication scheme provides additional amenities when using a water heater, having functions of precise water temperature adjustment, inclusion of heating in time, maintaining varying degrees of heating depending on the time of day.

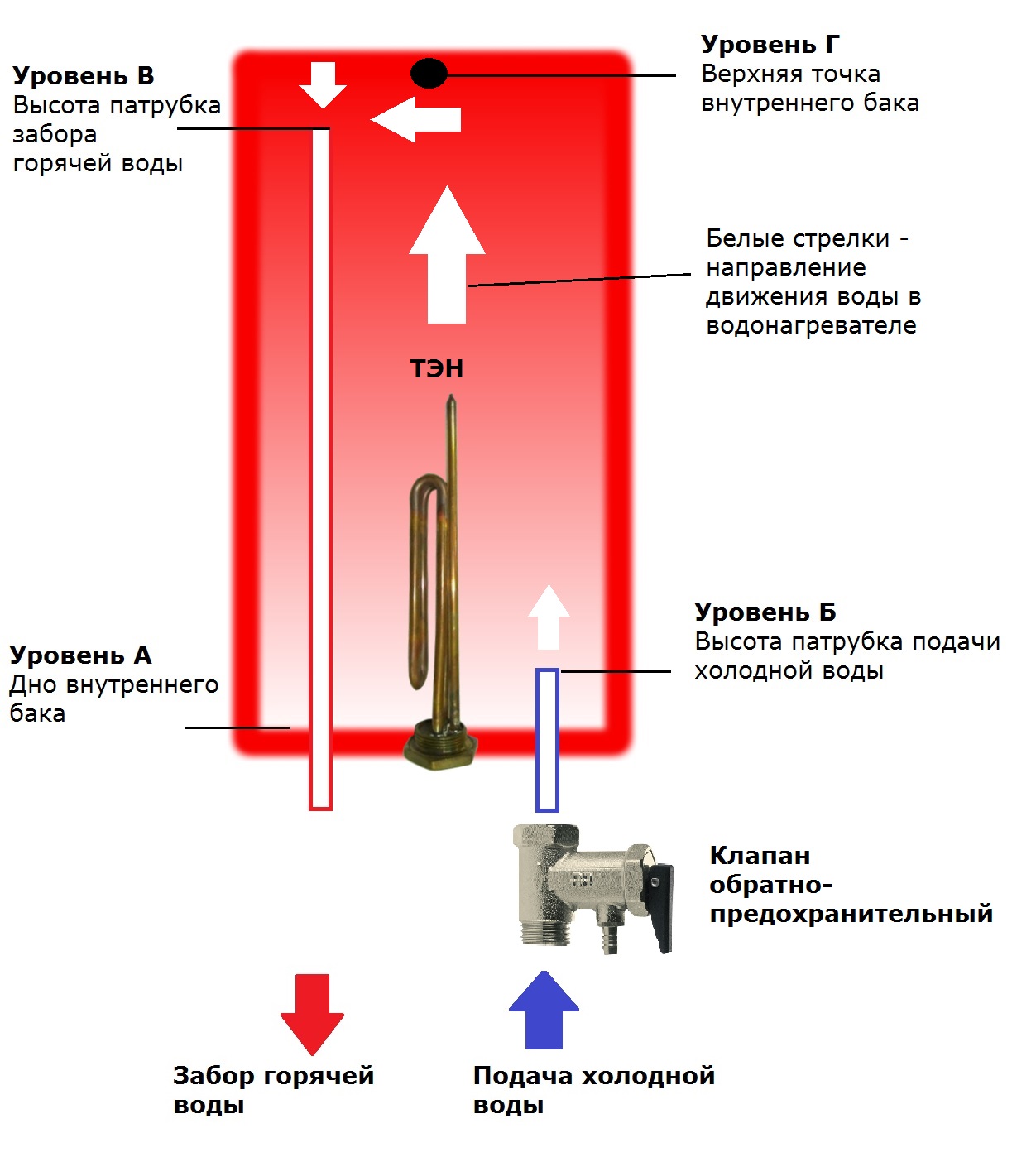

Principle of operation of accumulative water heaters

The scheme of operation of the boiler is built on the principle of separation of water layers with different temperatures. As you know, warm layers of fluid are at the top. Their selection from the water heater is carried out through the turning tube hot water, the length of which allows you to use the upper, the most warm layer. Cold water, on the contrary, enters the lower part of the tank, where water heaters are installed. In addition, a divider is installed on a short supply tube that does not allow fluid to flow and thereby contribute to the mixing of warm and cold water.

The peculiarity of the warm liquid rise up will not allow the use of a boiler of the vertical design, placing it parallel to the ground. It is worth paying close attention to it, choosing the type of device under your needs.

Heating of cold water is carried out by a TEN (one or more). It monitors the thermostat. When the specified temperature is reached, it opens electric chain Power supply heater.

Good thermal insulation allows you to maintain the desired water temperature, spending the minimum of energy on its constant heating.

In the case of using multiple heaters, one TEN is used to maintain temperature at a specified level. The remaining is included at a strong flow rate, repeatedly increasing the power of heating. Such a scheme increases the efficiency and reliability of the device.

The warm water selected from above is constantly replaced by a newly heated liquid, which is supplied from the highway. So the process is arranged continuous heating. With a large consumption, the water temperature at the outlet of the boiler falls over time, so it is necessary to choose the volume of the drive, based on the size of the hot water treatment.

A thermostat malfunction is possible, while water can boil, as a result of which the pressure in the inner tank increases to a dangerous level. To prevent an accident, a safety valve is installed on the cold water supply tube - when the limit pressure is reached, it opens, thereby throwing out part of the fluid into the feeding line. The same valve is used to drain water from the device during preventive work.

A detailed video on the boiler device is presented below:

It is not necessary to neglect the conduct of periodic preventive measures consisting in cleaning the boiler from scale and rust. They will allow the device to work reliably and efficiently, and also will be removed from unplanned spending.

At this time, autonomous hot water supply in apartments and private houses is becoming increasingly popular. Centralized GVS has become expensive and uneconomical, because it gradually goes into the past. It is replaced by water heaters of various designs, the most common of them - the devices of the accumulative type. In this article, we just consider the device and the principle of operation of the boiler for water heating.

Types of accumulative water heaters

At the moment there are several varieties of aggregates for autonomous hot water supply. All of them are created with one goal, but reach it differently, then you mean, using various energy carriers. The homeowner has the opportunity to choose the one that best suits him in all respects.

So, the current market offers heating boilers of the following species:

- electrical storage heaters;

- corporate heating boilers;

- gas boilers;

- flowing heaters.

Note. Live with english word "Boiler" means "boiler". This means that they include not only accumulative, but also all sorts of flow water heaters. Do not take them into account will be incorrect in relation to users.

Electric boilers

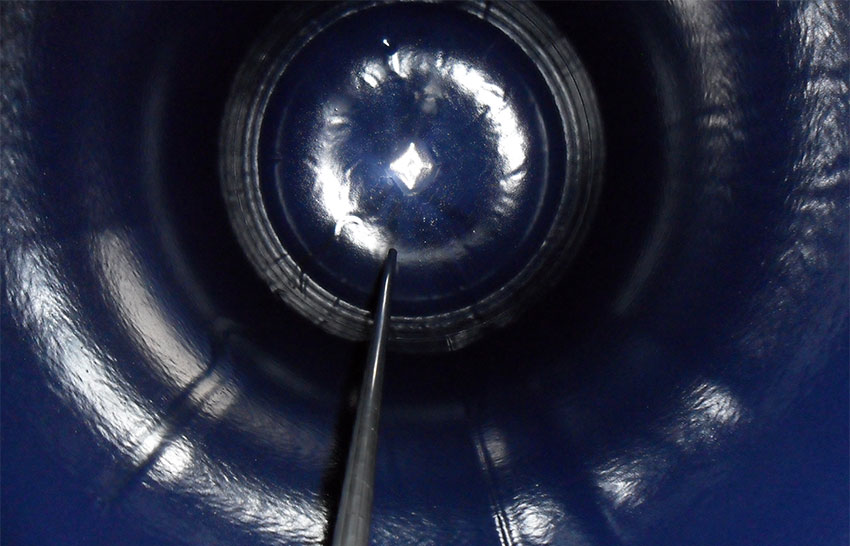

This is the most common type of devices for the DHW, most often used in apartments and small private houses. The reason for such popularity is a relatively low cost and simplicity of installation for which no permissive documents are required. The devices are quite reliable in operation and satisfy most user requirements. To understand the principle of action of the water heater, consider its device shown in the picture:

The unit is a tank, usually a round or oval shape, enclosed in a layer of heat-insulating material (as a rule - polyurethane foam) covered with decorative casing. The container itself can be made of materials:

- steel with enameled coating;

- stainless steel;

- plastic.

Electric TEN, located at the bottom of the tank, heats the water to the temperature limited to the thermostat. Its maximum value adopted in all electric boilers is 75 ºС. So far there is no waters, the device of the electric boiler involves maintaining the set temperature in the automatic power on and off mode. The latter has additional overheating protection and in an abnormal situation will automatically turn off when the water temperature is reached 85 ºС.

Note. The optimal mode of operation for the boiler is heating to 55 ºС. In this mode, the device provides the desired amount of water for the DHW and at the same time saves electricity. Unfortunately, often the accumulative water heater works at maximum power due to the fact that winter time From the water pipe flows too cold water and the TEN in economy mode does not have time to warm it.

The waterscence takes place through the tube, derived to the upper tank zone, where the hot water is hot. At the same time, the feeding of cold water is provided in the lower part of the boiler, where the TEN is installed. To protect steel tanks from electrochemical corrosion, the water heater device includes a magnesium anode. Over time, it is destroyed, and therefore requires replacement for approximately 1 time in 2-3 years.

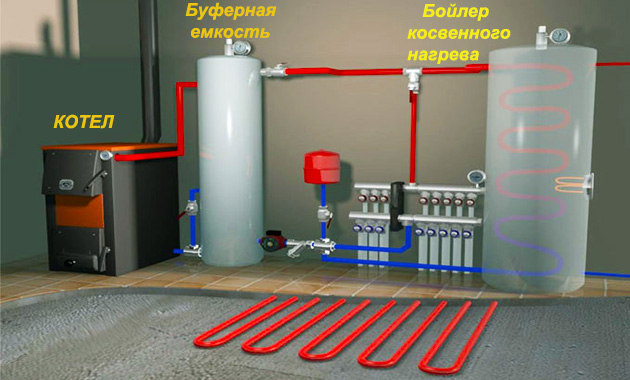

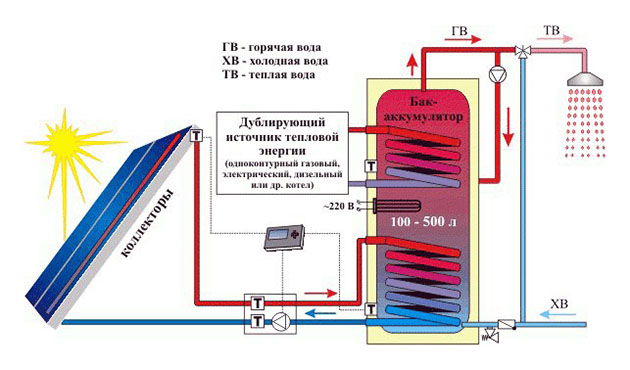

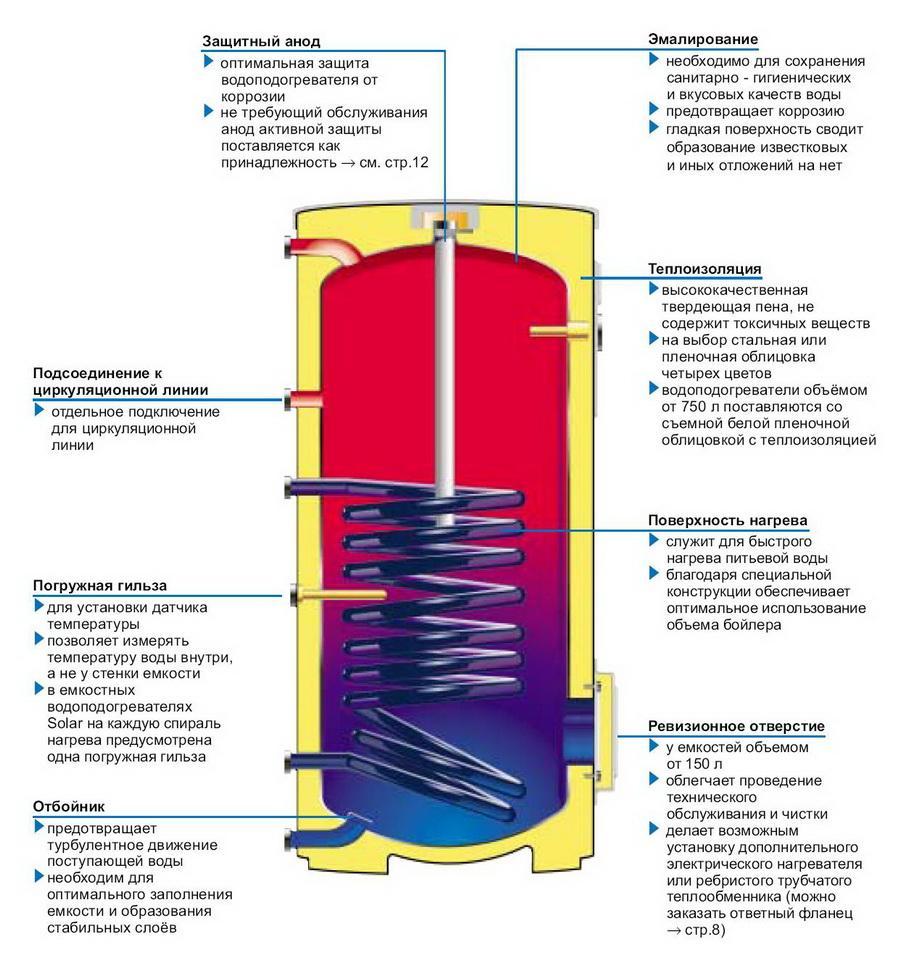

Boilers of indirect heating

These devices do not produce thermal energy Alone, although some models have a built-in TEN to maintain water temperature in different situations. In the usual mode, the boiler prepares water for the DHW, heated by its coil with the heat carrier. Below in the diagram shows the device of the boiler of indirect heating:

In the warmed tank of a large capacity (it happens to 1000 liters) a coil with a coolant from the boiler was built into it. As in the electric boiler, the supply of cold water is carried out in the lower part of the tank, the selection is hot - from the top. The unit is able to provide a significant consumption of hot water, and therefore applied in private houses with a large number of consumers.

The usual heat exchange between media with different temperatures is the principle of operation of the boiler of indirect heating. But in order to get water from the tap with a temperature of 55 ºС, the boiler must heat the heat carrier at least 80 ºС, it is one of the disadvantages of this water heater. The second drawback is a long time of loading the tank of a large capacity, so in the case of intensive water treatment, people living in the house must be adapted to use the DHW on a specific schedule.

Like electrical boilers, indirect heating water heaters are equipped with a magnesium anode to protect the steel tank from corrosion. Bole is complex and expensive models are equipped with two coils, a coolant from the boiler flows through one, and the second can be attached to an alternative source of thermal energy. They can serve another boiler or a solar collector. To maintain the temperature in different situations, a TEN with a thermostat is embedded in the upper zone of the container.

Indirect heating units are made in wall and outdoor performance, can work with any sources of thermal energy. Manufacturers of boiler equipment often offer them in a bundle with double-circuit boilers. In this case, the heat generator maintains the heating temperature and loads the boiler, alternately switch between these two systems.

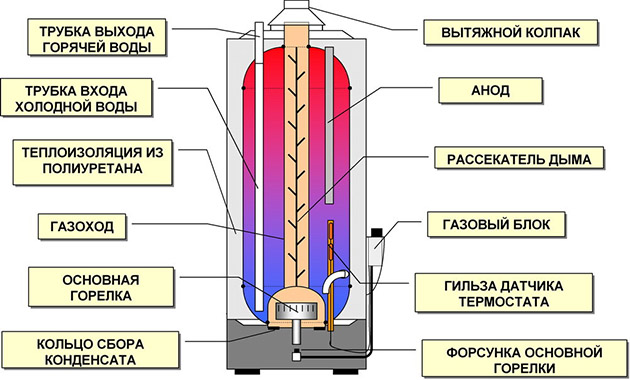

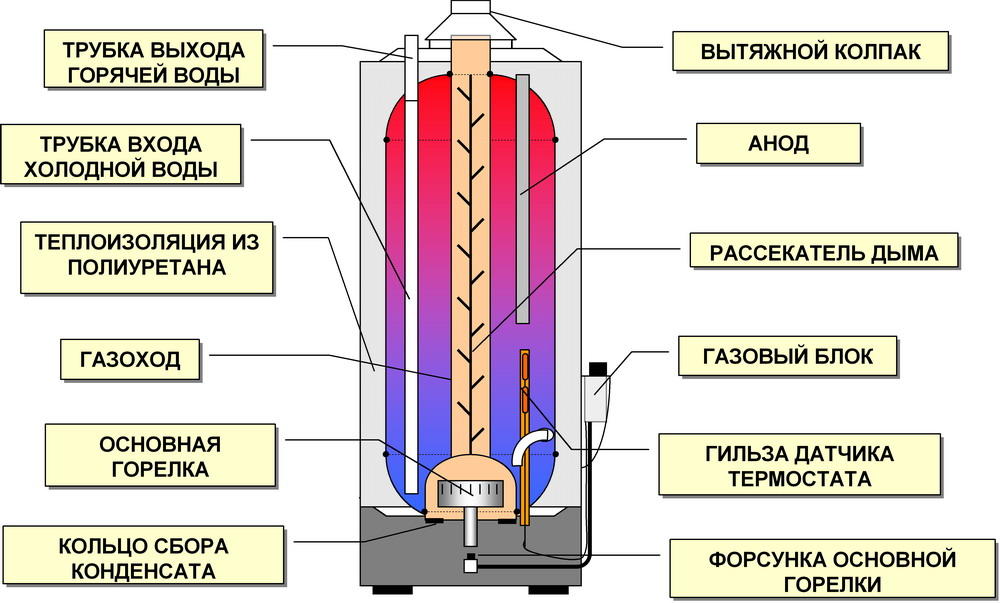

Gas accumulative water heaters

These devices are constructively and externally resemble electric boilers. All the same tank hanging on the wall, covered with a layer of insulation, only at the bottom set gas-burner, and at the top there is a flue of the chimney. The gas boiler works on the same principle, only the source of heat serves as a burner, heating water tank. The water heater device is shown in the diagram:

As can be seen in the figure, the heating is carried out not only from the burner, but also by selecting heat of combustion products. This is achieved at the expense of the steel gas plant with divisions passing vertically through the tank and the heat exchanging with water. The burner operation controls the electronic unit, whose task is to put out or ignite it when the set temperature is reached or its decrease. As usual, to protect the case, the boiler design provides magnesium anode.

This type of water heaters is not too popular due to difficulties in the design and connection of gas-grade installations. In addition, it will take a full chimney for the operation of the gas boiler, it is not always possible or too expensive.

The advantage of accumulative water heaters is that they can make a large water consumption for DHW, but for a limited period of time. After that, they need a break for the preparation of another portion of water.

About flowing water heaters

Unlike accumulative boilers, the principle of operation of the flow water heater is not in advance, but quickly warm the flow water as needed.

Sources of heat are the same electric tagne and gas burners, only they are included after the house offers a hot water a faucet. These heaters include:

- gas columns;

- flowing electric heaters.

Note. Sometimes a plate boiler is used to ensure a private house of a private house, which is a water heat exchanger. Like an indirect heating boiler, it transmits the energy of the coolant water, only does it in the flow mode.

The design of the gas column is quite complex, and therefore deserves a separate topic. The electric water heater is simple: there is a powerful tan in it. With such dignity, as small size, the device has too high power consumption and its sphere of its application is limited. The device of the flow electric boiler is shown in Figure:

The advantage of flowing hot water apparatus is that they can serve heated water without preparation and for unlimited time. But it has its limits, which is important with a large number of consumers.

Conclusion

If you distribute all the listed instruments in popularity, then the first place will confidently occupy electric boilers, the reasons for this are understandable. In second place there are gas columns, the third remains for the boilers of indirect heating.

In order for in the apartment or in a private house there is always a hot water, install such a device like a boiler, it will even fit in kindergarten. The water heater design is with direct heating, indirect heating, combined heating method. The principle of operating the electric heater is very simple. To be more accurate, the water is heated inside the tank, and their feature is that the unit itself produces this very heat.

The device of the boiler for water heating depending on the type

Such devices are electrical and gas type. As for the design features, the product consists of a tank in which water is recruited, as well as thermal insulation and an external case on which the control panel is installed.

Inside is installed:

- Heating element or, in other words, TEN;

- Special magnesium anode;

- Thermostat;

- Special nozzles.

Water heater with indirect heating is installed in apartment house Or a private cottage, which has autonomous water heating, with a permit for installing a single-circuit boiler. Increased temperature inside the tank of indirect heating occurs, not by exposure to the source of energy, but as a result of heat exchange with heating circuits.

The device has its own heat exchanger in the form of a coil.

It is located along the entire length of the tank or can be located in its lower part. Each of the two heat exchanger pipes is connected to the heating boiler. The coolant installed in the boiler moves through the heat exchanger, and due to this heats the water in the tank (due to the process as heat transfer).

The removal is carried out through a special nozzle that directs water into the boiler. As a rule, the heat exchanger is set alone, but there are models in which several heat exchangers. In this case, it is permissible to connect equipment to a gas boiler and similar sources.

The boiler with indirect heating can be without a serpentine, such structures are called "tank in the tank". In other words, another tank is installed inside the tank. Heating water suitable for operation occurs in the tank, which is located in the very center of the product.

Combined models are the combination of the two previous models in one. They go with indirect heating, however, they have a TEN in the cavity of the tank, by which the product can be used as a cumulative electrical board.

Fake or boiler: what it is

It is easy to guess that the boiler room is such a place where the boiler is installed for heating water. This room has special requirements. The finish must be from non-combustible material. There must be excellent ventilation. Heating radiators are installed in the boiler room. Connecting devices is carried out only by the rules to ensure that security is monitored in all respects.

Water electric boiler Sale in a large assortment and is it possible to purchase different equipment, choosing according to such parameters as:

- Dimensions;

- Power;

- Capacity of the tank;

- View of the location.

Electric types of heaters have differences from gas. He, and inside it works differently, and does not work as a gas. To be more accurate, then there is another structure of the heating element, and this is a TEN.

Only he is responsible for how quickly a certain amount of water can be warm up to what temperature.

Tanes are dry and wet. Dry is placed in an additional capsule, and the heating with such an element is carried out much longer. About the Tan must be installed a special thermal sensor, due to which the operation of the electromechanical or electronic thermostat is controlled. Thus, the water temperature support is ensured at a given level. When cooled liquid, the thermal sensor works, and the automatic heating of the tank content begins.

We understand how the electric boiler works

The tank of the tank is surrounded by the heat-insulating layer on which the decorative plastic or metal housing is installed. The intake of cold water is carried out using a special pipe installed from the bottom of the device. When using hot water, that is, when the tank tank is emptying, an automatic set of cold liquid occurs and its gradual heating occurs.

In other words, hot water is always present in the container, provided that the device is included in the network.

As a rule, the scheme of the action of such a device can be supplemented with such an element as a magnesium anode. It is he who contributes to the extension of the period of operation of the Tan, since at contact with rigid water, salts are attracted. The result becomes what the scale is formed on the anode, and not on the tan, it can be seen in the context. Replace the anode is much simpler, and it costs much cheaper.

Gas boilers are set less frequently electrical and than cumulative, they are cheaper than analogs, not the safest devices for heating water, and besides, they are produced in limited quantities, and there are many difficulties in order to carry them out.

Namely, if there is a need to install the product in an apartment building, then it is required:

- Coordination with neighbors;

- Installation of chimney;

- Excellent ventilation;

- Registration of the device.

The devices can work from natural gas. The design consists of a water tank, an incoming pipe with a cold water supply, a nozzle for the withdrawal of hot water. The body of the product is thick and between it and water tank there are additional space, due to which the water inside is preserved for a long time.

The heat exchange process is carried out by means of the bottom wall, since it is where the combustion chamber and a gas burner is located. The heat can be transmitted along the inside of the tank from the central channel, according to which the combustion product flows, formed in the combustion chamber in the chimney.

Non-flat design of the gas boiler

The boiler control is carried out due to the temperature sensor and thermostat. They are responsible for fixing a certain level of water temperature, and as soon as the heating reaches the desired mark, the system is automatically shutdown. Gas boilers are equipped with a security group or, in other words, a special safety valve that resets too high pressure. Thus, it is prevented by an explosion of the product and the like consequences. To eliminate the formation of scale on the product, it also establishes a magnesium anode, which over time must be changed, as it is destruction due to the effects of salts in rigid water.

Boilers can be of various types, type, shape and even installation method, but the requirements for their purchase on average are the same, as you need:

- Inspect the housing to integrity;

- Pay attention to the availability of certificates for GOST;

- Buy products only in specialized sales points;

- Be sure to specify the terms of warranty.