However, boilers indirect heating successfully used for the same purposes for apartments, office premises, in the enterprise and any other object, where without hot water In the pipes can not do. What is such a boiler, which are the types of boiler of indirect heating, how to choose and install such an assembly in their home, let's figure it out in this work.

Boyler of indirect heating

First of all, it should be understood: an indirect heating boiler differs from other types of heaters by the fact that water is heated in it not due to electricity or gas burner, but using the heating system. In this case, the heating source can be both inside and outside the tank, or the boiler is able to combine from two or more heating elements. Such a combined source allows the use of heating elements, even when the heating season ends and there is no longer necessary in the housing heating.

2

As a rule, the combined boiler is a pressure (or closed) and non-pressure (open) species. And it is the view of the closed boiler of indirect heating that is used if there is not one waterproof point.

Combined boiler pressure

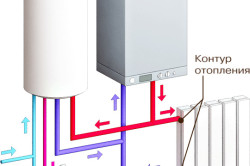

Outside, an indirect heating boiler has a barrel-shaped form, but new models are manufactured using more standard, rectangular shape of the enclosures. This allows them to be installed in the immediate vicinity of the boiler, thereby saving space. Depending on the installation method, wall and floor water heaters distinguish. The wall boiler, in contrast to the floor, has a limited capacity that does not exceed 200 liters, but the floor does not have restrictions on the tank and are used mainly in large country houses or production.

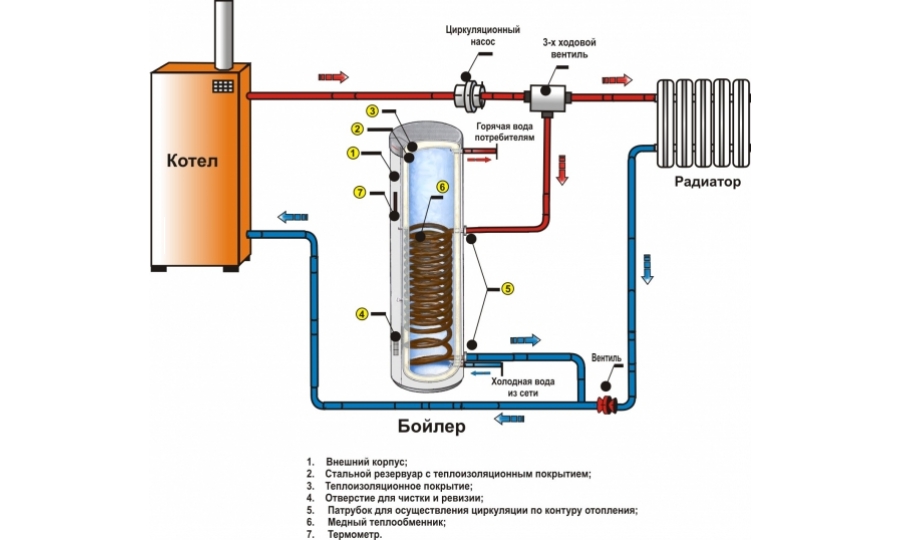

To understand the principle of operation of the boiler of indirect heating, to begin with, let's look at what it consists of. It must be said that the device of the boiler of indirect heating is very simple, and some craftsmen even make it independently. But at the moment it is still about this version of this device that is easy to purchase in the store.

3

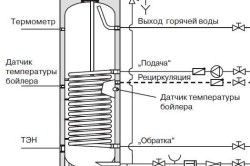

So, the whole design of the boiler of indirect heating consists of a housing (metal or plastic), a tank, a device for measuring the water temperature, magnesium anode and heat exchanger.

Manufacturers make a tank for a boiler of indirect heating from stainless steel or copper, and sometimes from the same steel, only covered with a layer of enamel. And in the tank itself there is a heat exchanger in the form of a serpentine (steel or brass), according to which water is conducted from the heating boiler system, thereby heating the water in the tank.

In addition, in order to avoid excessively high pressure, a boiler with a thermostat is provided with a boiler, and from corrosion protects the magnesium anode, which from time to time requires replacement. At the same time, the combined boiler can be additionally equipped with a Tan to warm water in summer period.

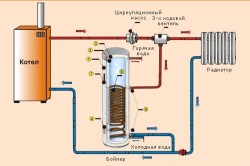

Actually, based on the listed, one can already guess the principles of the work of the boiler of indirect heating. Water from the heating system, passing through the heat exchanger, heats the water, sprinkled into the boiler tank. So that it circulate continuously, is provided automatic pump, and reduce heat loss in the aquatic tank helps the heat insulation layer.

Principle of operation of the water heater of indirect heating

Like any aggregate, an indirect heating boiler has its advantages and disadvantages. And in order to choose the model suitable for your case, it is desirable to clearly understand what parameters to navigate when buying such a heater. One of the most important parameters is the volume of the boiler, which is selected, based on the number of people who enjoy hot water, their rhythm of life and habit. On average, it is assumed that one person accounts for consumption from 80 to 100 liters of water. These are quite approximate calculations based on the average for one person:

- from 15 to 25 liters a day for washing dishes;

- from 5 to 15 liters on personal hygiene;

- from 50 to 100 liters for the adoption of the soul;

- from 150 to 200 liters for bath adoption.

Of course, each person has these indicators to differ in one direction or another, depending on the individual characteristics and habits.

Therefore, in the line of heaters, you can find aggregates with a total volume of 200 to 1500 liters.

However, one should not make a choice in favor of the maximum volume, as this is not always economically justified: except that such a heater will be quite expensive, it will require a lot of resources for its work.

It is best if the boiler will be provided with the ability to remove the heat exchanger for periodic cleaning.

4

First, during the operation, the boiler of indirect heating does not use electricity (at least in the heating season), and therefore the wiring and power grid are not experiencing significant overload.

Secondly, its performance allows hot water simultaneously to several waterproof points, which means that several people in the house can immediately use hot water without negotiating the sequence of its use (as it happens with flow heaters). At the same time, it is not necessary to take care of the device of an additional chimney if a solid fuel source of energy is used.

Moreover, any source of energy installed in the building can be used to warm out water, even solar panels. In addition, in the presence of accumulating capacity in a volume of 1000 liters, the boiler of indirect heating can provide water supply not by 150 liters of warm water, but for all 1000 liters of capacity.

Thirdly, the additional advantages of the heater include the absence of contact with flow waters, which is favorably reflected on the service life of the unit, and the flow of heated water is almost immediately, when opening the appropriate crane, without having to lower cold water or expect its heating.

Heating water boiler

However, it is impossible to say that an indirect heating boiler has no negative sides. First of all, the disadvantage of this heater is its significantly higher price compared to gas or electrical types of similar devices.

Yes, and initial water heating after starting the heater takes from 60 to 120 minutes, and at this time the quality of heating can decrease.

The most significant disadvantage of the heater, perhaps, is its large size.

So, if its volume is more than 100 liters, it will be necessary to allocate a separate room to accommodate such a large unit.

5

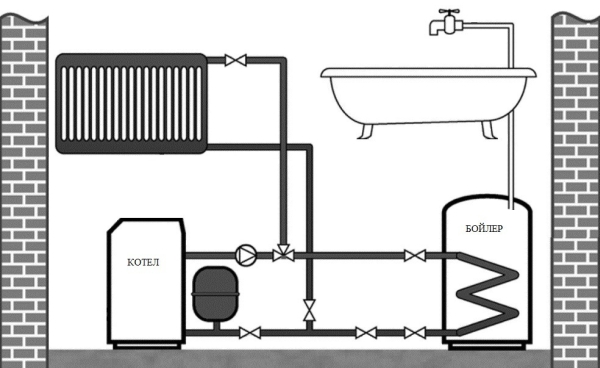

Before making the boiler installation, you must make sure that you choose the installation site of the heater. It should be located as close as possible to the heating boiler or in the immediate vicinity of the output of the central water supply.

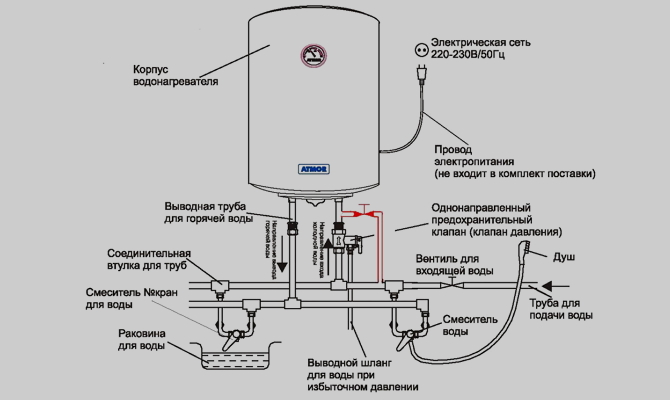

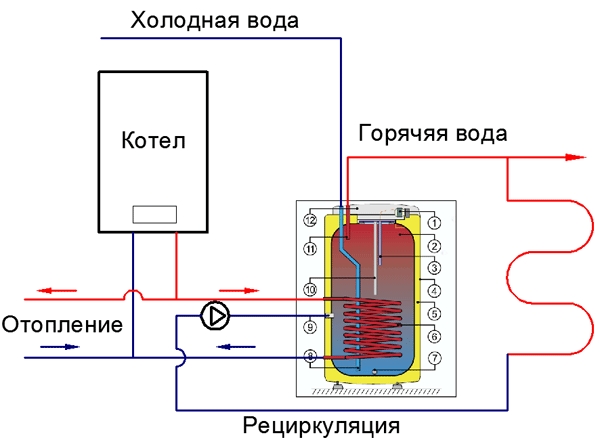

Water supply in a boiler takes place to two contours: heating and plumbing. Connecting Unit K. watering systemIt is important to trace that the flow of cold water came to the tank, and the outlet for heated water was located in his higher point. At the same time, to connect the heating circuit will be required so that the direction of movement of the coolant passed from the upper point to the bottom (hot water from the heating system should be supplied to the upper nozzle, and the cooled to go out into the lower). The location of the recycling point is located in the middle of the boiler room. Observing the above rules when connected, you can count that the boiler will work with the maximum efficiency.

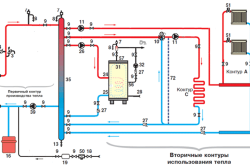

As for the connection schemes, the three main schemes are used mainly. The most popular scheme is the connection through a three-way valve. The thermostat signals are controlled by this valve, which, when cooled by water, redirect the coolant stream in the heating circuit. As soon as the water temperature reaches the required value, the thermostat again switches the valve to the initial position, returning the flow into heating radiators.

Water heater connection scheme

This connection is most often used with a large consumption of hot water. But it should be carefully referring to the adjustment of the thermostat so that the exhibited value of the boiler temperature was less than in the heating system. Otherwise, the boiler will be looped on water heating in a boiler, without returning to the heating system.

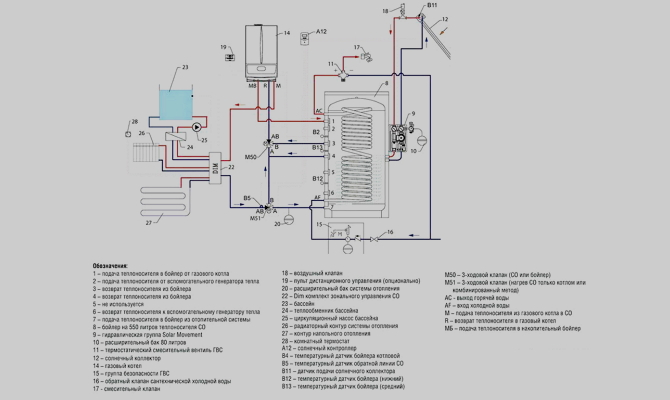

The following scheme in popularity involves the use of circulation pumps and is called a two-axis connection scheme. In this embodiment, the connection of the heating line of the boiler and the heating line occurs in parallel, and a separate circulation pump is connected to each of the lines. In this case, the pump operation mode is switched the same thermal sensor signals of the water heater.

Also, as in the previous scheme, a short-term shutdown of the heating line is assumed in a two-way DHW circuit operation, but, as a rule, a significant decrease in the room temperature does not occur in a short period. However, you can avoid such a situation by connecting two boilers instead of one, while the second function will focus on switching modes.

And the latter of widespread connection schemes - a diagram involving the use of the hydrocollector, or, as it is also called the "hydraulic arrow". Such a scheme should be designed and installed only by experienced specialists, since in this case it is assumed to use several heating systems at once: radiators, a warm floor, the contour of the heating of the boiler itself, etc. It is to equilibrate flows in different contours and a hydraulic distributor is used, which includes a combination of said hydraulic arrow and a collector.

Thus, choosing an indirect heating boiler, you should pay attention to several parameters immediately. After all, it is necessary to consider not only the manufacturer and the price, but also the provided water volume, the presence of a built-in electric heater (for the summer use of the boiler) and many other nuances. It is best to get a competent consultation with the seller, as well as carefully view passports and accompanying technical documentation. After all, with the right approach, this unit will serve you not one dozen years.

- How is an indirect heating boiler

- Principle of operation of the device

- The advantages and disadvantages of the system

- How to choose a boiler?

What is an indirect heating boiler and why is it needed? This question is often asked by owners of private houses. Many are rightly believed that if they already have a installed heating system, which allows you to supply a house not only with heating, but also hot water for economic needs, then why spend and install an indirect heating boiler? At first glance, it really looks like an excessive waste of funds. But it is not.

An indirect heating boiler has a very low heat loss coefficient.

An indirect heating boiler is a water heater that allows you to ensure uninterrupted hot water supply of all households at the same time.

In addition, its design does not assume the presence of its own heat source. External heat sources are used as thermal carrier for the boiler of indirect heating. They can be a heating boiler, central heating, etc.

So, why do you need an indirect water heating boiler? Take as an example the situation when the owner of the house decided to wash the dishes, and the owner of the house in the meantime decided to take a shower. In this case, both will face either a shortage of hot water, or with a sharp decrease in the water temperature, which is also unparalleled. The device of this water heater will avoid such situations, since it can compensate for the occurring shortage of hot water.

How is an indirect heating boiler

Outwardly, an indirect heating boiler looks like a large tank having a cylindrical shape. And itself consists of the following parts:

- boiler housing;

- insulation;

- a tank made of stainless steel;

- thermometer;

- heat exchanger;

- magnesium anode.

Due to the presence of a layer of insulation between the tank and the housing of the boiler itself, the heat transfer coefficient is 3-4 ° C per day. The thermometer allows you to control the desired water temperature in the tank. The heat exchanger is a helix-shaped steel or brass tube, which is located inside the boiler. Very often, this tube has a complex shape and is located closer to the bottom of the boiler. Manufacturers claim that it is thanks to this fact that can achieve uniform heating of water throughout the tank. The magnesium anode is designed to protect the tank from galvanic corrosion. Almost all electrochemical reactions will affect the magnesium anode, not the toneway of other parts of the water heater. Over time, this part of the water heater will have to be replaced, as it is subjected to constant wear.

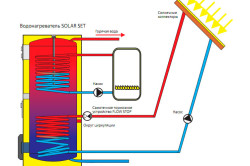

Almost all new models of modern boilers have an alternative source of heat. Such devices are called even combined. In the summer, when the heating season is over, boilers are used to heal water or electricity or gas. There are also models that can heat water due to sunlight.

Back to the category

Principle of operation of the device

The boiler of indirect heating is easy, and the principle of its work will be understood by anyone. Inside a large tank passes a hollow inside a spiral tube, most often it is called a coil. In the tube continuously circulates the coolant. Permanent circulation provides a pump specifically mounted for these purposes, which, in turn, is equipped with an automatic control system. As soon as the water temperature reaches the specified parameter, the pump is turned off. Since the source of the coolant is the working heating system, then at the time of heating the water in the boiler, a slight decrease in the temperature in heating elements is possible. However, water heating in the tank occurs fairly quickly, so it is possible to notice a decrease in temperature for a short time only with the help of a thermometer.

After the water in the tank becomes the desired temperature, it will still remain so long. Significantly reduce heat loss in the tank. Modern insulating materials help. Polystyrene foam or polyurethane foam is perfect as thermal insulation for boilers.

Each boiler has two nozzles for input and output, and they perform different tasks. The input pipe is connected to the heating boiler, where the coolant is incorporated into the serpent, thereby heating the water in the tank. And the output of the output will give already heated water directly to the place of its feed.

Before you decide on the purchase of a boiler, be sure to check the power of your heating system. After all, if you acquire a boiler with a large volume, there is a possibility that standing at your home the heating system is simply not cope with the task. Either heating will occur very slowly, and during this period the temperature of the heating devices will decrease sharply, which will be extremely negatively affecting the comfort of people living in the house. You still need to choose in advance which type of boiler you want to purchase: outdoor or wall. If you have a wall water heating system, then the boiler is best acquired the wall. And vice versa. Specialists are advised to acquire the heating system and a boiler of indirect heating from one manufacturer. In this case, installation and installation will be easily and quickly. And the results of their work will be effective and productive.

Back to the category

The advantages and disadvantages of the system

The main and main advantages of indirect heating boilers, in contrast to flow-type heaters, are considered:

- The ability to heat the water in large quantities.

- Compensation of the emerging short water deficit during peak load. For example, when the hostess decided to wash the dishes, and the host to take a shower. Thanks to the boiler, several people in the house can use hot water, without causing discomfort to other users.

- The cost of water heated by an indirect heating boiler is extremely low. After all, for its production there was no additional energy. An indirect source of heat fully satisfied the need for water heating. In winter, the use of a boiler becomes extremely relevant due to the high savings of the spent energy for heating and heating.

- Compared to a flow-through water heater, the use of an indirect heating boiler makes it possible to supply hot water at once in several directions.

- The ability to use alternative heat sources (gas, electricity, sunlight, etc.).

The disadvantages of delicate heating boilers include the following:

- High cost of equipment. Considering the fact that it is necessary to pre-establish the heating boiler, the installation of the first falls around a heavy financial burden on the owners of a private house.

- In order to heat the water in a capacity weighing 100 liters, takes several hours. For this period of time, the temperature of heating in all residential premises will be reduced.

- The whole design takes quite a lot of space. Usually heating boilers and an indirect heating boiler are installed in close proximity to each other. And since the dimensions of the equipment are rather big, then sometimes for them a whole small room in the economic zone is given.

An indirect heating boiler is designed to improve the comfort of hot water supply. Devices of this type can be used as household sources or in small enterprises with an enlarged need for hot water. Corporate heating boilers are similar to cumulative water heaters, but instead of electricity or gas, a heat exchange device is installed in them. Hot water heating occurs due to the connection of heat exchangers to the heating system or another source of energy.

Design

What is an indirect heating boiler and for what to install it? To find an answer to this question, it is desirable to consider the device of the boiler of indirect heating. By analogy with accumulative heaters, the aggregates consist of the following elements:

- water tank with fittings for its supply and selection;

- layer of heat-insulating material;

- external metal or plastic coating;

- control and control devices.

This similarity ends. Electric heating element in classical design is missing. For warming water, a serpentine is used, connected via additional fitting to the heating system or another source of hot water. The change in the temperature of the heated medium occurs due to heat exchange through the walls of the tube. The boiler device for heating varies depending on the shape and sizes of the heating element. It can be:

- bent into the spiral or spring tube;

- a set of straight tubes collapsed in pipe lattices;

- additional tank.

![]()

For the manufacture of heat exchangers, stainless steel or brass tubes are used. The main requirement is a small wall thickness that ensures the most efficient heat exchange without compromising strength.

Modern water heater of indirect heating, except for the main heat exchanger, is equipped with a backup source of heat. Some models may have a gas heater or an electrical heating element. Models are manufactured in which an additional coil is installed to connect to solar batteries. The common name for boilers with alternative heat sources - combined. To combat scale, all devices are equipped with a magnesium electrode.

Work technique

How does an indirect heating boiler work? Very simple: inside the coil or component replacing it, circulates hot water or other liquid. The coil, heating, transfers heat into the outer medium, that is, in water, filling the tank. After a certain period of time, hot water is heating to the medium temperature, and the heat transfer process is reduced to the minimum value. When the temperature drops due to the loss of heat or the analysis of the water, the indirect heater again begins to warm the water.

Modern materials with a high degree of thermal insulation provide minimal heat loss, so in the absence of parsing the temperature of the hot water will change slightly.

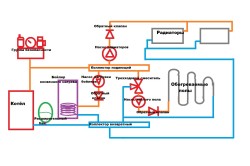

More an important point Is connecting a hot water boiler to the heating system. There are two main ways:

- serial connection;

- parallel connection.

With a sequential connection, the flux of hot water will pass through the heat exchanger and then go to the heating system. This method requires an increase in the temperature at the outlet of the boiler and a certain bandwidth of the boiler. The advantages of such a connection at a higher temperature of the heated medium, which means that it is possible to reduce its consumption due to dilution in a cold mixer.

The disadvantage is the need to stop the heating system when device faults requiring access to inner space. This flaw is easy to eliminate. Connection diagram may contain bypass line and shut-off valves for turning off the unit.

A parallel connection is the usual connection to the heating system. The indirect water heater is connected to the feed and reverse tube, respectively. Circulation and heat transfer occurs, as in a conventional radiator. The advantage of such a system is the simplicity of maintenance and repair; disadvantage - more low temperature Water at the exit.

Criterias of choice

Having understood with the question that such an indirect heating boiler, one can consider the properties of these aggregates. The advantages of indirect type boilers include:

- the possibility of heating and maintaining a large amount of water;

- smoothing the effect of peak loads;

- reducing the cost of production of hot water;

- the ability to pave water at several points;

- use additional sources of heat.

The most effective is the use of heaters if the house has a gas boiler heating. All gas appliances have an automatic system that supports the specified temperature. When a certain maximum value, the burner is turned off, with a decrease - automatically turns on.

The sequential scheme of operation of the boiler for water heating will increase the period of time between the disconnection and turning on the burner.

When the temperature of the heating system decreases, the inverse heat transfer transmission will begin. There will be no significant effect on the water temperature of the water, but gas consumption will decrease.

Disadvantages:

- high costs of acquiring and installing;

- long period of primary warm-up;

- the equipment has significant sizes.

Based on the above considerations, it is possible to navigate and choose the most suitable device for home. Also, the disadvantages include the installation of an additional circulation pump with alternatives heating.

Like all devices, boilers are not solving all the problems. Cumulative water heater Also has impressive sizes, flowing in most cases can ensure analysis only at one point. The advantages of the device will be especially bright with large numbers of living: in a large family or with several generations living under the same roof.

In large cities, very often turn off hot water. To solve this problem, many use water heaters of various designs. They are:

- Flowing;

- Cumulative;

- With indirect heating.

With the first two most of us familiar. But the water heater having indirect heating often causes many additional questions. So, the water heater of indirect heating, what is it? A similar question often defines the owners of country houses. What is the purpose of it applied?

Many people believe that if the heating system is functioning in the building, there is a hot water, it is not necessary to specifically mount an indirect water heater. This system allows you to create a simultaneous supply of heated water to all living in the house.

Indirect water heater, what is it? Let's try to answer this question. For example, imagine the situation when the kitchen needs to wash the dishes, and someone takes a shower. Each of them will need hot water, but it may simply not be enough, or the temperature suddenly falls. It is the indirect water heater specifically created for such situations. It is more than compensates for the missing volume of warm water.

Device of an indirect heating water heater

When the question sounds: the water heater of indirect heating, which is, then for the answer you need to talk about its design. Appearance Reminds a huge tank having a large cylinder form. The design has several components:

- Housing;

- Insulated material;

- Tank, usually welded from stainless steel;

- Thermometer;

- Magnesium anode;

- Heat exchanger.

Due to the thick insulation layer, the heat loss is not more than 4? With one day. The installed thermometer controls a certain temperature, not allowing it to fall.

Inside the water heater is a heat exchanger having a view of a tube made of brass or steel. In most cases, it is characterized by a complex configuration, it is set closer to the bottom of the tank. According to manufacturers, thus you can get a uniform heating of the fluid throughout the volume of the container.

Magnessed magnesium anode guards the tank from corrosion. All the emerging electrochemical reactions have an impact only on this anode. Other details will remain not touched. Anode, over time requires replacement, due to the big wear.

Benefits of the system

The main positive properties of the indirect heating system include:

- Water heating occurs in large volumes;

- Use warm water at the same time several people will be able;

- Low cost. To heat the water does not require additional energy. With the onset of winter, the use of such a water heater saves electricity;

- Indirect heating makes it possible to supply heated water simultaneously in different directions;

- You can use other thermal devices, such as gas or sunlight.

Disadvantages of the system

When erecting a housing, various engineering communications required to create comfortable conditions are mounted. Their constructive execution, functional features depend largely on the materialities and preferences of the owners. But among the diversity of such systems there are those that are mandatory.

One of them - . It is clear that for household needs, water is not only cold, but also hot. If it is impossible to connect to the central highway, users establish autonomous units. One of the types of such devices providing DHW are boilers. According to the principle of operation, they are divided into water heaters directand indirectheating. Here on the latter and stop.

It is clear from the very name that in the design the heating "element" is not provided. Heated water in the container is carried out by means of heat exchange. It occurs between it and the liquid, the temperature of which has already been raised by any heat generator. It circulates by the inner contour of the boiler, giving thermal energy Water in the tank, thereby ensuring its heating.

The advantages of the boiler of indirect heating

This is a good alternative heating boilers With 2 contours. And according to some indicators, boilers with indirect heating together with a single-circuit generator of heat even more convenient.

If the hearing of hot water is made at once from several cranes (for example, in the kitchen and in the bathroom), the pressure in the system begins to drop. This leads to "jumps" of temperature and changes in the mode of operation of the boiler, which does not most effect on its durability. And the boiler provides several points of the simultaneous water parsing at its unchanged temperature.

The possibility of uninterrupted ensigning DHW at any time of the day, without frequent inclusion of the boiler (in the summer), because in fact the boiler is nothing more than the thermal size. Such a device is particularly convenient if there are problems in power supply, interruptions with cold water supply.

Connecting the recirculation system creates additional amenities in the application.

In some cases, this option is more economical. In rural areas, rarely where there are centralized hot water supply. With gasification, the situation is not much better. And considering electricity tariffs, the use of electric - it's more expensive. The boilers on solid fuels are constantly known in summer (for DHS) there is no point in time, it is possible to periodically turn on electrical.

disadvantages

Connecting an indirect heating boiler to the heating system, it should be understood that it will provide a DHW only in the heating season. Therefore, at other times of the year they will have to be periodically turned on the boiler. The use of other thermal energy sources is associated with certain difficulties and costs. For example, installation thermal pump, solar collector. But in some cases, the change of hot water source to "feed" is quite convenient.

Inertia of the device. For boilers with a large capacity of water, considerable time is required for its heating.

In size, it exceeds (gas columns), so there is more free space for installation.

Main characteristics

- Capacity capacity.

- Mounting and position - on the floor or wall; vertical installation or horizontal.

- The maximum values \u200b\u200bof the parameters: heating temperatures, pressure in the "thread" of the supply and circuit of the DHW.

- Power (heat exchanger).

- Water heating time to maximum temperature.

- The presence of protection elements (thermostat, safety valve).

- Dimensions.

Depending on the manufacturer and the specific model, other characteristic features may also be, some of which are described below.

What to take into account when buying

The feasibility of acquisition. An indirect heating boiler is suitable if the consumption of hot water in the house is quite significant - from 1.5 l / min. This happens, as a rule, if in the family 4 or more people. In addition, it makes no sense to connect it to an electric heating boiler, since the consumption of electricity them will generally grow significantly, given the heating time of the capacity.

What kind of volume is suitable for joining the boiler installed in the house? This largely depends on its power. Did it "pull" the heating system at the same time, and the boiler in case of its inclusion on heating?

It is necessary to pay attention to the structural execution of the boiler. If the inner circuit is made in the form of a serpent, then how is the latter fixed? After all, it is clear that in the process of operation, salting deposits appear on its inner walls, and it should be served periodically. In the devices sold at a low price, this tube, as a rule, "tight" is welded to the corpus. Consequently, it will be impossible to remove it. It is better to acquire with a removable coil.

How many of them in the design of the device? If 2, this makes it possible to connect a boiler to two independent hot water sources (for example, a heating system + solar collector), which creates additional convenience in operation.

Cide making material. It is better if it is brass or silver coated.

The material used in the manufacture of containers. There are models where the heat exchanger consists of 2 tanks (one in the other), in the space between the walls of which heated water is circulating into the boiler. Durable is the devices that have a tank internal - stainless steel.

If it is from another material, then what is internally protective covering? The most reliable is done by spraying titanium. But the cost of such products is relatively high. For cheaper models, "Protection" is used, for example, from glass fluorofore. Even cheaper, if enamel, fiberglass. But the service life of such tanks is small - over time the protective layer is covered with cracks, and it is necessary to make a replacement. By the way, is it possible in this model?

It is important and which material is used as a heat insulating layer. If foam rubber, it is better not to buy. Qualitative is considered made of polyurethane.

Anticorrosion protection method. It can be anodic or cathode. Modes are more common with built-in magnesium anodes, which change as "generating"; it depends on the chemical composition water and intensity of the operation of the device.

The presence of other elements of the protective system - safety valve and thermostat.

More advantageous devices, where, instead of anodes, devices that perform the same function are mounted. They do not change, but they work only when the industrial voltage is applied. Consequently, such boilers are partly energy-dependent.

Is the recycling system connecting? There must be an appropriate nozzle.

Is Ten installed? In some models (combined), it is, which ensures the autonomy of the device.

Diameter of a snake tube. What it is thicker, the faster the heat exchange process will occur. At the same time, there will be a great power of the heat generator, as the water on the "feed" will be faster. This must be considered depending on how the source of hot fluid is supposed to connect a boiler.

Place installation. Boilers can be mounted on the wall or on the floor.

Warranty period. Availability at the place of residence of service organizations that have accreditation for the repair of devices of this manufacturer. The ability to purchase components, for example, magnesium anode.