Having bought a steel door, you have the right to expect that it will become the reliable guard of your home. But if the design is not firmly fixed in the opening, strong metal can be useless. In this article we will tell about how to control the quality of the installation of the entrance door.

- 1 of 1.

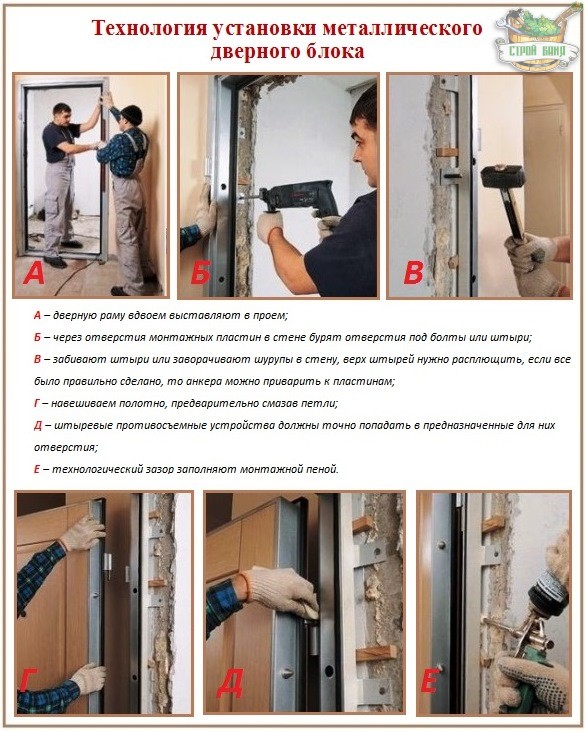

On the picture:

Where should the door be opened?The Ministry of Emergency Situations forbids changing the direction of opening the door, if the evacuation conditions from neighboring apartments deteriorate. This means that the sash when opening should not blow up common corridors and block the door located nearby. In practice, it is quite difficult to implement, so it makes sense to discuss in advance the issue with neighbors and come to the agreement. Note that the opening directions are important for the convenience of using the door, but it practically does not affect bonus resistance (if we are talking about a high-quality door block).

In the photo: Turri factory C120 entrance door.

Important questions

Do I need to strengthen the wall? Internal bearing walls and partitions in the overwhelming majority of urban high-rise buildings are made of monolithic reinforced concrete. They are strong enough and do not require additional strengthening. If the partition is composed of bricks or blocks, the opening will be required to strengthen the double welded frame from the corner - it should be ordered with the door. The need to find out during the measurements preceding the order.

Is it necessary to expand the discount?The inlet metal door often requires the expansion of the opening during installation. In the homes of some common series, for example P44 width door Piece It is less than 900 mm. The door frame and the mounted gap will reduce its value by about 80-100 mm. As a result, the discovery will be very narrow and inconvenient: it will be difficult to carry furniture and large-sized equipment. In addition, it may be disturbed by SNIP 21-01-97 and the order of the Ministry of Emergency Situations No. 313, according to which the width of the overwhelming "in the light" should be at least 800 mm (so that the stretcher can be carried). The extension service is relatively inexpensive - 4-6 thousand rubles. But if the Wall is carrier, these works will have to pre-receive permission in the housing bodies.

- 1 of 1.

On the picture:

In Russia, there are traditionally input metal doors with dimensions (height and width) 200, 210 cm for 80, 85, 90. Before buying the door, correlate its dimensions with the door sampled (in the homes of different series the width of the opening can be different).

How to locate a box? There are several ways to install a box in the opening: a folding, flush with the surface of a wall or with a shift toward the room. The first is extremely unreliable. In addition, the installed folding inlet metal door is very badly isolating the sound. This method of installation is resorted only when the discovery of narrow, and it is impossible to expand it for any reason. Blowing the box is optimally optimally from the point of view of burglary, however, the method is lost the possibility of installing the second (internal) door and limits the opening angle of the sash. Therefore, most often the box is installed flush with the outer surface of the wall, thereby providing satisfactory resistance to hacking and ease of operation.

In the photo: Impronta Materia Materia Door.

How to fix the box? Bond mounting nodes to the wall play an important role in ensuring resistance to hacking. As a rule, the box is fixed with steel pins (not less than 6 pcs.). These pins must be located so that they cannot be littering from the wall or cut off with a baccoon. Therefore, it is possible to mount the box through the holes in the racks only when it is blown out in the opening. If not, then the so-called mounting ears are welded in advance - steel plates, allowing to shift the attachment nodes towards the room. The greatest strength of the connection with the wall provides a box concreting. But not any inlet metal door can be installed in this way. It is necessary that its box be made of a special profile (with an open circuit of the section).

Installing Door

Preparatory stage. By visiting the brigade of installers, it is necessary to prepare thoroughly. First of all, check if there are no closer and other communications near the wiring and other communications - they need to be removed or protected. If you change the door in an already renovated apartment and at the same time decided to expand the opening, then, first, order the cutting of the wall with a disk saw equipped with an industrial vacuum cleaner (or "wet" cutting). Secondly, thoroughly cover the furniture and floors and try to seal the doors in the living rooms: dirt and dust will still be abused.

We accept work.Signing the act of work acceptance is not empty formality. We have the right to express complaints, so they are simply obliged to make sure that the door is installed qualitatively. First of all, pay attention to the attachment nodes: welding locations should be cleaned with a grinder. Make sure that the finish is not damaged anywhere, and the locks work gently, without jail. Walls B. panel houses Far from ideal, so it is often that the feeling that the entrance metal door is installed unevenly. As a rule, this impression is wrong. And yet, it does not interfere with checking the position of the racks in two planes by level.

The final stage.Installations can be carried out by laminated panels (the cost of the service is 2.5-4 thousand rubles). However, if the repair is in full swing, you should not hurry with these works. It is better to wait for the purchase of interroom doors, to acquire additional good things and arrange all the outlook in a single style.

03.09.2016 3817

Someone builds new houseAnd someone makes repairs in the old one. In any case, reliable security deposit and comfort of the hosts. Installation of steel doors consists of several stages. Their sequence and quality of execution are the key to long-term operation of the product.

Who installs

Behind the difficulty of choosing the design of steel doors, picky selection of color solutions. The door to your citadel is delivered and the question arises about who will perform the installation.

Right will be the decision in favor of specialists.There are several important arguments for this.

- Steel doors must be installed in compliance with the rules that masters know. Their violation will lead to difficulties in opening and closing doors, loop overcast and even the destruction of the wall.

- An experienced specialist always has required tool. Therefore, if I don't want to buy: Bulgarian, welding machine, drill, screwdriver, lomik, perforator, chisel, hacksaw - invite those who have it all.

- The master knows exactly the sequence of stages, the scope of work.

- In case of ne. proper Installation Will ask anyone.

Stage preparation of the door of the door

Installation of steel doors is made both in a wooden and or panel house. In each case, the preparation of the opening will be different.

AT wooden house:

- when dismantling the previous door, the discovery should be well cleaned, remove old anchors, nails;

- perform thorough measurements;

- to prevent the consequences of shrinkage, the discovery should be greater than the planned design. By perimeter, up to 7 centimeters are added to mount the cluster. It will protect the door block from various offsets. If they coincide with the old casing, which is in good condition, it is left;

- for the expansion of the loop in a wooden house used electric saw. If the house is a log, in the end of the birch, drink holes located vertically, which are filled with packles. Then placed the bars, the number of which corresponds to the number of fasteners points;

- then the placade and self-drawing is attached to these points. The number of points of fastening the loot and boxes in a wooden house are greater. So the severity of the design will be evenly distributed around the perimeter of the day.

In a brick or panel house, the extension of the door loan is obtained in two ways:

- knocking with a sledgehammer, perforator, grinder;

- cutting with a diamond disk.

In the first case, there is a savings, but there is a risk of cracking, which will lead to serious wall defects. The second option will cost more, only a specialist can perform it. To reduce the amount of dust, a special moisturizing vacuum cleaner is useful. Plus this method consists in accuracy of the cut. But, the use of diamond cutting is significantly complicated in the house with brick masonrySince serious deformations may arise. To avoid this, it is necessary to strengthen the opening over the door, having laid a jumper.

To reduce the opening, a frame of metal or a chapellor is used, insulating slopes and, eliminating cold bridges.

If the output suits, it is carefully measured and cleaned. Little gaps remain between the opening and design for the final leveling of the vertical and horizontal doors. They are then laid with concrete and bricks, or fought.

After preparing the workplace, go to the next stage.

Methods of fastening boxes

A big role is played by matching the dimensions of the doorway. In the house with wooden walls, its thickness is more massive. The box is installed in a cluster and levels.

If it is necessary that the face's face remains in the wall plane, the box is fixed, overlapping special plates for mounting to the inner edge of the day. Then the steel bars or reinforcement are driven into special holes for mounting plates. After that, the rods weld. There should be a small distance (10-20 mm) on the sides between the box and the wall.

When the door is "token" in the opening, the mount is carried out through the holes in the box itself. They can be provided by the manufacturer. In this case, the box is fixed with metallic anchors. If the holes have to drill, steel rods are clogged into the wall and weld to the profile. The side distance between the wall and the box is 1.5-2 cm.

Anchors are more expedient to use than steel rods, as the anchor expands and creates increased strength.

Sometimes these 2 methods are combined. After selecting the method, the process of fixing the box in the opening, withstanding clearances with wedges.

Steel doors with opening inward must be protected from pressed. The rigidity of the structure plays a big role. When installing such doors, you should pay attention to the additional increase in fasteners of locks and places from which the riglels go into the wall or boxes.

Installation of doors and sealing gaps

Installation from several steps.

- First, screw the door handle using a crusader. Check the maintenance of locks using keys. In an open and closed position, everything should work easily and effortlessly. Then the canvas are removed from the loops.

- On the perimeter of the inner side of the deck, the self-seeping sealing tape is glued.

- By installing steel doors for a private house, more often use installation on the border street - house. Therefore, it is necessary to thoroughly seal and apply all the seams.

- With the help of paint tape protect paintwork on the inside.

- Insert the insulation into the appropriate grooves if they are in the product.

- The doorframe is installed on 2 layers from below, which provide the required gap of 20 mm. Across the horizontal of the box, changing the height of the gasket. Then with the help of the level check its verticality.

- With the help of wedges, lock the box, while maintaining verticality. With wedges, the horizontal and verticality of the box finally remove.

- To attach door box Anchor bolts pick up the wall. To clarify the depth of the severity, the rapid tape is used. It is noted by the length of the bolt on the 30 centimeter drilling of the perforator. Not the touch of the box, we kill the first hole from the loop side. An anchor bolt is placed in the hole and takes off until they should be preserved into the plate. Then he slightly pulls up. Before you start drilling the second hole, with the help of a level, they are convinced that the box did not move. Install the 2nd anchor and pull up. Again check the verticality of the installation.

- Then the blade is padded to the box and check how the locking box is installed.

- If everything is fine drilled holes from the castles.

- Consistently perform the door mount through all the mounting holes.

- The steel door box is fought using a mounting foam. If the pistol with foam is not inserted deeply, the blowing is carried out with an increased flow rate. Foam should fill all the cavities. Scattered, making sure in the absence of emptiness. For the faving of narrow gaps use a special nozzle for a pistol. Wedges that hold the box are taken out when the foam is frozen. The cavities that remained from the wedges are carefully rolled. Plugs cover mounting holes. When the foam dries, it is cut and removed with greasy tape. Steel doors to the house are installed.

- The last item is sealing door jambs. It can be performed using various finishing materials or ordinary cement mortar and plaster.

Checking the performance of the door

Check is carried out in several stages.

- After installing the first two anchors from the loop side. With the correct installation of the locking rack, the locks and handle work easily. Otherwise, the rack is adjustable by gaskets.

- After mounting the anchor bolts of all holes, check the correctness of the installation again. In mad weather, a slightly open door is not moving. The door latch should be closed without effort.

- With the help of eccentric, adjust the latch adjoining.

Errors Installation

- Conformity technical characteristics Selected doors to your room. This item relates not to the installation itself, but plays a big role in achieving positive result. If you do not take into account the mass, structural features and dimensions of the doors, you can get a poor-quality installation.

- Measurement and preparation of the proof was incorrect. High-quality installation is in this case it is impossible.

- The gaps remain more than provided by the rules. Safety and hack resistance of such doors is very low.

- The installation of the doors was carried out without careful control of verticality and horizontal level. In this case, will be fixed in the correct position.

- Lack of necessary gaps Box - wall.

- Door slopes are not aligned. This means that the door can lighten to the box.

- The close layout of the holes for fastening to the edge of the wall. Over time, the wall can cause damage.

- Weak door mount, which is due to the insufficient number of attachment points.

- Disruption of the gap between the box and the beigels of the door lock. It may lead to a quick breakage of the locking mechanism.

- Anchor bolts are overly tightened. This will violate the installation level.

- Insufficient depth of holes for fasteners.

- Violated installation technology for wooden house. There are no necessary clearances for the clusade.

Steel doors are reliable if you were seriously prepared for their installation and did not allow listed annoying errors.

The installation price of the steel door will always be less than the price of eliminating the catastrophic destruction obtained with poor installation. Always remember this.

Repairs are a very complex and time-consuming process, which involves a large number of both physical and moral costs. For a modern person, the concept of repair includes not only long-term operation and quality of work performed, but also its moral satisfaction, i.e. Designer idea and modern stylization. In order to start and quickly finish repairs, you need to understand the whole process and follow a certain action algorithm. The first stage has always been and remains

When choosing an entrance door, you should always pay attention not only to design, but also for its functionality. The entrance door must work as a kind of shield for a person to secure him from "unwanted guests" - apartment thieves. First of all, of course, you need to pay attention to the locking wells, its elements (latches, peculiar necks and their placement) and reliability of their protection. Of course, entrance door Must be well insulated and made of high-quality material. To order the entrance door, you need to know the technical point, namely the size of the entrance door. That's where the most interesting begins.

Consider typical series of residential buildings.

By temporary sign, you can distinguish them as:

- Stalin's houses that were built in the 1950s. They are characterized by high ceilings, big halls and very spacious rooms;

- Khrushchev houses built from 1956 and 1964. Constructed from both bricks and from blocks. The big minus was that they had very small kitchens and there was no elevator. Also the bathroom was combined.

- Brezhnev houses were built, starting in 1965 and ending in 1980. They had more successful layouts, the number of floors increased to 9, and then to 17. They had very high popularity, both then and to date;

Modern construction of houses began since 1990 and to date. Every year, projects for the construction of residential multi-storey houses will be enhanced and become more comfortable for housing. The floors of the houses increase from 17 floors to 25. Basically, the "new buildings" are built on, where the old, emergency five-story buildings are demolished, outside the Moscow Ring Road, and build whole quarters of the so-called residential quarters. We will consider typical series modern housesAnd what entrance doors in Moscow you need to order for them.

The most popular on development are residential high-rise buildings of such series:

Series of houses P-3M.

These residential buildings were greatly popular, both in Moscow and in the Moscow region. The apartments of the houses of this series use modern methods of noise insulation, rounded balconies and erkers have been added.

Houses P-3M series are built from the panels and have overlaps from reinforced concrete plates. Each entrance has a passenger elevator with a carrying capacity of 350 kg and a cargo lift with a carrying capacity of up to 500 kg.

The size of the door loop in the houses of the P-3M series - width 90.0 cm, length - 207.0 cm.That is, in such openings you can install entrance doors with mounting dimensions 86-88 cm width, and 205 cm - height;

Series of houses P-44T

Series of houses P-44T

This type of houses is the most popular series of residential complexes. Features are noted by increased thermal insulation of walls, loggias that are glazed and the fact that the house is separated from the house under the red brick.

The walls of the houses of this series are made of panels with a brick finish. The entrances are equipped with elevators: passenger with a carrying capacity of 400 kg and cargo, with a carrying capacity of up to 630 kg.

The size of the doorway in the houses of the P-44T series - the width of 80.0 cm and the height of 200.0 cm. Such openings are definitely expanding on the sides and from above, because The standard mounting dimensions of the entrance doors under such opening are not manufactured.

After expanding the doorway, you can install the entrance door of any standard size: 86-98 cm in width and 205 cm in height.

Series of houses P-111M

Series of houses P-111M

it panel houses Modern buildings, which were designed back in 1990, commissioned by the Ministry of Defense and began to actively construct since 1996 and to date. The most important thing is that these houses are not subject to demolition.

Dimensions of doorways in the houses of the P-111m series:

- width - 90.0 cm, height - 210.0 cm.

- width - 100.0 cm, height - 210.0 cm.

Door openings in these houses are universal, so they can install the front door of any standard size: 86 - 96 cm in width and 205 cm in height.

![]() Series of houses P-55M

Series of houses P-55M

These houses were built only thirty buildings and all in Moscow. They became famous for their noise-protective panels. Construction went starting from 1997 to 2008. When designing, an emphasis was emphasized that all windows of the bedrooms of these houses were required to go into the courtyard, and the windows of the kitchens and staircases, on the roadway.

The size of the doorway in houses P-55m: width - 90.0 cm, height - 207.0 cm;

In such an opening, you can install the input door of the standard size: 86 cm wide and 205 cm high.

Copet Tower House Series (Candle)

Copet Tower House Series (Candle)

This is a series of houses that are built on the basis of only one entrance and have the technical structure of the skyscraper. This series began its development since 2008 and to this day is one of the most prestigious and popular. All loggia glazed in these houses. Significantly increased the area of \u200b\u200bthe kitchen, respectively, the area of \u200b\u200bthe apartment itself. Modern high-speed elevators are also used.

The dimensions of the doorways in the CE-Tower series houses are: 90.0 cm width and 207.0 cm height.

By such a size of the doorway, you can install the door with the mounting dimensions of 86 cm wide and 205 cm tall.

In any case, if you have doubts about the size of the doorway, it is better to call the insurgent masters, which will come and remove the size of absolutely free! Sometimes it is better to trust professionals))

What to agree: Expansion or strengthening of the opening?

How often have you asked about why when choosing a steel door at an exhibition point or by phone, you are talking about one price, and when the measurement arrives, the cost is completely different? Why the final cost may increase? What is additional work and why are they worth more money?

To answer these questions, let's consider the most frequent moments arising from the arrival of the measurer and inspection of the doorway.

1. Expansion of the Owl

In the panel houses of the series P-44, P-44T, TM-25, CE, P-ZM, etc. prerequisite The correct installation of the steel door of the outer opening is the expansion of the opening or in other words, the cutting of concrete quarters. As a rule, it is in them a box with the opening of the apartment in the apartment at the departure of the house.

Such an extension is not redeveloped and allows you to increase the running opening, eliminating, thereby, there are problems in the future with a row of large-sized (technique or furniture).

2. Strengthening the opening

Strengthening the opening is usually necessary in cases where the wall in which the installation of the steel door is supposed to be elevated from plaster or slag block. The thickness and strength of such walls is not sufficient for the installation of a heavy model (over 80 kg). To solve this problem and use the so-called. gain. Often, it is necessary in brick, block, some panel and monolithic and groan houses. The enhancement methods of the opening may be somewhat: with the help of the corners cooked with each other for the strapping of the opening, it can be a pipe, a channel, or another vertical-installed profile, fixed with mounting pins to the floor and ceiling. To give greater stiffness, it is possible to mount with pins driven into the wall and welded to the profile.

3. Installing fraumuga or sidewalls.

It is not uncommon and such cases when the so-called is installed above the door. transom. It can also be found in brick, block, some panel and monolithic brick houses. As a rule, it is made of plywood or organic and overlaps the gap between the door block and the ceiling. When dismantling the old model to save this design Most often it does not work, and there is no point in this. The presence of fraumuga above the door is also determined by the measurer wizard, but the material, from which it will be done is determined directly with the customer. It can be done metal (in the color of the canvas), and if its size will allow, then decorative panel. You can also lay it with foam blocks or bricks, after setting the jumper.

The love of compatriots to metal entrance doors is justified by the reliability of structures. Sometimes, not so much the door itself is protected from unauthorized penetration, as unwillingness of representatives. criminal Mira Sound your actions with a scraping and ringing. Therefore, they equip our fellow citizens with them, both private suburban buildings and urban apartments, reasonably buying not the cheapest options. When it comes to security, there is no point in saving. But Installation metal doors With your own hands, it will reduce consumption, since the value of the installation is often equal to the quarter of the price of Iron Protection.

Video Instructions for Installing the Input Block

Nuances Mounting Steel Doors

Metal door block, as well as analogs of wood or plastic, consists of a door box and a canvas hung on it. It is distinguished by the mandatory presence of the lower crossbar - the threshold, as well as often embedded in advance locks and attached loops. In advance, the installed fittings without doubt makes it easier to install, but it makes it often and thoroughly tap horizontals and verticals, repeatedly hang the cloth to check the door stroke. It is impossible to neglect the control actions, because it will be necessary to stockday, not only by the construction level, but also a muscular assistant.

We are equipped with metal doors of the structure of bricks, wood, gas-silicate blocks, foam concrete, etc. It is important to take into account the technological features of the building material, on the basis of which decide how to install the inlet metal door and how to prepare the opening.

Depending on the technical specificity of the carrier wall, the Contractor will need:

- clean the plaster to the brick or artificial stone so that the technological gap of 2.0 - 2.5 cm remains between the door block and the wall;

- build an opponent in a brusade or a log structure, and then it is then attached to it to mount the door frame with a gap at a minimum of 10 cm.

The owners of brick and foam concrete property will require a perforator or an electric drill and a chisel with a hammer, the owner of a wooden building instead of a perforator will be needed by chainsaw and a knife, instead of chisel.

Important. Since the steel door blocks are equipped with the entrance, the canvas should be opened. According to fire prescriptions, the entrance door should not create obstacles to forced evacuation.

The web of the steel door is undesirable to free from the packaging material until the end of the installation procedure. However, it is not so impossible to check the quality of the product. Note that deciding to install the rail door personally, the owner automatically refuses the provider's warranty obligations. No claims for scratches and dents after installation will not be considered. It is better to remove polyethylene, examine the purchased goods, and then attach the packaging back the mounting ribbon, so as not to spoil the decor to the instrument or mounting foam.

Preparatory stage

Few differs from the standard installation procedure of any door, includes three traditional stages:

- preparation of the opening with the adjustment of its size in the case of incorrectly produced measurements;

- fastening the box in the opening with anchor plates, steel rods or screws depending on the building materials of the wall and the location of the door frame in the opening;

- verification of work, adjustment, if necessary, marching technological gaps and pads.

Basically, the input steel unit is flush with the outer plane of the wall, but it can also be "bold" in the opening. The first option involves fastening with anchor plates. The second method predetermines the fixation of the door frame-box by means of the anchor bolts existing in the configuration of the unit through it, or replacement of factory anchors of steel pins. The most reliable experienced installers recognize the combined method when the installation of the iron door performed by its own hands is carried out on the anchor plates, bent along the surface of the opening, and bolts or pins.

Note. If in the configuration of the budget door Block No anchor bolts, you need to independently buy hardware, 10-15 cm long. The diameter of the bolts depends on the size of the mounting holes, is usually used 12-15 mm. As an alternative, the segments of the steel bar with similar dimensions are suitable.

Standard installation sequence

We assume that the old design is dismantled, and the opening to upcoming work Prepared. That is, it allows it to leave the process frame to be left around the perimeter, the technological gap required to fill the space by mounting foam or cement mortar. So, you can install in the prepared opening the air door without increasing or decreasing:

- We put together the box of the steel door without canvas in the opening, laying on the perimeter wooden wedges. They are necessary to adjust the position and fixation of the box, as well as to provide technological retirement.

- Expanding the horizontally and vertical by the construction level, shift the wedges in the required side. That is, we drive them deeper or, on the contrary, pull out slightly. Make sure that the indents from the wall along both shoals were approximately the same.

- Adjusted and found a loyal position, firmly secured with a frame with wedges so that when drilling holes in the wall it did not shift.

- Through the mounting holes of the first looped jamber, the hole in the wall of the opening under the anchor with the appropriate sizes.

Note. If the manufacturer of the cheap input block does not make holes for the bolts on the door frame, they need to be drilled independently before starting work. 3 on the feigned and looped jamb, 2 on the threshold and perts.

- Bolts insert and tighten nuts.

- Temporarily inspired by the cloth to check its stroke. It should not be opened spontaneously and require an effort for closing / opening.

- We remove the canvas, install fasteners from the fictional side, fix the threshold and sod. We are inspired again to check. If necessary, change the position of the box by loosening or tightening nuts.

- Again, we leave only the door frame in the opening and look at its construction tape to protect against assembly foam.

- We blow up technological indents from the wall by mounting foam according to the recommendations of its manufacturer, cut off.

After the polymerization of the assembly foam material, all unattractive areas are closed by navigating.

Nuances Installation of the Iron Door in Credit

Regardless of the material from which the doors are made, an opponent is required to arrange the entrance to the wooden structure. The need to facilitate an additional frame under the door box is dictated by the property of wooden buildings to settle after construction. In the first year, the crowns will fall intensively by 7-10 cm. It will decrease in an altitude even a bath of glued timber, though not so much. Therefore, in the first year wooden cuts In general, it is not customary to equip doors, windows and finishing.

The magnitude of the shrinkage is difficult to calculate in advance, it depends on the period of forest harvesting, and on the quality of drying wood, and from climatic conditions. But the stock for the peculiar to the tree should leave the move, otherwise the door jershits at an inappropriate moment or the crown located over it over with the roof will hang on the door, and there is a significant gap between him and the previous crown.

According to the peculiarities of the wood, we developed a special installation technology in the cutters of metal doors:

- In contrast to the installation method wooden doors The top plank is not satisfied, since the perturbation of the metal frame will be the support itself.

- In order for the "unshakable" the steel door did not overlook the structure, it is attached to the boilers inserted into the groove formed in the wall.

At the expense of the groove attachment, the wafes will keep the position in the shrinkage of the crowns and protect the door frame from turning up the bolts, which is inevitable if the fasteners will "go" down together with a log.

What should be done:

If the opening is formed during the construction period, the door design is selected so that there is at least 10 cm between the priolok and the plane, and 6 cm remains with each side. For the opposites we buy a timing of 100 × 150.

- In the height of the door with the monster and screaming the boilers. Drink along the central axis one of the sides of the groove bar with a depth of 5 cm.

- Carefully chainsaw inspi on both sides of a cut of 5 cm approximately a quarter wall width. Finally, the crest form the chisel, slowly cleaved wood. No need to hurry and forget that in case of an error, you will have to buy the door with a greater width and increase the opening.

- Stapler fix on ribbon ribbon pass.

- Breppy on top of the panewood flap to the wall.

- We set the steel door according to the standard rules, retreating from both yokes one by one centimeter and from the top of the door lumen 10 cm. Breakfast is only for refractors and a wooden threshold with self-draws.

- Technological gaps need to fill the packles and cash from both sides.

Three years later, instead of the paneling, the gaps of the axial opening can be filled with foam, but it does not recommend that they do not recommend so. After all, as a result, the shrinkage of the foam can crack and lose her tightness.

There is still an easy installation option with the mounting frame of the iron door with self-drawing to wooden wall. Builders used this scheme argue that the owners simply have to periodically get out and screw the bolts again when they begin to turn out of the wall from the shrinkage. However, the holes in the building material will have done a lot, which does not contribute to its strengthening. It is better to suffer, find out how to properly install the metal door into a wooden structure, and proceed according to technological prescriptions.

Video example with alteration of opening

It is impossible to say that the home master does not have to suffer with the installation of the steel door. The case is time consuming and not easy, but tangible savings will please pocket, and the heart and bath will warm up a qualitative result of its own effort. No one will do better than the caring owner of his beloved country property.