The boiler with two contours warms the water not only with electricity. Inside such a water heater there is an additional heat exchanger, "extracting" energy from the housing heating system.

As a result, users of two-kinning boilers pay for water heating less than the owners of classical (single-mounted) water heaters. Therefore, in this article we will consider the most sought-after models of such boilers, paying attention to the device and the principle of operation of the two-circuit machine.

Device and principle of cumulative boiler

How is a double-circuit water heater?

The design of the two-circuit unit is practically no different from a single-mounted version. "Double" boiler has and cumulative capacity, and a pair of fittings (for cold and draining hot water), and an explosive valve, and a temperature sensor, and even a TEN.

However, in addition to the "classic" set of nodes and parts in the design of such a water heater, there is a special element - a copper coil - a spiral heat exchanger, the taps of which come out of the housing. According to this coil, the heating system is "launched", which heats the copper circuit.

As a result, water in the accumulative container is heated not only by a tubular electric heater (TEN), but also a spiral heat exchanger. And the boiler itself works as a thermal battery. Therefore, such water heating settings are the recommended elements of the strapping of solid fuel boilers.

What is the benefit?

Connecting a two-kinning boiler guarantees the owner of a similar water heater the following advantages:

- Minimizing electricity consumption . After all, most of the energy for the DHW generates a copper coil.

- Align the temperature of the coolant in the heating system . The water accumulated in the boiler removes excess energy allocated at the beginning of the combustion of solid fuel.

- Reducing gas costs, firewood, coal feeding heating boiler . After burning out the fuel, the coolant begins to absorb the energy accumulated water, giving the heat boiler with batteries.

- Independence of the hot water supply system from the power supply . When interruptions in the power grid, the work of the DHW will provide the contour indirect heating.

Boyler scheme with two contours

In a word, a dual-circuit version guarantees an increase in the energy efficiency of the hot water system, simultaneously solving the problems of the operation of the heating boilers. By purchasing such a device, you get a water-drift installation, and a thermal battery.

How to choose a boiler two-door indirect heating

- First of all - by the volume of the drive . At the same time, at least 20 liters are allocated for each potential user. That is, for a family of three people need a boiler with a capacity of at least 60 liters.

- In second place - by the number of secondary heating contours . If you plan to connect a boiler only to the boiler, then you need only one inner coil. If your boiler will work from the boiler, and from a solar collector, saving electricity and winter, and in summer, then you need at least two coils.

- In the third place - on the size of the installation . Such a heating device will have to be raised above the level of wiring and heating batteries. Therefore, before buying, you should measure the distance from the windowsill before the ceiling in the room allocated for the placement of the boiler.

How to connect a double-circuit boiler

- Initially, the boiler put on the podium or attach to the wall using the bracket.

- Further to the "cold" (lower) nozzle connect the removal from the home water supply, and to the hot (top) "connector" - the collector of the hot water system.

- After that, a removal from the pressure branch of the heating system is connected to the upper branch of the serpent. The lower pipe of the heat exchanger is connected to the feed branch, having embedded the tee behind the pump and the expansion tank.

- In the final, the boiler is connected to the power grid using the UZO and the automatic fuse by 16 amps.

Popular models of double-circuit water heaters

![]()

- Ariston double-circuit boiler - 80 liters. Capacity.

- Thermal capacity is 21.3 kW.

This model is compatible with the wall boilers of the same company. The manufacturer guarantees uninterrupted hot water supply of a family of 3-4 people for at least 10 years. Other advantages: magnesium anode, high-quality housing welding seams - Micro Plazma TIG technology, guaranteeing leaks, outdoor or wall mounting (optional owner).

The main characteristics of the heating device:

- Capacity of the drive - 80 liters.

- Square Zmeevik - 0.5 square meters. m.

- The water temperature at the exit - 70 degrees Celsius.

- The height of the case is 0.78 meters.

- Case diameter - 0.56 m.

- Power TEN - 3 kW.

- Cost - 27-30 thousand rubles.

Gas double-circuit boiler and boiler in one case. One contour of this unit works on the heating system, and the second is on the DHW system. Therefore, such a heat generating unit can also work as a flowing water heater, and as a boiler, using the cheapest type of fuel - gas.

The main characteristics of the boiler boiler:

- Heavy Power - 32 kW

- Performance in flow-up mode - up to 800 liters per hour.

- Capacity of the drive - 60 liters.

- The water temperature is up to 90 ° C.

- Pressure in the DHW circuit - up to 7 atmospheres.

- The dimensions of the rectangular case are 800x850x600 mm.

- Cost - 190 thousand rubles.

- A double-circuit boiler with a thoughtful thermal insulation system.

- This model cools at 1 ° C for three hours.

- Consequently, during the day the temperature of the water in the accumulative capacity will fall only at 8-9 degrees Celsius.

And this is when the TEN is turned off and a cold coil of indirect heating contour. Additional options for the heating instrument: built-in thermostat, the lower location of the hot and cold fitting, resistant to corrosion housing with a polymer coating. Complete supplies are a regular wall mount bracket.

Installation features:

- Tank capacity - 240 liters.

- Rated power - 68 kW

- Power TEN - 2.2 kW.

- The temperature of the water is up to 90 degrees Celsius.

- The area of \u200b\u200bthe heat exchanger is 2.3 m2.

- Height / Diameter - 1.75 / 0.56 meters.

- Cost - 106 thousand rubles.

Gorenje GBK 120 LN

The boiler is a device with which you can implement uninterrupted hot water supply in the apartment or in a private house. The boiler is considered a variety of water heater having a container for accumulating the heated fluid. Also, water heaters can be flowing. Boiler equipment (BO) is divided into electrical and gas, most often used electric cumulative boiler.

Boyler equipment for hot water supply

Building and principle of work

A distinctive feature of boilers is the possibility of accumulating hot water for its subsequent use. In the design of such a device, a tank for a liquid is provided, which is heated using a Tan or gas burner. This is a direct heating equipment. There are also water heaters with an indirect water heating method. In this case, a water or steam heat exchanger is used.

It is worth noting that the tank of the device is protected by the heat-insulating layer and the casing. From the outside, the control buttons are located, with which the temperature can be changed. When the water is cooled to the value, the thermostat is triggered below.

The open and closed boiler differ. Open equipment provides supply hot water One point. Its work applies the principle of overlapping the power supply of water at the entrance to the device. Closed equipment is used to supply hot water at once in several points. In this case, the accumulative container is made of stainless steel coated steel or copper.

Flow-type water heaters have one significant difference from storage: the volume of space in which water is heated, significantly less, and high power is required for rapid heating of the fluid. In this case, the implementation of tanes, uninsulated spirals, gas burners are used for implementation.

The boiler for heating the water is preferable, since it requires smaller energy consumption and easier to operate.

Device scheme cumulative water heater

Device scheme cumulative water heater

The design of the electric boiler includes the presence of the following components: water supply pipes, temperature controller, flooding, heating element, fuse, hot water output pipes, containers, housing, thermal insulation and power supply. In the container with the help of a tan, water is heated, which comes through the feed pipes. If necessary, water comes out of the device by opposite pipes. The fuse ensures the safety of use, since it makes it impossible to use equipment in the absence of water in the system. The flow rate is needed to stabilize the flow of cold water at the entrance to the device.

Pros and cons

Benefits of boiler equipment:

- the ability to independently install;

- safety operation;

- the electric boiler does not imply special documents and permissions for installation;

- water pressure in the water supply system does not affect the operation of electrical devices;

- a wide range represents models with different technical parameters, a color solution, sizes;

- rational use of space;

- aesthetics.

Disadvantages of boiler equipment:

- when planning a large consumption of hot water, a more overall device must be purchased;

- long heating with a large volume of tank:

- the need for regular maintenance.

Choosing Bo.

When selecting a specific model of the accumulative water heater, you must pay attention to the following details:

- The volume of the boiler. When choosing a device, it is necessary to take into account that on the day one person needs a minimum of twenty liters of hot water. Therefore, the model is required to select after calculating the consumption of water on the family.

- Variety of the inner surface. It is performed from titanium coating, enamel or stainless steel. It is better to choose water heaters with enamelled or glass fluorophore coating. But in this case, it is better not to heat the water above 60 degrees so that the coating does not crack.

- The heating option. The boiler uses gas or electric heating, and choose a certain of them from the installation capabilities. Electrical equipment should be selected if the gas is not applied in these conditions.

- Indirect heating is required to choose when in the house several points of water intake and is expected to be high water consumption.

Manufacturers

There are many manufacturers producing boiler equipment. The most popular and in demand includes the following techniques:

- AEG (Germany);

- Baxi (Italy);

- Gorenje (Slovenia);

- NEVA (Russia);

- PROTHERM (Slovakia);

- Thermex (Italy);

- Reflex (Germany);

- Stiebel Eltron (Germany).

Presented brands are distinguished by high quality and reliability. The optimal combination of cost and technical parameters is characteristic of the Equipment Thermex and Gorenje. Stiebel Eltron is considered the best in the European market.

Connecting electric boiler

The electric boiler applies more often than gas, so it is important to deal with the features of its installation into the water supply system. The installation of such water heaters should be carried out in the sanitary wardrobe, in the immediate vicinity of water distribution systems and water intake. It is important that the installation of boiler equipment is implemented in two stages. First, power supply is supplied to the place of installation of the device, and the socket is installed, and then the boiler connects to the water supply, that is, a strapping is implemented.

When connecting power, it is important to maintain a device that is implemented using a three-core cable. Based on safety requirements, it is impossible to install an electrical outlet next to an open source of water. Power supply should be allocated in a separate group.

It is very important to install the device for a protective shutdown to make the operation of the equipment safe.

The second stage, that is, connecting the boiler device to the water supply, is implemented as follows. When installing, inflexible pipes made of steel, copper, metalplastic are used. Water supply is implemented along a separate line or from a tee, depending on the wiring option: collector or tee, respectively. The device is heated water and transmitting it to water intake nodes. To disabling the equipment requires installation of shut-off cranes. It is also important to establish the filtering system of the incoming water. In addition, it is planned for a drainage for emergency drain of water.

The scheme shows a boiler connected to the water supply system. It is shown with cold water, connection to it pipes for water supply to the device. A gearbox is also specified that stabilizes the pressure for the correct operation of the system. After heating, the water enters output pipes and then goes to the mixer, after which is used for its intended purpose.

Double-circuit boiler

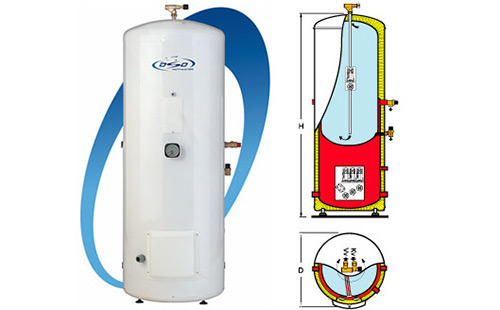

A double-circuit boiler was developed to optimize the use of water heating equipment. It is a container with elements of thermal insulation, the heating of water in it is realized due to the coil, that is, the copper spiral pipe along which the liquid is moving, heated in the boiler. Also in the design of such a boiler, the presence of nozzles for the receipt and output of water is envisaged. A double-circuit boiler sells indirect heating of water by means of a serpentic heat exchanger.

Scheme of cumulative water heater indirect heating

Scheme of cumulative water heater indirect heating The diagram presents the pipe input and output pipes, the thermostat to maintain a constant temperature, the tank to maintain the heated liquid, the heat-insulating elements, the casing, and the heating element - the serpentic heat exchanger, along which the fluid is moving, heated in the boiler.

Dual-circuit equipment is characterized by impressive dimensions to ensure the reserve of hot water for the whole family for household and hygienic needs.

In addition, double-circuit boilers are characterized by significant energy savings, since hot water is capable of retaining its temperature for a long time, and the re-heating when cooled is carried out quite quickly.

A similar device of the water heater allows you to mount it together and simultaneously with the heating boiler. It is possible to purchase wall-mounted and floor gas boilers equipped with a boiler. This allows you to improve the functionality of the device and save cash on energy consumption during operation.

The advantages of double-circuit systems include:

- fast water heating;

- long service life;

- full heating of the entire volume of the liquid;

- safety;

- functionality.

Selection and installation. Video

Current advice on choosing and installing the boiler are collected in the video below.

Cumulative water heaters are characterized by functionality and ease of use. Their use allows for economical and uninterrupted hot water supply.

In contact with

Ensure uninterrupted hot water supply round year You can in any house. To do this, you need to install a boiler - an electric or gas water heater, which supplies the local water supply system with hot water. It is under pressure above atmospheric.

The modern market offers customers a wide selection of water heating devices. Therefore, choose which better boiler is very difficult to purchase. The most frequent solution is taken towards an electric boiler, or a cumulative water heater.

Such a boiler has an advantage over other water heaters due to its balanced construction in terms of installation, reliability in operation, efficiency, production performance.

Types of devices for continuous heating of water

Water heater is a special device for continuous heating of water. To achieve a certain temperature, various fuel is used: liquid, solid, gaseous, electricity or coolant from an external energy source. All water heaters are divided into two categories - accumulative and flowing.

Boiler is a storage device for water heating. In other words, this is a special tank for filling fluid, which is constantly heated. The source of heat in such heaters is inside (tan) or under the container itself (gas burner).

Boilers (water heaters) of indirect heating are heated by water with a steam or water heat exchanger. Hot water in cumulative boilers circulates in a closed circuit, and heats up with a heating boiler.

The market offers both accumulative boilers of a combined type. When water is heated with a TEN, heat exchanger and other methods. The tank outside is protected by a layer of thermal insulation and a protective casing. On the outside, the control panel is embedded, which allows you to control the temperature regime. The established bimetallic thermostat is triggered when water cools up to the level below the set temperature.

There are models of closed and open type.

- A closed type device is used by a centralized water supply system of different points where water is closed. Capacity for the accumulation of water is made of metal (enameled steel, stainless steel, copper).

- Open type capacity provides only one point. Works on the principle of overlapping the network water, which is under pressure, at the entrance to the boiler.

Flowing water heaters are significantly reduced in volume and have an inner tube. Water flows through the heating capacity and heats up. To heat the water, a TEN is used, uninsulated spiral, gas burner., indirect heating.

To use gas flow boilers, a smoke system should be installed on a special project. Such water heaters are also closed and open.

For consumers there are also variants of combined flow-accumulative water heaters.

Pros and cons of cumulative heaters

When choosing a gas boiler, the buyer is guaranteed to heat water with greater speed. If we compare the water heating time about 80 liters, then the electrospode of indirect heating will be needed for more than an hour, and for the gas device there will be enough forty minutes.

It is enough to solve the problem of the absence of hot water in non-gasified settlements. Installing the boiler or boiler, as an indirect heating device, which is powered by the power grid, the best solution in such a situation.

In addition, such heaters are characterized by a number of benefits:

- installing an electrical device for indirect heating does not require permission and collecting documents;

- you can install on your own, having the necessary knowledge and experience;

- plastic pipes are used for mounting;

- the indirect heating device works without open fire - there are no strict installation requirements;

- water pressure force has no effect on its temperature regime, in contrast to the gas columns;

- due to the correct form and beautiful design solved the problems of aesthetics and optimization of space;

- dimensions, color schemes, a variety of models according to specifications allows you to satisfy many requests.

As each device, the accumulative equipment has a number of shortcomings, both electrical and gas:

- the dependence of the size of the boiler on the number of family members;

- for a large tank, long heating time;

- regular care and replacement of parts;

- installation in specially designated places with easy access when servicing.

To decide what is better to purchase - a gas and electric water heater, it is necessary based on the individual conditions and requirements that are presented to an indirect heating device. From right choice The comfort of the whole family depends.

Two contours of the water heater - the principle of operation

A two-circuit device is a heat insulated container in which water is heated due to the coil. This is a special copper tube in a spiral form at which the movement of the coolant from the boiler takes place. The work of such a water heater is designed for a long time.

In addition to the coil, the boiler is equipped with nozzles through which water is received and excreted. It is necessarily the necessary hole, intended for maintenance.

Dual-circuit devices are manufactured in large sizes. This allows you to ensure the reserve of hot water for the whole family and in all rooms - in the kitchen and in the bathroom. For a two-circuit device, energy efficiency is characterized. The heat water retains its heat for a long time, and when cooled heats up in the shortest possible time.

Favorable combination

IN lately In private homes, a double-circuit heating boiler is installed, which is part of the heating boiler. This saves on devices and on the installation of equipment.

In a two-circuit boiler, water heating in the second circuit occurs in the flow-through mode. After opening the crane, the cold water passes through the coolant, heats up to the desired temperature, then enters the taps in the form of hot water.

The performance of the boiler, which works as an indirect heating device depends on the power of a particular model. It is appropriate to use a boiler with a capacity of 20 to 24 kW.

For the acquisition, outdoor and wall gas boilers with a boiler are offered. Boilers with integrated indirect heating instrument for the price, of course, more expensive. Gas boilers With a water heater, the most expensive, but they justify themselves through saving money on installation and control water consumption.

The advantages of two contours

Water heater, in which water is heated according to the principle of indirect heating, has a number of advantages:

- High water heating rate due to a copper spiral heat exchanger, hot water does not have to wait for a long time.

- The duration of service life is at least 10 years. But the boiler works for a long time subject to maintenance and preventive measures.

- The cylindrical form provides a full warming throughout the volume.

- The presence of the casing does not allow damage the boiler, does not allow water leakage.

- Adjustable supports make it possible to install a boiler in the most inaccessible places.

What to pay attention to

When a boiler connects with an indirect heating system to the heating system, you should pay attention to such moments:

- By buying a boiler, consider water consumption for each family member - 20 liters per person;

- The device needs to be grounded;

- At the outlet of the heated water, it is important to establish a hydroaccumulator for the effect of depreciation of water blows and the compensation of thermal expansion;

- Near the boiler should be a socket. It is necessary for the uninterrupted use of hot water in case of disconnection of heating. Then the agents are used;

- Cranes are installed on the feed and inverse pipe of the heating system. This is important for shutting down the boiler for servicing or repair, makes it possible not to interrupt home heating;

- The boiler is located as high as possible so that the water is heated faster. Radiators must be lower.

The gas or electrical device of indirect heating is ideal to use for a large family, where there are points of water intake simultaneously in several rooms.

Boilers with indirect heating system are an indispensable component of heating and hot water supply systems. To save money and create greater comfort, it is better to install a two-circuit device.

Unlike apartment buildings, providing a private cottage with hot water supply has always been the concern of the homeowner. Now water heaters are purchased for this purpose. different types, including electrical. The latter are very popular, as relatively inexpensive, reliable and easy to connect. But if you have conceived to take electricity as an additional or the main energy source for heating your home, then why not immediately buy a double-circuit electric boiler? This will help you with the go to resolve the question of water heated to economic needs.

Device and principle of operation

On the modern market of heating equipment are offered two-circuit electric boilers of heating three types:

- with an additional flow heat exchanger;

- with built-in accumulative boiler;

- with the possibility of connecting and joint strapping with a remote boiler of indirect heating.

In all heat generators with the possibility of water supply for DHW, heating is carried out using tubular electric heaters (TAND). Tennes are installed inside a closed container filled with coolant. The heating elements must be constantly immersed in water, so an automatic airport bucket is installed at the top of the tank. If the air is not reset, then the part of the Tan tube will cease to be washed with the coolant, as a result of which its tungsten spiral overheats and brave in a short period of time.

For reference: The usual tap water contains a certain amount of air, when heated in the container, it begins to accumulate in its upper part, forming an air layer. In industrial boilers, the heating system is filled with water that has passed the procedure for removing air bubbles. It is difficult to perform it on the household level due to the high cost of equipment.

Electric concurrents with a flow heat exchanger

Heat exchanger two-kilt

In these aggregates, heat heating for the DHW is carried out from the already heated coolant through an additional heat exchanger. Here, the principle of operation is as follows: In the usual mode, the TEN is heated by the coolant to the required temperature, it moves along the main contour using the built-in circulation pump.

As soon as the hot water valve opens, the duct sensor fixes this fact and transmits the pulse to the control unit. Then the coolant stream switches from the main circuit to the secondary, giving the two-way valve drive command distributing streams. At the same time, the heating of the house ceases to focus, since the heat generator works on the DHW.

Circulation pumps for heating

A heat exchanger is built into the secondary contour, in which two streams move towards each other, having exchanging warmth. That is, the coolant intensively gives the heat to heating the flowing water. As soon as the crane is closed, a reverse process takes place: the controller on the sensor signal gives the command of the two-way valve drive and he switches the streams back, the double electrocotel is functioning again as usual.

The heat generator of this type is advisable to use when there are 2 or 3 small hot water consumers, such as a bathroom and a kitchen. Then the performance of the flow heat exchanger will be enough. In addition, electric double-circuit boilers with a flow heater possess other disadvantages:

- The presence of hot water drops while using two consumers.

- Turning off the heating system During the operation of the DHW contour, it begins to affect the microclimate when heated large rooms, especially in disgraced buildings.

- The heater requires maintenance (flushing), because on the internal surfaces over time there is a scale that impede the good heat exchange.

Copper boilers

Connecting the flow and cumulative boiler

The disadvantages associated with the flow heater are absent in the double-circuit electrical boilers with a built-in hot water cumulative capacity. In this case, its consumption and the number of consumers depend on the capacity of this container and the thermal power of the unit. Manufacturers offer wall-mounted and floor versions of heat generators for home and DHW heating, in the first installed boilers of small capacity (up to 100 liters), in the floor aggregates, the tank capacity can reach 300 liters. This allows you to provide the necessary hot water consumption for all economic needs with a large number of people living in the house.

The principle according to which the operation of an electrocotel with a boiler is working, reminds electrical installation with a heat exchanger. The difference lies in the fact that the switching of streams is carried out when the coolant in the system scored the required temperature.

Double-circuit boilers Navien.

In one-connecting units, when the required temperature of the coolant is reached, the control unit turns off the tanes and includes them after the water cools up to the minimum lower threshold.

In the two-kinetic apparatus, the Teni continue to work, they are now heated now water in a tank tank. It turns out that the DHW system is always ready to work with a high consumption of hot water. Nevertheless, their drawbacks lie here:

- Electricity consumption is higher, as the Tanes constantly heated water in the tank.

- The overall dimensions of the heat generator are more due to the presence of a tank.

- Electronics is configured to maintain the temperature in the rooms, and in the second stage heated water in the container. For this reason, in particularly cold days, the water temperature in the boiler can fall, so it is important to initially select the power unit correctly.

Attachment of the boiler of indirect heating

Connecting the boiler indirect to the electric boiler

Many double-circuit electrocotes are equipped with controllers that manage not only elements of the aggregate itself, but also by outer devices. Such is also a remote boiler of indirect heating, water in which heats off from the coolant circulating in the heating system. This process can control the electronic unit of the heat generator, controlling the electric drive of the three-way valve, activated in the scheme in this way:

Here the electric boiler works on the same algorithm as with the built-in cumulative Bak. So far, the coolant in the system will not reach the maximum temperature, the three-way valve on the controller command directs the flow to radiators, and the rest of the time switches to the boiler's coil. Accordingly, the power of the electrical installation should be enough to ensure the warmth of both systems.

To save electricity for DHW, some controllers have a programming function for a week ahead. The readiness of hot water can be "order" at a certain time of the day, then the boiler will not warm it around the clock.

The disadvantages of such a DHW system are considered a relatively high cost and the need to allocate special space for heating equipment.

Conclusion

Dual-circuit electrical installations can successfully replace a separate electric water heater, especially in cases where hot water consumption is small. If the expense is required large, then there are options covered above. Therefore, the purchase of a separate electric boiler is not always justified.

The heating boiler is a device, using the combustion of fuel (or electricity) heating the heat carrier.

Device (design) of the heating boiler: heat exchanger, heat insulated housing, hydraulic block, as well as safety elements and automation for control and control. Gas and diesel boilers in the design there is a burner, in solid fuel - firewood and coal firebox. Such boilers require the connection of the chimney to remove the combustion products. Eleklocks are equipped with Tanni, do not have burners and chimels. Many modern boilers are equipped with built-in pumps for forced water circulation.

The principle of the heating boiler - The coolant, passing through the heat exchanger, heats up and further circulates through the heating system, giving the resulting thermal energy Through radiators, warm floor, heated towel rails, as well as ensuring water heating in an indirect heating boiler (if it is connected to the boiler).

The heat exchanger is a metal container in which the coolant (water or antifreeze) is heated - can be made of steel, cast iron, copper, etc. Cast iron heat exchangers are resistant to corrosion and rather durable, but sensitive to the sharp temperature drop and have a lot of weight. Steel can suffer from rust, therefore their inner surfaces are protected by various anti-corrosion coatings. Such heat exchangers are the most common in the production of boilers. Copper heat exchangers corrosion is not terrible and thanks to the high heat transfer ratio, low weight and dimensions such heat exchangers are popular, often used in wall boilers, but usually more than steel.

In addition to the heat exchanger, an important part of gas or liquid boilers is a burner that can be different species: atmospheric or fan, single-stage or two-stage, with smooth modulation, double. (A detailed description of the burners is presented in articles about gas and liquid fuel boilers).

To control the boiler, automation with different settings and functions (for example, a weather-dependent control system), as well as devices for remote control of the boiler - GSM module (adjustment of the device through SMS messages).

Basic technical characteristics Heping boilers are: boiler power, energy type, number of heating contours, combustion chamber type, burner type, mounting type, pump availability, expansion tank, boiler automation, etc.

To determine necessary power The heating boiler for the house or apartment is used simple formula - 1 kW of the boiler power for heating 10 m 2 well insulated room with ceiling heights up to 3 m. Accordingly, the heating of the basement, glazed winter garden, premises with non-standard ceilings, etc. The boiler power must be increased. An increase in power is also necessary (about 20-50%) when providing a boiler and hot water supply (especially if water is needed in the pool).

We note the feature of the calculation of power in gas boilers: the nominal gas pressure at which the boiler operates on a 100% power producer, for most boilers is from 13 to 20 mbar, and the actual pressure in gas networks In Russia, there may be 10 mbar, and sometimes below. Accordingly, the gas boiler often works only on 2/3 of its capabilities and it must be taken into account when calculating. When choosing a boiler power, be sure to mark all the features of the thermal insulation of the house and premises. In more detail with the table of calculating the power of the boiler heating can be

So which boiler is better to choose? Consider the types of boilers:

"Middle class" - average in terms of price, not as prestigious, but it is quite reliably, the standard typical solutions. These are Italian boilers Ariston, Hermann and Baxi, Swedish Electrolux, German Unitherm and boilers from Slovakia Protherm.

"Economy class" - budget options, simple models, service life is less than that of boilers higher category. Some manufacturers have boiler budget models, for example,