If you look at the smoke and ventilation pipes of residential buildings, then the variety of smokes on them (deflectors, flugas) amazes. But the main task of the deflector does not decorate the chimney, but to increase and stabilize the thrust depending on the weather, and thereby improve the efficiency of the heating device and reduce heating costs. Deflector on ventilation pipe It can provide non-volatile (and free) supply-exhaust ventilation, see below. But at the same time, the opponents of the installation of deflectors on the pipes of residential buildings are also enough, and the arguments in their favor they lead weighty. The purpose of this article is to help the reader to figure out, in what cases it makes sense to put a smoking deflector or ventilation, as then choosing suitable or make it yourself.

The most important question

Before selecting or make a deflector on the pipe, you need to decide - and is it necessary at all? The deflector can frozen, delay the soot or nagar (smoke), tied to fallen leaves that are rapid rubbish or dust. In any of these cases, if the deflector on the chimney, the inhabitants of the house risk will be careful. The efficiency of the furnace or boiler the deflector increases slightly, but requires regular inspection and cleaning. No less than 3 months for furnaces on solid fuel And no less often half a year for furnaces and boilers on gas, liquid fuel or pyrolysis. More details about the dangers that may entail an inappropriate attack on the pipe, see video:

Video: What is dangerous deflectors, umbrellas and flugers on chimney?

Therefore, if you have an old woodwood or coal stove, but the thrust is unimportant and the wind blows into the pipe, instead of a complex deflector, it is better to put a simple smoke, for example. umbrella or tent. And in other cases it is necessary to clearly figure out which deflector is needed for this particular furnace / boiler with this particular chimney. It is also important not to confuse the smoke deflector with ventilation - small traders and the authors of some popular publications do not see the difference between them or do not.

Evolution of deflector

Deflectio in Latin means "reflect" in the sense of "throwing out". Not sentiently in a certain way as a reflector, but if only. Cap on the chimney pipe from the skins, large seashells, etc. There were already primitive people to avoid strangling the wind into the pipe.

On the role of a deflector in the creation of thrust, its stabilization, contrary to the whims of the weather and the ability of the deflector, to increase the efficiency of heat generating instruments for the first time seriously thought about the TsAGA almost 100 years ago on the task of just hatred to the Soviet government. Before that heat engineering tried to improve for this purpose. chimneys. We saw in old photos of huge puzzled, as an inverted pear, American steam locomotive pipes or long thin, with a rosette at the top, English?

In TsAGI, the masted aircraft designer D. P. Grigorovich was engaged in the creative community with the Mathematical apparatus by A. F. Volpert. The latter is also, and even more, known to work in the field of radio engineering (Chart of Volpert Smith, etc.). Together and the Porn Grigorovich with Volpert developed several types of deflectors for various purposes, therefore, in special literature, various grirani, Volpert and Volpert-Grigorovich, are described in special literature.

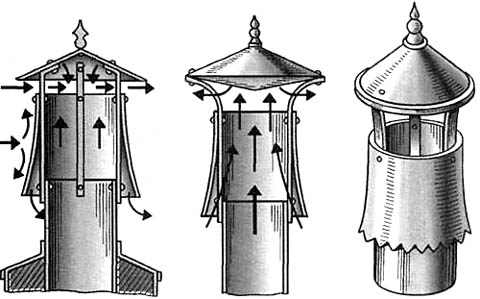

Grigorovich began with the fact that the usual chymnik-umbrella correctly calculated the aerodynamically, pos. 1 in fig. This has already significantly improved the device performance; Cone Grigorovich - Remember, very useful. Volpert proposed to provide a deflector-umbrella with an aerodynamic skirt-diffuser (pos. 2), but the deflector remained aerodynamically imperfect, see below. It was complemented by a streamlined body of rotation instead of a cap and a cylindrical case-shell. In the end, after repeated purges in the aerodynamic tube, government Commission A deflector of the TsAGI (pos. 3) was presented, fully satisfying the issued TK and its far overlapping.

The deflector of the TsAGI is still most common in the world due to its technical excellence. There are modifications for different purposes, see below. But the other developments of Grigorovich with Volpert did not disappear for nothing - they are based on the majority of models of modern flue deflectors. Which one is more suitable for what, we will talk about it further.

Types and schemes

All variety of trade names of flue deflectors is placed in a limited number of constructive types and aerodynamic schemes. First of all, the interaction with the natural chimney deflectors are divided into:

- Active - with integrated working smoke. To ensure the specified characteristics of the deflector, the smoke must work constantly until it burns in the furnace.

- Active-passive - the smoke is low-power in the extreme case: complete cresturity, storm, redundantly intensive firebox, etc. Minimally admissible specifications The chimns are ensured when the smoke is turned off.

- Passive-active - the deflector creates a small one with a non-volatile method.

- Passive - there is no own deflector thrust.

Active deflectors like energy-dependent and not optimal for house heating devices of low power We do not further consider. From active passive, one, calculated on the low-power 12 in the fan and suitable for manufacture with their own hands.

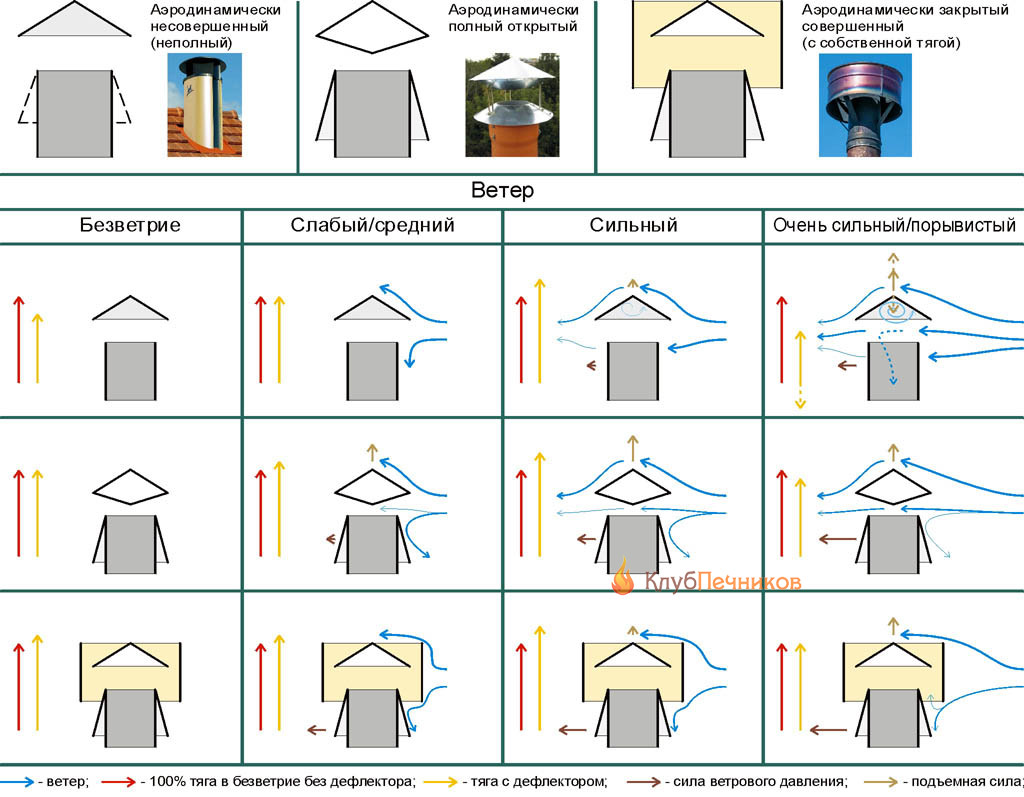

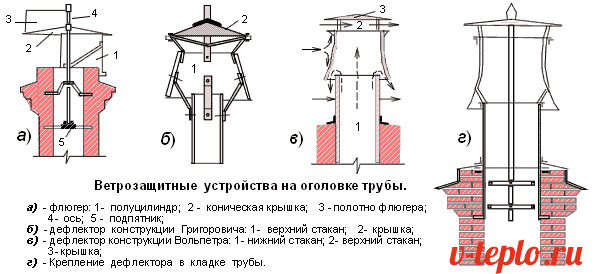

Under the aerodynamic scheme, the smoke pipe deflector is possible to follow. way (at the top in fig.):

- Aerodynamically imperfect (incomplete) - in a busy space deflector there is a "pocket" - the region of the tangling, in which air, flue gases or mixtures thereof may be possible;

- Aerodynamically full open - wind pocket no, but the wind is open access to the workplace of the deflector;

- Aerodynamically perfect closed - there is no wind pocket, the wind does not have the wind in the working space;

- Deflector Wheel (see below);

- Vortex deflector.

The aerodynamically perfect indoor deflector is most structurally and technologically, but has a huge advantage: due to the heating of the shell, the aerodynamically perfect closed deflectors almost all give their own non-volatile traction. This is the only passive type of deflector, capable of increasing the natural thrust of the chimney in full calm.

Note: Aerodynamically perfect closed deflector and there is a mentioned deflector of the TsAGA. This aerodynamic circuit was invented in the TsAGA.

The vortex deflectors are easy to learn on the "torn" design with sharp protrusions. In their aerodynamics, as in the vortex aerodynamics, in general, there is still much unclear (Navier-Stokes equation was solved in general form only 2 years ago). Predict the behavior of the vortex deflector at any external conditions With any chimney it is precisely impossible. Therefore, the vortex deflectors are not considered. Believe it or not to manufacturers are your personal matter.

Aerodynamics

Flue gas circuits in deflectors in public sources is sufficient. But from the point of view of the homeowner and the master it is more important than the nature of the interaction of the deflector with the natural thrust of the chimney and the wind in the next. Aspects:

- Does the deflector do not worsen the initial craving?

- Is the deflector able to increase the original craving in the windless?

- How and how and how does the deflector increase the wind load on the pipe?

- How much is the deflector of this scheme prone to icing / clogging and is convenient for cleaning?

The wind is then better to consider not by Meteoskale, but by coarse gradation of strength and dynamics of the speed field:

- cutelessness;

- weak / medium (moderate) - up to 6 metelecale points;

- strong - 6-8 points;

- very strong - over 8 points;

- pusty - the wind of any strength is really impetuous, or sharp (strongly spilled top or down), or swirl.

The idea of \u200b\u200bthe aerodynamic properties of passive flue deflectors gives rice. above.

Simple Cap

Normal smoking chimney In the form of an umbrella, if it is made in the form of a Migorovich cone, not so bad:

- With a massive heat-chimney, it holds the thrust in the limits permissible for wood / coal oven on the smooth wind force to the cruel storm (10 points).

- On any wind, up to hurricane does not create destructive loads on the pipe; Rather, it will break and fly away.

- Constructively simple.

- It is poorly clogged and clogged, it is easy to clean in the order of annual inspection and solving the chimney.

- Due to imperfect aerodynamics, little sensitive to the configuration of the umbrella. If the house in the Testrails, the smoke smoke can be made with tent (see fig. Right), which simplifies work and gives great opportunities for its design.

- With 2-3 channel chimneys (see below) provides technical indicators (except for increasing thrust in the windless) is not worse than the aerodynamically perfect closed deflector.

The shortcomings of the imperfect deflector-smoke are also quite serious:

- In moulderness reduces the original craving is the stronger than the stove intensively. What is especially dangerous harshly quiet winter: the furnace can choke and smear the fill.

- In a strong wind, it is capable of creating excessive craving, which dramatically reduces the efficiency of compact channel stoves (for example, Dutch 2.5-3.5 bricks) and fireplaces.

- On a very strong / pousy, the wind is not excluded in the pipe and the appearance of reverse thrust.

In general, the imperfect deflector-umbrella is the optimal smoke on a brick tube of a properly built and well-groomed house furnace on solid fuel, operated in places where hurricanes and storms are extremely rare. Ways to make a smoking-an umbrella in an unlucky (see below), but complicate it before you most often have to choose an aerodynamically complete or perfect deflector.

Open

The aerodynamically open deflector does not reduce the initial craving and on any wind holds it within the limits permissible for furnaces and boilers on solid, liquid fuel and gas. Quite greatly frozen, it is clogged and mad, but easily accessible to clean. The disadvantages of it are:

- The streamlined body of rotation instead of a cap is a technologically complex node.

- The resulting vector of wind loads is such that the aerodynamically open deflector tends to turn the pipe, while the umbrella is to fly from it.

- In the wind, 8 points lateral load on the pipe increases sharply and further grows in a power law.

- It is bad for the dynamic load from the gusts of the wind, so it is impossible to install an open deflector on the brick tube.

- It is not suitable for pyrolysis thermal instruments: pyrolysis gases and oven / boiler goes out on a strong wind.

- Little is suitable for the design: Pretches and figures spoil overall aerodynamics. The only one, where it is possible to place the decorations - the upper pole of the body of rotation and the lower edge of the diffuser (see below).

Note: At one time, we and in the United States conducted experiments on the use of open deflectors on steam locomotives, to increase the efficiency in small go. The result is deplorable - on the middle move from the pipe showed the language of the flame, and none could accelerate to the structural velocity.

In general, the aerodynamically open deflector is suitable for all types of heating devices, except for pyrolysis. Provided that the deflector is inspected and cleaned not less than once in 2 months, and before each traction is checked. Very well suitable for chimneys with insufficient load and, especially for bath furnaces: Cases of reflector in the baths due to an open deflector not marked. It is not easy to escape the bathhouse correctly, and the check of the deflector will not complicate it noticeably.

Note: There are types of open deflectors that practically do not create side loads on the pipe and suitable for fragile ceramic and glass chimneys, see fig. on right. However, dust, garbage and soot are accumulated in the open body of rotation, which spoil the aerodynamics of the device, and it is difficult to clean it. Therefore, manufacturers recommend such products only for gas boilers in places with not strongly dusty air.

Perfect

The advantages of the aerodynamically perfect closed deflector are partially indicated above. Moreover:

- The aerodynamically perfect closed deflector ensures the stability of thrust in any external conditions sufficient for any household furnaces and boilers.

- It does not clog and does not frozen inside, but frost and dust outside affect his work.

- With small modifications, suitable for use as both smoke and ventilation non-volatile, see below.

- Excellent extinguishes the dynamic load from the gusts of the wind and therefore is suitable for installation on pipes from any materials.

- In one oval, triangular or square shell can be condensed with a beam 2-3-4 chimney.

The disadvantages of the closed deflector are not so significant:

- The lateral force on the pipe in the wind to strong gives more than open, but further with the amplification of the wind it grows linearly, i.e. The pipe under an open deflector can always be strengthened or strengthened with dehs.

- It is quite complex constructively and technologically.

- It is not suitable for the design: any mallepting and figures spoil overall aerodynamics, and the coloring is only enhanced by the utilitarian type of deflector.

Technological tricks

First rule - do not do smoknikov like double roof or cylinder arch (see Fig. Right). Such suitable only for mobile devices only when the axis of the umbrella is possible to arbitrarily orient the wind. Or as decorative for a falsemost. There is such a fashion in houses with biocamines. And in other cases, the thrust will walk by the will of the elements right up to the reverse.

Further, to make a deflector for chimney with your own hands, you need to master some tested tires. First of all, the connection of sheets in Falts (fold), or folding, see Fig. below. Most often, the details of the deflectors are connected by a single layer fold, but for the umbrellas of imperfect deflectors in decorative purposes, the double standing folding is used.

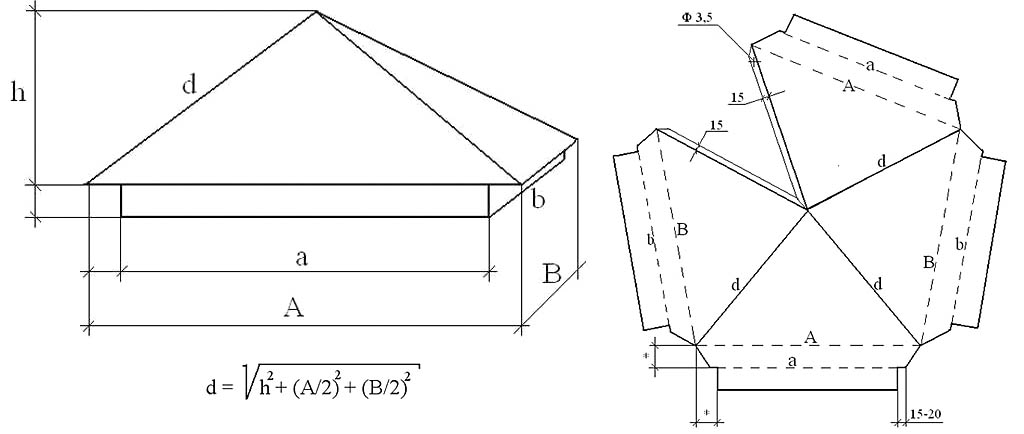

Round umbrella:

Pyramidal umbrella (tent) with a vertex in the center:

Umbrella extended faceted:

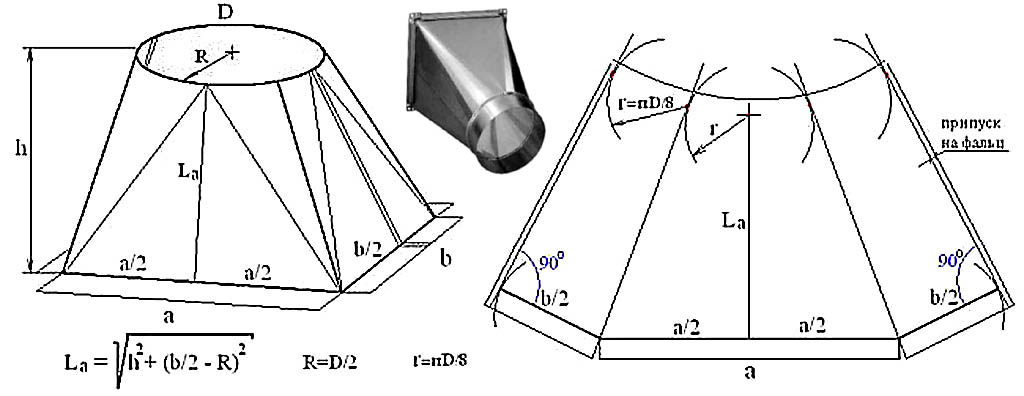

Transition from a square on a circle (square inside the circle):

It is very important for closed deflectors to low-power furnaces and boilers, see below.

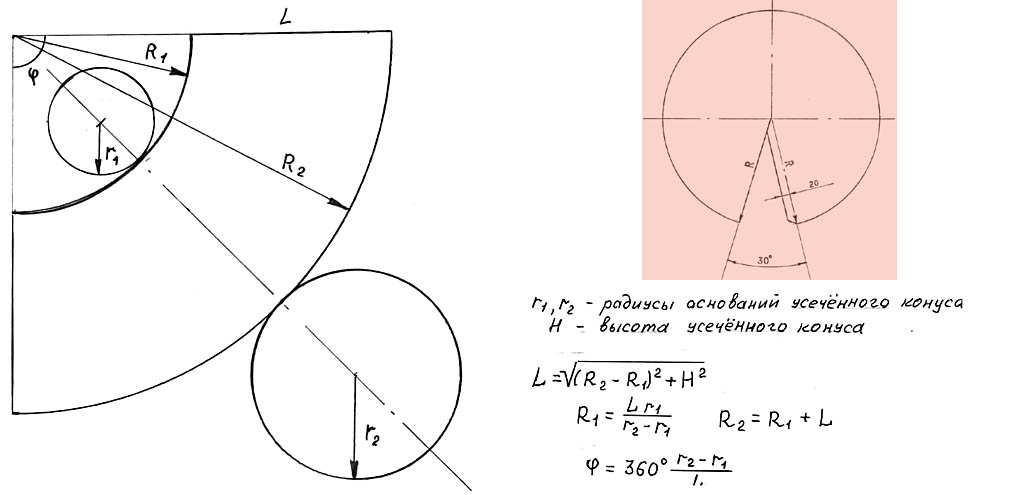

Transition from a circle to a circle:

All these patterns can be built, using only a ruler and a circulation - goat leg (in which a pencil is inserted. Well, for those who are inclined to in-depth study The basics, before taking the case, give a selection of projections and formulas to accurately construct details. Pay attention to the elongated umbrellas: they are put on 2-3 running chimneys. Smoke channels, each minimally allowed for a given heating device of the sections, are in a row. The probability of strangling immediately 2 channels is extremely small, and there are practically no 3-x.

Here in fig. - Data for constructing a truncated cone, which in deflectors are even debugged. The initial data is the height of the cone H, the radii of the vertex and the base R1, R2. Also pay attention to the insert marked with red: it is the scan of the very cone of Grigorovich. The forming angle (in this case is 30 degrees) is like φ \u003d arcsin (H / R), where H is the height of the cone, and R is the radius of the base. Radius R is defined in the same way as l for a truncated cone, but H and R are elevated into the square. However, those who have not forgotten the theorem of Pythagora, this is so understandable.

After the cones, it is not possible to deal with the discharge of a single center-based work tent, see fig. Only "BUT": the allowance on the example of the pattern (right in Fig.) Dan is given on a single riveting (for strength) of the soldered seam.

To connect to a single metal folding metal to 0.6 mm thick, on one side, it is necessary to take 20 mm, and from the other 21 + 2 + 20 mm. If the metal is 0.6-1.5 mm, then 30 and 31.5 + 3 + 30 mm acc. But, generally speaking, soldering and gluable on the edge of the seam make it easier, it looks careful and better resist corrosion than folded. If the roof lies the roof, then it is clear, to flip and solder sheets is simply technically impossible. But the umbrella of the deflector is another matter. Collect it on soldering with riveting so:

- Place and cut off the scan;

- Drill holes under the rivet;

- Flexing inside at 90 degrees of the side (wings) of the allowance;

- Barrow edge;

- Through wooden lining bars, clamps compress the boards;

- Possess seam.

A sweep is built in a similar way and a flock tent (umbrella) is assembled, see fig.

And finally the most sophisticated detail: The diffuser of the aerodynamic perfect closed deflector, it is the adapter-skirt from the square on the circle (circle inside) to install the smoke-to-brick tube. The rules of construction are not complicated (see Fig.), But require accuracy and accuracy in work.

Note: Additionally align the thrust of open and imperfect deflectors on a round tube, and also to be reduced to the insignificant probability of stuffing into the latter, if you can swing the diffuser / skirts inside, see fig. But this work is complicated - after assembling an adapter from a circle to a circle, it must be deducted on a solid dryer.

Designs

Now let's see what is possible and how to make a deflector on the smoke pipe yourself. The easiest way to start with an imperfect deflector-umbrella; Its opportunities are much wider than it may seem, and the materials and not very difficult work requires a bit.

What is the umbrella

In the climatic conditions of the Russian Federation, the deflector-umbrella to the chimney is most often enough, especially since the Ugona is also not marked by its fault. But - if the hem is made correctly. The most common error - the cap is too high on the racks. Return 100% of the original craving does not help, but the likelihood of strangling into the pipe increases sharply.

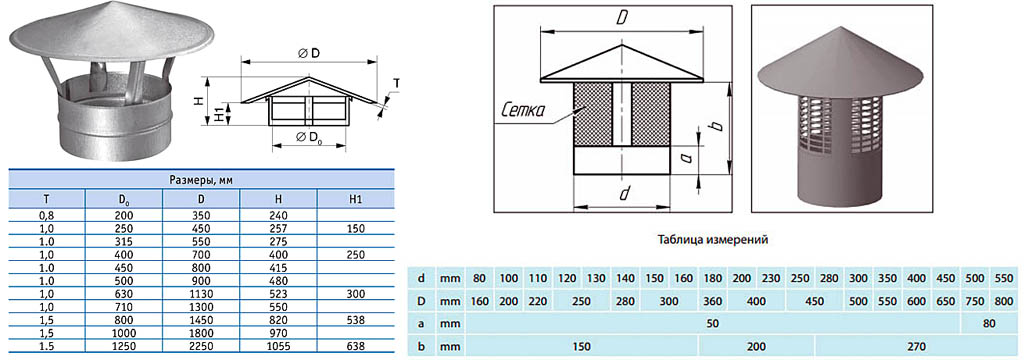

The correct dimensions of the deflector-umbrella to the smoke pipe are given to the left in Fig. For pipes with a lumen with a diameter of 100-200, they decrease proportionally, and then the value H1 increases 1.3 times for pipes 150-200 mm and 1.6 times for pipes 100-150 mm.

Right in fig. The dimensions of an unlucky deflector-umbrella are given, but in the conditions of the Russian Federation it is better to put on the ventilation tube of natural ventilation, because The grid quickly turns the soot or the condensate of flue gases, and then dust sticks very well on it.

Also does not fond, keeps the original craving and even slightly increases its two-story deflector-umbrella. The scheme of its action is given on the pos. 1 trail. Fig.:

For chimneys of low-power household furnaces / boilers (approx. Up to 40 kW), it can be simplified by performing floors the same, pos. 2. Each floor - circumcised twice in height of the grigorovich cone (see above); The distance between the floors is equal to the height of the floor. Upper floor forceps, i.e. Cutting the peak of the cone is closed with a deaf lid. A 3-storey umbrella on the ventilation pipe (pos. 3) is less likely freezing and is clogged less than an umbrella with a grid. For pipes 130-200 mm, dimensions vary proportionally. And, finally, the deflector of Kiryushkin (pos. 3; All cones - Grigorovich) is used mainly as active - under a small cone, a low-power smoke is 12 V 100-200 mA.

TsAGI

Before it is taken for the aerodynamically open deflector, let's see how modified under a private house The most perfect deflector of TsAGI. Its initial design was calculated primarily on industrial facilities and then at apartment buildings.

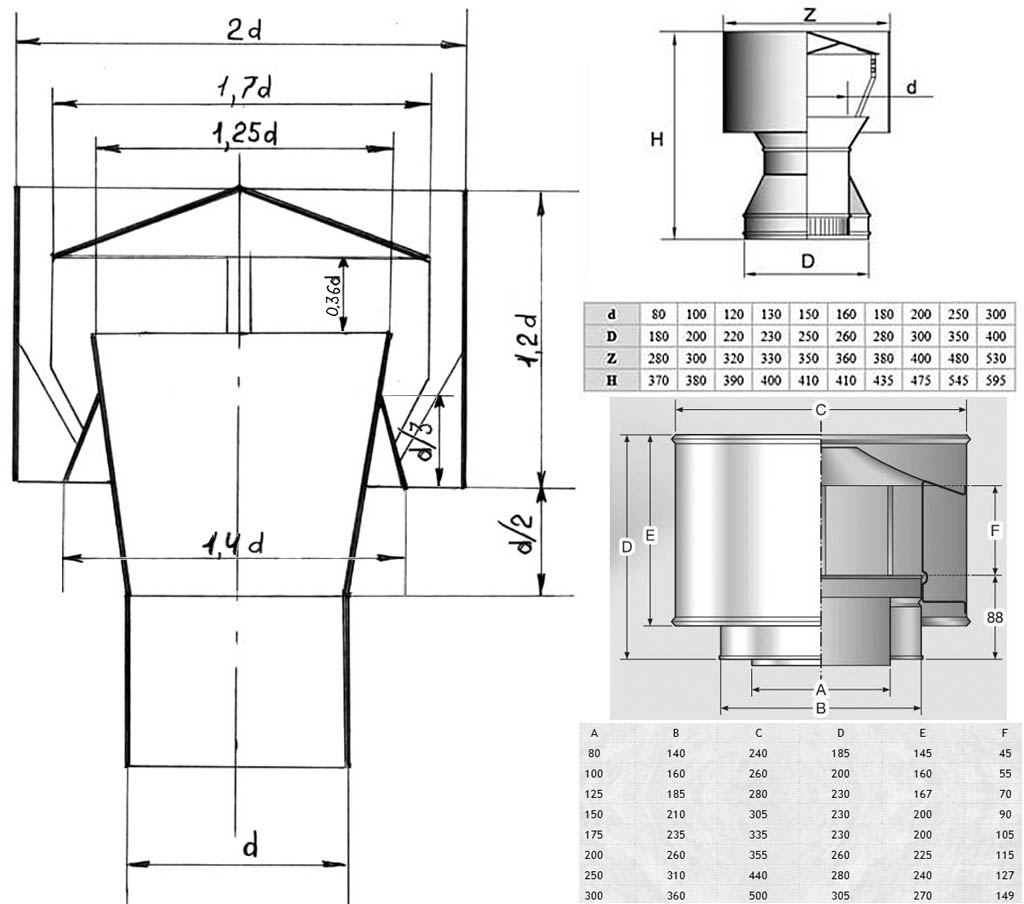

Drawings of 3 variants of the deflector of TsAGI are given in Fig. The sizes of the original industrial option are shown on the right above. Not completely, because It is designed for a solid tube and not at the sandwich chimney. For the chimney of private home ownership, the Hangzhenkov deflector (left in Fig.) Is more suitable for the same scheme. It gives a smaller horizontal wind load and can be inserted into the pipe as described below.

And on the right in fig. - Dimensions of the Ventilation deflector of the TsAGI. It can be transformed from passive into passive-active, cutting the shell with a black blacksmithing ticket or other paint, well absorbing the thermal radiation of the Earth and the objects surrounding the house. Fans in the outstands of the domain ventilation system need, of course, leave, but occasionally occasionally. How to make your hands the deflector of the TsAGI, see video

Video: TsAGA's deflector from metal tile do it yourself

Note: Ventilation deflector is not so luxury as it may seem. When the wind poices in ventilation, in the bathroom it is cold, and the kitchen chad and the toilet odors are spreading around the house. Flap valves do not solve problems - slammed, in the bathroom and kitchen is stuffy.

What is obtained from cones

Open-type deflectors are most accurately available, and, throughout the complex of technical indicators, the deflector of Volpert-Grigorovich is optimal for private home ownership. Although how many in it really and the other, they knew only themselves.

Canonical (initial tests of the TsAGI) The proportion of the deflector of Volpert-Grigorovich is given to pos. 1 Fig.:

On the left - modification under an asbetic pipe, well holding longitudinal loads, but fragile across. Increased twice height of the upper body of rotation of the cone gives a large lifting force, seeking to break the deflector from the pipe, but the tight clamp will hold it on any wind. For pipes 130-180 mm on inside the sizes vary proportionally.

Note: More about one version of the self-made deflector of Volpert-Grigorovich, see the next. roller:

VIDEO: Migrithorovich Volphalt Deflector to increase the thrust in the oven

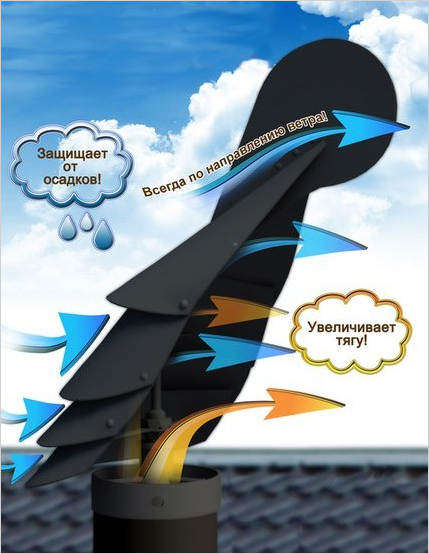

Fleugers

Deflectors for pipes - FLUGERS are still called flugars. Sometimes it is called all the smokers in general, but it is incorrect, because The fluger by definition the device is rotating.

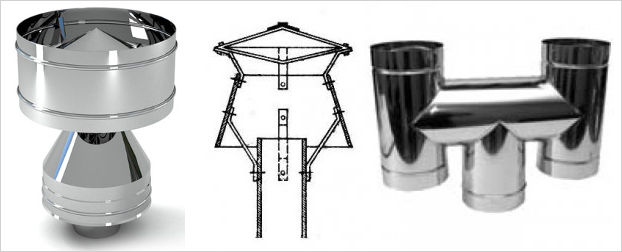

The pipe deflector - the vane can be performed by a swivel self-orienting and rotating. The latter are also called turboodeflies, and self-orienting smoke teeth, which is also incorrect. Chimney tooth is part of the chimney of the English fireplace. Weak place of all vane deflectors - bearing. It is very easy to clog and is delayed with soot, and the seals are susceptible to reinforced wear. Therefore, it is necessary to inspect the deflector-voger at least 2 months. But the deflector-weatherman himself almost never becomes the main enemy of all stationary deflectors - icicles.

Pipe deflectors - Fluggers

Multiborable deflector-vane (pos. 1 and 2 in Fig.) It gives a stable pull in the wind to 9-10 points with minor pipes on the pipe, so it can be placed on sandwich, ceramic and glass chimneys. The one-grade deflector-vane in a strong wind loads the pipe strongly, so it must be durable and the house is located in a place where the storm wind is not walking. But the one-grade deflector-vogen is easy to issue in the form of a bird (pos. 3 and 4).

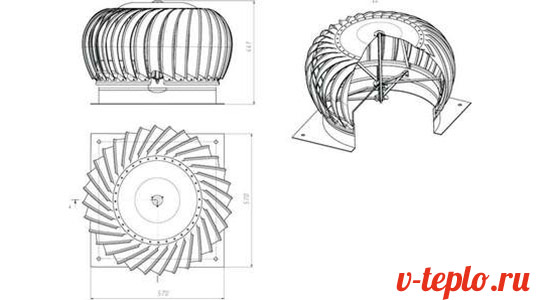

Turbodefliktor (pos. 5) - Remember and do not believe anyone - not smoke! It is ventilating or for gas boilers with an electro-shirt. The turbine rotates both wind and air current in the pipe, and the turbine is properly performed, as in some types of wind turbines, self-prompted: the most weak initial thrust go to a light blow of the breeze so that the turbine is spinning and pulling the air, but it will only stop And the wind will completely stop. In the ventilation system at home with turbo brekers, turn on the fans in the outstands, as they say, once a year is not every year. Unfortunately, the turboFlert is easily delayed with dust and garbage from the air, so it is also not less to check it in 2 months.

The technical properties of the turbo breeder are the same as the multibane self-orienting, but it loads even less pipe. Turboodefliktor is quite possible to make it yourself, see the video below.

Video: TurbodaFliktor do it yourself

How to put a deflector

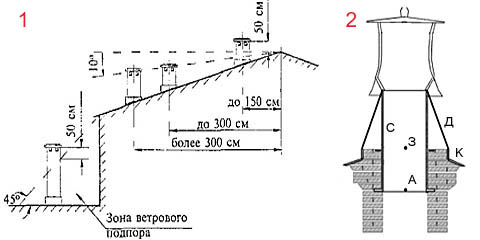

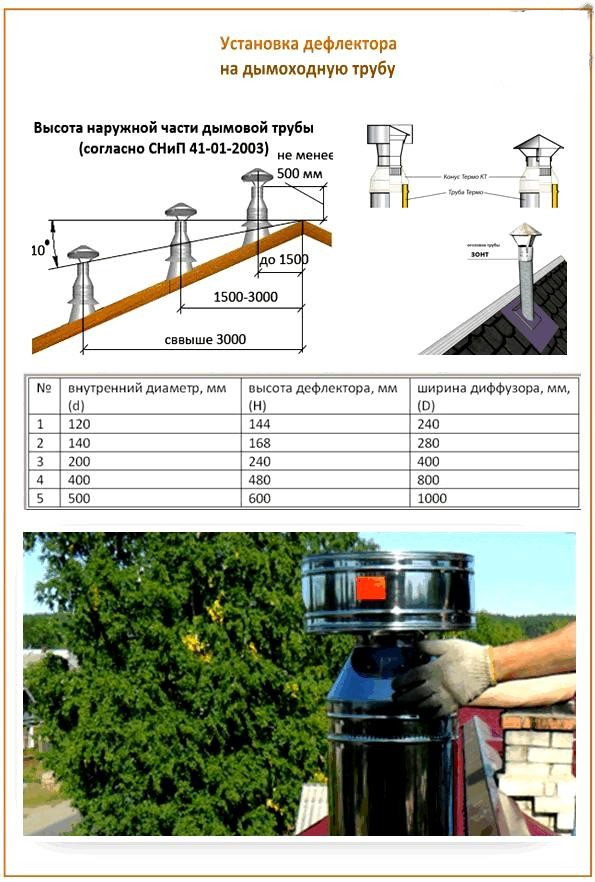

It is possible to put a deflector on the pipe only if the chimney is performed exactly according to the rules of SNIP 41-01-2003, pos. 1 in fig. below. It is very desirable that the pipe to which the deflector will be installed on, was located on the sub-directional direction of the roof of the roof. For reference: lever means the opposite direction, from where the wind blows.

Bashed the deflector to the otter (the upper extension of the brick pipe) is definitely possible only if the pipe is initially calculated under the deflector. If not, or in the pipe laying there is at least the slightest violations, it is necessary to fix the deflector to it as shown on the pos. 2 rice:

- A solid sleeve is inserted into the pipe (cup; adapter square-circle) C;

- The glasses are fixed with deaf anchors and at the level not higher than the lower row of the masonry of the otter and the mortgage pins s in the groove at the mouth of the pipe. Anchors and mortgages are lit. cement-sandy solution from M200;

- On the glass you wear a diffuser / skirt d with a cornice (tint) K. necessarily for a deflector of any diagram, incl. Merifest!

- The diffuser is attached only to masonry with small anchor bolts. Not self-drawing in plastic dowels! To the glass skirt / diffuser are not fixed!

- At the gate (upper edge) skirts / diffuser firmly fix the working structure of the deflector.

Only with this method of fastening the deflector never breaks the old and / or the brick tube has not designed.

Discussion of the topic "Deflector for chimney"

Normal operation of the ventilation system involves the presence of thrust in the channels and air ducts. But over time, garbage can get into the mine, the channels can simply be clogged with dust, which further sticks to their walls, especially if they have a fatty flask. All this reduces the diameter of the air ducts, which negatively affects the operation of the entire ventilation system.

That is why many homeowners are installed on the ledging pipes special devices called deflectors.

Features of the device

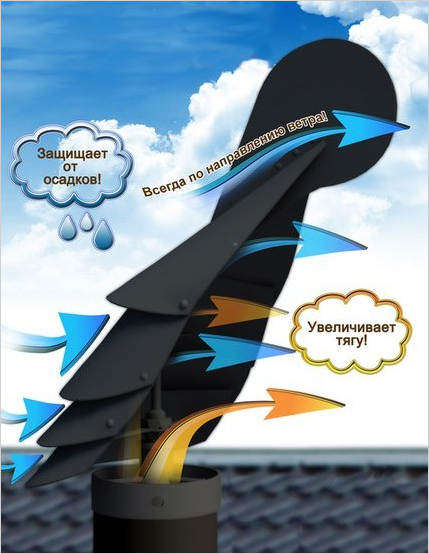

The ventilation deflector is installed to increase the thrust in air ducts, mines and channels. This device, deviating the air flows created by the wind, creates a zone at the exit of the ventilation system reduced pressure. The air masses in the pipe, trying to compensate for the discharge, rise to the tube's head, thereby increasing the traction.

This is a description of the principle of action of all deflectors, the designs of which there is a huge amount. Many devices not only deflect the air flows, but also increase the speed of their passing over the headband of the ventilation pipe, due to the narrowing of the channel, thereby significantly enhancing the craving (the principle of the airbrush).

Competent use of the deflector contributes to an increase in the performance of the entire ventilation system up to 20%, it is especially useful on ventilation channels with large horizontal sites and bends.

In addition, the deflector on the ventilation tube perfectly protects from entering various garbage, small birds, insects, and most importantly, atmospheric precipitation. Basically, the material from which these devices are manufactured, resistant to corrosion manifestations. This is galvanized or stainless steel, ceramics or plastic.

Existing types of deflectors

To date, there is a huge number of different designs of such devices. Among them, the most popular models are:

- TsAGI - Effective and simple constructively wind redirection device.

- Grigorovich is also a very popular deflector design.

- H-shaped appliance to effectively increase the thrust in the ventilation and flue pipes.

In addition, various designs of open deflectors are often used both on the ledges of ventilation and chimneys.

All varieties of models can be classified according to some distinctive qualities:

All varieties of models can be classified according to some distinctive qualities:

- In the form of the apparatus of the device.

- Rotating (rotor or turbine).

- Deflectors-freezes.

In addition to such a common material as a metal, these devices are made of plastic. Deflector ventilating plastic less durable than its steel analog, but has a lower cost and more sophisticated appearance.

That is why plastic devices decorate the ventilation mines of most private houses. But he, in addition to the service life, there is another serious drawback. Plastic does not make high temperatures, so it is not recommended to use it on chimneys.

Fluggers - deflectors, usually installed on flue pipes, but also for ventilation systems, they are quite suitable. The air flow, passing through the system of visors and the slots in the body of the product, is redirected due to which the zone of reduced pressure is created above the pipe. It should be recalled that the fluger has a design that allows you to constantly turn to this device, the working side to the wind.

Fluggers - deflectors, usually installed on flue pipes, but also for ventilation systems, they are quite suitable. The air flow, passing through the system of visors and the slots in the body of the product, is redirected due to which the zone of reduced pressure is created above the pipe. It should be recalled that the fluger has a design that allows you to constantly turn to this device, the working side to the wind.

The rotating deflector ventilated due to its design not only enhances the thrust in the ventilation miner, but also effectively protects it from various trash and insects. This device, as a rule, has a spherical shape, so it is allocated among all the original design.

There is another original type of ventilation deflector - rotational, or as it is also called the turbine. This device converts the energy of air flow into the rotational movement of the turbine, which spins the air, according to the principle of the tornado, thereby creating an increase in the duct. This apparatus shows excellent results even in the warm season, creating a craving in the ventilation system.

Production of the simplest device with your own hands

Despite the complexity of the design, every home master will be able to make a deflector. Just have enough required tools and materials. For independent manufacture of this device, you will need:

Despite the complexity of the design, every home master will be able to make a deflector. Just have enough required tools and materials. For independent manufacture of this device, you will need:

- Tight paper or cardboard sheet.

- Galvanized metal sheet.

- Drawing of a deflector with calculations relative to the diameter of the pipe.

- Rivet gun.

- Scissors for metal.

- Drill with a set of drilled.

- Marker or checker.

After the preparation of the tool, material and means of individual protection (glasses, gloves), you can start making the ventilation deflector with your own hands.

- First of all, the contour of the product from the metal drawing should be translated. There must be a sweep of all major parts of the device: the cap, the diffuser, the external cylinder, racks.

- After that, you need to cut all parts of the device, according to the resulting pattern.

- Connect all parts of the device, according to the drawing or sketch, with the help of a rivet pistol.

- Connect two parts of the deflector using racks cut from the same metal.

In order for the smoke ventilation system to work properly and well, it is necessary to install a special device - a deflector, which will help optimize the process of working the chimney. Due to the fact that in the pipe often the garbage and dirt is postponed, the drawing of the hood deteriorates, therefore you need a ventilation deflector. Such a device is not necessarily acquired in the store, although it is simpler, it is possible to build a deflector yourself.

The price of ventilation deflectors and their varieties

| Model | Price | Characteristic |

| Ventilation deflectors D100  |

Normal view The deflector, which works due to the action of wind streams. Each deflector has its markup, the figure in which is equal to the diameter of the shaft pipe. The numbering of deflectors occurs in accordance with the amount of air, which is removed from the pipe. The devices that are needed for the chimney compound are optimized for a typical design. Connection methods have appropriate performance technologies. The material from which the unit is manufactured is galvanized steel. |

|

| D125 | 1820 | |

| D160 | 1950 | |

| D200 | 2100 | |

| D315 | 2700 | |

| D350 | 3100 | |

| D400. | 4400 | |

| D710 | 6600 | |

| D1000 | 30500 | |

Floon deflector T 110  |

2570 | Made from metal, which is resistant to corrosive processes. The possibility of applying on different types of roofs. The ability to install for ventilation as a room and a whole hangar. Resistant to different precipitation. It is necessary to install on the air duct that is already laid. |

| T120 | 3380 | |

| T150 | 3380 | |

| T200. | 3500 | |

| T300 | 4300 | |

| T500. | 8300 | |

| T680. | 12300 |

Marking of any type ventilation deflectors Depends on the size of this device. The larger the diameter of the base, the higher the figure, respectively, the price. To achieve the required amount of the airflow of the airflow, several deflectors should be installed

How to install and make ventilation deflector

So that the process of designing the deflector was not too heavy, you need to adhere to a specific scheme of actions and recommendations. It is paramount to determine the following moments that can be attributed to the preparatory phase:

- be sure to pretend to work, make all the drawings necessary for further reconstruction of the device. In such a drawing, it is necessary to take into account how the chimney pipe itself, after which it will be possible to determine the height of the deflector and the diffuser width;

- another point in the preparatory stage will be the choice of material from which the chimney device will be made. It is usually made of steel from steel, which lasts galvanized, but exists and alternative option - This is a metal that is coated with a chemical protective composition of polymers. There are plastic material, but it can only be used in cases where the contacting of this material with high-temperature combustion products will be excluded;

- the last preparatory stage will be the acquisition or preparation of instruments or materials? necessary for design and installation. These include: a sheet of selected material, up to 1 mm thick, scissors cutting metal, drill, device for breaking rivets, cardboard with a marker and a hammer from a tree.

How to make drawing

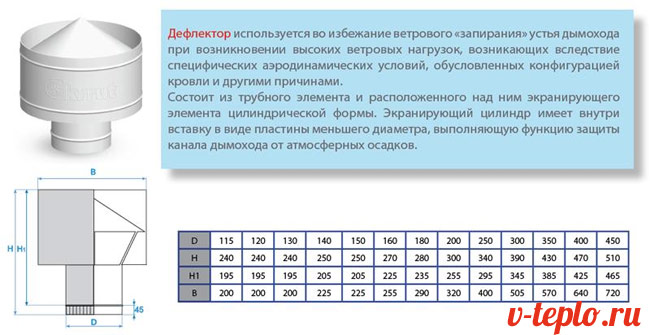

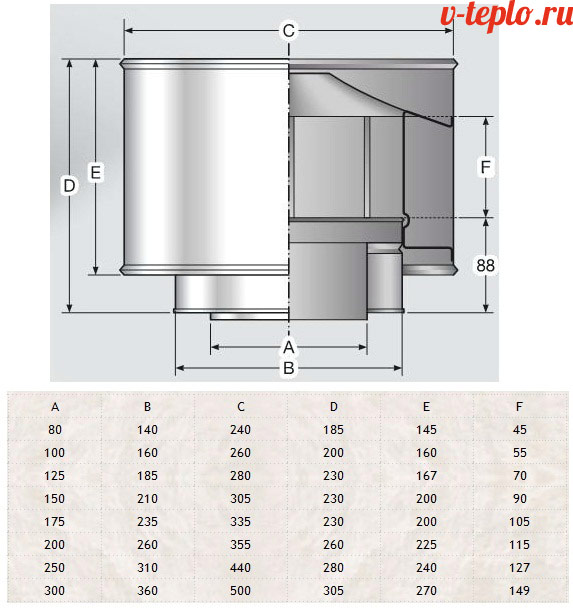

| Internal d, mm | 120 | 140 | 200 | 400 | 500 |

| Height of the device H, mm | 144 | 168 | 240 | 480 | 600 |

| The width of the diffuser d, mm | 240 | 280 | 400 | 800 | 1000 |

In the event that the specified table does not have a specific size that needs to be built, then there is a formula for which individual parameters can be calculated:

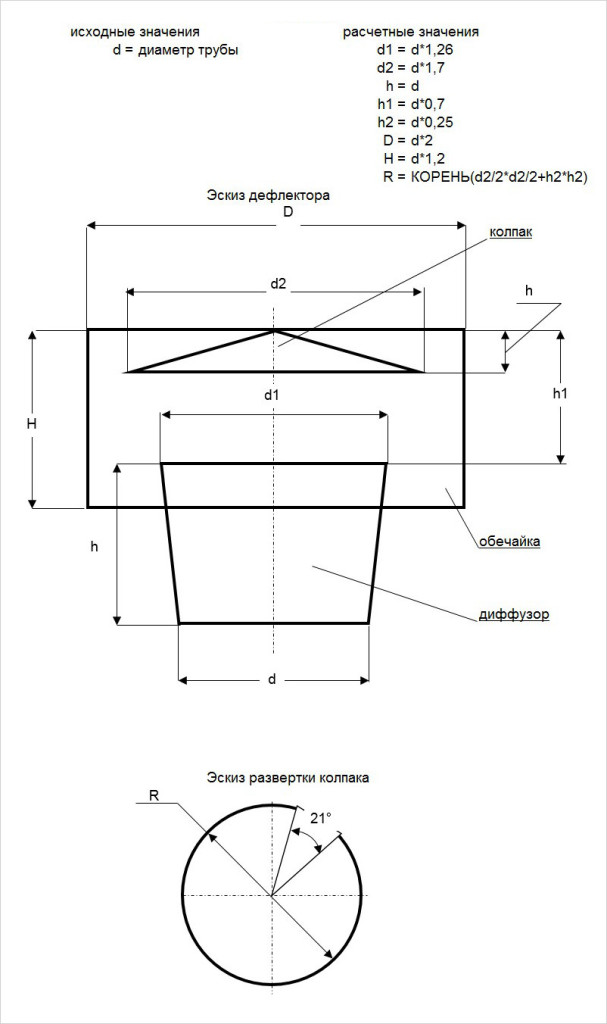

- the width of the diffuser (D) \u003d 2 * inner diameter.

- device height (H) \u003d 1.7 * Inner diameter.

Important: When measurements, it is extremely accurate, so that in the future it does not have the need to rewar drawings. Calculations also need to be recovered because it important moment In the future installation of the deflector and its performance.

Important: In the process of making a deflector, you need to be attentive to all proportional ratios of parts of the device so as not to disturb the high level of efficiency.

Stages of design

After the calculations were made and checked, you can proceed to further assembly stages:

IMPORTANT: on pipes in which there are many turns on the design, it is necessary to put a deflector necessarily.

Features of the assembly of the deflector Grigorovich

If it was decided to collect the grigorovich deflector, the whole design is complemented by the reverse cone. It turns out that one cone should be less than another 4 centimeter. Larger need to make a protective element. After these parts are cut out, you need to attach one to the other and from the inside to circle the smaller size on the larger cone.

After that, you need to cut a large part to the stroke line in such a way that there are 8 probes, which are located on equal distance from each other. Such bands serve instead of any mounts, it is worth a bandage.

To attach a reverse cone to the diffuser, it is better to use the hairpins. Initially, you need to drill three holes in the reverse cone around the perimeter of the entire circumference. In such holes should be inserted along the heel and fix the nuts.

The upper part of the diffuser, its outer side is a place where the loop made from metal is attached, with the help of which the design will acquire a holistic appearance.

Such a device in design is more reliable and in operation will be longer.

Nuances during work

To build a deflector correctly and be confident as his work, it is necessary to take into account the following nuances:

- The internal pressure of the deflector increases depending on the stream force, which goes down the pipe.

- In the case of the diameter of the main pipe as much as possible, you need to install additional stretch marks from the wire.

- To install the device for chimney to the channel gas duct, top Devices are recommended to shoot. The workbench will help. After installation, the installation is made at the starting position.

Separate varieties of deflectors

Reflectors are suitable for some types of chimneys - this is one of the varieties of deflectors. Such a type of deflectors is installed on heating devices that work at the expense of liquid fuel.

Such deflectors additionally put fasteners, as they may be subjected to strong winds.

It must be constructed with the gas heating equipment parameters.

If such a reflector is too large dimensions, it will not be able to provide the necessary thrust, plus the combustion process is slowed down. It is explained by the fact that the large dimensions of the deflector are able to pass substantial mass of air, which are able to put out the flame. The consequences may be unexpected.

The deflector, which put on the gas boiler, should be equipped with a special device called the sparking. The thrust force is not always uniform, it can become very strong, and can weaken - it all depends on the wind speed in the environment. In order not to be dependent on such phenomena, you need to install a fluger smoke. The principle of installation is similar to the rest.

In the deflector of this type there is an additional component, which is similar to the fan. Inside the housing there are blades that have a certain bending. A certain amount of blades is connected in it by a central node, which serves as the axis of rotation.

Due to the fact that the blades are located inside the case, they are protected from wind streams outside, and due to warm gas or other combustion products, force the blades to rotate than the thrust is significantly enhanced and remains stable.

IMPORTANT: Trying to build a vane deflector independently makes no sense, because without certain equipment, its manufacture is not possible, it can only be purchased in the store.

Choosing a fluger type deflector is very important to approach the process to thoroughly and not save funds. The material from which the device can be made is different, it is necessary to carefully approach the material quality selection. The vane deflector is susceptible to frequent precipitation, snow, rain, which come with windy threads. Moreover, such a device will be protected for this kind of phenomena, and therefore the material from which it should be reliable and durable.

The part that is in motion should always be clean and have the ability to move freely. It is necessary to regularly carry out its inspection and lead to the proper form, otherwise it can lead to a breakdown of the system.

An important characteristic of the material for the manufacture of the vane is the ability to withstand high temperatures, while not exposed to deformation. Many materials under such an impact begin to change the volume. Such a nuance should be remembered and clarified when buying.

IMPORTANT: Flu-step-type deflectors can be used to any type of chimneys from any heating structures.

Varieties of deflectors and the principle of their work

Before deciding which deflector to do, and whether it is worth practicing it in principle, you can familiarize yourself with it from all points of view. Deflectors can be described as follows:

- the design characteristic is such that it is capable of protecting the pipe from rain, snow, dust and dirt, while increasing traction;

- the disadvantages of such a structure can be classified that during the wind blowing from the bottom, the flow will fall under the trick of the deflector than the obstacle to the air from the pipe goes into environment;

- to avoid any instability or interference in this device, it is better to resort to the design of a deflector containing two cones. This should be taken into account yet at the stage of drawing work.

The varieties of deflectors that distinguish their designs:

- Grigorovich.

- Volper round.

- TsAGI.

- open Astato.

- star Schieng.

- N-shaped type.

The principle for which the deflector works can be described in such a system:

- The upper cylinder is in such an obstacle to air output. Memorable streams, hitting the deflector cap, pushed out. This happens by picking up their part of the air that rises next.

- The force of thrust increases due to the fact that the speed of the smoke of the pipe becomes greater.

- The upper cylinder has a certain amount of gaps, with which the smoke is delayed. This ensures the stability of the heating device, because with such a design of the impulses and the direction of the wind I do not play the role.

Conclusion

The adaptation of the deflector is very useful and even indispensable, especially those whose permanent residence - vacation home. Without heating, which works reliably and stable, comfort in the house is hard. The deflector made independently will not only provide better thrust in chimney, but also protects it from unwanted effects. Who does not want to resort to the manufacture of such a device, can purchase it in any construction store.

Section: Country Construction and landscaping

The deflector is a device that improves the trigger in the pipe. It does this due to the fact that as a result of the flow of a deflector with air, the areas of reduced pressure are formed directly above the pipe. And this entails the air supply (or chimnery gases) From the pipe. Those. The effect of elongation occurs, lifting the pipe is about 15-20%. But this often more than enough to provide good traction in short (low) pipes. Deflectors are known for a long time, since the opening of the laws of aerodynamics, but they are massively used only on industrial systems. And although their production is very simple and for each other, the cause of their absence on our pipes is solely ignorance and lack of information. As a result, the "creative" umbrellas are looked over the roofs - the product of local liveshists who think a lot about the "beauty unusual", and about the pull in the pipe and the quality combustion of fuel is significantly less.

There are many systems of deflectors: TsAGI, Volpert-Grigorovich, Hangzhenkova, etc. But the most common option for heating is the deflector of Volpert - Grigorovich. Although for some reviews, the deflector of the TsAGI has proven itself better for ventilation systems.

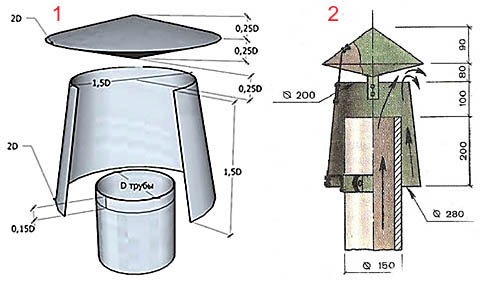

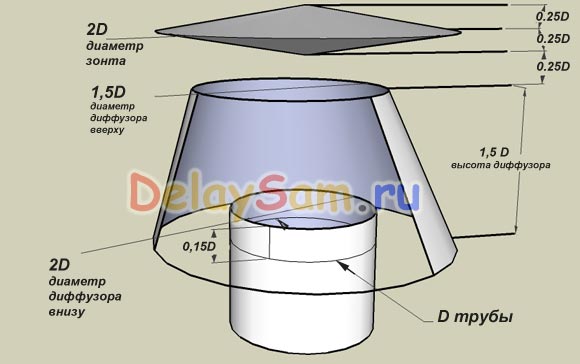

The deflector scheme is quite simple. A truncated cone is installed on the pipe, the diffuser, so that the pipe would be a little in it. A protective umbrella is installed above the pipe, as usual. But to compensate for harm (zone increased pressure Under the umbrella), an inverted cone is attached under the umbrella. As a result, inside this design, with a lateral blowing, the wind forms low pressure, and smoke is more willingly rushing out of the tube. In fairness it should be noted that with a strong downward stream of the wind "top down" the pressure inside the deflector increases (due to the shielding umbrella). This must be considered when choosing a place of installation and height of the pipe. The best blowing of the deflector - on the side or bottom, and this is 99% of cases.

Before proceeding to the manufacture of a deflector, it is necessary to calculate its dimensions. All of them are binding to the diameter of the pipe. (If the square is square, then make a square deflector, although it works worse due to angularity). The diameter of the pipe is considered for the original value of D. And all other sizes are calculated with the corresponding sketch of coefficients. The diameter of the diffuser at the bottom is 2D, at the top - 1,5d, the height of the diffuser is 1,5d. "Dive" pipes in the diffuser - 0.15d. The height of the cone umbrella, reverse cone and the distance between the umbrella and the diffuser - 0.25d. All these dependencies were obtained as a result of the blowing of the deflector in aerodynamic pipes. Therefore, it is strongly recommended to adhere to them.

So, knowing the dimensions, proceed to the calculation and cutting of the workpiece. Perfect material For the deflector would be a thin stainless steel. But the usual galvanized steel is quite suitable. She will serve for many years, but to make new - work for several hours. In the calculations of the sizes of the billets, it will help you the article. The pattern for the diffuser is a curved strip of steel, and for the umbrella - two circles, with cut segments. Do not forget to leave a metal strip in 2-3 cm on one of the edges for docking. Umbrella make 2-3 centimeters more than reverse cone.

Whatever it is fooling with the bends and steamers, I applied exhaust rivets and a riveter. Since the tightness is absolutely not needed here, to fasten the edges of the pattern rivets much faster. It is convenient to use any mandrel in the form of a hanging bar, which is put on the diffuser. Holding the item, drill holes at once in two edges, insert the rivet and "pull out" by a riveter. Fast and reliable fastening. Rivet slightly straighten with a small hammer.

We also make both the cones of the umbrella and reflector, but so far we do not connect them together. For mounting an umbrella to the diffuser at the desired height, I used the segments of the threaded stud. For a sustainable attachment of enough 3-beam star. On the diffuser, the studs are attached in special loops made of metal strips and also attached to the diffuser rivets. Studs simply screwed into the loops and fixed with nuts. Such a system allows you to very accurately and quickly set an umbrella to the desired height.

In the reverse cone, 3 holes and the reverse cone are fixed with nuts with rotted washers at the desired height. Now you can fix the protective umbrella. Since it is a little more diameter than the reverse cone, on its perimeter, in several places, the protruding edge is cut into a width of 1-2 cm. And this strip is bent onto the lower cone. Such strips 6-10 and both cones are very reliably bonded. And due to the fact that the upper cone - the umbrella is greater than the lower, atmospheric precipitates will not accumulate inside this "flying plate".

Now it remains to secure the deflector directly on the pipe. To do this, it is convenient to use a short cut pipe that does not rush and high qualityly connect it in a deflector, and then install the entire design on the smoke tube.

By placing and drilled the necessary holes and in the diffuser and in the pipe, fix the deflector as well as with the help of threaded studs, providing the desired value of the pipeline into the diffuser. Now you can install everything on the pipe.

Perhaps someone will seem somewhat cumbersome. However, the deflector really significantly improves the trigger. Even with a minor wind, the thrust even in a cold furnace is felt very clearly "bare hand" and on rumor. During the combustion, during the ignition, the traction ovens increases as the pipe heats up. And the strong wind creates a very significant craving, as if the air is forcibly served in the furnace, as under superior.

According to the subjective sensations and experience, the pipe height is approx. 3 meters work just like with a height of 5 meters. If the furnace's fuel is not overloaded with fuel, and a good air supply is ensured, then the height of the flame in the furnace is not more than 15-20 cm, against the usual 40-50. In this case, the combustion process is very active.

Having spent on making a deflector for only a few hours, you can significantly improve the burning process in your furnaces.

The correct work of the chimney contributes to the high-quality functioning of the heating system and protects the health of residents from poisoning with combustion products. Deflectors allow it to ensure. About them and will be discussed in this article.

General provisions

The word "deflector" itself came to us from Latin and means "reject". This is the main function of the instrument under consideration - to change the direction of the wind in the event that part of the smoke falls back into the residential premises, and the generated thrust is not able to maintain the flame sufficiently.

Causes of low-quality chimney work

Let's consider in more detail why this happens:

- The presence of a strong impetuous wind, which is able to poison a portion of the smoke again into the pipe, while creating the opposite pressure.

- The erroneous height of the chimney and improper location relative to the ridge of the roof.

- Too small size of the exhaust cross section, unable to create a stream of air of the desired force.

Tip: To calculate the height and width of the pipe, it is recommended to involve an experienced specialist.

This will allow you to exclude some of the problems that arise in the future.

Functions performed by deflector

- Creating a low pressure zone and a thrust enhancement by deviation of wind threads in a more favorable side.

- Increase the efficiency of the chimney to 20%.

- Protection against penetration into the pipe of atmospheric precipitation and other possible garbage.

Tip: The use of two-four pipes will allow you to maximize the thrust of the smoke.

Use of use

- General or individual natural ventilation and chimneys.

- Channels for outputting gases combustion products.

- Garbage chutes.

Deviflector device

Structure

Tip: The deflector on the chimney with your own hands is recommended to supply additionally by the sparking in order to comply with fire safety.

As a result, any weather conditions work only on the increase in thrust from the chimney. The only one is not the most successful direction of the movement of the air masses is the lower, since the gases leaving the chimney bend into an umbrella and are partially returned back. In order to prevent this, an additional reverse cone is installed, which dissects the flow of combustion products, directing outwards.

Installation

Let's look at how to install a deflector with your own hands for round pipe:

- Fix on the lower cylinder rack. Usually, the M6 \u200b\u200bbolts are used for this.

- On the racks using the clamp, mount the diffuser with an expanding side down.

- On the fold we produce a reverse cone assembly.

- From above brackets fasten an umbrella.

Sometimes you have to install a round design into a square pipe. In this case, you should apply the transition nozzle.

Before making a deflector, check out the following table of the ratios of the size of the chimney and its elements that need to be observed strictly:

| D, see | W, see | H, see |

| 12 | 24 | 14,4 |

| 14 | 28 | 16,8 |

| 20 | 40 | 24 |

| 40 | 80 | 48 |

| 50 | 100 | 60 |

Designation of letters is indicated in the picture:

Conclusion

If the chimney is assembled not well enough, the load has increased or there is a constant windiness around the building, it can lead to the burning of burning products back to the house. In order to prevent this, you need to install a deflector. It will reduce the power of the wind to gain the thrust of the ventilation channel.

It consists of such a design of three elements that are easy to mounted and with their own hands, the main thing at the same time adhere to the presented recommendations and the correct ratio of all sizes.

The video in this article will provide your attention to the study of additional materials that are directly related to the topic considered. Parentate about the qualitative and full removal of carbon monoxide from the room to avoid health problems.