The editors of the magazine comes with letters of readers with various issues regarding construction. Grigori Yasenev appealed to the editor with a request to advise him the most economical material for the construction of the house. The experts of Valery Mostovich and Evgeny Sherster are talking about how to make the house is economical.

A private house: What includes the concept of "economical house"?

Valery Mostovich, Architect: First of all, it should be small in size.

For example, we recently did an area of \u200b\u200b6 to 6 m. It is planning it quite suitable for a family of three. On the ground floor there are living rooms, kitchen, dining room, bathroom; Upstairs - two bedrooms.

The second property of an economical house is compact. The smaller the area of \u200b\u200bthe exterior walls, the cheaper the house is to pull. The same with electricity and water supply.

Thirdly, an economical house is simple. The basement or the ground floor increases its percentage of 30. And the foundation in this case will cost it somehow: it must be buried to the depth of freezing (for example, for Northwest it is deeper than 1.60 m). Waterproofing plastic windows It is described if in the ground excessive humidity, you will have to do reinforced waterproofing. This requires additional expenses.

Standard dimensions of aerated concrete blocks - 60 × 30 × 40 cm, it is easier to work with them - you can save on wages of workers.

And, of course, the cost of the house is largely determined by the material.

Today is the cheapest and heat efficient of all wall materials - aerated concrete.

By thermal insulation properties, it is preferable to traditional bricks. In addition, the brick itself is more expensive, and its masonry requires a higher qualification of mason. Foot concrete blocks are larger ( standard dimensions - 60 × 30 × 40 cm), it is easier to work with them.

A private house: What are the main "rules" of the handling of aerated concrete?

Evgeny Sherster, Designer: Different manufacturers produce aerated concrete of various sizes and properties. The main plus of porous aerated concrete is high heat efficiency. Conversely: the less in the pores concrete, the stronger, but such material requires additional external heat insulation. If the walls are thin and cold, it makes no sense to warm from the inside: the heat-insulating layer will wet from condensate and deteriorate. That is, choosing more porous material, you can save. If aerated concrete complies with the requirements of the region on heat shielding properties, it can be simply covered with decorative plaster or facade paint.

However, the more porous concrete, the less his carrying ability. It is impossible to lay heavy designs on this wall. First, the reinforced concrete distribution "belt" is made around the perimeter of the walls, and it is already possible to put reinforced concrete beams, and metal, and even the plates. It does not greatly increase the cost of construction.

The problem can be solved and building a one-storey house of a larger area with a light roof.

However, eyeliner engineering networks will be more expensive than in two-story house, and heating costs will grow - they will need more heating devices.

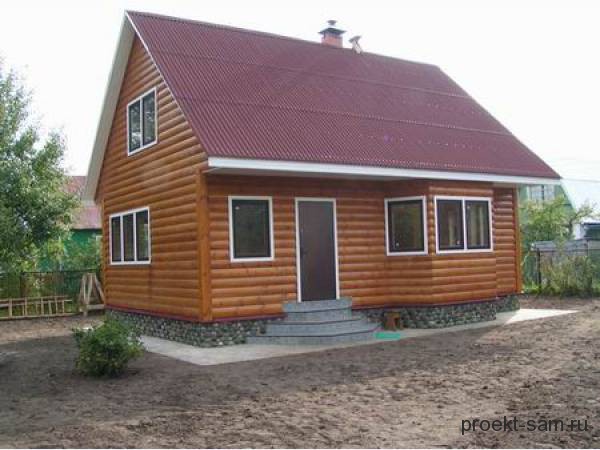

Project E-0841-0. Visual example of an economical house: Total area 85 m 2, Foam concrete walls, monolithic foundation From reinforced concrete.

A private house: Does the use of aerated concrete any restrictions on the architectural appearance of the house?

Valery Mostovich: I like architect this material suits me. It makes it possible to make compact volumes and immediately indicates a specific direction in architecture. The buildings are more stringent and simple from the point of view of the volume of the scattered solution, but not boring. For example, in an attic house, a high complex roof with bellows, partially closing a fox concrete facade, can become the main plastic element of the house.

Of the aerated concrete, it is impossible to create minor rounded elements: turrets, round erkers, like bricks. You can combine brick and aerated concrete, but The difference in thermal conductivity of materials can create difficulties, And the brick part will have to either further insulate, or do much thicker. But from aerated concrete, you can make triangular erkers, placing walls at different angles. It crepts well (though, the sawing on the construction site increases the cost of work).

A private house: What else construction Materials Can be called economical?

Evgeny Sixers: All of the above can be attributed to foam concrete. Moreover, it is easier and better at heat engineering properties. It can be used for partitions (it is very effective in terms of sound insulation) and as an element of insulation with monolithic reinforced concrete, frame or brick Walls. And for carriers and enclosing structures, a more dense aerated concrete is better.

Valery Mostovich: Traditionally, the category of economical buildings referred shielded houses, but for year-round accommodation In our climate they are not suitable. The wood is still used as a frame, and it is quite expensive. The frame is filled with mineral insulation and is squeezed: outside - siding, inside - plasterboard.

The panel house can cost the cheaper aerated concrete, if you buy a small prefabricated house from ready-made items by typical project. You will be brought to you, put it on the foundation, equip. But he will be completely uninteresting in architecture and is unlikely to be personally yours individual housewhich you have invested not only money, but also the soul.

In projects implemented by various construction firmsValery Mostovich acts as GAP (chief architect of the project), and Evgeny Sixers - as a hypothe (chief project engineer).

Evgeny Six, Designer Developer (on right)

The student years participated in construction workers, and later took an active part in the construction of the first houses designed by him. In 1983 he graduated from Lisi's graduate school, defended his thesis on a town-planning topic. Candidate of Technical Sciences. Special attention relates to the economy of houses and the ability of the material to withstand adverse climatic conditions. He teaches at the Department of Urban Construction.

Economy house projects are a budget version of high-quality, durable and beautiful housing. In addition, such projects can use construction companies to build cottage settlements.

Cottage settlements economy class

What to build an inexpensive house

Based on its preferences and financial capabilities, you can choose perfect material For the construction of your own home.

- One of the most popular materials is wood, with which you can build a reliable, warm and environmentally friendly facility.

- The brick project of the economy class is the optimal choice for people who value the safety and strength of their housing.

- The houses from the aerated concisely combine an acceptable cost and high quality.

- Projects frame houses Economy class allow for the shortest possible time to obtain a durable and reliable dwelling without extra cash spending.

The project of an inexpensive brick house

Economy Houses Projects - Benefits

Many construction companies offer their customers inexpensive houses that have a number of benefits:

- short exposition time;

- the ability to choose a suitable project and material;

- full range of construction services;

- internal I. exterior finish building;

- providing all the necessary documentation;

- cash savings;

- engineering maintenance of a finished typical project;

- the ability to start the construction of the house immediately after the project approval.

Typical project wooden house Economy class

Construction of a frame house

One of the most popular options is the construction of country houses based on framework technologies. However, in this case, some points should be taken into account:

1. The calculation of all structures and bearing elements is carried out taking into account the snow and wind loads, as well as the weight of the house itself. In case of insufficient section of the beams and frame racks, the service life of the house may noticeably decrease.

2. The heat level in the house depends on the quality of the insulation used in construction, as well as the lack of so-called "cold bridges". The insulation layer must be at least 150 mm (in the cold regions - even thicker).

3. From the inside the wall of the house it is recommended to completely close the vapor insulating film, which will protect the fibrous insulation from the effects of moisture and thereby keep its properties. From the outside of the insulation, it is necessary to close the diffuse membrane, which is able to protect perfectly from wind and moisture, while freely releases the extra steam. Otherwise, for normal ventilation rooms will have to arrange the supply and exhaust ventilation, which will result in further additional expenditures on the heating of dwellings.

Frame house economy class

Given all the above nuances, it is advisable to repeal your decision once again before making the final choice in favor.

Construction of a warmed house from a bar

The optimal option for the price / quality ratio among wood houses can be considered structures from a non-stroke of a natural humidity with outdoor insulation, which is performed in accordance with the "ventilated facade" technology.

In addition, insulation using the "ventilated facade" technology can protect the bearing walls of the building from adverse effects ambientWhat will significantly increase the service life of your home.

Projects of cheap houses from wood allow you to use when outdoor finish Practical any materials: ceramic brick, Block House, vinyl siding, brusal imitation. For interior decoration Brusade imitation, lining, wallpaper, drywall under the color.

Saving funds in this case is achieved due to inexpensive material of the bearing walls, the possibility of building a lung foundation, a simple design of the "ventilated facade", saving on heating and heating boiler.

Draft House of Economy Class from Bruus

Building houses from foam blocks

When it comes to the construction of houses from stone, then primarily imply projects of houses from foam blocks. Savings in the construction process can be achieved due to the abandonment of the additional insulation of the enclosing walls (despite the fact that their thickness is not too large). It is necessary to carefully make sure the blocks themselves must be carefully. Qualitatively produced blocks allow you to lead the masonry on glue, and not to the solution, so that the thickness of the masonry seams can be reduced to 2 mm.

When building houses from blocks, it is necessary to take into account the light absorption of moisture with the material, which can be solved using one small tricky: increasing the vapor permeability of the material closer to the outer surface of the wall. In this situation, you can use all sorts of paints, putty and plaster suitable for outdoor and interior decoration.

Project of the inexpensive house of economy class from foam blocks

Building a brick house

To date, the construction of an inexpensive brick house is a completely feasible task. In most cases, carrying walls are performed using masonry bricks, insulation is carried out using the "ventilated facade" technology, and facing is an artificial stone or ceramic tiles.

Economy Lasse Brick House project

Economy Garden Houses

Special attention deserve to garden houses, which for reasonable money combine strength, beauty and ecological purity.

Project of the Garden House of Economy

Naturally, the operation of garden houses is associated with some nuances. If the construction was erected from an unstorned bar, then there is a need for additional measures on the surfaces of the surfaces by siding or clapboard. In order to avoid such work, you can immediately use a specially treated bar, which can significantly increase the external attractiveness of the house.

Cheap Little Garden Brous House

To date, the shield frame houses - The most popular projects of economical houses.

The concept of "gradation" of the object of suburban real estate in the realities of the modern market country construction It became very conditional. However, the criteria for determining the middle class in today's Russia are also very vague. The draft miniature cottage overlooking the bay in the resort area performed by the architect "with the name" will be considered elitar, and frame house A large area created by the work of the hired brigade will still be an economical country house. Nevertheless, the customer today offers a large selection of country house projects in a wide price range, the boundaries of which in each case are determined by the structural type of structure used by building materials and an area of \u200b\u200bhome ownership. None of these factors is determining, but in the aggregate they allow us to conditionally classify the preferences of customers when choosing projects country house.

Popular projects of economical houses

Currently, the most popular projects of economical houses with an area of \u200b\u200b140 - 200 square meters. m., middle house houses, from 250 to 500 square meters. m., in demand significantly less. Demand, in general, is the only difference in economy class houses from the conditional average, but in both cases it is economical construction. The desire for savings is also explained and the popularity of finished projects, which are significantly cheaper than individual developments. Some customers are generally minimized the stages of design and construction, acquiring the finished house for finishing. Which option is more profitable - depends in each case from specific conditions and circumstances. But, of course, find a suitable project is much more real than the already built house. In addition, the design bureau perfectly understand the preferences of the Customer: quality and reliability at minimal costs. At the same time, the projects of economy class houses cannot be called primitive - there are a large variability of design solutions due to changes in various elements of the house.

Moreover, the relevance of the project is evidenced by the number of options arising from its database. The basic principle of design in the format "Economy" is rational and concise planning with a sufficient level of comfort, and during the dialogue between the designer and the customer, a country house project can always be improved, taking into account the interests of the client.

For reasons of saving, most of the ordered projects provide for two floors in the house, and the second floor usually makes attic. The construction of the attic allows not only to maximize the entire potential of the vertical design of the building, but also give it an additional architectural aesthetics. For attic it is especially important to correctly calculate the size of the windows, their number and optimal installation height. Vertical windows create a sort of "attic" twilight in the attic, so it is better to use inclined window designs. However, all such nuances should be foreseen at the design stage - in this, in fact, it is expressed to its purpose.

Opinion of our expert

Regarding the orientation of the houses, there is a principle: it is advisable to pay auxiliary premises for north, for example, auxiliary garage, staircase, bathrooms, hallways, pantry. South, respectively, better orient the veranda, common room, dining room. This approach is convenient from the point of view of the conservation of heat in the house, and in terms of lighting. To make it convenient to check projects on this principle, draw a simple scheme with a plot, where the parties are indicated, mark the entrance direction to the house and check-in to the site. Keep this scheme at hand when you will watch projects.

Before choosing a project, try to decide on the spatial scheme of the house that you would like to implement:

- With the location of one floor. Such a house is convenient for communication, monitoring children. For such a house, a relatively large area is needed. The cost of the square meter is relatively high.

- First floor and attic - a comfortable classic scheme. The most economical option at the cost of a square meter.

- In two full-fledged floors. Attic is fully used (the walls of the second floor are raised to such a height, which allows the operation of the entire area, including under the scenes of the roof) or there is a second floor in the house. The classical, most common scheme is fully justified economically.

- In three floors. Such a layout is forced with the constrained land plots. The disadvantage is long vertical communications: once again from the first floor you will not run away on the third.

Vladimir Tarasov, Architect, cEO LLC "Architectural and Designer Studio" Alfaplan "

Economy materials

In projects small houses Economy class can be provided with almost any wall materials. Build both bricks, but the requirements of economy are forced the customer to abandon the houses of high weight, requiring the appropriate foundation. Houses from bar, foam concrete and aerated concrete, and even more frame structures Have a smaller load on the base. Expensive ribbon foundation Replaced with pile, including screw piles.

Significant market share ready projects Make up frame and panel-frame houses, which are produced on the streamlines in the factory conditions, after which they are transported to the construction site. Work on the construction of the house can be produced by a pair of workers without the use of special equipment. But the benefit here is not only in economical construction: compared to other technologies, walls frame house They have the smallest thickness, which makes it possible to increase the useful space of the premises. By the way, the framework technology has a methodology for construction of light metal structures in its arsenal. The cost-effectiveness of such a carcass allows him to compete with a wooden price, but it is used often to build mentioned above the attic floor. Based on a frame that performs functions rafter system, laying insulation and roofing. The design of the maximum factory readiness is assembled without the use of the crane, and its low metal allows you to erect an add-in without a significant increase in the load on bearing structures houses. "Achilles' heel" frame construction - The problem of air permeability, since the space between the racks is tightly filled with insulation to eliminate cold bridges and reduce the cost of heating at home. Again, the project in this case should provide for the effective combination of thermal insulation, the irreparableness of the outer shell of the house and its ventilation.

An important moment in the design of budget houses is the thoughtfulness of the design and optimization of the material consumption. With dimensions of the house 6 x 6 meters, it is possible to use building materials in overlaps with almost no residue. For the same purposes, the height of the ceilings in the room should be selected taking into account the length of the racks. If there is a second floor, a multi-sighted roof allows you to most effectively use its space as opposed to houses with a two-tie roof.

Finishing of an economical country house

The project of the house may not take into account his finish, but it is also good way Save. For example, one of the most affordable facade materials for low-rise economy-class housekeeping is vinyl siding. In addition to good performance properties, this material mimics the texture of bricks, stone or wood. Of course, this simulation is quite conditional - from close range a discrepancy is seen, however, the appearance of the building is quite aesthetic. Not so long ago, an alternative was an alternative to polyvinyl chloride panels - galvanized steel siding with a polymer coating. A little more expensive stands fibrotental siding, made of cement, water, sand and fibrovolok. In general, on the environmental friendliness of the material today pay attention to any price segment of construction. AT budget houses Used, as a rule, artificial facing materials, which are an order of magnitude cheaper. At the same time for the manufacture of artificial finishing materials Either natural components or neutral components are used. For example, artificial stone is produced from sand and cement, adding various dyes and fillers. Absolutely environmentally friendly fiberglass, another version of the imitation of finishing with natural stone. In the process of manufacture, the molten mass is poured into the appropriate forms that relief repeat different species Natural stone.

The advantage of artificial materials is also expressed in the ease and simplicity of installation. The reverse side of the facing panels and flat tiles, so they are conveniently fixed to any surface. And the panels from fiberglass are attached using self-tapping screws or sealants, which gives a time gain and cost in comparison even with an artificial stone. True, they have a higher price, but this is already a matter of choice.

Text: Eduard Dominov

Consultant:

LLC "Architectural and Designer Studio" Alfaplan "

Country construction №3 (79), 2013