Many summer residents or people who have a house outside the city in the winter time experience difficulties with the operation of a conventional stove. The fact is that its design involves a rather long period of heating to an acceptable temperature, and the process of its cooling is also prohibitively long, which makes it difficult to use the device in short intervals.

That is why many summer residents create stoves. long burning do it yourself from bricks, so as not to spend a lot of time heating the room and reduce fuel consumption.

Types of devices

At the moment, the most popular are two types of stoves with a long burning function. The first of them involves the independent production of all elements, including the firebox and chimney.

The second type is a finished product of factory production, which can be used independently or as an element of a brick oven.

Project selection

Before choosing an ordinal plan for the manufacture of the entire structure, it is necessary to understand that brick ovens long burning have significant differences from standard type and slow burning devices.

They have separate air supply systems and a hermetically sealed firebox. This allows you to regulate the strength of the fire and carry out the complete combustion of the emitted gases.

That is why it is necessary to select a project especially carefully, focusing on the presence of these elements in the structure or a clear description of the principle of operation, which would correspond to the function of long burning.

At the same time, do not forget that the stove must fit into the dimensions of the room in compliance with all fire safety and safety standards.

Foundation

One of the main features that a long-burning brick oven has is its heating rate and surface temperature. This is due to the fact that it should go into operation in the shortest possible time, while warming up the entire room.

That is why the foundation, milking such a furnace, must be located at a distance of at least 70 cm from the base of the house itself and pour sand into the space between them:

- First, you need to dig a pit about 70 cm deep, the dimensions of which would be 10 cm on each side larger than the dimensions of the furnace.

- Next, a bituminous-based waterproofing is laid on its bottom and covered with sand by 5-10 cm.

- On top of it, you can lay a small layer of rubble or broken brick, on which you can lay out the foundation, tying the rows together.

- As a solution for a brick foundation, cement with sand is used in a ratio of 1 to 3.

- After the base is ready, a layer of waterproofing and asbestos can also be laid on its surface.

Advice!

For the manufacture of the foundation, you need to use only tempered brick, which tolerates moisture well.

Silicate construction material not suitable for these purposes, since it is not resistant to the aquatic environment and temperature changes.

Masonry

For the manufacture of stoves of this type, it is worth using red-hot bricks, and the furnaces must be made of heat-resistant and refractory materials... Normal and double sand-lime brick M 150 is not suitable for this.

However, some craftsmen use ceramic materials, which have shown themselves to be positive when working with high temperatures.

- Masonry must be done in strict accordance with the ordinal plan of the furnace.

- For this use cement mortar, with sand diluted 1 to 3.

- Only used for the manufacture of fireboxes. The usual refractory material used in devices using wood as fuel is not suitable in this case.

- It is best to use clay with sand as a bonding material. It must be diluted in a 1 to 1 ratio and this should be done a day before using.

Advice!

When making the installation, it is necessary to use accurate measuring tools and a plumb line. They will help to avoid the appearance of irregularities in the form of depressions or bulges.

Additional elements

Unlike standard heating devices of this type, long-burning brick ovens have a number of additional elements that are made of metal and serve to organize the correct functioning and control. These include latches, flaps, sealed doors, grates, etc.

The installation of these elements must be carried out in seats that are made several mm larger than the actual dimensions of the parts. In this case, asbestos gaskets should be installed between the brick and metal. Also, special mixtures based on sintering materials and industrial compositions are suitable for these purposes.

Advice!

Fireplace silicone or chamotte can be used as planting compounds for metal elements.

These materials not only tolerate temperature well, but also ensure tightness.

Chimney

Even ordinary building bricks can be used for the manufacture of a ventilation system and a chimney. This will not affect the quality of the combustion process in the structure, but will significantly reduce its service life and complicate maintenance. That is why professionals recommend purchasing composite elements.

They are special brick blocks, inside which there is a ceramic pipe wrapped in an insulation winding. At the same time, there is a special instruction for specific types of similar products, which gives recommendations for the installation of products from specific manufacturers.

Advice!

When choosing components for the manufacture of a chimney, it is necessary to consult with the seller about which mixture is best to use for the connection.

This will greatly facilitate the installation process and the degree of reliability of the entire structure.

Ready designs

Prefabricated ovens should be used in accordance with the technical documentation attached to the specific model. If you need to sew the finished firebox with bricks, then you should first shift it with asbestos or fireproof insulation.

Some masters use refractory brick, but then the meaning in the very principle of long burning is lost.

Safety engineering

It should be noted that stoves with long burning systems are considered much more dangerous than conventional heating devices. This is due to their rapid heating and high sheathing temperatures.

They are often compared to sauna stoves and have similar safety measures.

- First of all, it is necessary to protect the device from other structures or interior items that are flammable.

- Also, in all places where the stove comes in contact with other objects (if this cannot be avoided), asbestos gaskets should be installed. The price of this material on the market is low, but it provides almost perfect protection against fire.

- The correct organization and hoods should be noted separately. This system must be constantly checked for blockages and cleaned periodically.

Mandatory requirements of the norms and rules of fire safety when installing stoves in residential buildings

Output

In the video presented in this article, you will find additional information on this topic. We hope you can clarify for yourself the differences between conventional stoves and long burning designs.

For most regions, gas or electric equipment is still unavailable at the moment. The first is due to the lack of gas distribution networks, and the second is due to excessively high electricity tariffs. And the question of using solar energy or geothermal sources for heating in the Russian outback is not even worth it.

Convection equipment appeared in the West quite a long time ago, and it is actively used there, but it is hard to take root in Russia. Only after the brilliant professor and engineer Butakov created long-burning solid fuel stoves, such devices began to appear in Russian homes. A similar design of imported furnaces was taken as a basis, in which he made some changes to make the work results much more efficient.

Design features and distinctive features

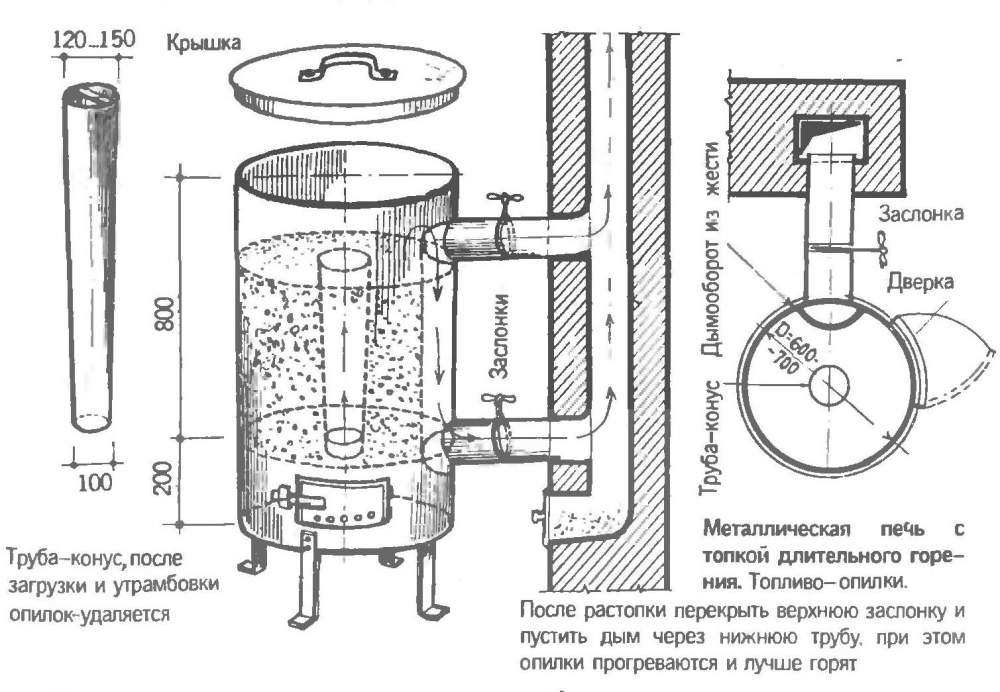

First of all, Butakov changed the shape of the furnace. Domestic devices were not cylindrical, like those of foreign counterparts, but rectangular with truncated upper corners. Thanks to this form, it was possible to significantly increase the heat transfer rates during the combustion of pyrolysis gas. Has undergone a whole range of changes in the long burning solid fuel furnace of Professor Butakov. The main transformation was the placement of the pipe intake holes as low as possible, at a height of no more than 100 millimeters from the floor level.

The next practical and visual distinction introduced by the inventor was the protective cover, which was located above the heat exchanger and completely closed the entire furnace. Thanks to this addition, it was possible not only to increase the temperature of heating the air in the heat exchanger itself, but also to increase the diameter of the pipes used, and this makes it possible to increase the volume of heated air. The surface of the protective casing in the upper part of the oven is flat, which allows it to be used as a cooking room, where food is heated and water is heated for household needs. Solid fuel stoves with long burning at maximum heating allow not only heating, but also cooking.

The equipment has received a rectangular shape, due to which it can now easily fit into any interior of a modern or rustic style.

Principle of operation

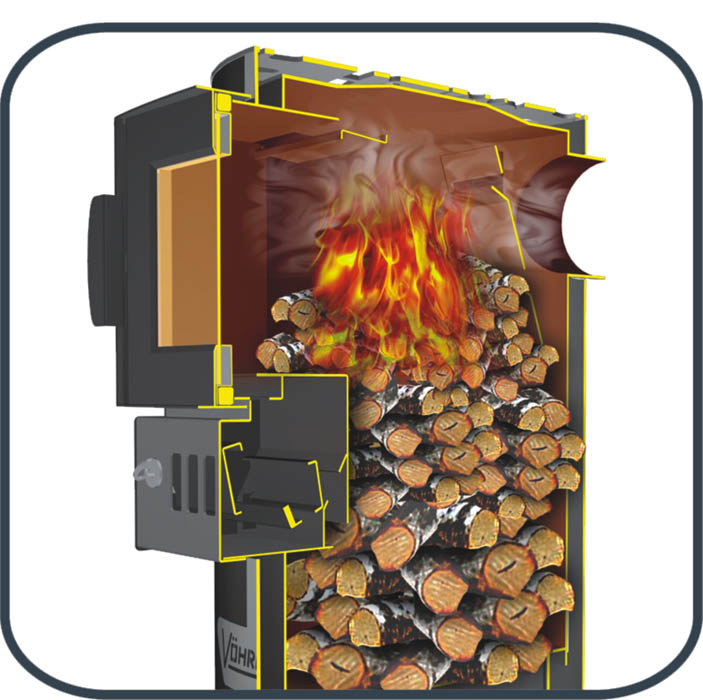

Solid fuel stoves of long burning, regardless of the model, can operate on one of the types of natural fuels: wood, pellets, eurowood, chips and sawdust, borax and coal. Considering that their device uses a pyrolysis method, in which wood gas is burned in a secondary furnace, then natural wood turns out to be the most suitable fuel option. Than better tree will be dried, the more gas it can generate, that is, give more heat as a result of the operation of the entire system. The fact is that moist smoke is obtained from damp wood, which combines with gas particles, which makes them heavier and does not burn out completely.

The combustion process of wood fuel takes place in the main combustion chamber located in the upper part - there is a small burner. Through it, the resulting pyrolysis gas enters the secondary furnace, where it is burned, giving off heat to the heat exchanger pipes passing inside. Long burning ovens do not use a forced air supply system. Oxygen is supplied through an adjustable flap, which is quite enough to saturate the secondary chamber.

The lower part of the furnace is equipped with a small container in which the ash is collected. Residual combustion products are poured into it through the bottom of the furnace. The ash-pan in the design of the furnace is used to clean the heater from the slag accumulated in it.

Smoke extraction

The chimney connection in this equipment also differs in its location from the convection ovens of foreign production. It is not accidentally placed vertically. This allows the rapidly forming condensate to drain back into the combustion chamber. This became relevant due to the fact that in the condensate of such boilers there is up to 35-40% of unburned pyrolysis gas, evaporated from moisture, and then consumed. Vertical arrangement pipes make it possible to install the stove as close as possible to the walls of the room. For smoke removal in this design, it is allowed to use any chimneys, starting with a simple metal pipe, ending with glass, ceramic or sandwich pipes, which are so popular now.

Installation

The design feature and characteristics made it very popular solid fuel boilers long burning. The installation scheme is selected depending on the room where the equipment will be installed. It is recommended to equip the place with heat-insulating screens. Free space should remain at least 150-200 mm from the furnace body to the walls, which allows you to save decoration Materials from overheating and ignition. Wood can be stored near the stove, thereby partially drying it before using it for its intended purpose.

Their appearance made it possible not only to make living in houses more comfortable, but also to solve issues related to energy saving, protection environmentas well as savings on fuel purchases. In addition, the improvement in the operational capabilities of the equipment should be noted, since it does not need constant supervision, like previous models. Solid fuel heating systems have great prospects today.

Automatic solid fuel boilers for long burning are currently widespread for the organization of heating houses, cottages, greenhouses, offices, shops, industrial and industrial buildings, car washes, service stations and other objects. Many Russians have abandoned gas boilers in favor of solid fuel appliances.

Benefits

The best solid fuel boilers for long burning have a number of undeniable advantages:

The highest degree of efficiency is ensured due to the fact that in Russia it is much more efficient to heat with solid fuel than with electricity or diesel;

Possibilities for installation in areas where there is no gas supply;

Solid fuels are a renewable energy source, making them quite a profitable option to use;

The combustion mode does not need constant monitoring - the best solid fuel boilers for long burning provide fuel combustion without human intervention for a week or longer.

Device operating conditions

The device needs to create certain operating conditions that will ensure the greatest efficiency. First of all, this is a boiler group, which includes the boiler itself, an expansion tank, a circulation pump, a safety group and other elements. A chimney is required, which must be selected according to the results of the calculations carried out, which does not allow insufficient or excessive draft to appear. Heating in the house will be organized through the use of a heating main, consisting of radiators and pipelines.

Of the whole variety of boilers that you can make yourself, rectangular ones will be the most aesthetic and compact. They are suitable for heating small rooms, and if they are modified, then you can warm up larger areas. The design of long-burning solid fuel boilers is quite simple, and its implementation will require quite affordable materials, the amount of which depends entirely on the size of the future unit. The whole point here is to keep the heated air from directly entering the chimney. For this, devices are installed inside, which consist of pipes and plates welded to each other in a special way, which allows you to create a kind of labyrinth between them, which ensures the slow passage of heated air through it. With the correct supply of additional gas, the upper compartments will serve as chambers. If desired, the unit can be bricked from the inside or you can make brickwork outside the device.

Materials

Self-made solid fuel boilers for long burning require the use of certain components: a metal sheet with a thickness of at least 3 millimeters, a steel angle and a cover for the hole in the furnace, a chimney of a suitable configuration, diameter and length. To begin with, all the details need to be cut in accordance with a pre-drawn plan. Then carefully cut everything, clean or sand the edges. Only with full compliance with the developed plan can you get high-quality solid fuel boilers for long burning. The diagram of such devices should contain the names of all components and their exact location.

The problem of gas supply exists in many parts of our country. Therefore, to this day, the possibility of installing a furnace is relevant.

One of the varieties of stoves for a private house are convection products, which have been used in the West for a long time, and in our country they are better known as a modernized one - a solid fuel stove for long burning.

Design features

A distinctive feature of the domestic oven was its shape: not cylindrical, like the western counterpart, but rectangular, the top corners are slightly truncated. This design contributes to an increase in heat transfer rates. In addition, the heat exchanger was also modified: the intake openings of the pipes are located as low as possible (the distance from the floor level does not exceed 100 mm). Protective cover that completely covers the entire oven. Thanks to this element, the heating temperature in the heat exchanger rises. And the surface of the casing itself, due to its flat shape, can be used as cooking - reheating and reheating food is now available on long burning ovens.

Benefits

Solid fuel stoves have important advantages over their liquid fuel counterparts, the first of which is the ease of making them by hand. Oil-fired stoves require a special construction element - a dropper burner for liquid fuel. Let's list the rest pluses of solid fuel structures:

- profitability: heating with solid fuel in Russia is much more efficient and more profitable than electricity or diesel;

- in the absence of gasification - the ability to install it yourself;

- renewability of solid fuel as a source of energy makes this option reasonably profitable; all the more, in addition to wood, the unit can operate on granular fuel - wood waste (pellets);

- there is no need for constant monitoring of combustion: products of long burning provide the process of heating the room practically without human intervention.

Principle of operation

A conventional solid fuel furnace has a fairly well-known operating principle. To begin with, firewood or other solid fuel is loaded into the combustion chamber, below which is located blow chamber... The oxygen required for the combustion process is supplied from the blower chamber. The combustion intensity depends entirely on the amount of oxygen supplied, so this process can be adjusted.

The combustion products enter the chimney, the bends and so-called elbows of which improve heat transfer, and, in part, increase the efficiency of the heating system. The fuel combustion process is extremely short-lived, releasing unreasonably excess heat into the atmosphere.

Therefore, for heating systems it is desirable to minimize the combustion process and ensure maximum emission pyrolysis gas, which will be the main source of heat. This principle is the basis for the functioning of long-burning furnaces.

Furnace making

Consider one of the options for making a long-burning stove for a private house with your own hands.

The cylindrical furnace is perfect for manufacturing, it has a compact size, and its design looks attractive and aesthetically pleasing. The design of long-burning solid fuel products, as we have already considered, is quite simple. To form with your own hands, you will need available materials and a simple tool. The main task in long burning ovens is hold heated air from the direct exit to the chimney. For this, a kind of labyrinth is built inside the structure of pipes and plates welded to each other, which will serve as an obstacle to the movement of heated air.

Necessary materials

A do-it-yourself solid fuel long-burning stove will require:

- metal sheet (thickness at least 3 mm),

- barrel;

- steel corner and cover for the firebox

- materials for the construction of a chimney or a finished chimney of a suitable length and diameter.

To start the process of manufacturing the unit with your own hands, you need to cut out all the parts, for this it is better to use the prepared drawings, diagrams or do it relying on video instruction. The prepared parts must be cut out and their edges sanded.

Now we do the following steps with our own hands in stages:

- The top of the barrel is cut off and its edges are leveled. For a cut, you can use a grinder, and bend over uneven edges with an ordinary hammer.

- A circle with a diameter smaller than the barrel by 1.5-2 cm is cut out of the steel sheet.

- a hole is made in the cut out circle, the diameter of which is 10 cm.To this hole is welded steel pipe the same diameter.

- Sections of the channel are welded to the bottom of the circle with the pipe, this is done in such a way as to ensure the free movement of these sections within the space of the barrel. Channel bars in the design are recognized to press down on fuel to ensure a long burning process.

- On top of the pipe, a shutter is installed, cut from steel sheet (with a diameter similar to that of the pipe). The threaded stud must be fixed inside the pipe. A hole is cut from one of the edges of the damper so that the damper, installed on the pin, covers the pipe. The damper is screwed in with a nut. This design will allow you to control the volume of air entering the furnace, i.e. regulate the intensity of combustion.

- If necessary, the lid rim is leveled with a hammer.

- A hole with a diameter of 10.3 cm is made in the lid, this can be done with a chisel. The pipe made in the previous steps will pass through this hole. Then the drain hole is welded in the lid.

- At this stage, it is necessary to prepare the base for the solid fuel stove. This can be a brick platform, for example.

- A hole is cut in the upper part of the body (for the passage of the chimney) with a diameter of 15 cm. The chimney length should be approximately 1.5 times the length of the body. In the upper part of the body, a piece of pipe is welded to the hole.

- A square hole for the door is now cut at the very bottom of the unit. Then the door itself is welded to it, through which ash and soot will be removed. A pre-prepared box (ash pan) can be installed directly into the hatch, so that it is possible to conveniently clean the oven by pulling out the box.

- The lower part of the chimney is hermetically welded, and the pipe itself is installed on the legs for reliability.

- A knee is welded to the chimney pipe. Then the stove is connected to the knee. It is better to fix the structure with a clamp, under which it is necessary to place glass wool to ensure fire safety and tightness of the connection.

Important! the device must be installed at a distance of more than 30-40 cm from flammable objects.

The do-it-yourself solid fuel structure is ready. Now you should test the long burning stove to determine the most optimal mode of operation.

The do-it-yourself solid fuel structure is ready. Now you should test the long burning stove to determine the most optimal mode of operation.

Starting the oven

- The cover is removed first;

- an element with a welded pipe is taken out (for air supply);

- then loads solid fuel; here it is necessary to ensure that the loaded fuel does not block the flue elbow; if firewood is used as fuel, they should be placed vertically, tightly to each other;

- small twigs or chips are stacked on top of the firewood, and then paper, which can be pre-moistened with kerosene;

- the pancake is set in place with a tube, and the structure is covered with a top cover;

- lighted paper or a piece of material is thrown into the hole of the air supply pipe (matches in this case will not help);

- then wait until the fuel is fully ignited and close the damper of the air supply pipe.

All. You should periodically check the operation of the long burning oven for private households.