In the article we will try to figure out, in what cases the calculation of the pipe is required and how it is done.

Why do you need it?

Calculation of metal structures

Before starting to make any metal structures - you need to calculate strength.

- If we are talking about the pipeline - you need to know, with what frequency you need to put supports so that the pipe does not sag.

Moreover, the mass of the pipeline is not only the weight of the transported fluid, but also the mass of steel pipes, of which it consists.

- When we talk about carrier frame Office buildings, sports complex or exhibition hall - we again need to calculate the weight of the structure.

After all, the foundation and supports will put on their weight not only in the building in the building.

In fact, the weight of the steel frame of the building from Senvich-panels is most of the total mass of the building along with all the contents.

Please note: a channel or a 2-way beam is used as a base for overlappings much more often than a pipe (most often square or profile). They provide greater strength with the same specific weight.

Calculation of the number of pipes when purchased

Suppose you have compiled a pipeline or metal structural project and calculated that you need to purchase 1200 meters of pipes with a wall thickness of 4 millimeters and with an external diameter of 100 millimeters.

However, a surprise will be expected on the metal suppression: the wholesale batch of pipes are sold not by meters, but tonnage. If so, the only way out is to recalculate the number of pipes from meters in tons you need.

Remember geometry

Round pipe calculation

- Calculate the length of the circle of the pipe. It is equal to the product of the outer diameter of the pipe to the number Pi.

- Calculate. It is equal to the product of the circumference of the ... That same meter.

- Calculate the volume of substance in the pipe meter of the pipe. With sufficient accuracy, it can be considered equal to the piece of the area on the wall thickness.

- Calculate the mass of the pipe meter. Steel has a density of 7850 kg / m3. The mass of the route meter will be equal to the work of this number on the volume of the pipe substance calculated by us.

- We multiply the resulting mass of the power meter on the length of the pipeline. In meters, of course. Celebrate victory.

Let's calculate the mass of the most thousands of two hundred meters of pipe with a diameter of 100 mm and with walls with a thickness of 4 mm.

- 0.1 * 3,14159265 \u003d 0.314159265 m.

- 0.314159265 * 1 \u003d 0.314159265 m2. Honestly, this operation could also be skipped 🙂

- 0.314159265 * 0.004 \u003d 0.00125663706 m3.

- 0.00125663706 * 7850 \u003d 9,864600921 kg.

- 9,864600921 * 1200 \u003d 11837,5211052 kg.

TOTAL, taking into account the errors, waste during trimming and other nonsense, we make sense to purchase 12 tons of cherished pipe.

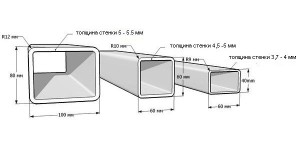

Square Pipe Calculation

Here, the calculation algorithm is slightly different.

But just a little.

- Calculate the length of the perimeter of the pipe cross section. It is equal to the size of the wall of the square tube to four.

- Calculate the area of \u200b\u200bthe pipe meter. As it is easy to guess, the number obtained at the previous stage is multiplied by one meter; As a result, it turns out, but no longer in the route, but in square meters.

- Calculate the volume of the pipe substance in the prayer meter, Again, multiplying the surface area of \u200b\u200bthe pipe meter on the wall thickness.

- Multiply this volume on the density of steel (7850kg / m3, remember?).

- Calculate the weight of the pipe you need, Multiplying a mass of one rode meter for a foot.

We calculate the mass of the same 1200 meters of the pipe with the same wall thickness in 4 mm and the size of the wall is 100 mm.

At the same time we will understand how the mass of the round and square pipe is correlated at such a close size.

- 0.1 * 4 \u003d 0.4 m.

- 0.4 * 1 \u003d 0.4 m2.

- 0.4 * 0.004 \u003d 0.0016 m3.

- 0.0016 * 7850 \u003d 12.56 kg.

- 12.56 * 1200 \u003d 15072 kg, or a little more than fifteen tons.

Calculation of the mass of the rectangular pipe

And here the difference is small:

- The perimeter of the pipe cross section is calculated as the double sum of its parties;

- The surface area of \u200b\u200bthe power meter is also obtained by multiplying the pipe perimeter per unit;

- The volume of the substance in the pipe meter is still equal to the product of its surface area on the wall thickness (approximately, of course);

- The mass of the rose meter is obtained by multiplying the volume from the previous paragraph by 7850;

- The result in kilograms must be multiplied by the length of the pipeline to obtain the total weight of the pipe.

Walking so walking: let's calculate what will mass pipes with a steel rectangular length of 18 kilometers, with dimensions of 180x145 millimeters and with twenty millionth walls.

This monster is really produced and used as a carrier element where high bending strength is needed.

- (0.180 + 0.145) * 2 \u003d 0.65 m.

- 0.65 * 1 \u003d 0.65 m2.

- 0.65 * 0.02 \u003d 0.013 m3.

- 0.013 * 7850 \u003d 102.05 kg. However, the meter of such a pipe will be able to tear off the floor not everyone.

- 102.05 * 18000 \u003d 1836900 kg, or 1836.9 tons of pipes.

The weight of metal rolling is an important characteristic that plays a large role when purchasing, transporting and calculating structures. The calculator allows you to quickly determine the theoretical mass of pipes.

1 for which it is necessary to determine the weight of profile pipes

Profile call pipes that have in contrast to the usual plumbing non-circular cross-section. The most common and in demand is the profile pipe products of the rectangular and square cross section. Its usually use for the manufacture of various kinds metal structures and their elements in the construction industry and various manufacturing areas.

First of all, data on the weight of the profile product is required for the calculations that are produced in the design and development of metal structures, as well as filling out a variety of technical and accounting documentation. It is necessary to know the mass of the rolling and when it is purchased and selling, since all payment calculations are made, as a rule, per kilograms (tons) and only with a rare exception for the route meters, pieces. Determine how much weighs the transportable party is necessary and to select the method of transportation and product delivery tools.

In addition, in the market of metal and rolling and building materials There are unscrupulous sellers (or suppliers and manufacturers) who are trying fraudulently to prove on the consumer. They can offer a non-concerted, defective, non-standard tube products that are not appropriately provided by the norms and gestures, which is externally indistinguishable from high-quality. For example, there are often cases of attempts to sell products of Chinese production, in which the stated (technologically regulated) sizes of the walls (thickness) are present only at the edges, where, in fact, it is carried out on the compliance of the sizzy. And in fact, the pipe 100x100x5 mm in the middle can have other parameters - 100x100x4 mm. So in the process of production, metal is saved, and as a result of the sale, "body kit" can occur - if the implementation occurs for piecks or rose meters. The buyer will receive low-quality metal products that do not stand the money spent and can lead to serious negative consequences. Such a "shortage" is easy to reveal if you know the weight that the pipeline pipe should have.

2 Methods for determining the weight of the profile pipe

All existing ways to determine the weight of metal rolls without weighing it make it possible to obtain theoretical value according to the existing dimensional characteristics (diameter, width, height, thickness, length). Only weighing will show the exact mass. There are the following methods for determining theoretical mass:

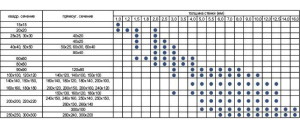

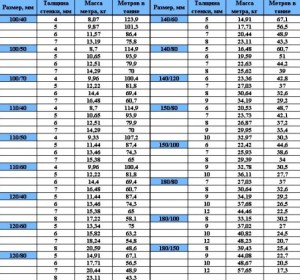

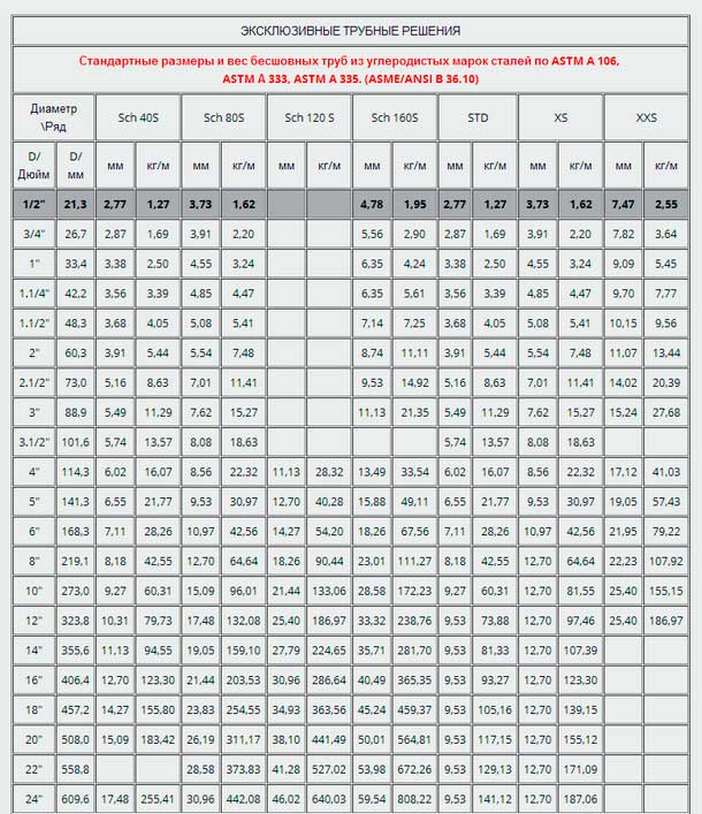

- using tables for this type of metal;

- using the profile pipe calculator;

- by calculating the mathematical formula.

In all cases, the theoretical value of the metal density used for (for steel 7850 kg / m 3) is used to determine the weight; standard dimensions Products provided for by the technical conditions of the GOST.

But there are many different alloys and their actual density always, at least slightly different from the theoretical value. The real dimensions and shape of the metal product may also not coincide with the tables within the tolerances regulated by GOST. Therefore, the mass defined by these methods is theoretical.

The tables indicate the weight of 1 of the circuit meter of profile tubular products (in kilograms) for each size and number of meters in 1 ton of the product. To determine the total mass of the batch of metal rolling, you must multiply the weight of 1 mp. For the total length of the entire volume of pipes (in meters).

The fastest way to clarify the mass of profile products - using an online calculator. Manually by the formulas - the slowest and less reliable, as in this method more than in the first two, the possibilities of making any error (it is possible to use the formula or to be mistaken during the selection and entering data).

3 Calculation of the profile pipe using an online calculator

Special calculators posted on the Internet allow you to quickly calculate the mass of the profile pipe.All that is required for this is to contribute to the appropriate calculator fields, the parameters of the metal:

- length of the side (height and width) of the profile;

- wall thickness;

- pipe length.

Then it is necessary to specify the steel brand (alloy), from which the profile product is made, and click on the input button. As a result, the value of the theoretical weight of the pipe will be obtained. Moreover, the calculators do not calculate the mass calculation of 1 meter of profile products, and standardized table values \u200b\u200bare immediately substituted in accordance with the product number. This is the fundamental difference from calculations by the formula where this parameter is determined independently. Thanks to this, the calculator is more accurate.

On the calculator, it is possible to calculate for pipes from the following types of metals:

- cast iron;

- become;

- copper;

- bronze;

- aluminum;

- brass;

- titanium;

- magnesium;

- other alloys.

Also determine the pipe of the pipe for its weight (the number of meters per 1 kg or ton of the product).

4 Calculation of the weight of the profile pipe by the formula

The calculation of the profile pipe according to the formula is based on calculating the volume of the metal wall walls of a length of 1 m. When multiplying this value to the density used for the manufacture of rolled alloy, the theoretical weight of 1 m pipe is obtained. The multiplication of this weight for the total length of the product is determined by its mass. The formula for calculating 1 M of profile tubular products: 26,376 * 200 \u003d 5275.2 kg

The theoretical weight of 1 m obtained by the formula differs from the table value taken from the GOST - 24.18 kg. Such a discrepancy is due to the fact that the proposed formula for calculation does not take into account the external and internal roundings in the corners of the profile real pipe. The calculations were carried out for the product of the right geometric shape (with straight corners), but such products are not really released. And theoretical values \u200b\u200bfor the GOST tables were calculated taking into account the real geometry of the pipe product profile, so they are more accurate. Since the formula used in these calculations is much more complicated above and require considerable larger time for calculations, we do not give them. Under conditions, when the Internet does not turn out to be at hand and the directories will be sufficiently simplified fast counting to determine the approximate weight of the pipe. And it is better to find out the exact mass by weighing products.

Each has its own reasons for determining the mass of one pipe or the entire party. For example, it is necessary to resolve the issue with the communication gasket, with a vehicle carrying capacity. But mainly it is required to verify the correctness of cash settlements.

The specificity of pipe products is that its cost is more "tied" not to the length of the products, but by their weight, and the price mainly depends on the raw component, that is, on the amount of metal in 1 pm, so that the weight of the pipe can be calculated On the diameter and thickness of the wall - they are in this case the most important indicators.

How to find out the weight of the pipe

According to tables posted in profile reference books or on thematic sites. In many of them, the estimated weight of 1 pm is indicated in the right column. Pipes for each sample, depending on it and the thickness of its wall.

Using an online calculator. If you have a PC and access to the network at hand, it is enough to put the original data in the corresponding "windows" (wall thickness, outer diameter), and the result is ready.

According to the formula. It is given in GOST No. 8732 from 1978 and is common to any pipes, therefore, the mass data obtained as a result of calculations will be approximate. Nevertheless, they do not go beyled beyond the limits of the error and it is quite possible to operate.

M \u003d 0.02466 x s x (DN - S)

- M - Weight 1 P.M. Pipes.

- S - wall thickness.

- DN - diameter (external).

There is another formula that is less common, but it gives, firstly, in some cases a more accurate result, secondly, applicable for any kind of products - steel, copper-iron pipes.

On a note!

When calculating according to formula No. 1, the correction coefficient is indicated at the calculation of the fact that the density of steel is taken by an average equal to 7850 kg / m³. Therefore, when determining the mass of pipes from other materials, the error may be significant.

As a basis, the ratio is taken as the basis - M (weight 1 pm) \u003d p (density) x V (volume).

What to take into account - as for further calculations, it is enough to know a lot of 1 perm. Pipes, the volume in this case is equal to the area of \u200b\u200bits cross section. This can be seen from the formula - V \u003d S x L (and length \u003d 1).

Determine the cross-sectional area is easy (again, remembering the native school). There are 2 techniques:

- find the area of \u200b\u200bthe outer and inner circle (S \u003d π / 4 x D2), and then determine the difference of the values \u200b\u200bof the obtained values;

- to change this formula, substituting the values \u200b\u200bof diameters (outer and internal) - S \u003d π / 4 x (D2N - D2B) into it.

Note

- Linear product parameters are taken to indicate: section and thickness - in "mm", length - in "M". Using to calculate the weight of the pipe, one or another formula, all initial values \u200b\u200bare necessary to translate into one dimension. If the density is in "kg / m3", then diameters and thickness should also be expressed in "M".

- Real deviations of the thickness of the pipe wall from the specified value can be essential (up to ± 8%), and this is not a violation. If you need to find out the weight of the pipe with maximum accuracy, it is better to make an independent measurement of this value, and not be guided by the data from the accompanying documentation. With a large length of samples (and their quantity), the difference in the marked mass of the batch and the actual can be significant. Consequently, in real value - too.

- To learn a lot of pipes from a specific material more accurately, it should be determined to determine its specific weight (density). These data are reflected in GOST No. 1050 from 1988 (steel), 1412 from 1985 (Cast iron gray) and a number of other standards. Find the required documents is easy to drive the required query to the search string.

If you are not a professional on pipes, but you needed to know how much steel pipe will weigh, then you should not despair. You will be able to calculate the weight of the pipe steel rectangular or any other using modern technologies In the form of a worldwide network where you can use online programs in which there are tables for calculating the weight of different steel pipes.

We know the weight of the pipe by the formula

If you have no access to the Internet, then for calculating the specific weighing of pipes there are formulas. It is necessary to know that it is customary to consider the weight of one meter of the pipe from steel in kilograms. There are two formulas for calculations and practice shows that both are effective and issue results that are not different from each other. According to the formulas, the calculation of a larger number of pipe sizes, for example, weight round pipe Steel electric welded from the pipe seamless is no different and depends only on the thickness of the wall.

1. Option of the first formula: MP \u003d ((Du - TS) / 40.5) * TC. Du is the diameter of the pipe indicated in millimeters, the TC is the thickness of its wall in millimeters, and Mn will be the result. The result will show you how much weighs in kilograms one meter of the pipe.

2. Option of the second formula: MP \u003d (Du - TC) * TC * 0.0246615. In this case, the Du will also be the diameter of the pipe in millimeters, the TC - the thickness of the pipe wall in millimeters. The result MN will show weight in kilograms of one meter of the power pipe.

We know the weight of the pipe with the calculator on the Internet

Currently, there is a fairly large range of steel metal rolling. Sometimes certain difficulties arise, if you need to know, for example, weight steel pipe Profile. The above formulas are not suitable here, since in order to learn the weight of the pipe with the square steel or the same profile, it will take to consider and cross-section of pipes: rectangular or square. For this, there are programs that allow you to easily calculate the necessary weight of the pipe. Calculator can easily download from the Internet and you will always have numbers on the characteristics of pipes with different sizes. To take advantage of the calculator, you need to know the thickness of the pipe wall and its cross section. Find this calculator is absolutely easy, for this simply use any search engine.

Currently, there is a fairly large range of steel metal rolling. Sometimes certain difficulties arise, if you need to know, for example, weight steel pipe Profile. The above formulas are not suitable here, since in order to learn the weight of the pipe with the square steel or the same profile, it will take to consider and cross-section of pipes: rectangular or square. For this, there are programs that allow you to easily calculate the necessary weight of the pipe. Calculator can easily download from the Internet and you will always have numbers on the characteristics of pipes with different sizes. To take advantage of the calculator, you need to know the thickness of the pipe wall and its cross section. Find this calculator is absolutely easy, for this simply use any search engine.

When is the calculations of the weight of pipes?

ABOUT next reasons here are the following:

— to calculate the strength of the erected construction. If the framework of the modular building is mounted from the profile or round tube, then the weight of the loads of the useful - opening windows, people in the house, furniture, and the like will be prescribed. This also includes the weight of the upper levels of the frame. A fairly often carrying skeleton of the building weighs much more than everything that is in the building;

— by weight, the purchase of pipes and other metal. If you do not know the weight, the storekeeper will never agree to measure for you a roulette of one and a half kilometers of pipes of the mains;

— there may be difficult when loading pipes on vehicles, if you do not know their weight. FROM plastic pipes It is much easier, it is enough to know the cube and commend it with the capacity of vehicles on which transportation will be carried out. But when transporting pipes from steel, everything is different. It is necessary to calculate everything for sure, since such pipes weigh every ten more, and the vehicle simply does not move from the place of reboot.

Pipes can be electric welded and seamless, round, water-gas, or profile. Determine the type pipe. Specify it outside diameter and wall thickness in mm. Measure the length of one pipe In meters and number of pipes in order.

Find in the directory of theoretical scales of steel pipes of the appropriate GOST Type and Calculated mass one row meter pipe The desired diameter and wall thickness. Multiplying the magnitude of the mass of the route for the length pipe, get the weight of one pipe in kilograms. Calculate the overall weight of the order, moving weight 1 pipe on their number in order.

Calculate the same method of polyethylene pipe, knowing it type, diameter, wall thickness and length. Use for computing the reference data of the GOST for polyethylene pipes. To determine the weight of a single rapid meter of polyethylene pipe By reference book you need to calculate the SDR or standard dimensional ratio.

Exercise the amount of polyethylene diameter pipe On the thickness of its wall. So you will find SDR in mm. Knowing standard dimensional ratio, find the GOST reference data mass Running meter pipe The desired diameter. Next, calculate the weight of the desired segment pipe or all the bay, multiplying mass Running meter pipe on its length.

Typically, the pipe has the shape of a hollow cylinder, so its mass depends on the thickness of the walls, the material of manufacture and length. If these parameters are given in the conditions of the problem, it is reduced to finding the formula in general formula, substitution of values \u200b\u200bof variables and calculate the result. For practical calculations of the mass of the pipe as an industrial product, the values \u200b\u200bof variables can be obtained from the regulatory documents - guests.

Instruction

To compile the formula for calculating the mass of the pipe, it is necessary to find out the cross-sectional area of \u200b\u200bthe hollow cylinder. To do this, the wall thickness must be known (a). If there is no internal (D) and external (D) diameters under the problem of the problem, express the wall thickness after half the difference of these quantities: a \u003d (d - d) / 2. The cross-sectional area is determined as multiplied by the number of Pi difference between the product of the outer diameter on the wall thickness and the square of the wall thickness: π * (D * A-A -²).

Using the sections area formula, determine the volume enclosed between the outer and inner walls - multiply the formula obtained in the previous step to the length (L) of the pipe: π * (D * A-A²) * L.

Submold in the formula the values \u200b\u200bgiven in the conditions of the task, and calculate the result. At the same time, take into account the dimension of the initial values. Suppose the outer diameter of the steel pipe is 30 cm, the wall thickness is 5 mm, the length is 4 m, and the steel density is 7.95 g / cm³. In this case, it is possible to substitute in the formula all the values \u200b\u200bin centimeters, get the result in grams and translate it into kilograms: 3,14 * (30 * 0.5-0.5²) * 400 * 7.95 \u003d 3,14 * 14, 75 * 400 * 7.95 \u003d 147281.7 g ≈ 147.3 kg.

In practical calculations to determine the values \u200b\u200bof the variables that need to be substituted into the formula, use the marking applied to the pipes or the accompanying documents specified in the accompanying documents. Knowing it, it is possible to determine the desired values \u200b\u200bby regulatory documents - Gostas. For example, the density of steel pipes can be found from GOST 9941-8, and the plastic density is given in GOST 18599-2001.

Sources:

- Online calculator

- how to calculate the weight of the pipe

Need to determine diameter pipe It often occurs when replacing sewage pipes, selection of heated towel rail and other homework. You can determine it yourself, for this you will need only a roulette or caliper.

You will need

- - pipe;

- - roulette;

- - caliper;

- - line.

Instruction

Measure the tape measure or centimeter ribbon pipeTo do this, wrap it around and look at the value on the scale. Next, divide the obtained value to the number Pi, equal to 3,1415. As a result, you will get an external diameter pipe.

If you have a caliper, you can measure external diameter Directly (for pipes up to 15 cm). To do this, clamp the pipe with sponges of the instrument and look at the double scale, how many centimeters is diameter.

In order to learn the inner diameter, measure the thickness of the walls on the cut pipe. Spend measurements using a ruler or caliper (a second method, of course, more precisely). Substitute external diameterand the wall thickness multiplied by two - the obtained number is internal diameter.

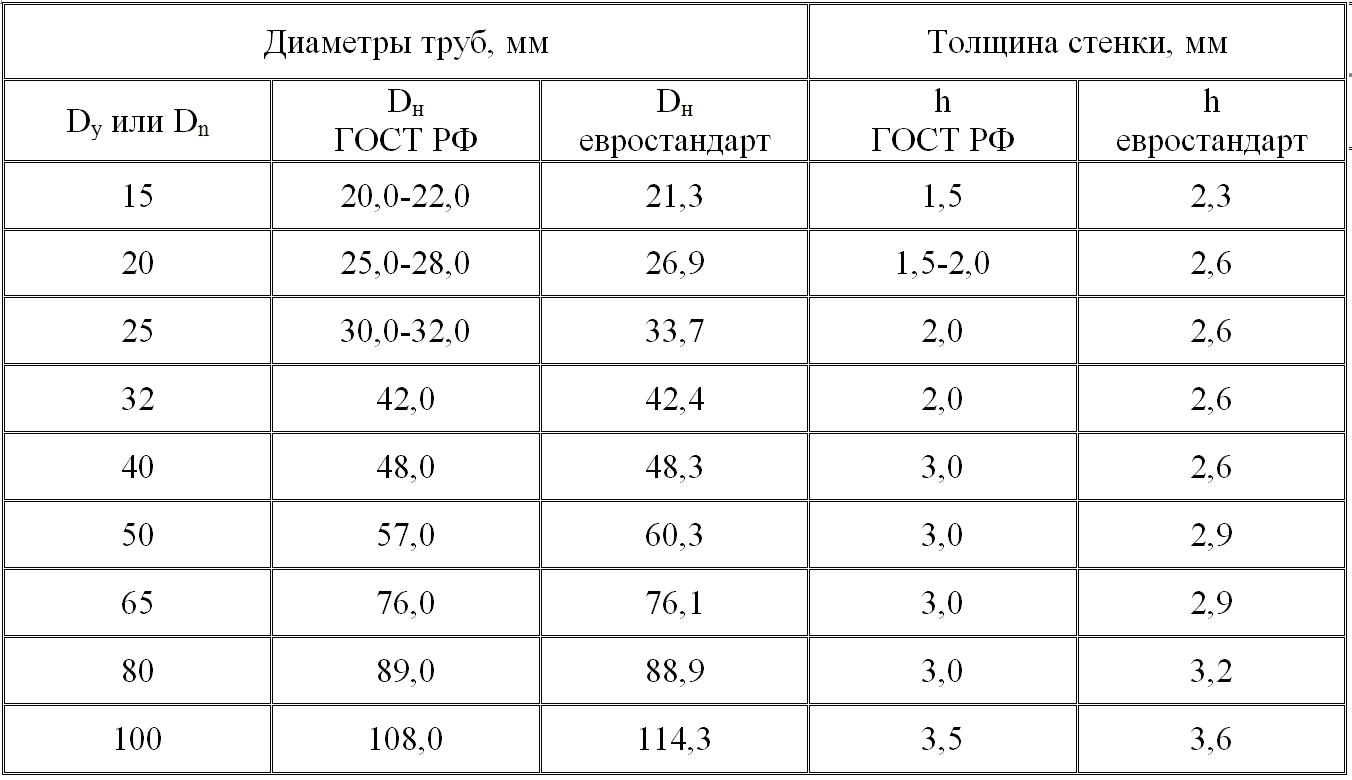

When choosing a heated towel rail or other works in which you need to know diameter Standard plumbing pipewalking at your home, use the following simple way. Attach a line to the pipe and count its approximate diameter. If it sees on the eye that the pipe has a width of about 32 cm - boldly conclude that the landing diameter Its 1 inch. Size 25-28 cm corresponds to a standard pipe in ¾ inch, and a value of 16 mm is 1.2 inches.

note

When designing a pipe metal, for example, the pipes for metal structures or stainless pipes are used by outer diameter and wall thickness. For example, the recording is as follows: 530x12. For water-gas-wire pipes, the inner diameter is of great importance, so they are indicated, for example, 15x2 (at first glance, just). To determine which pipe in front of you, look at GOST. Water-gas pipes (VGP) are made according to GOST 3262.

Accurate calculation of quantity concreteto be put in formwork - one of the terms of competent execution construction work. Excess concrete, as a rule, to use nowhere. The mixer either takes the ordered and pre-paid concrete, or will drop it into the specified location by creating an "monument" to your dignity. Violation of construction technology due to lack concrete will lead to even more serious consequences. Consider on the example belt FundamentHow to avoid similar errors.

You will need

- - line,

- - Roulette,

- - Calculator.

Instruction

Commodity concrete of various brands, which is a semi-liquid mass, depending on its composition, has an unequal shrinkage - the smaller in it cement and water, the incognent of changes volume is concrete when hardening. In addition, the magnitude of shrinkage concrete Other factors, for example, the method of its sealing are affected: when the shovel shovel shovel is less than when sealing concrete Deep vibrator. When calculating the required amount concrete A single average shrinkage coefficient is usually used, equal to 1.015-1.02.

Consider the amount of concrete structure, according to the project (sketch). To do this, multiply the width, height and length of the foundation.

Check after the formwork structure, the composition of the height, width and length of the foundation design values. Small deviations of the sizes in the large side lead to a significant increase in the required amount. concrete. The use of inventory formwork from steel frames and moisture resistant plywood allows you to minimize these errors.

Multiply the resulting volume on the shrinkage coefficient.

Deduct from the resulting value the volume of all openings and niches for engineering networks (Pipes, box). To do this, it is necessary to calculate the corresponding volumes by the formulas of determining the volume of the cylinder (the area of \u200b\u200bthe circle multiply the height) or the parallelepiped (the length multiplied by the width and height). The resulting value and will be number concretewhich is necessary for the fill of this design.

note

In order to avoid errors in counting, all measurements (length, width and height of the foundation and openings in it) should be carried out in some units - meters.

It is very important that in the case of using a milking formwork, it was maximally aligned and rigidly fixed, otherwise the formwork can spread from the mass of the concrete poured. The lack of cracks between the boards are considerably, and the lack of cracks between the boards, which will be sealing when the concrete is sealing, which also leads to a change in the shrinkage coefficient.