How to knit fittings? It is this question that arises from those who are going to increase the reliability of the foundation designs and make them more resistant to non-characteristic loads. Concrete characteristics, which is actively used for the manufacture of various construction systems, allow it to successfully resist compression loads. However, this material and designs are very sensitive to stretching and bending, which they can be regularly subjected.

Methods for connecting reinforcing elements

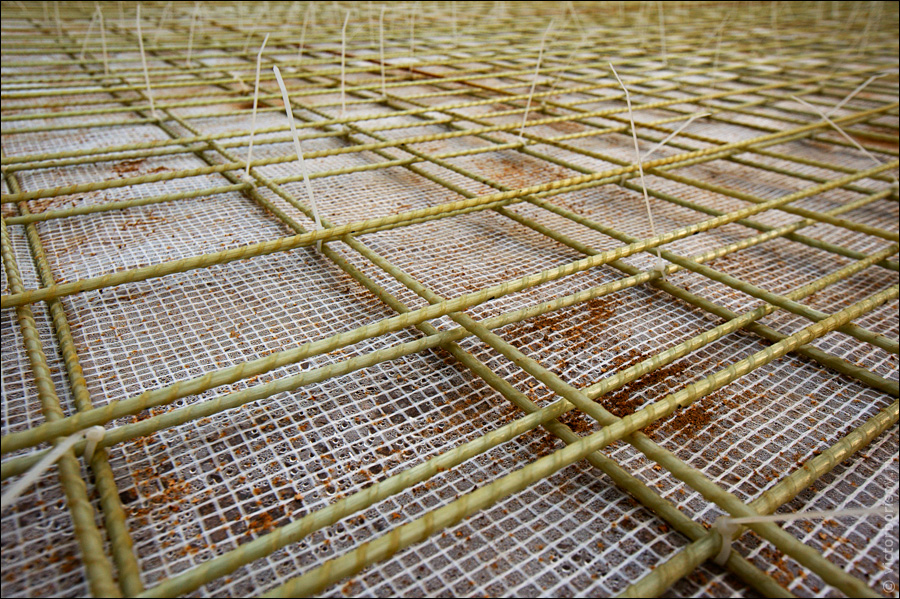

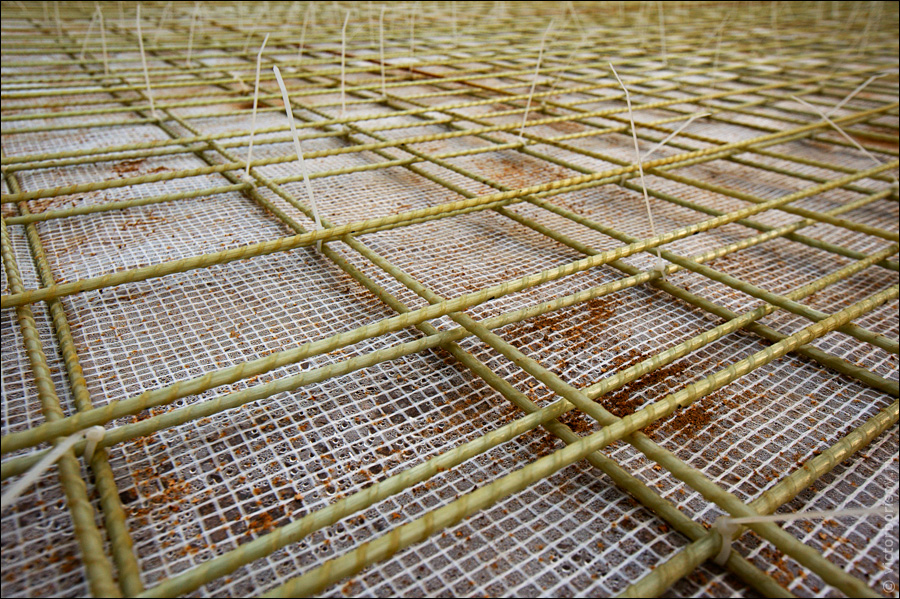

With the help of fittings consisting of metal rods, a power frame is formed in the foundation, which for its geometry resembles a cell. Such a reinforcing cell, as a rule, consists of a minimum of two horizontal layers, including both horizontal and vertical jumpers.

In order for the reinforcing frame, consisting of separate metal rods, has the required reliability, it is necessary to properly connect all its elements. If they are not fixed accordingly, the entire reinforcing design may be exposed to the deformation under the influence of the mass of the filling concrete or due to the loads affecting the entire construction system.

Knitting fittings must be performed in places of crossing metal rods, as well as in those areas where they cross each other at their length.

For the foundation can be performed in several ways. The choice of concrete of these options depends on the required reliability of the reinforcement framework and the conditions for its creation.

Clamps from polymeric materials

The assembly of fittings for the foundation can be performed using clamps made of plastic. This method is the most advanced and does not require special preparation of materials. It consists in the fact that the reinforcement rods are manually associated with plastic clamps, connecting them in those places where they intersect. The material from which such a clamp is made is not subject to corrosion, therefore the mating made with its help is obtained very reliable.

Binding of reinforcement with welding

Often, welding is selected as a method of mating fittings. However, you should know that you can weld among themselves only the reinforcement rods, in the marking of which there is a letter "C". In such situations, point welding is usually applied.

It should be borne in mind that this method of compound will require the use of the welding machine, as well as the availability of experience with such equipment. In addition, welded joints are very poorly withstanding vibratory loads arising from the use of sealing devices, as well as devices with which air bubbles are removed from concrete.

Fixation of reinforcement elements with wire

Most often bid reinforcement elements Performed with wire. This method does not require special skills and makes it possible to achieve the required parameters for the reliability of fixation. Solving the question of how to tie the reinforcement, most often choose this method of fixation.

This knitting is performed very simply: the reinforcement elements are fixed with the wire, which is then delayed and reliably connects all parts of the structure.

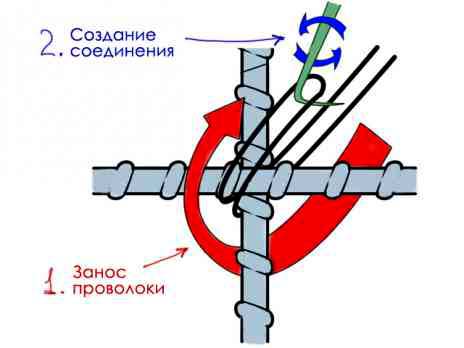

For mating fittings, the wire is used by a special crochet, with which you can get connections in various schemes. Such schemes differ in the wire spinning method.

Wired reinforcement compound technology

Before knit fittings, it is necessary not only to see the corresponding video, but also to properly prepare the connected parts. Such preparation is as follows:

- cut a piece of wire with a length of 20-30 cm, but you can more accurately determine the necessary length you can, when you put the mating of several parts of the reinforcement;

- roll down the sliced \u200b\u200bpiece twice;

- wrap the location of the compound diagonally diagonally obtained by the harness;

- the curved end of such a harness is put on the bar of reinforcement, the second end also lock on it;

- manually, or taking advantage of the crochet, tighten the ends of the obtained wire loop.

Mechanization of the process

The most common way to mechanize the process of mating fittings is the use of a special hook. Such a hook is easy to make it with your own hands, for this you can use a piece of reinforcement, which on the one hand bends the eye (for the convenience of rotation), and with the other, it is slightly strung and sharply sharpened. You can see the process of manufacturing such a hook on numerous videos posted on the Internet.

How to knit fittings for foundation with such a device? Everything is very simple: it is enough to put the sharpened end of the hook into a wire loop and rotate it to a tight twist.

How to simplify the process

If aimed at simplifying the mating of the reinforcement elements is to simplify, then the power tool can be used for this. This task is solved quite simply: an ordinary screwdriver takes, in the cartridge of which a bellged nail is installed. Such an easy device will allow you not only to correctly connect the reinforcement design, but also to ensure its required reliability.

There are also even more convenient ways, but for their implementation, a special tool will be required. Such, for example, as a gun for mating fittings. Similar equipment is quite rarely available when independent constructionBut, having it at hand, the process can be accelerated at times. The convenience of such a tool is difficult to overestimate, however its value (from 35 thousand rubles) disfixes many private developers who save funds above speed and convenience in carrying out vehicle versatile.

Favoric builders can be understood, since in most cases this tool will only be needed once, and spending money on his acquisition is impractical.

(Votes: 2

, average rating: 5,00

out of 5)

Hello, dear readers! Our interview will be devoted to unusual work, which, despite all the simplicity, many are afraid to do themselves, namely how to knit fittings. Today, the curtain of the secrets of this case will open it young, but despite this is a very experienced, built a lot of objects, foreman Nikolay Nikolayevich.

Hello, Nikolai Nikolaevich. We have accumulated a number of questions for you, perhaps they sound simple and unprofessional, but we are not yet familiar with the right names and terminology.

- Good evening Dear readers! I will try to answer the most accessible and full of all your questions. So, let's begin.

Why does the reinforce knit in most cases, and not cook? Does the connection of the reinforcement differ with welding from the mechanical connection?

- Armature, in most cases, knit, not cook. Because with a welded joint, the composition of steel changes, as a result of which weaknesses appear in the rods of reinforcement. Another disadvantage of the welded compound is the deadline, in comparison with the so-called mechanical method (actually, viscous). Also, much depends on the experience of the welder, and if it is "green", in most cases the design will not be able to perform its main purpose - to withstand the load. However, the welded compound is often used in the construction of panel buildings, due to the fact that during the construction of such houses, integrated brigades (welders installers, carpenters, concreteers are mainly used) and take a separate specialty, reinforcers, economically not profitable. As for the mating, this is a simple and fairly fast method of fixing fittings that do not require special skills, this method is most often found in monolithic construction. Live performs the same function as the welded connection, only with the help of knitting wire. In any case, welding, and the nip must perform the same function. The main thing is that when pouring the reinforcement frame of concrete, the reinforcement rods did not change their position and form. The product strengths are not attached - the strength is ensured by the integrity of the design with a spilled concrete.

What are the necessary tools and materials for mating?

— Prod - This is very important element When performing knitting work, since the quality of the node depends on the quality of the wire and specifically fixing the reinforcement, and, therefore, the final product. When viscating, the burnt wire is usually used, a diameter of 1 mm, always round cross section. The difference between the burned wire from the unreleased in the fact that the first is well bend, it fits tightly to the reinforcement and has the property of tightness (i.e., it does not break with a knats), unless the second, unprocessed, which is seriously broken and breaking the knitting node and breaks . If you are not burned, then do not even try to use it, since it is actually impossible to knit it. Also for mating fittings (mechanical fastening) are necessary hook, or collet, and plastic baries (Locks).

Ordinary hook

Automatic hook

Knitting gun.

Plastic Basins (Locks) - What is it? And what are they used for?

- This is a plastic part that is stacked between the reinforcement and formwork to create a protective layer. Without them, the reinforcement may touch the formwork and, after the fill, it will stick out of concrete and rust accordingly, lose strength and destroy the design.

Please tell us about each tool - describe it advantages, disadvantages when you should apply (simple hook, homemade hook, screw hook, gun)?

As for each instrument separately, then the case is everyone who is used to work. The most common tool is hook or collet. Pistol Good on horizontal surfaces where it is not necessary to be subject to hard-to-reach places. The advantages of the pistol are the speed of work. The disadvantage is that it is extremely inconvenient to knit in hard-to-reach places, the battery and higher wire flow rate is also quickly discharged. Speaking of hooks, then most popular is homemade hook. If you decide to seriously engage in viscous, then it is better to make a hook for mating fittings yourself. Make it from the corrugated reinforcement, and the bearing is installed in the handle to facilitate rotation. Shop hook It is only good for learning, so they are usually short and quickly rust, because of this, a terrible sound is issued and the speed of work is reduced. Exist semi-automatic (screw) hooksBut I do not like to work with them: the cramps of the wires of the wire remain, then the team comes to those. Sneakers and forces it to redo the entire garbage in the overlap. And correctly does, because, maybe you noticed or from acquaintances on the ceiling, rusty stripes that appear on the surface of the ceiling? This is nothing more than a wire or a craft of a master who, when creating a protective layer, did not put under the frame of the bays when filling the reinforcement concrete.

Actually, how to knit fittings using various tools I propose to look at the video.

Video mating reinforcement ordinary hook

Video mating screw crochet

Video about knitting pistol

Is it distinguished by mating depending on the part of the house - wall, foundation, overlapping?

- In theory there are many ways of mating, but in practice two mains are one loop for connecting the brass and 2 loops for connecting to the joint. Almost everything knives of one loop, even the angular elements, although in theory, the angular elements knit with another node. The loop is good with its simplicity and reliability - it is possible to learn in literally in five minutes, and it is difficult to make a mistake.

How long does the assembly of fittings take?

- I did not hear about such a norm, all according to the abilities. Also, the veligation speed is highly dependent on the design: the overlap knit is much faster than the arch with the curved elements.

Is there a certain wire flow rate?

- As such, there is no standard for one knot, there is a flow rate. Such a norm is calculated in the project documentation for the object, based on the fact that 20 cm wires are required, if you knit with a crochet, and if the gun will be more. Calculate consumption, for example, for a wall or overlap separately, it is very difficult, since the part of the nodes will be broken and it will be necessary to bandage, and much depends on the wizard.

Manufacturers of knitting pistols argue that with the help of this device, all nodes will be tightened with the same effort! And as far as important is it - tighten the nodes with the same effort?

- For us, it is not the same for the screed force of the rods, and so that they do not change the position and the structure itself did not change when the shape of the form concrete, since when the protective layer changes, it will be improper thickness and, in the future, cracks and rust will appear on the concrete. In general, the same tightening force of the nodes is nothing more than the advertising move of the manufacturers of pistols, because it does not have such an important value. But all the same, when you knit crochet, specially "kosy" and delaying with obviously different effort is not worth it - such experiments can do it expensive, so we drag it more or less evenly and everything will be fine.

What will be the strength of the structure, if they are wrong to be associated, with insufficient effort, or in this case, the connection is bursting at all?

- If one connection bursts - nothing terrible. I repeat - the most important thing for us so that the design does not change the form when pouring. But still, the correct knitting of the reinforcement will determine the strength of the structure.

What other ways to fasten fittings do you know?

- I also heard about two ways - metal clips and knitting of reinforcement clamps from plastic. Unfortunately, I did not work with them, and I did not hear like friends. Apparently, these methods did not receive for some reason widespread. I myself am an adherent "Classics": I knit with an ordinary crochet, as it's easy and quick and not using all these new-fashioned innovations of the type of screw hooks, clips and pistols.

Thank you, Nikolai Nikolaevich, for your story about this work.

- You are welcome! Contact, I will always be happy to answer any of your questions.

The construction technology of the foundation consists of several main stages: marking, trench coppes, laying sand-gravel pillows, assembling formwork, mating frame of fittings and fill concrete. All stages should be performed in accordance with the necessary requirements and construction standards, as the foundation is the basis of the structure and the slightest errors in the process of its construction can significantly reduce the service life.

A special place in the construction of the foundation is played by the assembly of reinforcement, properly related framework will make the construction as strong as possible. Such a foundation is not afraid of external influence and does not burst with the slightest shifts of the soil. Therefore, in this article we will analyze the question in detail: how to knit fittings for the foundation?

Methods for connecting fittings

Consider the main methods for connecting reinforcement for the foundation. Experienced builders Four basic means of binding reinforcement for assembling various frames and grids:

- navocating vehicle assembly;

- connection of reinforcement adhesive

- mechanical connection of reinforcement with steel couplings.

All methods have their pros and cons. During construction small houses Most often, the installation of the reinforcement frame is used using welding or knitting of reinforcement with wire.

Knit or boil fittings

To compare two of these methods is not entirely correct, as these are different technologies, but still there are situations where the choice between these methods will help save time and money, without harming the strength of the structure.

Connection of reinforcement with welding is one of the most effective waysBut the use of this type of reinforcement of reinforcement is not always appropriate. Most often it is used for mounting large frames for multi-storey buildings and heavy brick cottages.

Disadvantages of reinforcement with welding:

- professional skills are needed or you will have to resort to the services of the welder, which will significantly affect the cost of the structure;

- reducing the strength of reinforcement products in welding places;

- it is not possible to use, for example, one of the most sought-after classes of reinforcement A-400 (A-III) can be combined with welding, it is impossible to cook and fiberglass fittings;

- the possibility of damage to the joints during the work on the seal of concrete vibrators.

During the construction of a private house, a bath or other construction, the rational means to use the mating of reinforcement with a wire.

Advantages and disadvantages of mating fittings with wire

Benefits:

- the speed of work is to knit the reinforcement with a wire simply and quickly, but with a manual method of viscosity of the reinforcement, the process becomes very laborious;

- easy to eliminate the shortcomings - the framework for the foundation should not be perfectly smooth, but still a slight deviation or breakage with a welding connection and will have to be resorted to additional operations, for example, to the use of a grinder for removing wrapped welding, and in the case of mating wire, we can not even remove the wire , wound over it new;

- mating can be made directly in the formwork;

- low cost in comparison with welding work;

The main disadvantages of the mating reinforcement are the wrestness of the resulting design.

The collected design has good strength, but when moving, for example, when immersed in formwork, the strength is lost, this effect is particularly tangible on fiberglass fittings. The fact is that the armature flexing changes the strength of the stretch in places of mating, so the whole structure begins to walk, but becomes not easy.

Tool for mating fittings

Mating reinforcement wires can be produced by different techniques and with the help of different tools.

Tools and appliances for mating:

- hook;

- screw tools:

- homemade hooks;

- crochet screw

- steel rod with a diameter of about 50 mm and 250 mm long;

- knitting gun;

- pliers or Passatia.

Armature hook

Live with the help of a shopping hook has two drawbacks:

- handmade;

- it is necessary to fill the hand for good speed.

Hook for mating fittings

As a rule, such hooks have a comfortable plastic handle, an instrumental tip and practicality in the work, the cost of them is within 1,000 rubles.

In stores you can also find automatic hooks for mating fittings, however, feedback about them. Many people talk about a small resource, others that the wire is a thick of more than 2 mm. This tool twists with difficulty. There are positive feedback.

Homemade knitting hook

Build a bathhouse? Need to tie a small frame, but there is no tool at hand? You can make it possible to make a homemade knitting hook from the remedies.

Homemade knitting hook

The material for such a hook can serve as a steel piece of wire suitable diameter, ordinary nails or other materials. You can use various tubes as a handle, or make a wooden handle.

Crochet screwdriver

To automate the mating process, you can use a self-made crochet screwdriver, which is easy to make from a slate nail.

Crochet screwdriver for fittings

Such a device allows you to speed up the process, and using a torque options regulator, the tool can be configured so that the ligament stretch will be maximum, and the wire will not be broken.

Pistol for mating fittings

Building pistols for mating reinforcement are the fastest and most convenient way to assemble the reinforcement frames of the foundation, but the high cost of this type of tool makes this option suitable only for large-scale construction. The cost of guns for mating reinforcement begins from 30,000 rubles.

Pistol for mating fittings in work

The speed of working with such a tool can reach up to 2 seconds to 1 node.

Wire for mating fittings

The most important tool in the viscosity of the foundation frame is a wire, the strength of the design, and the speed, and the cost savings depends on its choice.

The knitting wire is made of low carbon steel according to GOST 3282-74 - "Wire steel low carbon overall use. Technical conditions. "

There are also requirements for the wire diameter on the diameter of the valve:

- for reinforcement ∅ up to 12 mm, a knitting wire is used ∅ 1.2 mm;

- for frames from the valve ∅ 16-18 mm, a wire ∅ 1.6 mm;

- for reinforcement more ∅ 18 mm, a wire ∅ 2mm or 2x1.2.

Methods and vehicle vertoon mating schemes

Knit wire can be in different ways according to different schemes. As a rule, they do not differ much, in terms of saving and tightening. The main difference in the convenience of which method you will like, that and use.

The easiest way

This method is necessarily the most convenient and most common way. hand-knitty Armatures, reviews about it on the Internet are also only positive.

In more detail and clearly this method is shown in the video at the end of the article. By this method, knit fittings can be in a manual crochet, and semi-automatic with the help of a screwdriver.

Stock Foto Bonus assembling fittings

A small selection of 10 photos on viscosity of reinforcement for the foundation.

Video knitting fittings

In this video, it is described how to quickly knit fittings for the foundation. Considered two of different ways Matches of reinforcement:

- with the hook;

- using a screwdriver with a self-made nozzle from a slate nail.

And finally, if you do not know how to knit fittings for the foundation, try to borrow and come up with your way for mating.

Concrete used in ribbon base bases is extremely solid material. However, its mainstability consists in resistance to the compression vector. The foundation base made of pure concrete will be sensitive to stretching loads and bending. Meanwhile, such loads can act on the foundation, for example, during seasonal changes in the state of soils.

Video - knitting of reinforcement with a hook

Reinforcement of the foundation base

To avoid the destruction of the foundation bases from concrete with noncharacteric loads - it is formed by a power frame. It is usually manufactured from metal fittingswhich forms a spatial design resembling a cell. As a rule, the power "skeleton" of concrete foundation foundations consists of at least two horizontal reinforcement layers. Inside itself, the layers are combined with horizontal jumpers from a metal bar. Between themselves, the horizontal layers are fixed by vertical jumpers according to the calculation of the reinforcing belt.

Connection of metal barrels

Since the reinforcing power frame consists of separate metal rods, they need to be recorded relative to each other. Otherwise, without reliable fixation, the frame design may be deformed under the action of the mass of the poured concrete solution or with loads on the entire construction design.

The fixation of metal rods relative to each other should occur in the places of crossing rods, as well as in areas where metal rods enter each other along the length.

Metal fittings fixation methods

There are several ways to fix metallic rods of the power frame of a concrete foundation base relative to each other.

Plastic clamps

The most new I. simple way is the use of plastic building clamps. No preparation and special equipment is required - it is necessary to simply delay the plastic clamps in the places of crossing the metal reinforcement. Plastic, from which the clamp is made are not subject to corrosion and will honor himself perfectly in the concrete mass of the foundation.

Electric welding

An over ancient and authoritative way to connect the rods of the reinforcing frame is the use of electric welding. However, in the event of a desire to apply this method, it should be remembered that you can weld not any metal rods, but only those in which the letter "C" is present in the labeling. The welding technique is applied point.

By cons of such a method, it is possible to include that the use of the electric welding machine requires certain difficult technological skills.

In addition, fixing the places of intersection of reinforcement with welding forms a compound that do not even have the most minimal backlash. Therefore, when using vibration seals and drills, which are usually supplied from concrete air bubbles after filling the solution, the location of fixations may be damaged.

Metal fittings wire navigation

The most common way to fix the interstitations and joints of the metal reinforcement inside the power frame of a tape base base is the knitting wire. This is an extremely simple and affordable way, well established by many generations of builders.

Its essence is simple - the place where it is necessary to fix the compounds of the metal fittings of the power frame turn into a wire segment, which is subsequently twisted, firmly tightening the connections.

There are several ways to twist knitting wire on metal fittings. In any of them, a knitting hook is used, which is a bent at an angle and a pointed metal segment. Methods of mating are bred by a wire twisting.

Step-by-step technology

In any case, at the initial stage of mating reinforcement rods, a wire must be prepared:

- Cut a piece of wire for about 20-30 centimeters. More precisely, the size of future segments you can determine when you cover several fixtures and increase your technological level.

- Fold the wire segment twice.

- Wrap the wire harness around the connection site of metal rods diagonally.

- Put the bent end of the wire harness on the rod, in the same place, fix the second end of the wire harness.

- Tighten the ends of the wire loop.

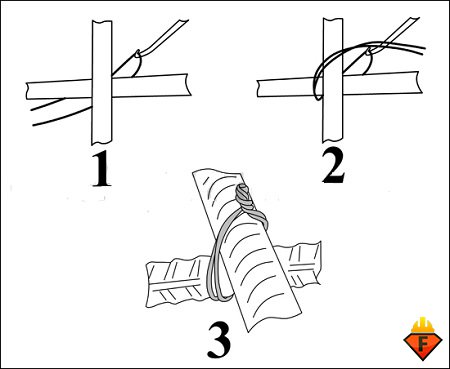

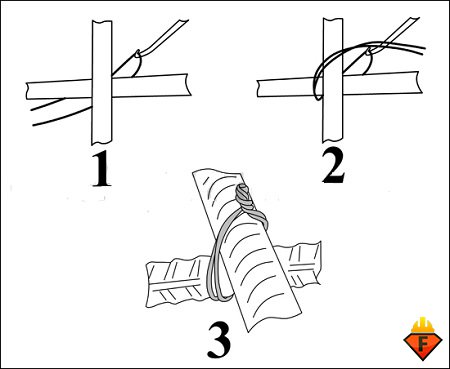

- The overall turning scheme of the wire loop around the connection location Metal reinforcement rods is shown in the following figure.

To spin the ends of the wire loop, you can use one of the methods described below.

Use of mechanical devices

The method of twisting knitting wire on fittings using specialized devices, such as those depicted in this photo, is less common. To twist, it is necessary after fixing the ends on the hook just pull the entire device on yourself.

![]()

Using a knitting hook

The following way is the use of a conventional hook, without any mechanization. Knitting hook can be independently for a relatively short time to make from the same piece of metal reinforcement. To this end, one end of the segment of the rod must be spinning in the form of an ear, so that it is convenient to rotate, and the other end is to get on about five centimeters and sharpened.

The device looks simple and acts too simple - it is simply necessary to rotate with the end of the wire loop attached to the end of the hook.

The disadvantage of such a method is the weak prevalence of such specialized devices.

Automation of work

But if you apply a bit of seamless, then the automatic power tool to twist the ends of the wire when fixing the metal rods of the framework of the foundation base can be assembled from almost girlfriend. To do this, take a conventional screwdriver and insert a broken nail into its cartridge. Such a device will help you to significantly save strength and time when mating fittings for the foundation and allow you to make a power reinforcing frame of your foundation reliable and durable.

![]()

The quality of the strength, reliability and durability of the foundation reference structure largely depend on the quality and correctness of the arming framework. The reinforcing belt can be considered as a kind of skeleton that contributes to a significant increase in the sustainability of the base for incoming loads.

Class

The second important indicator is the class of fittings. For a private foundation, the class A-3 material is suitable.

Armature Corrugated A3 Mark Steel A500C, GOST 5781-82

The reinforcement of this group is very convenient in operation (easily bends without the use of special tools), durable and reliable. Class A-2 rods are less likely (they can be bent 180 degrees, A-3 - 90 degrees).

Material

An equally important indicator is the material manufacturing material. Earlier, no questions arose in relation to this moment - the rods were made of durable steel, there was no alternative.

However, the construction market is developing tirelessly and expands. One of the confirmations of this was the appearance of fiberglass fittings.

The rods of this group are characterized by improved operational and practical characteristics. Among the main advantages of fiberglass reinforcement should be noted the following points:

- high rates of reliability, strength and durability;

- relatively low cost;

- low weight.

The use of fiberglass fittings allows you to save an average of up to 30-40% on the purchase and transportation of the material to arine the reinforcing frame compared to more traditional steel elements.

The small weight of fiberglass reinforcement makes it possible to transport it in a simple passenger car. Armature has no restrictions on the length. For cutting rods, ordinary Bulgarian applies.

Important! Before cutting fiberglass reinforcement, be sure to put the protective overalls, gloves, glasses and respirator.

Fiberglass fittings of various diameters are available on sale, involving the use of different mating options. Mostly for longitudinal reinforcement, 8-millimeter rods are used, for transverse - 6 mm.

The fastening of fiberglass reinforcement is most often performed in 2 ways:

- with knitting wire;

- with the help of plastic clamps.

The procedure for the implementation of both methods remains identical for steel and fiberglass reinforcement and will be considered in the relevant sections.

Wire, clamp, lock: Features of existing fasteners

Bonding reinforcement rods into a single frame can be performed using wire, clamps and special fixtures. About them in the table.

Table. Materials for fastening fittings

| Material for fastening | Description |

|---|---|

| The most traditional, budgetary and usual (especially for the builders of the "old school") material for mating fittings. It is made of annealed steel. Sold mainly "wholesale", i.e. In the packages (more convenient, because the material is already cut into pieces of suitable length) or special coils. The weight of the packaging and the length of the wire segments may vary depending on the manufacturer. The most convenient are 5-kilogram packs filled with 40-centimeter segments of the wire. In one such package, it is usually contained from 1000 to 1500 pieces of wire. |

|

| According to the principle of use, there is little different from the knitting wire - the same methods similar to the tools. It is characterized by great ease of use (easier to bend and twisted). It costs a little more expensive than wire. It has an increased diameter (on average 4 mm versus 1.2 mm of wire). To ensure reliable connection of reinforcement rods, it is enough to use a 20-centimeter clamp per point of intersection. | |

| The most modern version of the junction of reinforcement rods. Fixators are made of plastic. It is best to show ourselves in a complex with fiberglass reinforcement. Advantages over steel reinforcement and knitting wire are obvious. To fully understand them, you need to pay attention to only 1 lack of steel reinforcement - it is subject to corrosion. Rust is capable of increasing the diameter of the metallic rod. His durability, while changing not for the better. Corrosion leads to the appearance of pores in concrete. In the pores penetrate water. In winter, water is expanding and increases the size of the crack. The clamps do not rust, and the reinforcement is much easier to connect, more convenient, and faster than wire. Available, several varieties of fasteners are available, allowing to provide the connection of reinforcement rods in various spatial directions, equip the "stands" (as in the image) and solve other tasks associated with reinforcement. |

Due to the fact that the management under consideration is dedicated to the mating of the reinforcement, the order of the junction of the rods will not be considered special clauses - this process is not viscous in the traditional understanding and in general intuitively understood.

Wire and clamps should be given more attention.

- if it is decided to use steel reinforcement, you can knit both galvanized and non-zero-wire - if corrosion gets to the reinforcing frame, it will still be that "there is", even though the reinforcement, even a wire, and avoid deterioration of the quality characteristics of the foundation under such circumstances ;

- if it is decided to use fiberglass fittings, it is better to put a galvanized wire - thanks to this, the risk of corrosion will be minimized and a longer service life of the support structure will be provided.

As for the diameter, the most optimal for the convenience of use and reliability is the 1.2-1.4-millimeter option. "One" weak for the foundation, to work with the "Double" will be dedicated efforts.

Secondly, clamps.

This, as noted, a consistent and improved version of knitting wire. They are made of plastic, and not from steel, therefore, when using such fasteners, the probability of corrosion inside the support structure is excluded. Along with this, it is because of the material of the manufacture of plastic clamps, many developers arise a number of well-founded issues regarding the fasteners of this group.

- Will the clamps be able to withstand the loads created inside the foundation? Can.

- Will it break the fasteners with time, violating the uniformity of the distribution of loads and as a whole worsening the quality of the foundation? Will not break.

- Is the plastic clamp really reliable? Indeed, but you need to properly approach the question of his choice.

Helpful advice! Plastic clamps with the use of steel wire as a core are best hiking for mating fittings. There are similar fixators more expensive than steel wire, but they do not occupy the amenities.

Important note! Plastic clamps can not be used for mating fittings when working on the construction of the foundation in winter time - In the cold, the material of the manufacture of clamps almost instantly becomes fragile. Exception - special clamps from polyamide.

First, remember the main rule: the reinforcement is not connected by welding, namely binds.

Binding of reinforcement - scheme

The essence is as follows: Metal contact with the electrode helps to reduce the strength of the first so much that even the loads occurring at the minimum possible shrinkage of the foundation are capable of disastrous consequences, the sequence of which is usually the following:

- the locations of the reinforcement are destroyed;

- the reinforcing frame disintegrates;

- concrete construction begins to crack.

What it threatens erected on the foundation of the structure, in the comments do not need. As an exception, only special reinforcement rods can be considered, whose manufacturing technology according to GOST initially implies the possibility of subsequent welding.

Secondly, vertical support rods installed as a support for horizontally oriented rods, it is impossible to just score into the ground. Correctly do this: The lower reinforcing row is placed on special plastic locks (so-called "cup holders", showed earlier), and top part Vertical rods binds to the upper carcass. Such a placement will exclude the contact of the rod with the external environment.

Thirdly, the upper horizontal range of the frame should be imposed from the inside - it is so complicated, but more correct. Often, uncommonled developers make mistakes, leaving the top row of the frame is unlocked. If concrete is poured manually, nothing terrible in such conditions will not happen. When pouring the same special concrete pump, the mixture is supplied under pressure. The pressure being created will lead to the exploration of the reinforcement to the side, as a result of which the wire can burst.

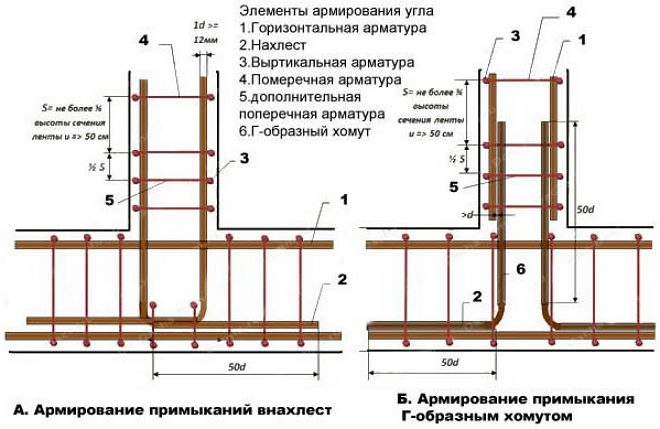

Fourth, when performing reinforcement, special attention should be paid to the corners of the structure, because They are the weakest place of foundation. In such sections, the rods do not fit at right angles, but bend. Overtegles, while hiding in the wall. It is important that the adjacent reinforcement rods do not overflow at one point. The principle is demonstrated in the image.

Reinforcement is considered correct, according to the results of which the rigid spatial frame is obtained, withsting human weight without visible changes in the structure.

For mating valves, you can use a wide variety of devices - from pliers to special automatic pistols.

The use of pliers and bodies with pre-blued teeth is the most primitive option. Its the only advantage is the lack of the need to purchase additional devices, but twist the wire with such impact means for a long time, inconvenient and tedious. Therefore, we refrain from their consideration.

If you are limited in the budget, do at least an elementary homemade knitting hook. To do this, you will not need anything other than a nail with a diameter of 4-5 mm, blanks for a handle or an old unnecessary screwdriver / sewed and hammer.

For the manufacture of the hook, do the following:

- prepare a handle. You can use any suitable wooden billet (it is more convenient to drive into the wood and easier to drive a nail), for example, from the home instrument. The handle can be completed from other materials, the main thing is to be convenient to use it;

- leave the nail into the handle, leaving 3-4 cm free;

- cut the nail hat, for example, with the help of a bustard or other suitable fixture;

- generate a nail into the hook. This is done as follows: you put the nail onto a suitable stand, for example, brick, and gradually with the help of a hammer give the workpiece the shape of a knitting hook.

The procedure for making a hook from a screwdriver / sewer is reduced to the fulfillment of the last stage of the above manual. At the output, you must get a fixture that has about the following form.

Knitting ordinary crochet

Prepare a homemade hook or buying a ready-made tool in a shopping store, proceed to perform work. To begin with, carefully practice on third-party pieces of reinforcement, until you thoroughly understand the principle of action. It is as follows:

- a piece of knitting wire with a length of at least 200 mm is folded in half;

- the resulting billet is turned on diagonally at the connection point;

- the hook is loaded into the created loop;

- the free ends of the knitting wire neatly stretched through the loop. At this stage, the hook also helps;

- without getting a working tool, it is rotated in the direction of the clockwise until a reliable connection is obtained. It usually grabs several (up to 3-4) turns. You shouldn't twist the wire too much - it will break. Unnecessary parts of the wire ends. If the ends turned out too long, you can cut off their impressions or another suitable tool.

Schematically, the process is shown in the following image.

For better understanding of technology, check out step-by-step illustrations.

There are several other options for mating fittings with crochet, but the method above is the most reliable, it is recommended to stick to it.

It also shows itself a way, according to which the performer must consistently execute the following manipulations:

- fold the segment of the wire twice as in the previous case;

- start the folded wire under the reinforcement at the junction site;

- capture a loop with a knitting crochet;

- leak through the hook remaining free "tail";

- split the resulting loop.

The procedure for performing work in accordance with this method is demonstrated in the following illustrations.

Video - knitting enforcement crochet

Candidate of semi-automatic crochet

Semi-automatic, it is also a reversible and screw hook is an improved and more convenient to use the version of the elevated device.

Length (as a rule, it is 32 cm) and in general, the features of the design of the reversing hook allow you to provide a high-quality twist of the wire from one tightening. Soft rubber handle makes work with a tool even more comfortable and safe, eliminating the likelihood of corns on hand.

The procedure for using such a hook is as follows:

- the performer carries the reinforcement rods with wire at the connection site (the procedure is the same as in the case of the use of an ordinary hook, all the necessary information was given above);

- the hook is inserted into the loop;

- the performer pulls the handle tool on itself.

That's all. As a result of such simple actions, a device working like "Yule" quickly delays the wire, ensuring a density, reliable and accurate node. The complexity and costs of time for work are reduced at times.

The tool is suitable for both professional and private use. In any special maintenance, the reversing hook does not need - only it is enough to periodically lubricate the working elements of oil.

The principle of operation of a screw knitting hook is demonstrated in detail in the next video.

Video - knitting semi-automatic crochet

Hook-knitting crochet is a rather protracted and time consuming event. And although the semi-automatic hook, considered in the previous section, it makes it possible to significantly ease and speed up the execution of reinforcing work, an excellent opportunity is available to do everything much faster and with even less effort. This will help a drill screwdriver.

All you need to do is make a hook (an ordinary nail with a diameter of 0.5 cm is suitable as a workpiece, with the principle of the manufacture of the hook, you have already familiarized in one of the previous sections) and fix it in the cartridge of the screwdriver as ordinary drills are installed ( Details of the working tool replacement sequence should be clarified in the instructions specifically to your screwdriver, because For different models of tools, these moments may vary somewhat).

Look such a design will be as follows.

The further procedure does not have differences from the technology of mating fittings by crochet: you still fold the wire twice, start it under the reinforcement, capture a hook with a hook, but twist it is no longer manually, but with a screwdriver, making the minimum effort.

When spinning the wire, the tool practically does not experience the load, so even the most budget drill screwdriver can be used for mating with minimal power. It is better that the model is equipped with a rotational speed regulator. Before working, put it at a minimum.

Video - knitting fittings screwdriver

The gun makes a viscix of reinforcement as fast as possible, simple and convenient - the most advanced models of such pistols are able to create a connection in less than a second. Any preparatory events It is not required: Wire is wound on the pistol coil, the user simply brings the tool to the connection site and presses the corresponding button. For information regarding special options and functions, specify the instructions for a specific tool.

It looks like this.

Cut the wire before work is not necessary: \u200b\u200bthe tool will do it yourself. This is a big advantage - waste in the form of criticism of knitting wire is absent, so that the magnitude of inexpedient costs and working costs significantly decreases.

The gun is convenient in work - it can be kept with one hand, the second, while holding armature carcassthat eliminates the need to attract additional labor in the form of assistants.

Automatic pistol, unlike hand toolsallows you to count on constant high quality mating. By default, in all models there are functions for regulating the length of segments and power of tightening.

| Brand of pistol | Weight | Armature size | Price |

|---|---|---|---|

| 1.4 kg | D19HD18. | 48 780 rub. | |

| 1.5 kg | D20XD22. | 60 920 rub. | |

| 2.25 kg | - | 52 000 rub. | |

| 2,4kg | from 20 to 35 mm | 165 000 rub. |

Among the disadvantages of the automatic pistol for mating fittings, the following points can be distinguished:

- high cost of tools and components (coils with wire);

- the need for preliminary training to work with a gun (in general, nothing complicated, but extra time is still spent. In practice, it is more compensated for by the savings of the time spent on a wire twist);

- the impossibility of using a pistol in hard-to-reach places. Even with such a serious assistant, you still will not be able to completely abandon the use of hand tools for mating. For example, the gun will not be able to link the rods in the corners of the reinforcing frame. In addition, only the hook you can sleep between whiskers to trigger the 2nd layer of the hardening frame.

Video - knitting reinforcement with a pistol

A few words about the clamps

For the mating reinforcement rods, as noted, special clamps can be used. They look like that.

Thus, one end of the clamp is free, and on the second there is a retainer.

The procedure for using a clamp is as follows:

- the product is started under the reinforcement rods at the intersection site;

- the free end is delayed into the opening of the retainer until it stops;

- the location of the fastener is fixed, due to which the connection of the reinforcement is ensured.

There are quite many varieties of clamps available. In the complex with the reinforcement, items produced by products made of polyamide 6.6. Such clamps normally "feel" in the temperature range of -40- + 85 degrees, without bursting, not cracking and not spreading. Good clamp should be elastic. You can check this parameter as follows: Take the product and bend it in half. If a crack appeared in the sefiba, refuse to use such a clamp.

Special pistols are available on sale, allowing to make the process of arranging clamps easier and rapidly.

Video - knitting reinforcement clamps

Metal clips (connectors) can be attributed to the number of similar fasteners to connect the reinforcement rods into a single frame. One end of such a mesh is equipped with a crochet, the other - loop. The diameter of the steel paper clips is an average of 2-4 mm. In the place of a ligament of the reinforcement, the hook and loops are engaged in the lower steel rod. The middle part of the retainer presses the upper rod to the underlying.