The most common foundation in private construction is tape. The ribbon foundation is a monolithic ribbon of reinforced concrete, sprinkled around the perimeter of the house. As a rule, it is made monolithic. The foundation of this type distributes the load on the base throughout the area of \u200b\u200bthe house, which prevents its sediment and break.

In addition, it takes less materials for it and preparatory workAs allows you to significantly save on construction.

When operating, various loads can be affected, ranging from the weight of the structure and movement of soils to frosty powder.

To compensate for the fondamation of loads, reinforcements produce its reinforcement.

In its properties, concrete is very durable to compression, but it is 50 times less durable for stretching. Steel fittings gives the strength to concrete on stretching.

Styling and knitting fittings

For reinforcement, hot-rolled construction reinforcement of a periodic profile is used, thermally treated or mechanically hardened. For foundation, class A 400 reinforcement is used. The use of classes A 240 and 300 is unacceptable. Use for reinforcing the class fittings is higher than and 400 is economically not profitable and not advisable in terms of using the strength potential. The diameter of the armature is usually used 12mm for working longitudinal reinforcement, 6-8mm for vertical and transverse reinforcement.

Locked fittings need to be connected.

Let's find out how to properly knit fittings for the foundation.

There are several types of fittings. Most often it is knitting with knitting wire. Also apply welding and fastening with plastic clamps.

Wire This time has been tested by a reliable option.

For knitting, a wire treated by firing is used, the so-called burden. The burned wire is more flexible and durable than the usual, as well as more resistant to stretching. The wire diameter depends on the diameter of the valve. As a rule, 1.2mm wire is used for reinforcement with a diameter of 8-12mm, for thicker reinforcements take a thicker wire. However, the use of wire more than 1,6mm is not advisable as it is very inconvenient to knit it and it will be difficult to tighten it. Wire with a diameter of less than 1.2mm when tightening will burst.

There are several ways to mating wire:

- Mating with reinforcement ticks;

- Knitting with a hook;

- Knitting with a drill with a nozzle;

- Knitting with a knitting pistol.

Hooks received widespread different species. There are simple with straight, curved, steel, plastic or wooden handles.

Hooks received widespread different species. There are simple with straight, curved, steel, plastic or wooden handles.

Also there are mechanical hooks in the handle of such hooks the spiral is embedded. When tensioning up, the handle slides over the helix turning the hook and makes a tight. There are many ways to work with crochet Here are some of them.

Method 1.

Cut the wire for the reinforcement with a diameter of 12mm, about 25mm long and fold in half. Next, we make a bend around your finger about one third. We do under the reinforcement and grab the hook loop. We put the second end on the sting, while pulling it on yourself, and begin to twist the hook. The number of revolutions is determined by almost. It is necessary to tighten well, while not breaking the wire. After the end of the tightening, pull the hook and bend into the inside the ends.

Method 2.

The wire is also folded in half pressed with fingers to the reinforcement, the ends bend the hook is inserted over and the tightening is made. After tightening the hook gets and the ends are bend.

Method 3.

The wire is also folded in half, it is done under the reinforcement, the loop is inserted into the hook. The second end is also embedded in the hook and bends down. I pull the hook on yourself and make a tightening.

This method is considered the most convenient.

Binding with plugs for reinforcement

Pliers for mating valves of reinforcement differ from the usual shape of the cutting part. They must hold wire.

Pliers for mating valves of reinforcement differ from the usual shape of the cutting part. They must hold wire.

The pluses of tick use is that there is no need to cut the wire. The wire is wounded into small machines and keeps in the left hand. Wire consumption is much smaller. It is with the use of ticks at construction sites, professionals knit reinforcement and claim that it happens twice as fast as with the use of a hook or pistol.

One end of the wire is valid under the reinforcement, is captured by the ticks the second end. Also embedded under the sponges, one or two turns are made. Surplus are dry.

Knitting with a drill with a nozzle

In the pursuit of the acceleration of the process began to apply a drill with a special nozzle. The nozzle is all the same hook. The inspection herself itself is faster, but the entire process is identical to the crochet, except for the watch. There are also minus drill application. Drill itself is quite cumbersome and not everywhere it can be brutalized.

In the pursuit of the acceleration of the process began to apply a drill with a special nozzle. The nozzle is all the same hook. The inspection herself itself is faster, but the entire process is identical to the crochet, except for the watch. There are also minus drill application. Drill itself is quite cumbersome and not everywhere it can be brutalized.

Knitting gun.

Allows you to increase productivity by 2-4 times. The feasibility of its use appears when it is necessary to produce large volumes of versatile fittings. Also, the plus can be attributed to the fact that all connections are tied with the same effort.

By the cons. We also consider it cumbersome as well as in a drill. And the need for consumables, special for a given pistol, or the need to charge the cassettes.

The technology of the work of all tools is identical to the wire mating on the valve. Accordingly, the choice of tool will be based only on your personal preferences.

IN lately Most builders began to pay attention to the recent plastic clamps that appeared. The advantages of clamps can be attributed to: ease of installation, the velocity, not a high cost.

Also on sale appeared - these are plastic clamps with a steel wire heart. They are more expensive, but more durable.

By cons can also include fragility in the cold and the inability to carry extra load. From frost, they immediately become fragile and burst.

Connection of reinforcement welding - This method has its advantages and disadvantages. The main disadvantage this method It is what needs to attract an experienced welder. The second disadvantage is the weakening of the metal at the welding points and the change in the plasticity along the entire length.

Fiberglass with respect to new Materialhaving, as well as the advantages and cons.

The advantages include low weight, corrosion resistance, high compressive strength and gap. Resistance to aggresive media.

By minuses include much less elasticity in comparison with traditional reinforcement, when heating loses reinforcing properties.

So how to knit fiberglass reinforcement for the foundation of the house?

The knitting of fiberglass reinforcements is particularly no different from the mating of the metal reinforcement, it should be noted that plastic clamps are used for these purposes.

In conclusion, I would like to note that the process of mating fittings is pretty much difficult, however, requiring attention.

The use of reinforcement in the process of mating foundation can significantly improve its power and strength characteristics. There are several ways to melt fittings, about their features and how to properly knit fittings for the foundation will look at further.

Armature for the foundation of the house: Features of choice and calculation

Before proceeding with the direct mating of reinforcement for the foundation, you should first select the materials to perform this process. It is from the diameter of the reinforcement for the foundation directly depends on its strength and rigidity of the frame.

Before buying fittings, it should be determined by its relative strength. The ratio between the frame of the frame and the foundation is 100% to 0.1%, that is, the reinforcement is 0.001 part of the foundation.

Foundation fittings Calculation:

1. For example, it is planned to reinforce the foundation, the width of which is 25 cm, and the height is 80 cm. In order to calculate the area of \u200b\u200bthe reinforced site, it is sufficient to 25 cm x 80 cm \u003d 2000 square centimeters.

2. The resulting number should be multiplied by 0.001 and the minimum diameter of the armature cross section in the foundation of 2000 x 0.001 \u003d 2 cm is obtained.

3. For one bundle, it is necessary to use 30 cm reinforcement. Each connection consists of four ligaments. Therefore, to determine the number of reinforcement, the number of ligaments should be calculated and multiply a value of 30 cm.

The use of mating in the process of manufacturing a reinforced frame for foundation is primarily due to the fact that such a connection is more reliable than welding. The seams that are formed in the process of welding reinforcement are inclined to gradually collapse, and therefore such a foundation is unreliable, and after several decades will be unusable.

The technological process of performing vertex of reinforcement is based on the connection of reinforcement rods in such a way that they are crossing each other, tightened and twisted with pliers.

A variant of using a special pistol is possible, which greatly simplifies the process of performing mating. Choosing the diameter of reinforcement rods should be proceeding from such parameters:

- number of floors in the building;

- the massiveness of the structure;

- foundation Type: Fine or Deeply Blowed;

- concrete quality, etc.

For the manufacture of reinforcement at the factory, special equipment is used, due to which the final product is distinguished by high quality and long service life.

In relation to constructive features, the surface of the reinforcement is two types:

- corrugated;

- smooth.

For the manufacture of perforated reinforcement rods, a special form is used, due to which a corrugated cross section is formed on their surface, the bars differ in the presence of a circular cross section. Such fittings are more durable and stable before mechanical damage. In addition, the valve with a corrugated surface is characterized by a higher adhesion to concrete, in the process of reinforcing the foundation. For the manufacture of such rods, various kinds of steel are used, the most popular variants of which is 35 Gs and 25 Gs. In relation to the class of valves, the strength characteristics of the material are changed.

In the ratio of the thickness of the reinforcement, it is also divided into classes, but the diameter this material Make an average of 8-25 mm. Maximum length One rod - 120 cm.

In the process of choosing reinforcement for the construction of the foundation, it is necessary to give preference to materials that differ:

- presence of resistance to corrosion;

- excellent adhesive characteristics;

- the presence of plasticity;

- high level of strength fatigue.

![]()

Armature for belt Fundament Selects from class A 2. There are several marking options for this reinforcement:

- And 300;

- A 400;

- A 800;

- A 1000.

The surface of the rod data has a kind of pigtail, corrugated. These features make it possible to improve its adhesion with concrete. In order to ensure the vertical retention of the reinforcement, it is recommended to use the fittings of a hot-type type. It is characterized by a smooth surface.

The optimal diameter of reinforcement rods for standard single and two-storey buildings is about 1-1.5 cm. Auxiliary fittings must be a diameter of at least 0.5-1 cm.

Please note that exclusively corrugated fittings are used as the main part of the frame, and the auxiliary - must be from smooth reinforcement.

Foundation fittings: basic types and their features

Composite fittings for foundation - is a non-metallic material used in the process of reinforcing the foundation. Among the disadvantages of this material note:

- reduced modestations of elasticity, compared with steel four times, so this reinforcement is more resistant to bending, but, it means there is a lower possibility of rupture;

- the temperature range of use is no more than 500 degrees, if the heating temperature is higher, then the armature loses specifications;

- it is not amenable to welding, although some manufacturers at the ends of the reinforcement mount steel tips, allowing you to weld with each other.

Despite this, composite reinforcement has a large number of advantages, among which should be allocated:

- high durability to rupture;

- ease than steel 8 times;

- the cheapness of the material is another advantage, since the cost of composite reinforcement is much lower than metallic;

- the convenience and ease of transportation, this fittings is quite easy, so in the question of its delivery to the object of construction does not arise problems;

- since the metal is not used in the process of manufacture of composite reinforcement, it is distinguished by resistance to corrosion;

- in addition, the composite-based fittings are not capable of carrying out electricity, differs in low thermal conductivity;

- differs in a long service life;

- easy in installation.

Plastic fittings for foundation - enough a good option For the arrangement of the foundation, under a small building. In addition, the use of this type of reinforcement will significantly save both monetary and temporary resources.

Composite fittings, in turn, is divided into two categories:

- fiberglass fittings for foundation;

- basaltoplastic-based fittings.

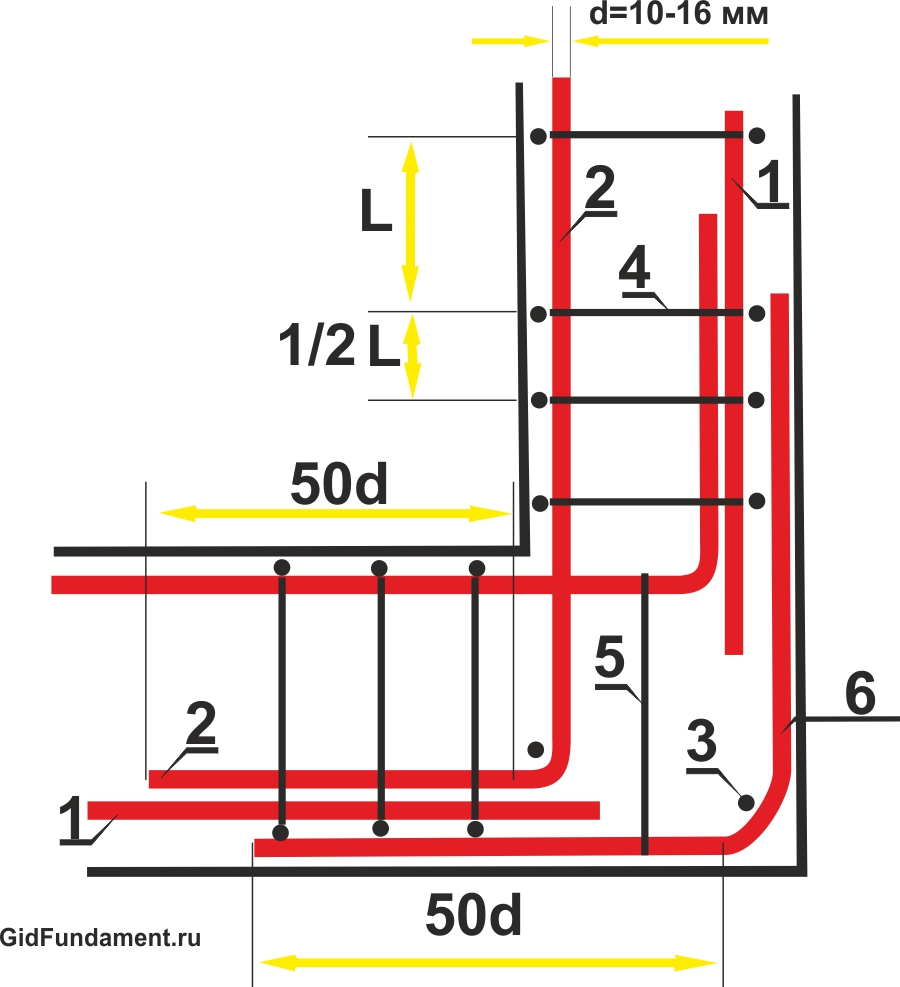

Foundament Reinforcement Scheme: Ribbon Foundation

Before starting work, it is necessary to determine the type of reinforcement used for mating framework. In addition, the tape foundation should already have a dug and prepared pita. The formwork is also mounted before viscous.

After preparatory work, the installation of vertical rods is followed, which are characterized by a smooth surface. The diameter of such rods is about one centimeter. The interval between them is 50-80 cm. Two belts arranged horizontally fit on these rods. They create the bulk of the frame and are the main reinforcing element.

The main purpose of this design is to hold a total load from the building, preventing cracking or deformation of concrete. In the process of installing a ribbon foundation, it is necessary to equip two horizontal belts, however, depending on the load from the building, their size and thickness of each are individually selected. If the maximum foundation width is 40 cm, then it is better to perform double reinforcement, that is, use two rods to form a belt at the bottom and two - in the top.

With a greater width of the foundation, it is necessary to use three rods, one of which is located between two others. The use of four rods is a fairly unpropered version, as to form a more rigid and durable frame, it is enough to choose fittings with a large diameter, rather than to increase the number of rods.

The determination of the height of vertical rods should be carried out on the basis of the immediate height of the foundation itself. The connection of vertical rods with horizontal is made in such a way that the vertical bars do not perform by more than 10 cm. Special attention is paid to the angular sections. Since they are most susceptible to voltage and compression. If improperly reinforced corner sitesThe system will lose strength.

Therefore, the rods, never put together at the angle of 90 degrees. They are bent and combined into crossbars. Each of the rods are laid on 25 cm. Thus, the frame will have high strength and will not bend under the weight of concrete.

For additional amplification of the angles, the reinforcement grid is used, the cross section of the cells of which is 200х200 mm. Their installation is carried out from above and at the bottom of the foundation, and the connection with vertical areas is performed every 50 cm.

Installation reinforcement carcass It should be carried out on a previously prepared concrete pillow, that is, the bottom of the pit is poured with concrete by 6-8 cm. The pillow helps prevent the reinforcement contact with the Earth, and means the metal will not be subject to corrosion.

How to knit fittings for the foundation manually

In the process of mating reinforcement, a special tool is quite often used, however, in its absence, this process can be carried out manually. To perform self-mating fittings, it will require a wire, in diameter about one millimeter, a passation or a special hook. It is the last device that will help to tighten the wire around the reinforcement itself.

It is possible to replace the wire with plastic clamps, however, in this case, it is forbidden to walk along the surface of the reinforced frame, when it is fill.

Instructions for viscosity of reinforcement with metal wire:

1. Cut the wire, 30 cm in size. Fold it half.

2. Wrap the straw wire first diagonally, put it on the hook.

3. The free end of the wire in the hook.

4. First, check it clockwise until the connection is securely locked. No need to press the wire so that it is not broken.

If it is planned to collect the framework from the reinforcement for a columnary type of foundation, it is possible to use an exceptionally smooth fittings. Note that it is much more complicated to knit such reinforcement, since the wire constantly clench. For these purposes, special equipment is used - knitting gun.

For versatility of reinforcement, the foundation requires a strength framework. For these purposes, it is necessary to use steel reinforcement, the diameter of which is 1.6 cm. It is it that will allow reinforcing the tile both in the upper and lower parts.

At the bottom of the stove, it is also recommended to use plastic compensators, it will help evenly distribute the entire load. Please note that the rods should perform from the frame in the form of spaces that can be interconnected with a wall and stove.

How to knit fittings for foundation: Methods and technology

For the manufacture of a hook with which the valves fit, it is enough to use the usual unnecessary electrode from welding or nail. Any of these materials must be bent into a hook-shaped form. More reliable - a nail, for flexing it will be necessary to use a screwdriver.

To knit reinforcement, it will be necessary to arrange the wire in the perpendicular position of the wire in two rows. Click it with a special device and start crochet or knitting mechanism in the form of a pistol.

There are two options for knitting pistols:

- electric;

- rechargeable.

The principle of their work consists in uniform coaching of the wire around the valve. However, the cost of this pistol is too large, so they do not apply for one-time use.

The use of mating, and not welding the reinforcement is primarily due to the fact that during cooking there is a change in the quality of steel and it becomes more fragile. The strength characteristics of the design deteriorate. To perform vertex of fittings, it is necessary:

- wire - This element is the most important in this process, since the connection strength of the connection directly depends on the quality of the wire; it is recommended to use the burned wire with round cross section and a diameter of about 1 mm;

- in addition, you will need the presence of a hook and plastic locks, keep in mind that if plastic retainers are used, then such a foundation is not allowed to leave for the winter, as plastic, under the influence of frost, cracks;

- plastic Bars must be put between the surface of the formwork and reinforcement, the main function of this element is to create a protective layer that will not allow metal to contact with soil.

If the assembly bits on the horizontal surface are planned, on which there are practically no hard-to-reach places, it is best to use a gun. Its main advantage is the speed of work. In addition, it is possible to use a shopping hook for mating, however, it is inclined to rust or break over time.

A very important factor determining the quality of mating fittings is the same screed on each of the framework of the framework. Thus, the design will be more stable and is not deformed under the influence of concrete, and then load from the building.

Armature for the Foundation Video:

For monolithic plate The assembly of the reinforcement is much simpler than for a belt foundation. Grids are created from rods on the construction site, it is necessary to work with a metal disk, a knitting device or a rechargeable tool.

Making Machine Making Technology for Foundation Plate

The assembly of the valve begins with the purchase of a metal, the amount of which must first be calculated with the minimum possible reserve. For Armopoyas Plata, it is necessary to take into account factors:

To create a lower protective layer, exclusively concrete or polymer gaskets are used. It is forbidden to lift the grid with pieces of reinforcement, pipes, put rubble, brick.

Calculation of the number of reinforcement

The assembly of fittings occurs according to the standard scheme, calculate the number of rods sufficiently easy:

- standard reinforcement rods 6 m

- 0.4 - 0.6 m Switch in joints

- minus 8 cm for each rod for protective layer of concrete

- cell 15 x 15 cm or 20 x 20 cm

- with an increase in the thickness of the plate, the cell decreases, the rods become thicker

It is more difficult to take into account the configuration of the Z-shaped tables of 6 - 8 mm of reinforcement to support the upper belt. The top P-shaped part typically has dimensions for 30 cm of a plate of 20 x 40 x 20 cm. Supporting paws are about 40 cm on each side. One table requires 1.6 m smooth reinforcement, their number is calculated depending on the project.

Thus, the number of rods is determined by the formula:

wall / cell length + 1, for example, for 7 m walls 7 / 0.2 + 1 \u003d 36 pieces

Then it remains to be taken into account that Armopois in the design of two, adhesive when connected. With the translation of length in kilograms, there may not arise in principle - there is a translation table on each store. There you can buy a knitted wire, knowing the number of joints, the length of the piece for each of them (30 cm - twice in 15 cm).

The most claimed wire 1.2 - 1.4 mm for 8 - 12 mm rods, respectively. A thicker wire is more difficult to form in the node, the twist sticks over the top armoomas, reducing the protective layer of concrete. With a thin rod, it is easier to work, but it can break when the torque is increased. Recommended by specialists the supply is 15%, both for reinforcement rods and wire. For smooth fittings, from which the tables will be bends, a 10% of the stock is enough.

Cutting rods

Curra fittings are more convenient to carry out the template. Separately cut the longitudinal pieces of two grids, transverse structures. With large dimensions, the formworks are cutting out pieces for increasing, taking into account 60 cm of the alternation, are screwed to the wire to long elements of the plate.

The most economical is a cut abrasive snap. The metal disk on metal easily copes with the reinforcement of any diameter. In addition, this is the most affordable power tools for individual developer. At the same stage, it is easiest to clear the reinforcement from possible rust. Later it will do much more difficult.

Making supports

To support the upper mesh from the reinforcement, the stands are needed - tables. They are bent, taking into account the thickness of the plate, reinforcement. For example, for 40 cm monolithic design The calculation is:

- plate thickness - two protective layers - the thickness of the rods of the top, the bottom mesh (4 bar of the mustache)

- 40 cm - (4 cm + 4 cm) - (4 x 1 cm) \u003d 28 cm

Then you need to make the table, calculate the bending radius or calculate it experimentally. Initially, the P-shaped structure is strung out, then the paws are rejected in opposite sides. The table acquires spatial rigidity, a greater supporting surface.

The optimal option for fixing the rods of the reinforcement to each other is the knitting of the annealed wire. Works depending on the budget, volumes can be made by several tools:

For the reinforcement of one plate of large format, individual developers can use a custom-made screwdriver, partially moving the process, avoiding the cost of the purchase of a professional burst pistol. In this case, the handle will have to cut off so that the hook is inserted into the quick-release cartridge.

When working in a conventional, mechanical crochet, the wire is started manually operated. The battery gun does everything alone, the purchase budget is 40 thousand rubles for the most budget models. Therefore, a mechanical tool is used more often, worth 500 - 700 rubles or a conventional hook, which is still cheaper.

The technology of mesh mesh from reinforcement rods has the form:

- layout of reinforcement along one wall after 15 - 20 cm depending on the size of the cell

- laying of rods on top of them with a similar step

- knitting knitting knack special wire

A piece of wire 30 cm bends in half, the resulting design is additionally bent in half, starts under the intersection of rods diagonally. In the loop, the sting of the hook, the free side envelopes the rod. Rotation (usually clockwise) The wire is delayed at the junction of reinforcement rods, giving spatial design necessary strength.

With a manual method, the tightening force is controlled by a wire tension wizard. If a mechanical device is used, the torque moment is more complicated (usually a visual assessment). When using a screwdriver, you can put the necessary tightening force (21-9 positions in different models). On the battery gun for mating fittings, there is also a torque adjustment.

Before laying up the top belt from the reinforcement, it is necessary to place the table on the bottom grid. They are installed according to the scheme:

- supporting paws are based on two rows of rods

- upper shelf parallel to the rod of the covering grid or is located diagonally

- paws are linked with two adjacent rows of rods

- the upper shelf is fixed with a wire minimum in two places to the top grid.

In practice, the tables are tied to the bottom grid, standing on concrete, polymer gaskets, paws every two rows. Dock with the upper mesh after aligning it according to the protective layer. Armature should not oppose the formwork over the project level.

All metal elements should be cleaned of rust, otherwise the corrosion of the reinforcement will continue inside the concrete. In the year, she "eats" about 0.01 mm, so after a few years the thickness of the armooyeas will significantly decrease. The stove will cease to perceive the load qualitatively, which threatens, not only cracks in the walls from brick masonryBut also the collapse of the power frame.

The main error of the individual developer is the use of ready-made reinforcement grids or pre-linked from 6 m rods on a convenient area in the building stain. In the manufacture of reinforcement cards in an industrial method, manufacturers often use welding, which is hazardous by weakening the metal near the welding compounds, the occurrence of corrosion in the joints.

With independent manufacture of grids 6 x 6 m (standard metal-rolling length) of this size is often not enough for the stove. The grids are jammed, but there is no dispersion in the neighboring rows, the stove on this site is relaxed by default. The only right way is to build rods on the place with a disintegration of the allen on 60 diameters at least in neighboring rows.

Subject to the specified technologies for the mating arms for monolithic foundation Plate You can achieve the highest possible resource of the construction. Any violation will automatically lead to a reduction in quality, which is very dangerous for plate bottomWith zero maintainability.

Armature in the foundation performs an important role - does not allow the design to collapse when bending. To connect the rods among themselves, one of two methods can be used: nipping or welding. The first method is most preferable, although it requires large labor costs. To competently perform knitting fittings, you need to get acquainted with the technology of work.

The connection of the rods among themselves can be performed in three ways: a pistol, crochet or pliers. The first option will allow you to do everything without unnecessary labor and time costs, but will require the availability of special techniques and the ability to handle it.

For mating reinforcement use knitted wire. The clamps need to be chosen in accordance with GOST "Wire steel low carbon overall use. Technical conditions. " The material must be treated by the roasting, which will increase the flexibility and simplify the work on the mating frame from the reinforcement. At the same time, the strength of the clamps for the compound does not decrease, which allows not to worry about reliability. When the diameter of the reinforcement for the foundation is not more than 16 mm, it is recommended to use a wire with a cross section 1.2-1.4 mm. Smaller clamps will not be able to guarantee the connection strength, so they are folded several times. It is important to remember that the thickness of the wire, the more difficult it will bend it.

When working with a special pistol, there are no problems, but with a private house-building, it is rarely resorted to its help. More often builders choose knitting hooks. To make the connection you need to act according to the following scheme:

- Prepared source materials. In this case, it is necessary to cut the knitted wire on a part of a length of 20-25 cm each and folded twice.

- The wire is slightly bend and fed diagonally under the intersection of the rods that need to be connected.

- The hook for mating reinforcement is set in a loop formed when the wire is folded in half. The tool also engages and the second end of the fastener. In order for the end not jumping from the hook, it is bent. At the same time, it is not necessary to produce a wire through the loop.

- The hook rotate clockwise, thus tightening the wire (loop and ends) until it stops. It is important to control the effort so that the wire is not damaged and did not break. In order for the connection to be reliable enough to limit the three-four turns.

- After the connection is performed, it is necessary to gently pull the hook from the loop and move to the next section.

Scheme of mating reinforcement.

Such a technology is used if necessary to connect two rods located perpendicular to each other. Especially many such sites in slab foundations, where reinforcement is made by grids.

Difficulties may occur when using smooth A240 fittings. In this case, the clamps can move freely, which leads to a decrease in the reliability of the compounds and the displacement of the grid nodes. Regulations do not recommend applying for carrier structures The rods are lower than class A240, so subject to the rules, there are no such problems.

To simplify work, you can make templates for mating. These elements work on the principle of workbenks. For the manufacture they take wooden blanks with a width of 30-50 cm and up to 3 meters long. They are drilled by grooves and holes, in which the rods will be fixed later. It will be necessary to decompose the segments of the knitting wire.

Read more about the way of connecting fittings, read.

Band assembly for ribbon foundation

When the design is reinforced, it is important to comply with all requirements. Ribbon should be strengthened by frames. The scheme includes the following types of reinforcement:

- Working. It is accepted depending on the cross section of the foundation and load on it. For private houses, it is assigned only on the basis of the size of the tape. The total area of \u200b\u200bthe cross section of rods is calculated as 0.1% of the transverse area of \u200b\u200bthe reinforced design. It is important to take into account the minimum value that for the tape with a length of less than 3 m is 10 mm, and for other cases 12 mm.

- Cross-structural. The minimum diameter is 6 mm.

- Vertical constructive. With a tape height, less than 80 cm must be at least 6 mm, in other cases - 8 mm.

When laying the frame, the rules on the protective layer of reinforcement, which, according to the "manual for the design of concrete and reinforced concrete structures from heavy concrete without prior voltage, is taken equal to:

- 40 mm for working reinforcement in the presence of concrete training, 70 mm in its absence;

- 35 mm for constructive reinforcement in the presence of concrete preparation, 65 mm in its absence.

An assembly of a ribbon foundation frame can be performed in two ways: in the pit or trench and on the surface. The easiest to control the accuracy and quality of the compounds during the second method. After all the elements of the reinforcement are connected, the frame is lowered and installed in the design position. When working, it is important to take into account the minimum nesting of the rods when the length is connected by length, which is 20 diameters of reinforcement, but not less than 250 mm. It is important to provide additional reinforcement at the corners of the tape. There are several schemes for performing such compounds (brackets, using additional parts), while the transverse reinforcement step is reduced by half.

One of the possible reinforcement schemes of the ribbon foundation.

Read more about how to correctly reinforce the ribbon foundation.

Assembly

The slab foundation according to the above-mentioned manual is reinforced from such a calculation so that the general cross section of the reinforcement rods in one direction was 0.3% of the plate cross section, the diameter of the rods of at least 10 mm (12 mm at a side length of more than 3 m). It is important to take into account the height of the design. If it is 150 mm and less, they knit one grid, in other cases it will be necessary to launch reinforcement in two rows, handling the vertical clamps between them.

The assembly work of the reinforcement frame is performed in the following sequence:

Read more about how to reinforce slab foundation Read.

Armature nippers

The technology here is similar to a belt foundation. The only difference is that it will be necessary to change the reinforcement scheme in the nodes of the fraud and separately standing support. Reinforced concrete woodwork can be installed for various foundations:

- reinforced concrete bar;

- buried piles;

- screw piles.

In all cases, the fastening of the tape and support is performed using fittings. At the same time, the frame knit so that two rods join the pile with the lower belt, and two with the top. Attachment only to the bottom row is incorrect. Reinforcement at the corners and places of the walls of the walls are performed in the same way as for the ribbon design.

Scheme of the proper arrangement of the pairing knot / pile.

Read more How to reinforce the reinforced concrete scarlet.

If the framework of the frame is performed independently, and the builders brigade is invited, unfair employees may suggest replace the knitting welding. Agree to this is not worth it. This attempt to reduce the labor-intensity of the process and increase the speed of work production can lead to a decrease in the strength of the rods in places of compound and premature corrosion of reinforcement.

Tip! If you need contractors, there is a very convenient service for their selection. Just send in the form below a detailed description of the works that you need to perform and offers to you in the post office with prices from building brigades and firms. You can see the reviews about each of them and photos with examples of work. This is free and does not oblige anything.

The service life of the building depends on the qualitatively performed base, reinforced by reinforcement. The reinforcement frame retains the spatial configuration of the foundation, the most common option of which is ribbon. Banding of fittings for a belt foundation is a serious construction operation that determines the durability of the construction, its resistance to external factors.

Naturally, important right choice Concrete for filling the foundation. However, the quality of fittings in the framework plays no less role. The correct knitting of reinforcement for a belt foundation ensures reliable fixation of steel rods among themselves and the constancy of the interval when pouring concrete.

To ensure the strength of the reinforcement frame, it is important to understand how to properly knit fittings for the foundation. The method is available for beginner builders who have mastered the manual technique of fixing steel rods. Let us dwell on this operation, consider how to knit fittings, and how it is properly knitting it.

Performing this operation will require the presence of certain skills and amplifies

Preparatory activities

Having decided to independently perform work on fixing steel rods, follow the preparatory work:

- Calculate the load that the future will perceive the base. Given the seriousness of the task, take advantage of the services of professionals.

- Guided by the results of calculations, select the necessary brand and the diameter of the rods, which should not be less than 12-14 millimeters. The use of rods, class A3 will allow in the manufacture of a frame to carry out their bend by 90⁰ without the appearance of cracks, and the class A2 rods - by an angle exceeding 90 ⁰, while maintaining their integrity.

- Calculate the need for knitting wire and steel rods. The basis for determining the total volume of material is the assembly of the novel of reinforcement for the belt foundation.

- Take care of the assistants, as the knitting process is quite time-consuming and tedious.

Methods of fixing rods

There are many ways to fix the steel rods of the mesh design. Providing immobility of steel rods frame for concreting is carried out:

- electrical welding that changes the structure of the metal and does not guarantee the immobility of the frame elements;

Bars with a ribbed surface facilitate the mating process

- purchased metal locks with a diameter of up to 4 mm, having a loop corresponding to the sizes of rods and clamp (hook). The use of connectors improves performance, but requires additional costs. Their use does not require the use of the tool;

- elastic clamps made of plastic, allowing you to quickly bind the rods. Disadvantage - increased fragility at negative temperature, as well as the possibility of disrupting the integrity of fasteners when moving on a frame;

- knitting wire with a diameter of 1 to 2 mm made from annealed steel with low carbon content. Optimally use the material with a diameter of 0.8-1.4 mm, allowing no further effort to knit reinforcement for the frame. The material with a diameter of 1 mm is not durable enough, and at 2 mm, efforts increase significantly.

Methods mate

Banding of reinforcement for the foundation of the ribbon using a soft and convenient wire is the optimal solution. Let us dwell on this option.

Methods viscous

Methods for fastening steel framework elements are carried out:

- Fully manually, which requires an application of physical effort, but it provides reliable fastening at low costs.

- Using semi-automatic methods that facilitate and accelerating the fixation process requiring additional costs.

If the rods are tied manually and the fastening is applied using hinges, it is necessary to connect the elements separately

Manual mounting option is carried out using the following tool:

- bustacles or pliers whose working surface is rounded;

- self-made hook from a welding electrode or a rod with a diameter of 3-4 millimeters;

- manual reversing device, the rotation of which is carried out with a reciprocating movement of the handle;

- special ticks, the principle of operation of which is similar to a reversing tool;

- purchased knitting hook, the use of which is one of the easiest options.

Semi-automatic methods for fixing the rods of the frame are carried out using the following devices:

- Automatic knitting gun, providing high efficiency and quality of work.

- A screwdriver or electric drill equipped with a special nozzle that allows you to quickly tie the steel rods. You can use a conventional nail drunk at right angles.

Consider the peculiarities of the main types of manual and semi-automatic tools by which the fitting versus is carried out for the foundation.

Crochet hook

Manual tool can be:

- make yourself from a durable rod or electrode;

- purchase in specialized stores.

Practical and universal option is knitted hook

Advantages of manual fixture:

- Easy to perform operations.

- Cheap tool.

The minuses include:

- Low performance work efficiency.

- The need for an application of certain physical efforts.

Knight crochet

Despite a number of flaws, manual tool Many developers prefer preference. With the help of a knitted hook, the assembly of fittings under the foundation is carried out reliably. To use a manual hook, it is necessary to pre-examine the methods of mating fittings.

Hand-knit technology technology

Consider how correctly knit fittings for the foundation using manual fixture.

There are several methods of mating under the foundation. Consider a proven method, guided by which, follow the work on the following algorithm:

- cut for each point of fastening steel wire with a diameter of 1.2-1.4 mm of about 20 cm;

- bend the wire in the middle of the segment;

- place diagonally at the conjugation point of the rods;

- credit the work part of the hook in the resulting loop;

- tighten into the loop, using the hook, the ends of the wire, located on the opposite side of the loop;

- turn the hook in the loop to ensure high connection strength.

Manually producing work, control the tightening force. By reclaiming the wire with an increased tightening force, you can cut it off.

Most often used wire, because it is a reliable and proven option

Manual reversing device

A reversing tool intended for manual twisting represents a screw working body that rotates with a reciprocating movement of the handle of the device. A screw rod and a reversing mechanism are placed in the instrument handle.

How to associate fittings for foundation using a reversing device? It's simple:

- enter the adaptation adaptation to the wire loop;

- move the handle on yourself in the axial direction;

- move the handle to its original position;

- check the hook re-without reinstalling the tool, tightening the handle to yourself.

Advantages of the device:

- Wire tightening wire.

- The possibility of applying in places with difficult access.

- Lack of fatigue when performing work.

- Long service life during lubrication.

- Easy to perform operations.

The only negative is enlarged, compared with the traditional hook, the cost.

A similar principle of operation in ticks used for mating. The working planes fix the ends of the wire and twist them when moving the ticks. Application reversing devices Reduces the duration of the rod fixing process, facilitates the execution of operations.

Knitting gun that independently captures the design and imposes it

Automatic knitting gun

The use of a gun provides a durable rod rod for base. The use of an automatic device has a multitude of positive:

- there is no need for individual cutting wire, which is pre-wound on the tool drum;

- the material is rationally, since there are no waste representing wire trimming;

- high efficiency of the device - loop tightening cycle takes no more than 1 second;

- the ability to perform work on the tightening with one hand, and the other is to maintain a rod without resorting to the help of utility workers;

- guaranteed quality hinge performance;

- adjustment of tightening force and length lengths;

- the ability to work against the battery;

- complete set by a ledger that allows you to tighten the loops without flexing.

The disadvantages include:

- Increased costs of acquiring a pistol and a special wire.

- The need to teach workers, how to knit fittings for the foundation.

- Difficult application in corners and places with limited access.

Despite the merit complex, in some cases, the work on fixing rods can be performed only with a manual hook.

To speed up the process, a drill is used with a nozzle

Deciding with the tool applied to mating, preparing the necessary materials and performing work, follow the following guidelines:

- provide the same distance (4-5 cm) from horizontally located elements of the amplification frame to the soil, using wooden lining or non-metallic supports. The rods should not touch the soil at the bottom of the trench;

- the immobility of perpendicularly arranged steel rods when fixing the wire can be provided using an easy fixture, clamping ends with rodboards;

- vertically located rods intended for fixing horizontal rods, do not score into the soil. Use non-metallic cup holders, which will prevent the rods from the ground and securely protect it with concrete from corrosion processes;

- check the reliability of fixation of frame elements with wire. Errors in fixing rods - slightly affect the location of the amplification circuit during manual fill. However, the use of concrete pump feeding the composition under pressure is able to affect the location of the elements, spreading them or shifting the design;

- additionally, check the reliability of the rods fastening in the corners of the frame, which are a vulnerable area of \u200b\u200bany foundation. The ends of the rods located at the right angle, which must be bend;

- criterion for correctly performed works on viscosity is the immobility of the spatial construction under the influence of human weight;

- the provision of the construction of the enhanced tasks is possible with the correct selection of the rods, determining the location and number of elements, according to pre-executed calculations.

Remember, the mating of the spatial design rods provides only fixation of the frame elements. When pouring concrete, fix the firmware of the gain, which guarantees the required operational characteristics of the monolithic foundation.

Conclusion

After reading the article with the article and studied how to knit fittings for the foundation, you can independently perform measures to fix the framework elements without resorting to the services of hired workers. This will save cash and guarantee the reliability of work, the result of which depends on the choice of the optimal method of mating and the use of quality materials.