Brick centuries are used to masonry furnaces and flue pipes, but no brick is suitable for this purpose. For example, it does not withstand high temperatures - silicate brick for this reason it is not suitable for the construction of chimneys.

Ceramic brick, often used for masonry flue pipes, too far perfect material. Ceramic brick, as most people consider, can withstand temperatures up to 800 degrees.

But the responsible manufacturers of this material are so on their products and indicate - up to 800 degrees. Only few takes into account that the prefix "before" can bring a lot of trouble, because "before", it is 650 and 700 degrees.

Positive properties of a brick chimney:

- Great looks In any design, the chimney, built of brick;

- Weak traction Such structures allow them to be used when heating with solid fuel devices.

- Build chimney from the brick is quite inexpensive;

- Brick during heating Great accumulates heat.

Negative properties:

- Chimneys built from bricks, weigh a lot and cumbersome;

- To create them, it is necessary to make a solid foundation;

- The inner surface of the chimney is rough, for this reason it needs to be cleaned, as it settles the soot.

Types of brick chimneys

Most often, chimneys for fireplaces and brick furnaces are made, at the place of installation they are divided into "wall" and "indigenous". The chimney of the indigenous is laid out in the Pollipich as a separate riser, on a separate basis. For heating devices of large size, the thickness of the chimney walls is 1 brick.

The size of the gas plant is most practical - 135x260 mm. You can install a native pipe for multiple furnaces, which are posted on the same level if the dissection is made for them as a transverse wall separating the gas channels.

In buildings with capital walls it is more convenient to arrange "wall" chimneys. They are very convenient and economical, they are manufactured simultaneously with the walls, and often at the same time, the ventilation channels are also created next to them.

If 2 ovens are located at different levels, then for them one smoke canal should not be used - they will have a traction of different strength, directly dependent on the height of the chimney.

For this reason, during the furnace of the furnaces, the next traction is noticeably better, and the uppermost efficiency will be very low.

The oven at the top level will begin to choke and smoke. In the walls of the house do chimneys only with particular need, moisture will be condensed in them and destroy the smoke canal.

To reduce the negative consequences of this chimney location, it is necessary to make such distances from the outer surface to the channel:

- If the outer temperature can fall below -30 degrees - 2.5 bricks;

- Ranging from + 20 to -30 degrees - 2 bricks;

- If exceeds + 20 degrees - 1.5 bricks.

Thickening the wall of the smoke channel must be sent towards the room.

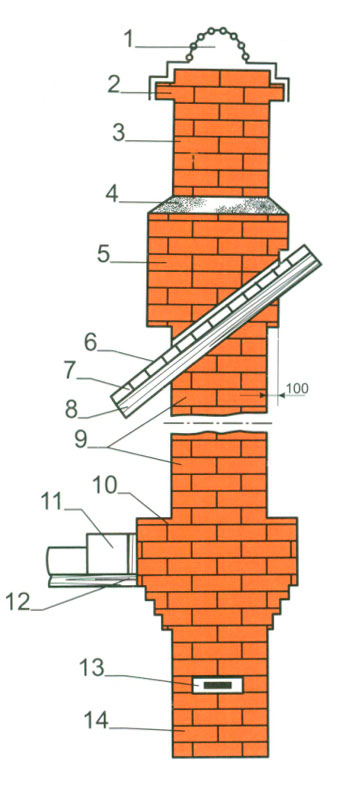

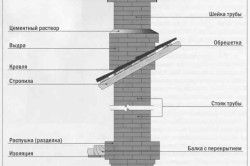

Elements of chimney

Before the construction, find out which items are in the chimney of the brick. Many people think that this is only a brick tube, but in fact, there are quite a few parts in this design, and it is better to get about each maximum information.

- Naddsadny trumpet - Located in the furnace, the valve is installed in it. It is important for an adsadd tube not to lift the 6 rows of bricks before the overlap between the floors;

- Flush - an element that begins before overlap, it is 300 mm wide in it, but the cross section of the chimney canal remains unchanged;

- Riser - is in the attic room, externally this is a flat tube rising to the roof;

- Otter - place where the width of the pipe increases from all sides by 100 mm, is necessary in order to prevent rain moisture from entering the chimney;

- Neck - The otter is above, it is a small riser;

- Oglong - Expansion to the top of the chimney, often a metal cap is fixed to protect the entire design from atmospheric moisture.

Requirements for chimnets

The chimney of the house is one of the most important elements of the heating device, but the owners of houses often do not pay attention to him, although specialists for them make very stringent requirements:

- Environmental characteristics. The heated air with smoke gases should not be reacted with the material of the pipe and allocate poisonous substances.

- High strength material. Do not change your characteristics and dimensions when heated.

- Tightness design. Fully eliminate the likelihood of burning products across the chimney walls, joints for the entire time of operation.

- Surface Pipes should not be heated.

- Lifetime. It is necessary that this indicator is maximum, and this is possible if the installation work was correctly performed.

Choosing a suitable brick for the construction of chimney

Refractory

Such a brick has a high resistance to fire and high temperatures, depending on the structure, the place of use, the brick is produced:

- Chamotnoe - The most popular view of the brick for heating devices, in its composition about 70% of the chamot (refractory clay). It can withstand an increase in temperature up to 1300 degrees, racks to aggressive substances.

- Clinker brick - Perfectly transfers heat, for heating devices it is better to use material with a strength of 250.

- Quartz brick - It is made of gerbil, although it is very dense, but is destroyed under the influence of acids, it can be used to masonry furnaces that do not have contact with aggressive compositions.

- Carbon brick - Made from pressed coke or graphite. Stands to fire and durable, has a high thermal conductivity, well retains its shape.

- Periclase brick - Contains in its composition: magnesia-ferrite, melted magnesite, spinel and fosterite. Such a material does not change its weight and shape, immacifiously immacified.

Heat insulating

To prevent the risk of fire-hazardous situations for the manufacture of outer walls of smoke channels, such a brick is used:

- Hollow - in the structure of each brick there are emptiness.

- Cement-sand - with high insulating qualities, this brick is not afraid of temperatures up to 900 degrees.

Masonry solution

Putting the chimney is necessary with a solution that has certain characteristics.

In its composition, the solution is a mixture of binding components with water and the addition of the aggregate. Together, all components of the solution during masonry bricks form from it and the foundation of the furnace of the required strength, and the monolithic chimney case.

Varieties of masonry mixtures

- Solutions are divided according to their properties., for example, in a dry form there are light (bulk weight of not more than 1500 kg / m³) and heavy (exceeding 1500 kg / m³ in bulk mass);

- Solutions exist: Special compositions, masonry solutions (for masonry of heating devices from bricks, special blocks and stone) and finishing formulations (used for finishing the outer surface of the furnace);

- By the appearance of the binder component on: cement, gypsum and limestone;

- By structure There are normal, fatty and skinny solutions.

The skinny solution has reduced strength and less plastic. On the contrary, the fatty compositions have excellent plasticity, but after setting and drying on the laying, cracks appear.

For this reason, a normal solution is suitable for masonry a brick chimney, which has an average durability and plasticity, it will give a very small shrinkage and after drying the masonry will not be cracking.

The thickness of the mixture is an important factor, if a solution is properly mixed, it will remind the sour cream in thickness and it will easily work with it, with a slight pressure on the brick, a small part of the solution will be squeezed out of the seam.

Clay mix

This mixture does not have great strength, chimneys are rare from it, mainly it is suitable for the masonry of the oven itself. Under the influence of atmospheric precipitation, the clay from the solution is washed away, for this reason it cannot be used for the pipes of the pipe above the roof.

The strength of the clay mixture can be slightly increased by adding about 100-150 grams of the table salt. Pontland cement is added to it, but such a mixture must be developed within an hour.

Mortar

The mixture on the base of lime is suitable for the chimney laying above the roof level. It includes: water, sacred sand and limestone dough to increase the strength of the composition, a small amount of cement is introduced into it, and for rapid hardening - gypsum.

Cement-based solution

Such a mixture is the strongest, it requires water, sacred sand and cement. Solution after mixing, it is necessary to work out per hour, otherwise it decreases the characteristics. The strength depends on the grade of the used cement and on its quantity in solution.

Laying smoke

What a height would nor the house, the chimney should be made of at least 5 m - in the other case, the thrust will be very weak. Put the chimney is needed from red or refractory brick.

Experienced masters on masonry furnaces and chimneys, can immediately chop out a piece of certain size with one blow - if you do not know how you do not know how, then it is better to use a marker for the mark and a disc bracker.

Using these tools will give you the ability to trim the plates for the otter and the smoke channel of the required dimensions.

The seams need to do thin - in this case the smoke canal will be reliable and strong enough.

To lay out the exterior and cutting, use the rods from the usual metal - lay them directly in the laying seams, so that the rods are not sticking inside the chimney. Take into account that the dimensions of the chimney will depend on the thickness of the masonry seams - it is necessary to make equal thickness.

The masonry of the chimney of bricks is performed, starting from the device above the oven tube, it is necessary to put it with the use of dressings, it ends for 5 - 6 rows without reaching the attic overlap.

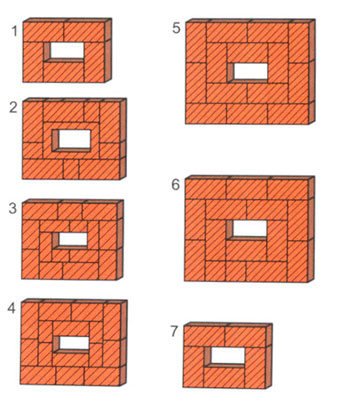

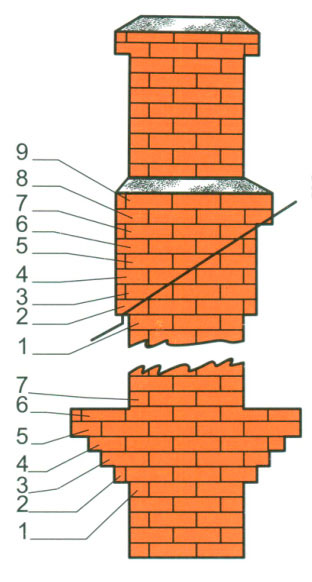

The device of the roller

After that brick laying chimney Enters the masonry of the neck of the roller. She is made of 5 bricks.

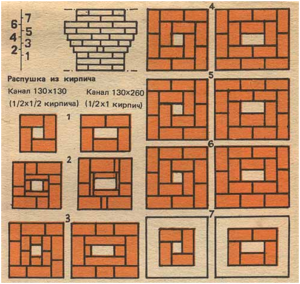

After that, the beginning of the cutting is underway, it is necessary to withstand outdoor dimensions in this place - 590 x 450 mm, this can be achieved by inserting bricks cut to ½ and 1/4. Persons of the brick and inside the canal are inserted, to save its size.

Put the riser of chimney

In the attic, it is necessary to immediately cut through the hole in the roof, into which output the smoke tube to the outside, it needs to be carried out through the roof and then the work will go on the roof.

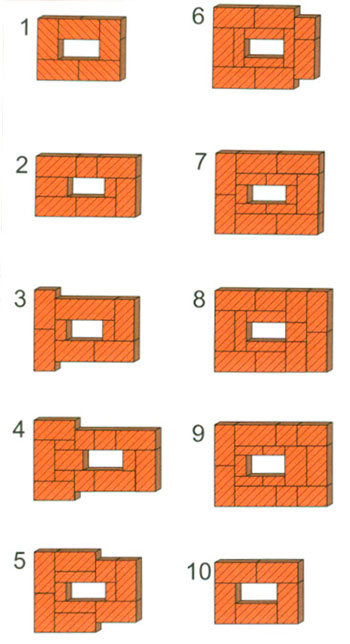

We fold the otter

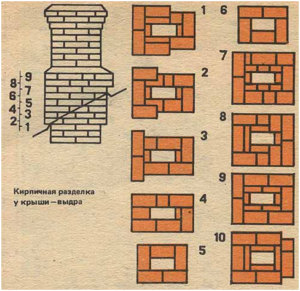

The riser is laid out on 2 rows above the roof, and after that the otter is composed of 9 rows.

It is necessary to consider at the same time that the next rows need to be wider than the previous 1/4 brick.

It is necessary to inside the chimney, lay the plates cut out of the brick.

Hole must be made the same over the entire length it should not be wider or already.

Be sure to make the protrusion of the otter forward (on roofing) All over the perimeter, and already above it will be easier to make a wider wider, just putting forward bricks.

In 4 row, it is necessary to make protrusions in length, and in 5.6 and 7 make them twice as much. In this way, any gaps and holes are overlapped, which can be formed between the roof and the chimney. In 8 and 9, a row still post the ledge, be sure to perform a dressing.

Ca Canal

After that, you need to decide which height you will lay the chimney, and lay out the neck of the smoke pipe on which you will do the headband.

Design of the headside

This element is placed, as well as the roller, after that it will remain to choose and install the flugark.

- Masonry seams in chimney must be made as thin as possible, it directly affects the strength of the whole structure;

- It is not terrible that pipe outside The first time it turns out not very correct form.

- To cut off brick parts or cut the plate from it, it is convenient to use a grinder;

- If you are not sure about your abilities On the masonry of complex elements of brick parts - they can be made of concrete.

The most frequent error belongs to a small height pipe relative to the roof of the house. The smoke canal, with a ledge, low, will be unable to create a good craving.

The efficiency of the functioning of heating devices is very dependent on how exactly the surface inside the chimney canal is made.

An uneven surface or a change in shape causes the formation of twist, and contributes to the deposition of combustion products on the walls. For fireplaces and furnaces, it is important to avoid deviation from the chimney from the vertical of more than 3 degrees.

The brick chimney is a classic solution that has already been used for quite a long time in everyday life and does not lose its popularity, despite the fact that today's increasingly modern solutions are being implemented.

Building this design At the installation stage of the object and may have a different configuration.

A little bit about chimneys made of bricks

The heating system and the outflow of combustion products in the house must be organized at mandatory. For this purpose, in particular, a brick chimney is used, through which the spent air is removed during the functioning of the heating devices. Usually, the discharge design of such material is activated for single heating and heating devices.

By configuration, the brick chimney can be square or round form. But the second option will cost more due to the complexity of the masonry. The discharge design is erected in parallel with the construction of the walls of the construction. Today, the chimney is allowed, the length of the side of which is at least 140 mm, and if the round configuration, then the diameter should be 140 mm. In the previous times, the allowable limit was 150 mm.

We look at the video, a little about the installation work of the chimney of the brick:

The thickness of the walls is also regulated by certain norms. It is not recommended to disturb the integrity of the design by holes under the cable and so on. The brick chimney must be solid, and in addition to this, the inner surface of the pipe should be as smooth, without brick protrusions and seams in the seams.

View of bricks for chimney and their features

Gas heating determines the type of material used in the construction of the discharge design. So, in this case, it is recommended to use a red full-length ceramic or chammed brick.

Gas heating determines the type of material used in the construction of the discharge design. So, in this case, it is recommended to use a red full-length ceramic or chammed brick.

The difference between them is the meaning of the temperature withstanding. So, in the first case we are talking about 800 degrees, and in the second - about 1,000 degrees.

All other options, for example, lightweight, porous or void material is prohibited. Unlike the walls of the house, brick differentty chims can not be placed from the inside.

The construction of different parts of the structure is noted by the use of cement mortar, which is different in composition. For that part of the chimney, which is located above the roof, is used by the cement-sand-sand. For laying below the roof level, a cement-limestone or lime solution should be applied.

If you compare brickly differentty chimneys with other structures, for example, with a sandwich chimney, then in this case a single solution is used. "Sandwich" is a two-way version, that is, it is assumed that the chimney consists of two pipes: a larger and smaller diameter.

Advantages and disadvantages of brick design

The high degree of popularity brickly dummy chimneys acquired thanks to a number of features that will be discussed below:

- Increased resistance to high temperatures, as already mentioned, chamoten brick withstands the limit of up to 1,000 degrees, while burning products from the furnace and the fireplace reach the border of 750 degrees;

- The increased degree of thermal conductivity provides a high efficiency of heating equipment, since brickly differentty chimneys do not contribute to the rapid outflow of heat;

- The cost of construction from this material is low;

- Aesthetic value is no less important, especially in cases where the construction is erected, designed in a certain style.

But besides the advantages, a brick square chimney has a number of significant minuses:

- The corners of the design contribute to the formation of vortex flows, which in turn are a factor of countering the outflow of combustion products;

- The walls of the discharge design are not always perfectly smooth, which contributes to sedimentation on the rough surface of the soot, and this will over time lead to a decrease in the working space, as a result of which the thrust deteriorates;

- The regular effect of aggressive media and temperature drops, which contributes to the formation of condensate, leads to the fact that chimneys for red brick furnaces are gradually destroyed.

Taking into account the foregoing, as well as, taking into account the features of other types of discharge designs, the user decides for itself, which of the options is preferable. But still the most frequently found today is the laying of chimney of bricks.

Preparation for work

Beginning construction work Any type is to draw up a project. To effectively function effectively, it is necessary to consider a number of rules:

- Dimensions of the pipe, namely, its height and diameter are determined by the characteristics of the heating equipment. But the brick different format pipe for the chimney cannot be less than 5 m. The relationship between these parameters and the force of thrust is obvious, since the larger the cross section of the pipe with insufficiently powerful heating equipment, the weaker the air outflow. And if the pipe diameter is too small, even if there is a sufficient height, chimneys for red brick furnaces will be "challenged."

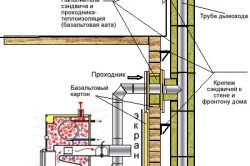

- Construction of a discharge design in rooms that are well heated is made without the insulation of the pipe. But on the site adjacent to the overlap (up to 60 cm of length), the "Sandwich" design is mounted.

- Construction of a chimney of brick implies the need to provide free access to service. For this, the stool seams are located at different levels ceiling overlap. Otherwise, in the event of difficulties in the work of the system, it will be very problematic to get to the desired section of the pipe.

We watch the video, the beginning of the pipe:

It is important to imagine well, from which elements the construction of a chimney of bricks is developing. So, the main components nodes:

- Naddsadnaya pipe - is conducted from the oven itself;

- The roller is so called the laying of a brick chimney pipe, which is produced with broadening to 300 mm, but at the same time the initial inner diameter of the pipe is preserved;

- Riser - towers in the attic and is underway until the roof;

- The otter is a smoking pipe laying, which is carried out with broadening to 100 mm and is an obstacle to the penetration of precipitation into the room;

- Neck - built on the principle of riser and is being built immediately after the otter;

- The head board is the last plot with broadening that crowns the pipe.

Description of work

About how bricks are placed different format chimney, above mentioned. Having understood with the stages of work, you can start closing:

- Truck is built. The laying is carried out through the dressing method. At this stage should be stopped, without reaching about 6 brick rows before the overlap.

- Chimney with their hands from red brick is further built with broadening, which is called the rush. Recommended dimensions of this element: 140x270 mm via the internal perimeter of the pipe, and the 590x450 mm values \u200b\u200bare selected outside. Construction is carried out using plates to get the desired result. The following series has parameters: 510x650 mm, while also plates with a thickness of 60 mm. The result is a series with dimensions of 570x710 mm. When the broadening is ready, another number of the same sizes are erected, taking into account the dressing.

- Brick multi-format chimney for metal oven It is built further by the sizes of the supporting tube, but above the roller. This part is called the riser. At this stage you need to pre-prepare a pipe outlet in the roof.

- Chimneys for red brick furnaces are built after the output of the riser outside the roof is not higher than 2 rows. Then the otter laying begins. This is another broadening. In height, this site is equal to nine rows, each of which is wider than the previous one half of the brick. Brick plates are still installed inside the broadening. As can be seen, a brick variance chimney for a metal furnace and other heating equipment is really built on their own, but the main complexity is precisely these sections with broadening.

- Thinking on how to build a red brick chimney as high quality, the need to cover the hole formed between the roof and the pipe should be taken into account. This is done by increasing the width of the rows of bricks.

- Choosing which brick is suitable for the chimney, you need to take into account the aesthetic side of the question. Since the construction of the neck is desirable that its quality and color harmoniously fit into the overall picture of the house. The head board is based on the principle of the roller.

Facial facilities

Additionally, it should be chosen for chimney, pay attention to the thickness of the seams. What they are thinner, the more durable design can be obtained as a result. If it was not possible to give a beautiful form of broadening, you can fix the flaws by concrete mixture.

We look at the detailed video, stages of work:

Suggesting of a brick different format chimney is not a prerequisite. But such a measure allows you to get a fully sealed pipe, which will increase the reliability and efficiency of the structure. Suggilzovka implies the installation of a stainless steel pipe inside the brick walls of the chimney. This option is possible only in rectilinear areas.

Thus, in addition to the main stages of work, there are also a number of nuances, which also need to first know that the design of the chimney turns out without flaws and served as long as possible.

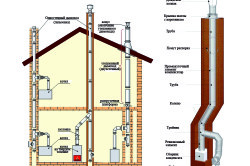

Without a smoke tube, no oven or fireplace will work, as they are necessary to create the required thrust in the furnaces and the subsequent removal of combustion products.

Construction of flue pipes is performed using one of the existing types of items.

- Nazadny;

- Indigenous

- Wall.

A group of exhaust pipes is considered the main one. They are installed at the overlap of the furnace and are actually its continuation.

Moreover, the pipes of the specified type are mounted on a concrete pipe, pre-laid on the blocking. The slab must be reinforced and make a thickness of at least 50mm;

Under the indigenous type tubes, its own foundation is pre-lays out. This design is used in exceptional cases and only if the pipe of the other design is fundamentally impossible.

As a rule, wall tubes are performed in the downtown capital walls. This is only possible when the specified walls are made of stone or bricks. In the form of exception, an option is possible to accommodate such a pipe in the wall outdoor.

But in this case, it will be necessary to perform a fairly large amount of additional work. Namely: from the inside in the form of pilasters, perform the thickening of the wall at the point of passage of the pipe; To eliminate the strong cooling of the chimney, as this may lead to a significant reduction in thrust due to the condensation of vapors.

It is possible to achieve this, providing the required distances from the chimney to the outer surface of the outer wall (see Table 1).

In cases where the walls are posted using slag blocks, silicate brick or concrete, then those of their sites for which you are going to lay the chimney must be put out of the brick red.

And the thickness of the masonry should be at least half the click.

A similar thickness should have walls and partitions performed between chimneys.

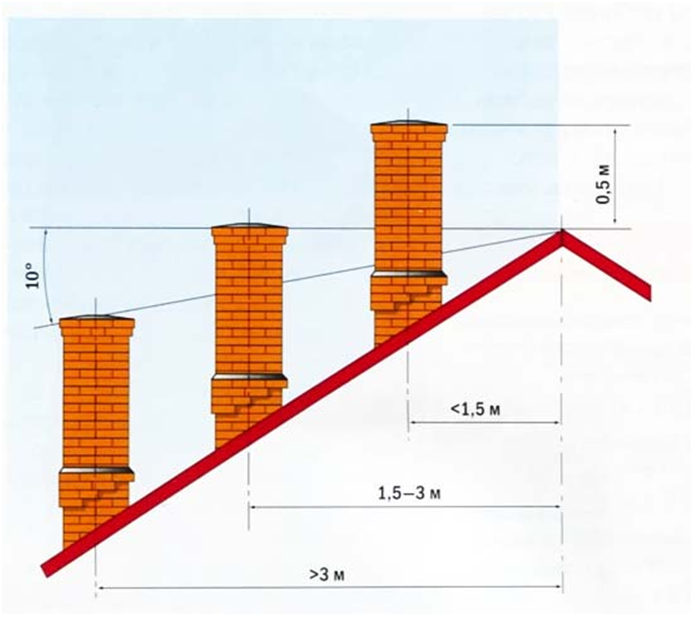

Remember that the height of the chimney over the roof depends on the place of its exit (with respect to the roof of the roof). This value fluctuates in the range of 500 - 1500mm.

But, in any case, the upper cut of the pipe is output to be higher than the ridge of the roof by 500 and more than millimeters.

Brick for flue pipes is better to choose red.

Features of chimney masonry and possible errors

Dwinkers are special channels inside the design of the furnace, which the fuel can be connected to the pipe.

They have a different form, are short, long or zigzag, they can have several or only one turn, which are denoted by the term "smoke."

In the spacious, they are called by channels or smoke channels.

In the designs of modern furnaces, channels are used to be divided into:

- Vertical;

- Horizontal;

- Lowered;

- Lifting.

Due to the fact that interior decoration Channels significantly depends the coefficient of resistance to the passage of combustion products, sufficiently high demands are presented to it.

The main errors when laying chimneys are:

- choosing an incorrect version of the channel for the oven you are going to lay (if the order is calculated by you yourself);

- low quality handling of internal channel surfaces;

- selecting a section that does not allow you to freely pass through the channel to the entire volume of allocated combustion products (less norm), or vice versa, the cross-section of the channels exceeds the optimal one.

In the latter case, the speed of movement of the assigned gases falls that a decrease in the temperature of the warm-up of the entire furnace is involved. Eliminating these disadvantages after the start of operation of the furnace is a very time-consuming process and long.

The main elements of the chimney pipe

Pipes of different designs in general have the same basic elements. Therefore, we consider them on the example of the tube of the nasadny.

1 - metal cap; 2 - tube head board; 3 - cervical tubes; four - cement mortar; 5 - otter; 6 - roofing; 7 - doom; 8 - rafters; 9 - Pipe risers; 10 - Roller; 11 - beam with overlapping; 12 - insulation; 13 - smoke valve; 14 - neck furnace.

Device of the foundation of chimney

Separate foundation is required only for pipes belonging to the group of indigenous. For example, the foundation for the flue pipe boiler room.

The foundation is placed similarly to the foundation under the oven, the same ways and taking into account the same requirements.

And the actual installation of the chimney of the boiler house is carried out according to the pre-calculated order.

Chimney

The laying of flue brick tubes is performed after the completion of the body masonry of the furnace and requires increased wizard.

Since the quality of the execution of these works, it depends largely how the laid out the furnace will work.

All elements of the pipe at its height are in orders for which the construction of flue pipes should be carried out.

With a brick chimney over the roof

Masonry of the chimney of the brick begins with the neck of the furnace (located on the overlapping). The neck is not communicated to the overlap of the attic to several rows (2-4). The valve is installed here. Next is the laying with expansion.

The resulting thickening on the pipe is called "Fravel" and is performed at the level of finding overlap. From her before the roof, through the entire attic (height) part of the pipe, called the riser, passes. From the outside of the roof (roof) there is a second thickening (otter).

To protect against moisture penetration inside the attic room in the place where the pipe passes through the roof, the waterproofing of the chimney on the roof is made.

Output 100 mm from the pipe hangs over the surface of the roof throughout the perimeter of the pipe and removes precipitation to the roof.

Just above the outer part of the roof, over the output, the neck of the pipe goes, the area of \u200b\u200bwhich is equal to the area of \u200b\u200briser. At the top end of the neck expands. Here is performed.

Above it, in order to protect the pipe from the moisture from entering it (rain, snow, etc.) and the improvements of the thrust is made by Flugark, usually performed from steel roofing.

To improve the thrust, the height of the chimney over the roof should be higher than the skate of the latter.

To protect the external pipe elements from harmful influences Their external factors are coated with steel roofing, or coated with cement mortar. In this case, they are attached to the inclined form that ensures the flow of water.

The flush and the otter are the most complex elements of the smoke pipe. They are flattened, extending from a row to a row of 60-70 mm in length and width.

The flap is put, retreating from the blocked for a short distance. A typical variant of the fooles and exterior cohesings and their placement on the pipe are shown in Figures 2, 3 and 4, respectively.

Masonry chimney more complicated than the installation of the tube sandwich. However, this design will last much longer and has the best decorative properties. The main task for the chimney of the brick is the leading of combustion products and the creation of thrust in firing furnace. When erecting a brick chimney with your own hands, you must follow the rules of fire safety. The chimney on the roof of the brick is durable, withstands harsh temperature differences, so that they will serve for a very long time.

Brick flue pipes are divided according to:

By material on:

- Brick;

- Metal;

- Asbestos cement (sandwiches).

By installation method:

- Indigenous

- Nazadny;

- Wall.

Indigenous chimneys are installed next to the oven, connecting them to chimney. They can bring several heating devices to them, but the construction of the indigenous requires more accurate calculations. With misunderstood, combustion products can get to the house.

The most common chimney from the brick-nasadnyh. This is a classic brick chimney. Chimney is installed on top of the heating furnace.

Warning is installed on the outer wall of the house. It can be indigenous or mandatory. More often they are erected to save money. Evaluate such chimney is easier, but it requires additional costs for insulation with isolation.

The design of the chimney on the roof of the brick

The brick chimney consists of several parts, consider an example of an atmospal:

- Cap. Mainly made from metal. It prevents snow, rain and dirt into the smoke system. Often serves as a decoration.

- Podle. The protruding part of the bricks, which prevents rain drops on the trunk of the pipe, performs decorative functions.

- Neck. The length of the neck depends on the bending of the roof. The height of the pipe on the roof affects the power of the traction.

- Otter. The otter performs several functions. It increases the resistance to wind loads. Increased diameter of the otter performs the function of thermal insulation between the roof and chimney. Special sealants or galvanized sheets are used to seal the seam between the roof and the otter.

- Pipe risers The longest part of the chimney connecting the flap with the output.

- Flap, like a otter, thickened part of the chimney. It is located in the overlap between the room and the attic, protecting the beam overlap from overheating. Sometimes instead of a roller, a metal container with heat-resistant materials (sand, clay) is installed.

- The entire lower part of the chimney is subjected to high heat loads, so for the channels optimally take fire-resistant (chamoten) brick. The smoke valve allows you to adjust the incoming air, it makes it from the metal (but such a valve can bend under the action of temperatures) or laid out of the brick.

General rules for construction

For all types there are general rules erection. Among which:

- The height of the pipe over the roof;

- Main material;

- Solution.

The height of the brick tube is calculated taking into account the inclination of the roof and the height of the skate.

Important! The power of air thrust depends on the correct height. Also, this is a regulation fire safety. Air twists can provoke a fire if the roof is not refractory.

Calculation of the height of the pipe

The masonry of the chimney is carried out by the red brick M200 brand. Red brick is able to withstand temperatures up to 800 degrees Celsius, but for laying channels near the heating part of the furnace, it is better to use chamoten, refractory brickTo avoid splitting or combustion of material. All folded bricks must be high quality (smooth sides). On the uneven surface, the formation of soot is accelerated, which leads to a decrease in thrust and even ignition. When laying the inner, you need to immediately clean on the seams.

The solution for laying a chimney is two types. Clay or cement-clay. Usually all furnaces laid out on clay solutionSince the clay of refractory and does not crack, but to increase the strength of the masonry, the cement can be added to the masonry solution.

Erection procedure

It is best to provide a stove with a chimney pipe made of brick at the initial stage of construction, otherwise there will be a problem with the hardening of the hole in the roof, overlap, in the additional foundation. Under the brick oven poured the foundation.

It is best to provide a stove with a chimney pipe made of brick at the initial stage of construction, otherwise there will be a problem with the hardening of the hole in the roof, overlap, in the additional foundation. Under the brick oven poured the foundation.

If you lay out the oven in the bath, then the channel of 250 to 120 will be enough. For masonry, you can buy shortened bricks or trim them with a grinder.

Try to do not make a large seam thickness. The more seam, the greater the likelihood of its expansion under the temperature, which means the possibility of cracks increases.

For a metal furnace, you can set the chimney from the preferential sandwich pipes and put them with bricks, it will provide a beautiful appearance.

First prepare tools. You will need:

- Kelma Masonic (for applying a solution);

- Kirk or hammer (for brick splitting);

- Bulgarian with a diamond circle;

- Level;

- Plumb;

- Rule.

- By selecting the desired laying schema, prepare tools and a solution. Measure the height from the smoke valve to the roller.

- Start the masonry from the furnace, how to lay out the first row, check the tilt level. To begin with, you can decompose the brickwork without a solution to understand the amount of work and dimensions.

- On the first row of brick, you can pull the beacons vertically to the ceiling, for the convenience of further masonry.

- Continue the masonry to the roller. You need to calculate the number of bricks. As mentioned earlier, the roller has an increased thickness. The extension needs to be laid on the ¼ brick thickness in each row., At the same time, the roller should be tightly pressed against the beams of overlapping.

Here is one of the laying schemes of the roller.

- The stability of the circuit depends on the reliability of the flip of the flip to the sides of the overlap. Under the influence of wind, the pipe can move. The movement will break the roof and roof tightness, which will lead to leaks.

- Similarly, go from the roller to the chimney barrel and take it to the roof.

- The wizard masonry is similar to the roller device, but more difficult, since the roof has an angle of inclination and an increase in the diameter will occur scenario. Overlay calculation scheme.

- The head board is laid out by a quarter of the brick. It can be put in several rows or one, depending on the appearance of the brick tube on the roof. In the last row of brick masonry, you can mow mesh metal. If the chimney is not used for a long time, then the birds can vote in it.

- The protective cap is fixed by dowels.

How to calculate the cross section of a brick pipe

The work of the chimney of the brick is in the movement of the air from the heat part, to the external exit. Chimney creates a thrust that appears from the temperature and pressure drop. The size of the section must be calculated based on the power of the heating element and the furnace. The chimney should be smooth so that nothing hinder the movement of the air and was not going to smoke. Sometimes, for this, a smooth tin pipe is embedded in chimney.

The inner diameter will depend on the total length of the chimney and the power of the boiler (furnaces). The number of channels inside the furnace also affects normal operation. If the pipe is too long and the chimney cross-section is too large, then at low power of the furnace (boiler), it will lead to its cooling or reduction of thrust. Often the question arises, what pipes provide better traction? The thrust does not depend on what material pipes are made - steel or brick.

For a fireplace with an open window, the distribution of the chimney cross section and the window will be 1 to 10 (cross-section of the pipe to the area of \u200b\u200bthe milling windows). This is applicable to all forms of the pipe.

In the stove with a closed system, the sections ratio will be 1 to 1.5

Hole calculation scheme:

| Height in meters | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| Pipe section | The ratio of the cross section to the area of \u200b\u200bthe windows of the mold in% | |||||||

| A circle | 11,2 | 10,2 | 10 | 9,5 | 9,1 | 8,7 | 8,9 | |

| Square | 12,4 | 11,6 | 11 | 10,5 | 10,1 | 9,7 | 9,4 | |

| Rectangle | 13,2 | 12,3 | 11,7 | 11,2 | 10,6 | 10,2 | 9,8 | |

For example: with the size of the windows of 600 to 700 mm, the total size will be 0.42 mq. For a square section of the pipe, with a height of a chimney of 6 meters, the best will be 11.6 percent. Now 0.42 is multiplied by 0.116, we get 0.0787 square meters. The pipe section must be taken into account based on the height of the pipe. Sememeter tube in the bath, two meters high, it will not look aesthetically.

Transition from brick on sandwich

Brick chimneys have a good thrust and they serve for a long time. but brickwork Pipes can be destroyed, especially under the action of the external environment. The destroyed layer may prevent the release of combustion products and reduce cravings. To install a new pipe, you can put the transition from the brick tube to the sandwich.

For dosilets, the adapter is used in the base, and cylindrical, on the other side. Inside the adapter is a layer of basalt wool.

When moving from sandwich panels to the brick, you need to use two adapters. One above the brick chimney, the second in the attic.

The distance from the sandwich tube to the combustible design of the house is filled with a non-heat material, about 400 mm.

For sealing seams in the design use refractory sealants.

When moving from a square pipe on a round, one cannot reduce the cross section of the pipe and make additional protrusions to not disturb the craving.

Facing the furnace and chimney stem ceramic tiles

New furnaces usually have a beautiful appearance. However, some prefer to separate it with tiles. This is not only beautiful, but also will increase the service life, especially in the bath, where the increased humidity of the air. How to put a tile with your own hands? (Well, if you understand how to fold bricks for the chimney, then you can handle it). The main thing is to correctly select tile glue and cladding material.

How to put a tile so that it does not dug? When cladding usual ceramic tilesThere is a great opportunity to dug or cracking it. Best Material There will be clinker, terracotta, porcelain.

Terracotta has greater strength. She is done under pressing.

Clinker and porcelain tiles have high impact resistance, thickness and high refractory.

The surface of the chimney is thoroughly cleaned from dirt and moisturized. From above, with a dowel, stretch the metal grid. The grid improves the clutch of plaster with brick masonry.

Plaster with cement and clay mortar. The ratio of clay to cement 3 to 1 and 0.2 pieces of sand. After plastering, the oven is molded. After, you can glue the tile.

Tile glue to heat-resistant glue using lighthouses and crossbars for alignment of the rows. For grouting seams use the same glue.

If you make an effort and patience, you can cope with the erection of the chimney with your own hands, saving at the invitation of specialists.

In addition to our article, watch the video:

- Types of chimney

- Installation of brick chimney

- Preparatory work

- Performing brick masonry

- Fasteners and thermal insulation

- Useful advice

Brick chimneys are a rather complicated design. Not in vain for the construction of chimneys, only experts were taken. The problem lies not only in choosing a material for work, but also in compliance with all stages. The chimney is collected by a pre-compiled scheme, use for this only a special ceramic red brick designed for furnace work. The design is performed strictly according to the drawing - the so-called spray, which shows the location of each element.

Upon the same order, it is easy for a masonry solution. The solution itself is used or ready, or in a dry form, which is only divorced by water. In this case, the consumption is indicated by the manufacturer. You can prepare it yourself based on lime and clay. Clay requires preliminary soaking, take the first one you can't. A chimney for a fireplace, a metal furnace is needed, for the overall heating system and in many other cases. Inside the design is allowed to install a special ceramic pipe, a sandwich pipe, which is a modern and reliable variant of the chimney. I. correct care Behind the chimney, the pipe should be cleaned regularly, for this, a variety of methods and means are applied. Their choice depends on the degree of pollution, design features.

Types of chimney

All chimneys that are used today can be divided into the following groups:

- Wall - structures that are mounted inside walls of buildings. The chimney is made from the brick outside, and inside metal or asbestos pipes are equipped. This design is convenient, but it can be constructed only at the construction stage of the house.

- Indigenous chimneys are structures on their own foundation, they can be located inside or outside the building, for them there is an inner lining.

- Natural tubes for furnaces. Such chimneys are performed only from asbetic, metal pipesBut may have both cladding if the conditions are allowed. Below, they rely on the furnace or other heat generating machine, may be used as a support the ceiling coating. The manufacture is considered simple, the inner surface is smooth.

Chimneys can be insulated, have branching, but it requires a special project.

Back to the category

Installation of brick chimney

The brick chimney is a complex design, to which the manufacture of which must be approached. It is necessary to immediately prepare the laying scheme, all materials used in the work, tools:

- ceramic brick;

- masonry solution;

- master OK;

- machine for cutting bricks;

- metal brackets;

- armature;

- insulation;

- fiberglass;

- putty knife;

- plaster.

Back to the category

Preparatory work

In order not to have difficulties with the furnace, it is necessary to get acquainted with the drawing before masonry chimney. It is important not only to correctly calculate the material, but also to determine exactly how the pipe will go, what additional funds and materials may be required during operation.

Before starting work, pour the foundation of the rectangular form. It makes from concrete or full-scale ceramic brick, Strengthens the design of the reinforcement. The height of such a foundation is approximately 30 cm, and the width must be 15 cm more than the chimney itself. The transition from the furnace is performed at an angle of 45 °, its length is no more than 2 m. You can make an angle and at 30 °, everything depends on the design of the furnace itself. The transition site is reinforced to ensure the safety and strength of the structure. The channel must remain free, nothing should overlap or brave it.

Back to the category

Performing brick masonry

The brick chimney is necessary to lay out strictly according to the scheme, which is also called apartment. It shows the size and location of the brick unit for each row. This allows you to make work faster, providing a high level of reliability of the finished design. In any case, the pipe height should not be less than 5 m, otherwise the thrust will not be. For masonry, it is necessary to take only ceramic chimney brick, which is resistant to heating, sharp temperature differences. For masonry, a solution is taken on the basis of hazed lime or clay, cement-sandy is rarely applied.

When the tube is laid out, it is often necessary to cut brick blocks. The experienced cook has it turns out quickly. But when there is no such experience, it is best to use a special grinding machine. During the masonry, it is necessary to ensure that the seams are relatively thin, 15 mm is quite enough. Otherwise, the design will be fragile. Brick before work it is necessary to moisten, so that when drying it, he could not pull the moisture from the solution. For the construction of otter and cutting, special metal fittings are applied. But it is necessary to lay it in such a way that it does not intersect in any case the chimney channel.

The wall thickness of the furnace pipe should be approximately 10 cm, the necessary fire safety is ensured.

It is impossible to make the walls with thin, as the strength of the structure will be much lower. For the inner surface, it is best to apply plaster that the furnace becomes smooth. This avoids the sediment of soot. If you do not comply with this condition, the cleaning of surfaces will be difficult, the permeability will significantly decrease. Says worsens cravings, the furnace ceases to perform its functions, and its use becomes quite dangerous, the room is constantly smoking.

Back to the category

Fasteners and thermal insulation

The fastener of the chimney depends on where it will be located. If the oven and, accordingly, the pipe is near the wall, then you need to use special metal anchorswhich are located in a step of 30 cm. In places of passage of the roof or overlap, the attic ceiling must be used asbestos tissue or fiberglass pads. This will protect building construction from overheating and fires. The brick itself is heated slowly, but with intensive use of the oven, the temperature may rise rather quickly, it keeps for a long time. For a brick or concrete house, this is not hazardous, but for finishing materials Or for the wooden structure, security measures become simply necessary.

During the planning of the chimney, it must be remembered that it should rise above the level of the roof of the roof. Its height should be at least 50 cm, and better more. The outer part of the chimney, which is located above the structure, must be insulated. After that, a special laying is performed. facing bricks or finishing with roofing materials.