It will be pro base under the metal furnace in the bathand the protection of the wooden floor. Although many mistakenly believe that the baths are burning from opening open fire. But in reality, wood can not light up from flame, but on temperature. That is why protect the design of the floor bath is necessary from high temperature. What? We read about dangerous degrees further.

250-300 ° C - the temperature of the flamm of the tree, and the combustion temperature of the tree is approximately 800-1000 ° C (Wikipedia). However, long heating of wood at a temperature of 120-150 ° results in its gradual char harness.

250-300 ° C - the temperature of the flamm of the tree, and the combustion temperature of the tree is approximately 800-1000 ° C (Wikipedia). However, long heating of wood at a temperature of 120-150 ° results in its gradual char harness.

The rate of ignition depends on many factors:

- From the volume and weight, the presence of a crust in wood, the power of the external heating source, the shape of the section of the wooden element, the weight of the part (log lights later than the match at the same temperature);

- From the air situation - the presence of oxygen in the heating zone by the position of the element in the thermal stream of hot air (horizontal, inclined, vertical), etc.

- Wood moisture and density. Dry and light (loose) wood lights up faster than wet and dense.

- Not a stranded surface of wooden parts flammives much faster than smooth and polished.

These features of the form, size and position we will be taken into account in the installation work that are closely related to.

All protective impregnations and antipyren are not protected from fire to the end. They simply do not give flammable gases that are obtained when heated burns on the surface of the wood. Gases fly through protective shell films and are oxidized away from the wood. The rate of decay (dry distillation of wood) is reduced, but does not stop! So that the tree does not deteriorate, it is necessary to take measures to protect against high temperatures, taking into account the removal from the heat source - the furnace.

Fireproof stand - base under the metal furnace

Therefore, the wooden floor under the oven must be insulated. Provide such a temperature regime in which the tree does not heat up above the critical point (so that the hidden counting is not passed) during the entire period of burning the furnace. Temperature can increase not only from air. The most dangerous method of heating is thermal radiation. It overcomes the distance. Therefore, it is necessary to observe such gaps called firefighters. Or on the path of radiation, it is necessary to put a screen with a large heat capacity and low thermal conductivity. Of course you can buy.

Stand under the bake of the bath, which I mount consists of three layers:

- stainless steel - reflective screen for thermal radiation

- brick layer 6 cm thick - thermal battery with high heat capacity and bad thermal conductivity.

- plate refractory 9 mm (magnesite) thick for fastening of refractory cake to wooden semi. Brick is glued to this stove easily and firmly.

Heat-resistant stove - modern technologies Made the plate (analog of plasterboard sheets). Moisture is not afraid, they are not afraid of fire, easily processed and cut with a knife for plasterboard sheets. Very low thermal conductivity. The semi is mounted with ordinary self-assembly for wood. Boards under the stove are treated with anti-antipers.

A reinforcing galvanized grid is used to secure the stand-screen bricks. The solution is cooked from sand. Cement and heat-resistant glue for cladding with tiles and fireplaces. Such a mixture does not comply with the bricks and the grid with the stove, how much will it not give the entire design to operate in pieces.

A reinforcing galvanized grid is used to secure the stand-screen bricks. The solution is cooked from sand. Cement and heat-resistant glue for cladding with tiles and fireplaces. Such a mixture does not comply with the bricks and the grid with the stove, how much will it not give the entire design to operate in pieces.

The seams between bricks are sealed to give the monolithic of refractory cake. At the edges of the slab for the convenience of installation are screwed to the floor of the servo. They limit the masonry zone, simplify the installation of angles, etc. Bricks are not temporable or facades with strict dimensions. Therefore, in order to lay the stainless steel sheet without distortion and did not form dents after installing the furnace to the stand-screen, it is necessary to align the surface with adhesive composition.

The seams between bricks are sealed to give the monolithic of refractory cake. At the edges of the slab for the convenience of installation are screwed to the floor of the servo. They limit the masonry zone, simplify the installation of angles, etc. Bricks are not temporable or facades with strict dimensions. Therefore, in order to lay the stainless steel sheet without distortion and did not form dents after installing the furnace to the stand-screen, it is necessary to align the surface with adhesive composition.

To prepare for the installation of the screen of infrared radiation (mirror stainless steel) on the podium for the furnace, it is necessary to align its surface. If this is not done, then the mirror sheet turns, the corners are unevenly raise and the appearance of such a stand will be, to put it mildly, crying. The mirror stainless screen will emphasize the disadvantages of the surface plane.

To prepare for the installation of the screen of infrared radiation (mirror stainless steel) on the podium for the furnace, it is necessary to align its surface. If this is not done, then the mirror sheet turns, the corners are unevenly raise and the appearance of such a stand will be, to put it mildly, crying. The mirror stainless screen will emphasize the disadvantages of the surface plane.

Stand under the oven.which is mounted on the wooden floor, with one edge relies on the strapping bar and simultaneously serves as the basis between the rest room and the steam room.

Construction of the sauna on the household plot is associated with difficulty - how to install the furnace in it. There are several types of designs of these bath aggregates. The installation of each of them has its own characteristics and rules. Before mounting, you need to decide on the type of machine that is best suited for the bath. To the selection of the place where the unit will stand, you need to approach thoroughly, and think carefully. It is also necessary to take into account safety standards.

What are the types of stoves for a bath

Bath furnaces are classified by the type of fuel that is used in them. Ban aggregates are the following type:

- solid fuel;

- electric;

- liquid-fuel;

- gas.

Bath units operating on solid fuel use stone coal, firewood or briquettes. These furnaces are considered the most acceptable structures. For example, bath furnacesthat work on kerosene is very, firewood in violation of the rules of operation.

One of the successful structures is also considered electrocamenakes. Small sizes are very popular. In the domestic market you can find a lot of similar specimens. Installation of these bath units will not be difficult. They differ compactness and security. However, the operation of such products costs very expensive. In this case, before installing, you need to upgrade the wiring.

If the site is gasified, you can install a bath unit that works on gas. However, due to fire safety, this is not the best option.

If evaluating the furnaces based on the mode of operation, then their you can select such models:

- bath devices of temporary action;

- bath aggregates of long-term work;

- combined devices.

Bath units of the first type - this metal deviceswho are drunk with firewood. They can be easily installed independently. Different with economy and security.

To the second type of bath furnaces include devices capable of adjusting the heating temperature. For their work, firewood, gas or electricity are used. Self install this model is difficult. The cost of bath aggregates of this type is very high.

Combined Bath Furnaces Are built from bricks. The unit has a lot of weight, so it takes a strong foundation for its installation.

Before installing the furnace in the bath you need to decide on the material from which the unit is manufactured. This choice depends the characteristics of the device. For example, the natural stone is well kept warm, but heats up for a very long time.

Often to install a bath unit used various materials. Such furnaces are called combined.

Metal devices for the bath are very quickly heated. Sometimes they are equipped with water tanks. Bath devices are easily manufactured independently. How to install such furnaces in the bathroom will tell below.

Metal furnaces: Benefits and Disadvantages

The main features Bath aggregates of this species are:

From disadvantages, you can mark the rapid cooling of the device case. Therefore, in the Bath furnace you need to support continuous burning. To avoid overheating of the wall, the floor and the ceiling must be equipped with appropriate protection. Compared to brick models for baths metal heat the space of a small volumeWhat is also a minus.

Possessing knowledge about the features of each type of bath units, you can make the right choice.

Installation of a metal model: Basic rules

When installing a furnace to a bath, you must follow some rules. So, for the furnace requires a solid base. With its manufacture, it is necessary to apply only non-combustible materials. If the base is done correctly, the foundation is not needed.

When installing a furnace to a bath, you must follow some rules. So, for the furnace requires a solid base. With its manufacture, it is necessary to apply only non-combustible materials. If the base is done correctly, the foundation is not needed.

Thermal insulation must be placed in front of the furnace and cover top metal. The furnace cannot be installed next to wooden or flammable materials. To avoid excessive overheating it is necessary set protective screens.

The furnace must be installed in a separate room. To do this, you need to create a channel for fuel that would connect adjacent rooms.

Below in the photo you can see what a metal furnace looks like in the bath. The photo represents a furnace in the finished collected state.

Tools and materials

How to install ovens in a bath without materials and tools - it is impossible to do it.

For installation, the following is necessary:

- steel with a thickness of 8 mm.;

- pipe, the diameter of which is at least 50 cm;

- metal rod with a cross section of 100 mm.;

- fire, perfume, the doors pondered;

- water valve;

- chimney;

- capacity under water to 1 KB. m.

For work requires tools: Bulgarian and welding machine.

Before making installation, it is required to make a floculating chamber and a heater. In the pipe of large sizes of a certain diameter, you need to cut a hole with a diameter of about 20.5 cm. For pissed. The fastener is welded inside, the grate is mounted on it.

After that it is worth doing the manufacture of the door. Usually she it has dimensions 20-25 cm. Fastening is welding from above, the rods of the frame of the Kamenka will be located on it. For water supply, a special hole is made. Also, the furnace should have a special space to fill in diabase.

The tank cover is manufactured so. Take a round blank, the dimensions of which correspond to the diameter of the pipe, and cut into two identical parts. In one of them, the hole for the chimney is cut.

The tank cover is manufactured so. Take a round blank, the dimensions of which correspond to the diameter of the pipe, and cut into two identical parts. In one of them, the hole for the chimney is cut.

With welding, it is attached to Baku. The handle is attached to another part, and the part itself connect to Baku with loops. A very important detail in the entire design is chimney. Many specialists advise to do chimney in the form of a sandwich pipe. Between the covers you need to install the insulation.

To the bathing stove keep heat should be given a lot of time lining. For this, used refractory brick. This increases the humidity in the steam room.

Masonry solution is made from chamotte powder, clay and sand. For kneading are observed proportions 2x2x1. Sometimes brick closes the whole oven. In this case, in the installation it is necessary to use metal corners. For a normal air exchange in the overlap, doors are needed. The opening is placed on one height with a stone. Water comes through it.

After installing the furnace in the bath, it is necessary to protrude it several times in a gentle mode. After that, it is possible to test with maximum load.

Fire safety rules

To comply with the standards, the furnace must be installed in a room that is specifically equipped for this.

To comply with the standards, the furnace must be installed in a room that is specifically equipped for this.

This is very practical and appropriate. If the stove is installed in the steam room, the pregnant will be unheated. In the cold period of the year, this is quite uncomfortable. According to the rules of fire safety around the furnace require free space, and the walls must be protected with metal sheets.

The furnace installed in the steam room will deliver discomfort to visitors. But you still need to throw fuel to the unit.

Bath unit is best placing. Stopping on this choice of installation, you should know that between the room for recreation and the steam room you need to make a hole of a small diameter to accommodate the fuel channel. Given that the pre-tribades usually has a small size, heating equipment is better to put next to the door. Well, when this moment is taken into account during the design of the bath and non-combustible materials are applied to manufacture the surface of the walls. If this could not be done, then the problem can be solved in the following way.

You need to take a sheet of cardboard made on an asbestos-based basis, and strengthen it in the hole for the fuel channel and around it. You can also use metal with a thickness of at least 4 mm.

An important role is played by the partition and the surface of the furnace. If there is no metal-asbestos protection, then they should be placed not closer than 32 cm. If the protection is available, then in this case the distance between the housing and the wall may be at least 26 cm.

Conclusion

When installing a furnace in the bath should not forget that in the sauna it is necessary create flow and exhaust ventilation. To do this, equip an additional channel, which is located just below the floor level near the metal stove.

The bath is good for health and is well up to the mood.

Even before buying or make a bath oven with your own hands, it is necessary to decide where and how it will be installed and how much space can be allocated for it. Since this largely depends the choice of its type and size. Only the correct installation of the furnace to the bath will make it, at a truly comfortable and safe place.

How to locate the oven in the bath

The most rational arrangement of the furnace in the bath is when it can be heated and a steam room and a place of rest and a pre-tribbon. It makes no sense to build several stoves for this, since it is not entirely convenient and requires high costs.

The most rational arrangement of the furnace in the bath is when it can be heated and a steam room and a place of rest and a pre-tribbon. It makes no sense to build several stoves for this, since it is not entirely convenient and requires high costs.

Of course, much here depends on the planning of the bath itself, and from the type of furnace and its size. So for the location of metal bathing stoves, the most suitable option can be considered the one in which part of the furnace with steam stones is in the steam room, and its front part, with a floppy door, goes into the rest room. In this case, both places of the bath will be heated. In addition, the process of the furnace will be carried out beyond the wage, which means there will not be trash from firewood, and the process itself can be carried out even when there are people in it, while nor slightly interfering with them to relax.

In the same way, you can arrange a brick oven, but since it takes more space and is built on the spot, the place under it must be chosen at the construction of the bath. Brick stove require a more reliable base. The foundation is best suited simultaneously with the basement device under the bath itself. If the bath consists of three rooms, the installation of the bath furnace is best done so that all these rooms outgoing from it, all these rooms are modeled for maintaining the necessary temperature in them.

Small-sized ovens, especially electrical, are often installed directly in the steam room. For heating other rooms, the bath in this case will require another source of heat. One of the options may be warm floors: water-connected to the water heating system or electric. Using water warm floors It is most advisable if the bath or sauna is within the house or in an extension to it, and the house itself is heated with the water heating system and there is a boiler power supply for connecting an additional circuit.

Deciding with the location of the location, it is also necessary to know how to install the stove into the bath is correct, given the rules of fire safety. In principle, it is easy to make it yourself, especially in the case of a small metal stove, but at the same time it is necessary to take into account all the nuances and the features of such an installation, which depend on both the type of furnace and the material of the bath itself. If the furnace was bought ready, then you need to consider all the requirements that are set out in the instructions for installing and operating. In addition, regardless of whether it was bought or was bought with their own hands, when installing it, it is necessary to observe general rules Installations that will allow conveniently and safely to exploit it.

Rules for installation of the furnace in the bath

Below are the basic rules that must be followed by performing independently mounting the furnace in the bath:

- Base. Bathing stoves of outdoor execution must be installed on a reliable non-aggravated base. It is best if it is a separate foundation from concrete or brick. Such a base should be smooth, horizontal and calculated on the weight of the stove. If it is installed directly to the floor, then in this place should be covered with asbestos sheet, a thickness of at least 12 mm and sheet gland, a thickness of at least 1 mm. The dimensions of such a coating should ensure the distance from the furnace case to the combustible material of the floor: from the heat door, at least 50 cm, from other sides - at least 3 cm.

- Distance to walls. The bathing door of the bathing stove must be located toward the door and not closer than 1.5 m from the combustible design of the opposite wall, and its side and rear surfaces are not closer to 0.5 m (for metal - not closer 1 m). It is best if the burnable designs of the bath in the furnace zone will be protected by a brick screen or sheet metal with thermal insulation material. The size of such a screen must exceed the size of the furnace at least 30%.

- Chimney. If the smoke tube is performed from the brick, in the places of its passage through the overlap, it is performed with the thickening of the wall to 25 cm, and in the place of the adjuncing the roof is insulated with sheet iron or special slats, depending on the roof material used. If the chimney is metallic, in the place of overlapping or walls from the combustible materials is satisfied with the cutting of sheet metal with filling with non-combustible material. To prevent the formation of condensate, the metal smoke tube, in the outer part of it, should be insulated or made of the "sandwich tube". But such a pipe cannot be installed immediately after the stove, first there must be a plot of a conventional tube from the heat-resistant steel. The distance from "Saintwich-Pipes" to the combustible structures of the bath should be at least 13 cm, and the usual metal - at least 38 cm.

- Ceiling over the oven. If it is made of combustible materials, its area above the stove, exceeding 1/3 of the heating device, must be protected by a metal sheet with thermal insulation layer of basalt cardboard or minit.

- Ground. If an electric furnace-heater will be used in the bath, then it must be grounded using a separate circuit, arranged in all the rules or circuit of the grounding of the house, if any. It is also desirable to use in this case a protective shutdown device (UZO).

- Isolation of a hot surface. To prevent burns from hot surfaces of the furnace (especially concerns metal structures) It is necessary to arrange a convection metal or brick screen around them. In addition to the issue of security, this screen allows you to more evenly heat the air in the bath and soften the thermal radiation from the heated metal surface. You can also, for this purpose, make a wooden fence around the stove, but at a distance not closer than 0.5 m from it. This will protect people from contact with a hot surface, if they slip.

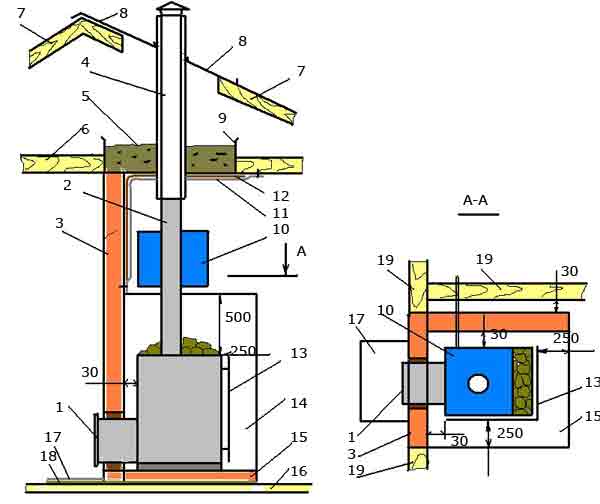

Fig.1One of the options for installing a metal bath stove with the supplied firebox in wooden bath: 1 - firebox; 2 - metal chimney; 3 - a brick wall with a thickness of 12 cm (1/2 brick); 4 - "sandwich tube" or ordinary insulated; 5 - filling the cutting of non-combustible material; 6 - overlapping; 7 - Wooden roof elements; 8 - metal adjoining sheet; 9 - Outlet of sheet metal; 10 - water tank; 11 - Screen made of metal sheet; 12 - heat insulation (minvat or other non-combustible material); 13 - screen providing air convection; 14 - screen (brick wall in 1/2 brick); 15 - non-combustible base (here a brick layer on the edge); 16 - floor; 17 - metal sheet; 18 - asbestos; 19 - wooden interroom partition;

Competent installation of the furnace in the bath provides for compliance with fire safety rules. Existing PPB standards negotiate the need for fire breaks, insulation of the walls adjacent to the body and the chimney pipe of the walls, as well as a non-combustible base for installation.

The best location of the stove is determined - safe and simultaneously providing uniform heating steam room.

In which place to put the stove in the bath

Several factors affect the choice of space for the bath furnace:- Construction type - installation of an iron bath oven with a remote furnace to a bath slightly limits the ability to choose a place to accommodate. Modern models are equipped with a telescopic fuel cell. If necessary, you can increase the length of the furnace, to fit the size under the thickness of the partition.

- The principle of operation - with rare exceptions, the furnace equipment for the bath uses the principle of air heating of the room. To ensure uniform heating steam room, the stove is installed in a place with minimal interference on the propagation of convection flows.

- Warming up efficiency - it is recommended that the heat chamber is as close as possible to the base of the floor. Such accommodation will provide an improved air flow and a uniform heating of the steam.

Some owners put a stove, deepening it by 10-15 cm., Which allows you to increase the heat transfer and the temperature of the heating of the sexual coating. The solution is characterized by efficiency. But, the installation of the furnace is significantly lower than the floor level, although it is possible theoretically, inconvenient. We will have to make a camaule of sufficient sizes to appear the opportunity to lay firewood in the furnace from it.

If you correctly install the furnace in the bath with a furnace from the pre-banner, it will be possible to simultaneously damn two adjacent rooms. For safety, the tunnel under the extended flue channel is made by 5-10 cm large in size. The gaps are filled with non-flammable insulation. After that, close with special linings, which are included with the furnace equipment.

A detailed mounting scheme of the furnace in a baker with a furnace from the pre-banker is described in the instruction manual.

Fire safety when installing a bath furnace

rules fire safety When installed iron furnace In the bath, they negate the requirements associated with the mandatory observance of fire gaps and measures aimed at preventing emergency situations.The housing and chimney pipe, during the firebox heavily heated. Over time, wood experiencing a constant thermal load is oxidized that it becomes the cause of ignition, even without the presence of open fire. For this reason, the requirements of fire safety during the installation of the furnace in the bathroom require compliance with three important rules:

- Provide safe distances between the furnace case and the walls of combustible materials.

- Install the oven on a non-flammable basis.

- Apply flame retardant material to reduce the thermal load on the walls located near the heated parts of the furnace.

Apply flame retardant material for furnace insulation and chimneys, prerequisite for safe operation.

Distance from the stove to the wall of the bath

PPB shows fireproof distances - ruptures that prevent possible fire. The standards indicate:- Between the housing of the furnace and the wall from the combustible material, leave the gap of 110-125 cm. After heat insulation, the distance is reduced to 50-80 cm.

- In the direction away from the opening door of the furnace chamber, minimum distance 120 cm.

Furnaces with a remote tunnel in the adjacent room, it is physically impossible to remove a sufficient distance. Therefore, the partition between the steam room and the pre-banker makes non-combustible material: Brick or GBL Plate.

How to install the oven on the wooden floor in the bath

The furnace in the bath is installed on the floor, at the level, as close to the base, or 10-15 cm below it. This rate is easier to observe if the foundation and place for the installation was prepared in advance.When concrete floorslined ceramic tilesThe furnace is installed without the need for additional protection of the base. Wooden floors will need to protect against fire:

Metal ovens have weight up to 80 kg. The rules for the installation of a metal bath oven on the wooden floor in the bath do not indicate the need for a complete foundation for mounting. Norms are aimed at defense wooden floors From fire.

What isolate walls around the oven

Heat insulation furnace OT. wooden wall, mandatory norm. The surface of combustible materials is protected in several ways:- Brickwork.

- Ceramic tile - you can bore the walls around the furnace, stitching them (in the case of wooden walls) pre-gypsum fiberboard (GVL).

- Thermal insulation material - for protection, special heat-resistant plates for wall covering or basalt wool are used. The material is fixed to the surface with hardware. The surface is closed with galvanized or stainless steel.

Mounting chimney in the bath

There are basic installation recommendations chimney. The flue gases temperature reaches 450-550 ° C. Normal metal pipe Shears hot.Safety standards negotiate that it is not enough only to isolate the furnace from a wooden wall, it is required to protect the surface in places of contact with chimney.

Necessarily envisaged fireborne cutting In places in passing the chimney through the slabs of overlapping and roof.

Metal bath furnaces have gained considerable popularity due to their relative cheapness and opportunities for self-assembly. We want to tell how to correctly install a metal oven in a bath, because it depends not only to the comfort of the unit, but also your security.

Steel has such properties:

- High thermal conductivity. Due to this, the unit is very quickly heated, and the temperature of the outer walls will be very high, which can lead to igniting or cutting air, as well as overheating around the surrounding items and building structures;

- Low heat capacity. With quick heating, the furnace also cools quickly, so it requires constant firebox for comfortable use;

- Reparatively small weight. This makes it possible to do without a massive foundation under the furnace, which reduces it and simplifies the process of installing the device to the workplace;

- Corrosion activity. Steel has a rust property, so it will not be superfluous to the additional processing of the device surfaces;

- Easy processing material. The furnace for a metal bath can be collected with their own hands using the angular grinding with cutting and credit discs, as well as the machine for manual arc power welding of medium power with electrodes;

- The price of the material is also relatively low, especially since the craftsmen most often use waste and used steel parts, the state of which allows the further operation of these parts.

Important! The listed characteristics define the basic rules of installation metal oven Bath. The presence of high temperatures on the outer walls and designs of the instrument requires special attention to pay fire safety, and also protect access to these places to avoid people's burns.

Advantages and disadvantages of metal models

Like any other device, the metal furnace for the wage has its own positive and negative qualities. To understand how to install a metal oven in a bath, it is better to know these qualities.

Let's start with advantages:

- The metal unit is quickly heated, so it does not have to wait a long time until the bath "takes out";

- The design of the furnace is quite strong and reliable, withstands mechanical and shock loads, high pressure and mass;

- Metal is a very heat-resistant material, so when overheated with it, nothing terrible happens;

- Metal surfaces are easier to clean and repair;

- The device of a metal furnace for a bath is relatively simple for self-assembly and repair;

- Relatively low cost of the device;

- Small weight oven;

- The tightness of the welding seams increases the reliability and safety of the device.

Important! All the above benefits are characteristic of furnaces collected according to the rules that contains SNiP, GOST and OTHER regulations. Otherwise, such a furnace can become a source of serious danger.

If we talk about flaws, then the main ones will be the following:

- High thermal conductivity and low metal heat capacity;

- Powerful aggressive infrared radiation of the external surfaces of the furnace;

- Danger of burning burns when contacting the parts of the device;

- Effect of airborne indoor;

- The presence of electrochemical corrosion of the metal;

- The appearance of metal aggregates is inferior to stone counterparts.

Important! Knowing the positive and negative sides of the metal furnaces, we can use advantages to the maximum and minimize disadvantages, applying some techniques and tricks when installing the unit.

Installation

Tip! Proper installation Bath furnaces requires the installation of the foundation. As we have already spoken, the small weight of the steel structure does not require a serious basis, as in the case of brick analogues, however, some preparation will be needed.

Instructions for installing the furnace will be given as a step-by-step manual for ease of use.

- In the selected place, we dismantle the floor on the plot, the same in shape with the bottom of the furnace, however, 10 to 15 cm wider in each direction;

- Digging the floor intake to a depth of 50 cm, the bottom of the pits are tamped and fall asleep with a thin layer of rubble and sand;

- We put on the bottom and walls double layer of plastic film for waterproofing plate;

- Cut from the road grid the frame, 5 cm smaller in width than the pit and lay it on the stands from stoves in the floor of the plugs of reinforcement tied to the grid knitted wire. You can use welding;

- Pour the pit to the level of submet to concrete or higher, and with the help of the vibroreke, align its surface. To raise the plate level, you can use a small formwork. Horizontality check the level;

![]()

- After rejection of the plate coating its surface with a double layer of runneroid and lay out chamoten bricks one or two layers on the shape of the plate surface, so that the level of the base is at the floor level. Sometimes the foundation is raised above the floor by 5 - 10 cm;

- After grapping and frozen brick masonry We establish the oven how it was provided for by the project;

- In the wall we mount the adapter in the form of a sandwich tube with welded plates, which close the wall near the chimney;

- To the adapter we weld the chimney pipe;

- From the side of the street we weld the second part of the pipe and cover it with a special nozzle so that there is no precipitation and garbage into the clearance;

- Fill the tank with water, in the prepared cobblestones and produce the first furnace;

- Watch that there were no smoke leaks from the places of welding and compounds, as well as water leakage from the tank in the furnace or on the stones, the cranes leaks, if any.

Important! The correctness of the installation of fire hazardous sites should check the experienced master of chimney or fire inspector, because this is a matter of not only the property, but also human life.

Output

Installation of the furnace in the bath is an important and responsible business, the correctness of which does not depend not only by the normal operation of the unit, but also your safety. Therefore, when performing work on the installation of furnace equipment, all rules and requirements of fire safety should be performed. How to do it, you can see on the video in this article, which we specifically picked up ().