The most common foundation in private construction is tape. The ribbon foundation is a monolithic ribbon of reinforced concrete, sprinkled around the perimeter of the house. As a rule, it is made monolithic. The foundation of this type distributes the load on the base throughout the area of \u200b\u200bthe house, which prevents its sediment and break.

In addition, it takes less materials for it and preparatory workAs allows you to significantly save on construction.

When operating, various loads can be affected, ranging from the weight of the structure and movement of soils to frosty powder.

To compensate for the fondamation of loads, reinforcements produce its reinforcement.

In its properties, concrete is very durable to compression, but it is 50 times less durable for stretching. Steel fittings gives the strength to concrete on stretching.

Styling and knitting fittings

For reinforcement, hot-rolled construction reinforcement of a periodic profile is used, thermally treated or mechanically hardened. For foundation, class A 400 reinforcement is used. The use of classes A 240 and 300 is unacceptable. Use for reinforcing the class fittings is higher than and 400 is economically not profitable and not advisable in terms of using the strength potential. The diameter of the armature is usually used 12mm for working longitudinal reinforcement, 6-8mm for vertical and transverse reinforcement.

Locked fittings need to be connected.

Let's find out how to properly knit fittings for the foundation.

There are several types of fittings. Most often it is knitting with knitting wire. Also apply welding and fastening with plastic clamps.

Wire This time has been tested by a reliable option.

For knitting, a wire treated by firing is used, the so-called burden. The burned wire is more flexible and durable than the usual, as well as more resistant to stretching. The wire diameter depends on the diameter of the valve. As a rule, 1.2mm wire is used for reinforcement with a diameter of 8-12mm, for thicker reinforcements take a thicker wire. However, the use of wire more than 1,6mm is not advisable as it is very inconvenient to knit it and it will be difficult to tighten it. Wire with a diameter of less than 1.2mm when tightening will burst.

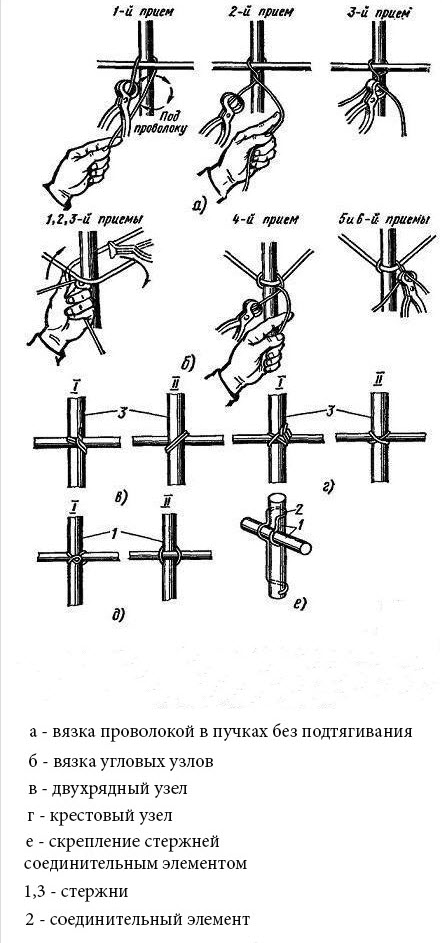

There are several ways to mating wire:

- Mating with reinforcement ticks;

- Knitting with a hook;

- Knitting with a drill with a nozzle;

- Knitting with a knitting pistol.

Hooks received widespread different species. There are simple with straight, curved, steel, plastic or wooden handles.

Hooks received widespread different species. There are simple with straight, curved, steel, plastic or wooden handles.

Also there are mechanical hooks in the handle of such hooks the spiral is embedded. When tensioning up, the handle slides over the helix turning the hook and makes a tight. There are many ways to work with crochet Here are some of them.

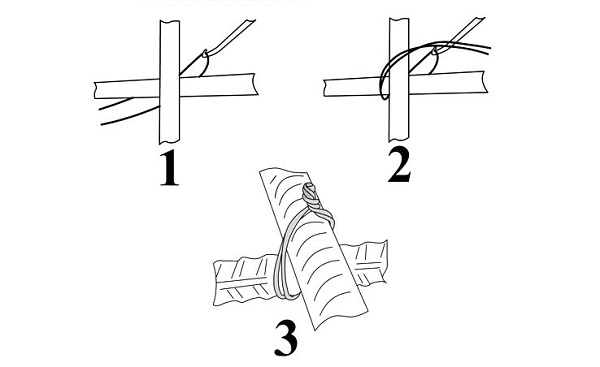

Method 1.

Cut the wire for the reinforcement with a diameter of 12mm, about 25mm long and fold in half. Next, we make a bend around your finger about one third. We do under the reinforcement and grab the hook loop. We put the second end on the sting, while pulling it on yourself, and begin to twist the hook. The number of revolutions is determined by almost. It is necessary to tighten well, while not breaking the wire. After the end of the tightening, pull the hook and bend into the inside the ends.

Method 2.

The wire is also folded in half pressed with fingers to the reinforcement, the ends bend the hook is inserted over and the tightening is made. After tightening the hook gets and the ends are bend.

Method 3.

The wire is also folded in half, it is done under the reinforcement, the loop is inserted into the hook. The second end is also embedded in the hook and bends down. I pull the hook on yourself and make a tightening.

This method is considered the most convenient.

Binding with plugs for reinforcement

Pliers for mating valves of reinforcement differ from the usual shape of the cutting part. They must hold wire.

Pliers for mating valves of reinforcement differ from the usual shape of the cutting part. They must hold wire.

The pluses of tick use is that there is no need to cut the wire. The wire is wounded into small machines and keeps in the left hand. Wire consumption is much smaller. It is with the use of ticks at construction sites, professionals knit reinforcement and claim that it happens twice as fast as with the use of a hook or pistol.

One end of the wire is valid under the reinforcement, is captured by the ticks the second end. Also embedded under the sponges, one or two turns are made. Surplus are dry.

Knitting with a drill with a nozzle

In the pursuit of the acceleration of the process began to apply a drill with a special nozzle. The nozzle is all the same hook. The inspection herself itself is faster, but the entire process is identical to the crochet, except for the watch. There are also minus drill application. Drill itself is quite cumbersome and not everywhere it can be brutalized.

In the pursuit of the acceleration of the process began to apply a drill with a special nozzle. The nozzle is all the same hook. The inspection herself itself is faster, but the entire process is identical to the crochet, except for the watch. There are also minus drill application. Drill itself is quite cumbersome and not everywhere it can be brutalized.

Knitting gun.

Allows you to increase productivity by 2-4 times. The feasibility of its use appears when it is necessary to produce large volumes of versatile fittings. Also, the plus can be attributed to the fact that all connections are tied with the same effort.

By the cons. We also consider it cumbersome as well as in a drill. And the need for consumables, special for a given pistol, or the need to charge the cassettes.

The technology of the work of all tools is identical to the wire mating on the valve. Accordingly, the choice of tool will be based only on your personal preferences.

IN lately Most builders began to pay attention to the recent plastic clamps that appeared. The advantages of clamps can be attributed to: ease of installation, the velocity, not a high cost.

Also on sale appeared - these are plastic clamps with a steel wire heart. They are more expensive, but more durable.

By cons can also include fragility in the cold and the inability to carry extra load. From frost, they immediately become fragile and burst.

Connection of reinforcement welding - This method has its advantages and disadvantages. The main disadvantage this method It is what needs to attract an experienced welder. The second disadvantage is the weakening of the metal at the welding points and the change in the plasticity along the entire length.

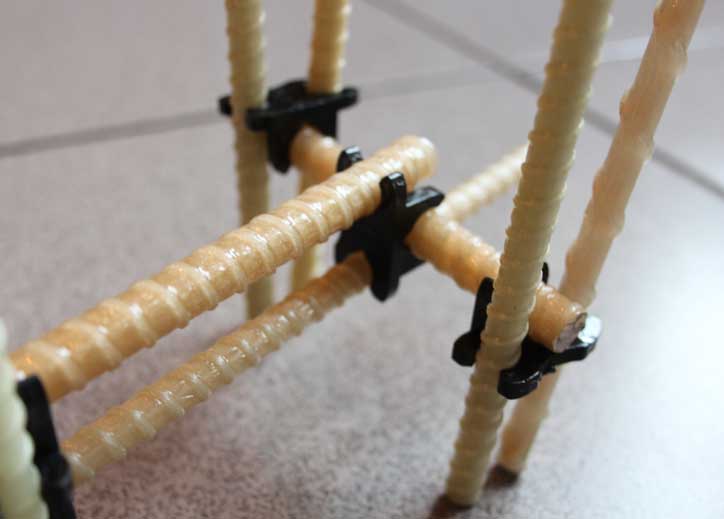

Fiberglass with respect to new Materialhaving, as well as the advantages and cons.

The advantages include low weight, corrosion resistance, high compressive strength and gap. Resistance to aggresive media.

By minuses include much less elasticity in comparison with traditional reinforcement, when heating loses reinforcing properties.

So how to knit fiberglass reinforcement for the foundation of the house?

The knitting of fiberglass reinforcements is particularly no different from the mating of the metal reinforcement, it should be noted that plastic clamps are used for these purposes.

In conclusion, I would like to note that the process of mating fittings is pretty much difficult, however, requiring attention.

In the construction of capital buildings and structures, it is almost impossible to do without the use of reinforced concrete structures.

These are foundations, overlaps, walls and more. The secret of the strength and durability of reinforced concrete is to apply the so-called reinforcement.

The fact is that a homogeneous concrete, like any material, is subject to change of volume depending on temperature.

In addition, the concrete itself has a rather low plasticity and tensile strength.

The use of fittings allows to eliminate the shortcomings of pure concrete and give it new positive qualities:

- Due to the same temperature expansion coefficient with concrete, higher plasticity and the strength of iron in the valve, the symbiosis of these two materials does not crack from the temperature drops and has significantly better strength characteristics for stretching (gap);

- With the help of the reinforcement, it is much easier to reliably connect several individual elements (blocks, panels, plates) and carry out loading and unloading, transport operations.

When appliances and foundations, as the most common types of base for the construction of private houses, under the bath, garage, in the thickness of concrete, laid designs made from reinforcement rods.

How to connect separate rods to each other, what principles must be observed to obtain a qualitative result from work - this tells about this.

Proper nipping reinforcement for belt Fundament It should provide such a connection of the elements so that they do not have the possibility of moving relative to each other.

Proper nipping reinforcement for belt Fundament It should provide such a connection of the elements so that they do not have the possibility of moving relative to each other.

If, for example, concrete on the reinforcement of irregular mating, its rods will differ and the desired strength of the reinforced concrete structure will not be achieved.

There are several ways to straighten the ribbon foundation reinforcement:

- With welding. Metal elements are connected in places of crosshair arc electric welding. Such a connection method securely fastens the rods, but for its implementation it is necessary for special equipment and a welder. In addition, many builders do not recommend using it in private construction due to the loss of metal strength at arc exposure. This method is not at all suitable for use with fiberglass reinforcement;

- Knitting wire, manually, with the help of a hook (it is not difficult to make it yourself) or an automated way, with the help of special pistols. Some masters accelerate and facilitate the bunch of a large number of compounds by inserting a hook from a metal rod into a screwdriver cartridge;

- Plastic tape clamps. This method is justified with a small amount of work and uncomplicated reinforcing structures;

- Plastic, steel clamps or brackets.

Manual knitting instructions

To reliably connect the reinforcement bars by hand knitted wire, you must perform the following steps:

- Cut the wire with a wire with a length of about 15-20 cm. Most convenient for knitting steel annealed wire with a diameter of 1.2-1.5 mm;

- Folded twice the segment of the wire skip the reserves of reinforcement rods, regenerate two ends on one side, and the resulting loop is on the other;

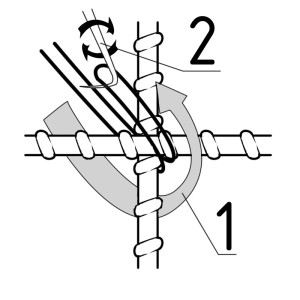

- Cross the loop and ends, start a twist with your hands, insert a metal hook into the loop and finish them to the needle to the necessary strength of the connection (the wire must make the rod tightly, but not be a tormented, on the verge of break).

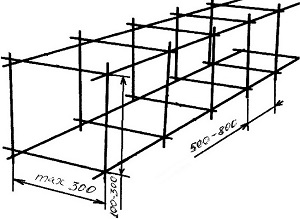

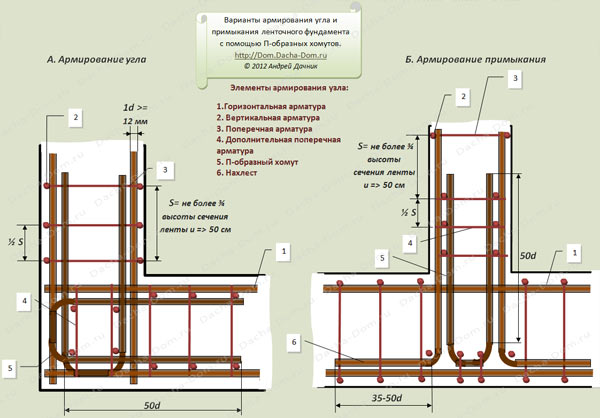

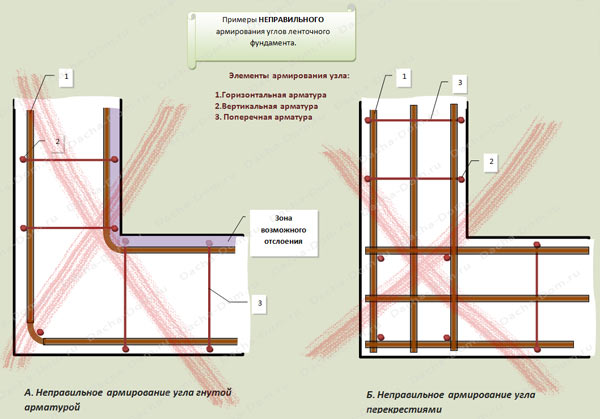

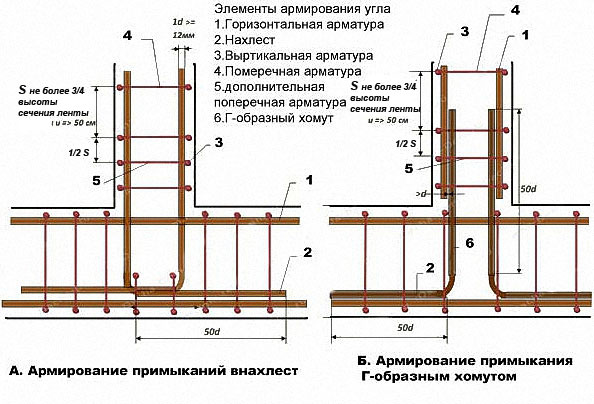

Fitting Matches for Ribbon Foundations

The armature for the belt foundation is associated, as a rule, in the form of bulk box designs. The diameter of the rods, the distance between the rods in horizontal rows and vertically is calculated, depending on the size of the foundation and is indicated in the project.

The armature for the belt foundation is associated, as a rule, in the form of bulk box designs. The diameter of the rods, the distance between the rods in horizontal rows and vertically is calculated, depending on the size of the foundation and is indicated in the project.

But, in any case, it is impractical to place the rods closer than 20 cm and further 40 cm among themselves horizontally and less than 15 cm vertically. The location of the rods and the correctness of the mating affect the strength of the foundation.

Tip! If you have decided to carry out a ligament of fittings ribbon base Alone, be sure to consider the rate of SNiP, according to which the minimum number of reinforcement is 0.1% of the area of \u200b\u200bthe foundation section.

For, as a rule, a greater number of reinforcement and concrete is required, due to the lower depth of the attachment. The diameter of the rods for the mating of reinforcement of such a foundation should not be less than 12 mm.

One of the most common options reinforcement carcass For a belt foundation - four lattices, of which the edges of the rectangular box are formed. The box is placed inward and installed on a stand height of about 10-15 cm.

The height and width of the parties are calculated so:

the total height (width) of the ribbon is minus 20 cm (10 cm on top and bottom, right and left).

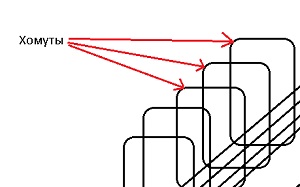

Another option - pre-rectangular rounded rings are connected by long rods around. The transverse dimensions are calculated similar to the first option.

Another option - pre-rectangular rounded rings are connected by long rods around. The transverse dimensions are calculated similar to the first option.

The third option is the most durable, but the most expensive. Armature is located in the image of a rectangular crystal lattice.

This method is a reinforced variety of previous ones. This option is used in the foundations for heavy, brick walls multi-storey houses.

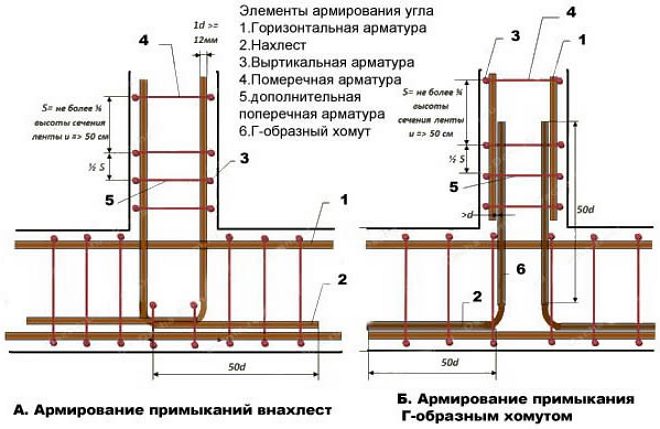

If transverse tapes are adjacent to the total ribbon of the perimeter of the house (for carriers inland walls), then the armature of them "Boxes" Tied to the perimeter bar.

Link of fiberglass fittings

Fiberglass recent fiberglass is increasingly distributed. It is cheaper and easier steel.

Fiberglass recent fiberglass is increasingly distributed. It is cheaper and easier steel.

Pants fiberglass has the best strength characteristics, despite the fact that they are deprived of the main lack of steel - corrosion exposure.

The mating of this modern reinforcing material is made according to the same rules as steel.

To use non-metallic reinforcements, the mating schemes without the need to benty rods at large angles are chosen, since the fiberglass is difficult to anticipate, not breaking, it does not preserve the desired shape.

For work, you can use traditional knitting wire, but it is better to use specially designed clamps from cast polyethylene with fiberglass.

From the following video You will learn how to knit fittings under the foundation:

Any reinforced concrete elements of the house, for example, the foundation, jumpers of windows and doors, overlap, are the main elements. They provide reliability and durability. The main role in such structural elements is performed by the compound of metal frames with the help of knitting wire and reinforcement. How to knit fittings under the foundation-made hands can understand almost anyone, not even having concepts in construction. And to understand how it is done is simply necessary, because The assembly of fittings for the foundation is one of the main stages in the construction of the house.

2.

3.

4.

5.

6.

7.

Features of mating fittings. Why it is important to connect manually

Builders' professionals do not advise welded joints during the manufacture of metal frames of foundations. This is due to the fact that over time, corrosion will be formed in places of welding. The guarantee from this disease will be the implementation of compounds using the mating of reinforcement.

All the work during the device of metal frames foundations must be performed in accordance with existing construction standards and technologies. A well-completed assembly of reinforcement with their own hands will increase the strength and reliability of the foundation or jumpers. For the durability of the foundation, do not forget to hold it. Armature, which fit in one frame, will actively resist various loads and significantly increase the compression zones of concrete.

Required materials for mating

Directly for the mating, you should choose the valve of a certain diameter and length. The recommended dimensions are not less than 6 mm in diameter and 6 meters long. What diameter you choose the rods will directly influence the strength of the entire structure. Of course, the larger diameter applies fittings for mating, the stronger the framework. The market presents a variety of reinforcement products - smooth, with edges, notches and ribs. It is worth saying that an uneven surface will provide a higher adhesion with a fill in concrete.

The assembly of the valve is performed specifically for this designed metal wire or plastic clamps. The wire thickness is chosen depending on future structures, but usually applied to 1.2 mm. Similarly, clamps are selected - up to 40 mm in diameter.

Types of compounds

Knitting the reinforcement for structural elements of buildings can be both in horizontal and vertical position. For household construction, mainly horizontal reinforcement is used. With this position, the load on the foundation monolith is effectively distributed. The frame is performed from the rods in 25-30 mm.

Technology mate

In order to qualitatively and most quickly performing the connection of metal parts, you need to prepare reliable special nippers. For monolithic foundations Simple nodes that can be made both with pull-up fittings and without pulling up. The wire is dragged in places of crossing rods, by twisting with pliers.

During independent fill foundation A special gun for mating can be useful. He will definitely help save both time and labor costs. With it, all manipulations on the connection are performed in semi-automatic mode, on average 5 times faster.

During work, all extreme intersections must be associated with necessarily, and all other compounds are in a checker order. At the first stage, it is necessary to lay the trunk rods that need to be set on one level from the base of the foundation. Alternally, the main jumpers are installed. Under them are installed longitudinal elements and knit to the transverse one.

For the manufacture of structures that are carriers, specialists do not recommend applying fittings and wire used or with rust.

It is also not recommended to grow an existing related framework. This is especially true of those elements that will be especially loaded. Any addition to be sure to calculate and produce brass and with additional nodes.

How to knit fittings? It is this question that arises from those who are going to increase the reliability of the foundation designs and make them more resistant to non-characteristic loads. Concrete characteristics, which is actively used for the manufacture of various construction systems, allow it to successfully resist compression loads. However, this material and designs are very sensitive to stretching and bending, which they can be regularly subjected.

Methods for connecting reinforcing elements

With the help of fittings consisting of metal rods, a power frame is formed in the foundation, which for its geometry resembles a cell. Such a reinforcing cell, as a rule, consists of a minimum of two horizontal layers, including both horizontal and vertical jumpers.

In order for the reinforcing frame, consisting of separate metal rods, has the required reliability, it is necessary to properly connect all its elements. If they are not fixed accordingly, the entire reinforcing design may be exposed to the deformation under the influence of the mass of the filling concrete or due to the loads affecting the entire construction system.

Knitting fittings must be performed in places of crossing metal rods, as well as in those areas where they cross each other at their length.

For the foundation can be performed in several ways. The choice of concrete of these options depends on the required reliability of the reinforcement framework and the conditions for its creation.

Clamps from polymeric materials

The assembly of fittings for the foundation can be performed using clamps made of plastic. This method is the most advanced and does not require special preparation of materials. It consists in the fact that the reinforcement rods are manually associated with plastic clamps, connecting them in those places where they intersect. The material from which such a clamp is made is not subject to corrosion, therefore the mating made with its help is obtained very reliable.

Binding of reinforcement with welding

Often, welding is selected as a method of mating fittings. However, you should know that you can weld among themselves only the reinforcement rods, in the marking of which there is a letter "C". In such situations, point welding is usually applied.

It should be borne in mind that this method of compound will require the use of the welding machine, as well as the availability of experience with such equipment. In addition, welded joints are very poorly withstanding vibratory loads arising from the use of sealing devices, as well as devices with which air bubbles are removed from concrete.

Fixation of reinforcement elements with wire

Most often bid reinforcement elements Performed with wire. This method does not require special skills and makes it possible to achieve the required parameters for the reliability of fixation. Solving the question of how to tie the reinforcement, most often choose this method of fixation.

This knitting is performed very simply: the reinforcement elements are fixed with the wire, which is then delayed and reliably connects all parts of the structure.

For mating fittings, the wire is used by a special crochet, with which you can get connections in various schemes. Such schemes differ in the wire spinning method.

Wired reinforcement compound technology

Before knit fittings, it is necessary not only to see the corresponding video, but also to properly prepare the connected parts. Such preparation is as follows:

- cut a piece of wire with a length of 20-30 cm, but you can more accurately determine the necessary length you can, when you put the mating of several parts of the reinforcement;

- roll down the sliced \u200b\u200bpiece twice;

- wrap the location of the compound diagonally diagonally obtained by the harness;

- the curved end of such a harness is put on the bar of reinforcement, the second end also lock on it;

- manually, or taking advantage of the crochet, tighten the ends of the obtained wire loop.

Mechanization of the process

The most common way to mechanize the process of mating fittings is the use of a special hook. Such a hook is easy to make it with your own hands, for this you can use a piece of reinforcement, which on the one hand bends the eye (for the convenience of rotation), and with the other, it is slightly strung and sharply sharpened. You can see the process of manufacturing such a hook on numerous videos posted on the Internet.

How to knit fittings for foundation with such a device? Everything is very simple: it is enough to put the sharpened end of the hook into a wire loop and rotate it to a tight twist.

How to simplify the process

If aimed at simplifying the mating of the reinforcement elements is to simplify, then the power tool can be used for this. This task is solved quite simply: an ordinary screwdriver takes, in the cartridge of which a bellged nail is installed. Such an easy device will allow you not only to correctly connect the reinforcement design, but also to ensure its required reliability.

There are also even more convenient ways, but for their implementation, a special tool will be required. Such, for example, as a gun for mating fittings. Similar equipment is quite rarely available when independent constructionBut, having it at hand, the process can be accelerated at times. The convenience of such a tool is difficult to overestimate, however its value (from 35 thousand rubles) disfixes many private developers who save funds above speed and convenience in carrying out vehicle versatile.

Favoric builders can be understood, since in most cases this tool will only be needed once, and spending money on his acquisition is impractical.

(Votes: 2

, average rating: 5,00

out of 5)

The assembly of fittings is a very important stage in the process of obtaining reinforced concrete, and it is precisely how this work will be performed qualitatively, the characteristics of this composite material will depend.

1

Construction often use concrete structures, because they are very resistant with compression loads. However, the same conclusion cannot be done if we talk about the resistance of such products of stretching stresses, and in order to improve this property, concrete should be reinforced. A special frame poured with a solution made of reinforcement reinforced concrete.

True, someone may argue that it is irrelevant to strengthen it, since the tensile stresses rarely act. But this opinion is erroneous, because if you take, for example, a concrete beam and try to bend it, then on the inside it will shrink, but with the external already stretched. Accordingly, the probability of destruction occurs. And now, the reinforcement significantly improves the characteristics of the reinforced concrete, thereby increasing its service life. The whole design becomes more reliable due to the increase in the compression zone, as well as active resistance A variety of loads.

Metal rods are mainly used for mating reinforcement, it is less common to make products from other sufficiently strong materials that are able to withstand a large pressure. Connect them between themselves so that the grid is. During the frost, the solution expands and more tightly adjacent to the ponds located in the volume, thus it turns out a very reliable connection. That is why in no case impossible as reinforcing elements, use hollow structures, since in this case they simply suck under pressure and will not be easy to fit enough to concrete.

In general, every novice master, even if he builds his own home, and does not work on a commercial facility, it is advisable to read generally accepted regulations For construction, when assessing fittings are planned, SNIP 52-01-2003, for example. This will allow, even without deep professional skills, at least correctly pick up materials and get a reliable frame for filling with concrete.

If we talk about the foundation of the house, then in this case, rods made from basalt fiber and fiberglass are suitable. They relate to composite materials and are distinguished by magnificent strength, while working with so much easier, as it is easier metal. Its inconsistency of corrosion is also of its indisputable advantages, so it is very important to apply it in the waterproof medium.

What about the sizes of the rods, they are also of great importance and directly affect the strength of the frame. They take a rod with a cross section of more than six millimeters and a length of at least six meters. The diameter of the wire for mating valves of reinforcement is usually from 0.8 to 1.2 mm. If you plan to make connections using special clamps, their diameter is up to four centimeters. In addition, the valve may be different in design. To date, a smooth, with different notches, ribs, or edges. All of them are popular, but it is worth considering that the smooth surface will have where less degree Adhesion with concrete compared to uneven.

2

Many wonder what is better - knit fittings or cook? In principle, the second option is quite acceptable to create a frame, because, in fact, it is formed a detractive connection, and may even seem at first glance that this method will be more reliable. However, this is not quite true. Experts are not particularly recommended to connect in this way. First, the welding seams are more susceptible to corrosion. Secondly, with such a design, longitudinal reinforcement has less strength when exposed to tensile stresses. Thirdly, special equipment is needed. Well, fourth, you need to hire a professional welder, of course, if you yourself do not have similar skills. So this process is very difficult.

Remember, it is very important that the rods are perfectly fixed and have not changed their spatial position. This can be achieved using high-quality burned wire, as it bends greatly, it has such a property, like drig, and fits tight to the reinforcement. So the obtained nodes will be strong, reliable, and, accordingly, the framework will be posted and the framework.

3

In principle, this process is not so complicated, and almost everyone can cope with it, especially if it is competent to choose a tool for mating fittings. So, if you knit barbell with steel wire, we will need a Bulgarian, which can be immediately cutting into pieces into pieces of the desired length. Of course, no one forbids cutting metal scissors, but then this stage of work will strongly delay. And so you need to just take the wire, bend it in a thick bundle so that it seems to cut a certain length, and the folding of the bend is cut off with a grinder.

It is twisted with ordinary passages or with a hook. In the second case, the work will be much easier and will go much faster. If there is a desire to mechanize the process at all, then a special building screw knitted hook should be purchased. Certainly change the position of affairs will be able to power tools, for example, with the help of an ordinary screwdriver it is also possible to knit reinforcement, and the physical force in this case is not necessary to apply it, it is enough to simply press the button. There is a professional gun for mating, however, he is quite expensive, so if you do not intend to earn in this way to live, then it makes no sense to buy it.

4

There are several ways to connect valve reinforcement. So, you can make twists with the help of pliers, then you need to take a piece of wire (its length is usually about thirty centimeters), bend it in half and throw a loop around the rods. Driving ends, you will get a sufficiently good connection. True, this method is very laborious. Consider what is a scheme of mating fittings with a knitting crochet. By the way, it can be used to be in the store, and do it yourself from the wire or the welding electrode with a diameter of 4 cm.

To automate the process, this hook should simply insert into the cartridge of the screwdriver, and then the rotational movements will be played by simply pressing the button.

Option number 1. Having reinforced the wire in half, bend it one-third from the loop around the finger and we throw the junction of the rods. Then, sketching the loop on the hook, we make a twist, while the second end must be pulled on yourself. After everything is securely fixed, take a hook, and the ends bend, if they were too long, then they should be trimmed with metal scissors. At the same time, consider the insufficient length of the wire or a small number of revolutions will negatively affect the connection strength.

Option number 2.. In this case, the twist will be more reliable. Folding the wire, everything will also in half, it is necessary to lean it to the reinforcement below. Then, bending over yourself, twist with the same hook. It is enough to make only 4 turns.

Option number 3.. As in the previous schemes, we make a loop and bring it under the reinforcement, and then grab the crochet. At the same time, the other end should be passed through the hook in such a way that another loop is formed and twist.

Remember, only understanding how to properly connect the reinforcement, you can count on a high-quality reinforced concrete structure. If you first start this operation, do not hesitate to show the option to someone more experienced, even if the forum is on the Internet. It is better to listen to constructive criticism and tips than to reap the fruits of destroyed w / w designs in the future.