"Heart" of any bath is a furnace, so its device should pay special attention. Of course, the easiest way to buy a finished design, but it will be quite expensive, so you can save and make the stove yourself. In this article, as an example, we will look at how the horizontal bath oven is performed from the pipe with your own hands, as this is the easiest and most economical option.

General

Feature bath Furnace It is that it performs several functions at once:

- Heats in rooms air;

- Heats the water that is needed for hygienic procedures;

- Heat stones.

It must be said that according to the principle of work, the bath furnaces made with their own hands from the pipe and the factory structures are no different. Of course, more functions may be present in factory products, and they have a more attractive design.

However, with a careful performance of work, the homemade furnace will adequately cope with the tasks set before it, and will not disappoint its owners.

Pipe furnace

Design

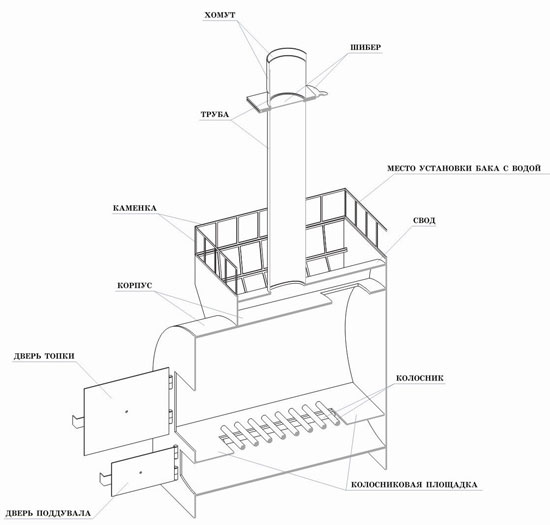

So, the design under consideration consists of the following main elements:

- Firebox;

- Capacity located outside or inside the case intended for bath stones;

- Ash bar camera;

- The chimney pipe that displays the combustion products of fuel beyond the premises.

Cameras are separated from each other with grate-grates. It should be said about such an element of the design as a water heating tank. In some models, it represents a part of the furnace housing, but more often is located above the chamber with stones.

There are also models in which the tank is a separate element, but connected to the furnace hoses or pipes ().

Homemade bath stoves are horizontal and vertical. The first is preferable for the reason that they leave longer and at the same time can quickly warm the room. Therefore, then consider the manufacture of exactly the vertical design.

Dignity

Of course, the bath furnaces from the pipe are far from the only design option that can be performed independently, but they have a number of advantages, among which the following points can be distinguished:

| Good resistance to high temperatures | Due to the properties of steel. |

| Ability to quickly warm the bath | Even the most simple homemade stoves Can warm the bath for 40-90 minutes (time depends on the ambient temperature). |

| Easy mounting | Unlike brick structures, Metal oven will be able to collect any person who can handle the welding machine and another metal tool. |

| Low price | Purchase of materials will not require strong costs, and if there is a suitable piece of pipe in the farm, the furnace will cost almost free. |

| Durability | If the design is performed efficiently, it will be able to serve not one dozen years. |

| Small weight | Due to this, the construction of metal does not need the construction of the foundation, unlike a brick analogue. |

disadvantages

Along with the advantages, metal products have disadvantages, however, there are only two of them:

Tip! In large baths, experts advise several stoves, which will avoid uneven warm-up.

Making a furnace

The instruction on the manufacture of a horizontal furnace looks like this:

- First of all, it is necessary to prepare a pipe with a diameter of at least 0.5 meters and about 0.8 meters long. The edges of the pipe must be carefully aligned.

- Then, from a metal sheet, a thickness of 10-12 mm is needed to perform a grain pad, which is a rectangle of 80x40 cm. In the site you need to cut a hole and attach the rod to it or use industrial grate.

- When the gratepoint is ready, it must be welded to the walls inside the pipe. At the same time, it is necessary to ensure that the seam of the pipe is under the platform, which will increase the life of the product.

In the photo - grille-grate

- Face walls should be made of sheet metal. Externally, it should be a rectangle with rounded riding. The height of the details should be 70 cm, and the width is 60 cm.

- Next, in the facade, you need to cut two rectangles - it will be the doors pondered and the furnace chamber.

- After that, the rear wall is performed in the form of a rectangle with a size of 70x90 cm. The upper part of the wall will serve as a limiter for the heater, which is located outside.

- Then you need to weld to the pipe facade and the rear wall.

- Next, in the middle of the pipe (outside), it is necessary to weld the front limiter of the heater, which should be revealed to the bottom of the pipe, and from above - the contours of the rear wall.

- In the upper part of the case, you need to cut a hole with a size of 15x15 cm. Above it is mounted with a leaf of sheet metal furnace with a chimney hole. Moreover, the hole must be shifted by 10-15 cm for the facade, which allows for the conditions of complete combustion of fuel.

- The field of this is a smoke trumpet.

- Next, to increase the walls of the height, the lattices with a height of 15-20 mm are welded to its limiters.

- The next step is to mount the doors of the ashtar and the furnace chamber.

- To the rear of the product you need to weld the shelf for the water tank. The size of the shelf depends on the size of the tank.

- At the end of work, the design needs to be treated with grinding circle to clean from rust and scale. After that procedure, the product can be covered with heat-resistant polymer paint and protruding so that the paint is baked (the procedure is performed outside the room).

Tip! Before proceeding to work, you need to make sure that the pipe for the bath furnace is high-quality, i.e. No signs of corrosion. The quality of the future product depends on it.

On this work on the manufacture of the Bath furnace completed. Now you can install the product and operate it.

Output

Recommending how to make a bath oven from the pipe, it's not really difficult to cope with this task. Moreover, the product will be safe and with a fairly high efficiency. The only one, to fulfill all the actions described above, must be carefully without disturbing technology ().

From the video in this article you can get additional information on this topic.

The easiest and most economically favorable way to cook the furnace for a bath is to use the usual cut steel or metal pipe. And cheap, and angrily. Such a furnace will function to fame, because its hermetic case will provide 100% security of a vacationer in a man's bath. Yes, and special fences are not needed for it, which is also its undoubted plus. And it is not difficult to make it - the case is just a few hours.

How to equip a place in a bath for such a stove?

But first, it is necessary to take care of the foundation for such a furnace - it is better to make it from concrete, 25-30 cm high. As soon as the foundation serves, it is possible to start laying out the area 70x70, from the brick in a row or two rows only on the clay solution. For this, the red or refractory brick. As a result, the edge of the site will rise above the floor by 15-20 cm.

It will be necessary to protect the walls of a wooden steam room from the strongest heating - protective screen From bricks on edges linked by clay mortar. Its height should turn out at least 1 m 20 cm, and the stove for the bath from the pipe will be at a distance of 20 cm from the screen.

Installing the already welded stove from the pipe to the bath must respond to fire safety techniques

Technological features of assembly and welding

For the manufacture of this furnace, such parts will be needed: a pipe 1.5 meters long and 0.5 meters with a diameter. The metal thickness should not exceed 1 cm so that the future stove does not warm up too long.

So, the pipe should be cut into two parts: 0.6 m and 0.9 m. The larger segment will go to the installation of the firebox and heaters, and the smaller will be used as a water tank. Now you can make the stove itself to the bath from the pipe:

- Step 1. At the bottom of the pipe is made a neckline for pondered with parameters: 18-20 cm wide and 5-6 cm of height.

- Step 2. Over the confusion it is necessary to mount with the welding of the steel round plate 1.2 cm thick.

- Step 3. Part of the metal must be cut in order to fit the chimney in the confusion. And to secure the latter, in the corners you need to fix four special "ears" - with the help of the same welding.

- Step 4. A niche for firebox is cut into the pipe and the door is made. For which a piece of metal with dimensions of 25x30 cm should be mounted on hooks or loops and make a latch.

- Step 5. Over the alloy, it is necessary to fix the segment of the pipe 30x35 cm is the future Kamenka. It is necessary to arrange it so that the bottom of the tank from its top was at least 10 cm. After that, the rear wall of the pipe should be completely brewed, and on the front to make the door 25x30.

- Step 6. In the ready-made height on half of the volume, you need to fill with cobblestones. And so that they do not fall out, it will not hurt to privar special steel bar for fencing. Of course, you can, of course, make another design of the heater, welding right above the furnace grille from steel rods, and placing stones already on it.

- Step 7. At the top of the furnace, the clutch from the steel tire is 5-7 mm thick, and a width of 50 mm. Half clutches need to be welded to the furnace housing, and the second half is the one that performs above the furnace - use as a detail for tank mounting.

- Step 8. To the ends of the finished tank for hot water From the bottom you need to secure the welding circle of 8 mm thick. It is necessary to cut in advance a hole for the chimney - 12-15 cm. After that, the lower side of the smoke pipe must be tightly fixed to the bottom of the tank - so that the water is not able to flow into the furnace.

- Step 9. Top The tank now should close the special semicircle of steel and make a hole for the smoke pipe in it, and welcome it to it. But the third part of the top of the tank must remain open to the water bay - it will be necessary to make a cover with a handle separately to closing it.

- Step 10. Now on the chimney it is necessary at a distance of 30 cm from the tank to weld the steel platform with a size of 30x30 cm - it is necessary for mounting the pipe with a valve.

![]()

Illustration to the technological stages of the furnace welding

Strong, durable and budget furnace for the bath is ready! It remains only at the bottom of the tank, just opposite the hole for the bay of water to make a tap with a valve.

This type of such type is simple and reliable metal stove For a bath from the pipe can be made. By the way, the volume of welding works in this case will be much smaller than in the manufacture of a furnace of direct metal sheets.

It is important here in advance to test the corrosion damage to the pipe and take into account how long the pipe itself was on the street in the open sky. And all the problem areas is important to privacy in advance by "piping", or directly in these places cut the stoves - also the option.

But it is the most simple design Bath furnace from the pipe, and folk crafts make such options:

How not to make a bomb from this stove?

Main elements

pipe stoves

No matter how it seemed ridiculous, but from the pipe, you can not only make a stove for a bath, but also a real bomb. This happens due to the fact that in the process of welding, gross errors are allowed. For example, if the bellarge of the future oven is too strong, for which it is necessary to make a valve in advance in smoky pipe, Moreover, mobility.

Secondly, it is important to prevent possible fire from the soot, especially the large number of it. And for this you need to equip the stove, if it is horizontal, by the horseman: at the top of the pipe, the horizontal tray is boiled in the top of the tube - on the floor of the stove. Further, almost at the top of the pipe, separating the main chamber from the entrance to the pipe, two holes are made in the wall of the stove itself. And so that they do not smoke, they need to be made by tubes, a little curved towards the pipe. This is such a simple design will add oxygen and will help burn all combustion products, significantly reduced the deposition of soot.

Banning construction plays a significant role in the list of joys and pleasures of most country house owners. In turn, the bath is simply impossible to imagine without a furnace.

Based on the experience, the easiest and economical option is a metal furnace for a bath from the pipe, while it is quite simple to make bath stoves from the pipe with your own hands.

The main thing is:

- decide on the location of the future stove;

- make a plan of action;

- stock needed.

Following the advice of professionals, it can be proceeded to the manufacturing process, which we will professionally try to explain and consider in more detail in the video in this article.

Preparation for work

Before starting the manufacture of the furnace, it is necessary to hold a number preparatory work . It is necessary to approach the preparatory stage with maximum seriousness and responsibility. First you need to find high-quality material for construction and purchase required tools.

Tools

For the assembly you will need the following tools:

- Welding machine;

- Electrodes with diameter 4;

- Bulgarian;

- Talco chlorite, to fill the heater.

Material Metal

It is very important at the preparatory stage to choose the right quality material, as the durability of the entire structure will depend on this. Price on making material homemade stove quite acceptable.

Metal material

- Wheels wheel;

- Sheet iron thick;

- Armature diameter;

- Sheet steel;

- Pipe diameter;

- Cooper

- Shikold for the door;

- Chimney pipe;

- Crane for hot water.

Construction material

- Brick;

- Cement;

- Crushed stone;

- Sand;

- Gravel, for the manufacture of the foundation pillow;

- Tree, for formwork;

- Ruberoid, for waterproofing the foundation;

- Capacity for mortar;

- Emery tools.

Furnace construction work

![]()

The process of construction of the furnace does not require any special experience and professionalism, but, in any case, a clear execution of the instruction and attentiveness to the details when laying and installing the furnace is extremely recommended.

Building foundation

At the initial stage, the stove for the bath from the pipe - with his own hands requires the construction of the foundation with the parameters of the height of 25-30 cm for the furnace.

For this:

- We bring up a formwork measuring 1x1 m and with a height of up to 20 cm;

- Put the reinforcement into one layer along and across squares 20x20 cm;

- In places of connection, the reinforcement is fasten with each other knitting wire;

- In the ground along the edges of the lattice, we drive 4 pieces of reinforcement, to which we bring the lattice on the weight;

Note!

When pouring the lattice should be found in the middle.

- After two weeks after the fill, you should open the doors and windows in the bath and the flooded foundation to put the wet segments of the fabric. This is done to avoid the formation of cracks when the foundation is drying.

Tip!

Washing rags follows for two weeks.

Preparation and assembly of the furnace

First you should cut the pipe in half. The longer cut of the pipe will be required to install the firebox and heaters, and the other for water tank.

![]()

Now you can proceed to the manufacture of the room.

For this:

- The bottom of the pipe is cut out the hole for pushed 18-20 cm wide and 5-6 cm high;

- Over the confusion, weld the steel plate of a round shape with a thickness of 1.2 cm;

Note!

In order to put the grinding part of the metal in the confusion, the ears are welded for fixing the grinding the corners.

- The pipe is also cut a hole for the furnace;

- For the manufacture of the door, a piece of metal 25x30 cm should be mounted on a loop and adjust the latch;

- Kamenka in the form of a segment of a pipe with a size of 30x35 cm, fix over the furnace so; so that the distance from the bottom of the tank to the top is at least 10 cm;

- Then the rear wall of the pipe is brewed, and in front do the door of 25x30;

- Kamenka is half filled with cobblestones;

- Fix the coupling from steel thick up to 7 mm in the top of the stove;

- To the hot water Baku welded from the end of the 8 mm circle, with a throat-cut hole for a chimney with a hole;

- Smoke;

Note!

1/3 From the area of \u200b\u200bthe top of the tank should be open to the bay of water, for its closure, a separate cover with a handle is attached.

- For mounting, weld the steel platform with an area of \u200b\u200b30x30 cm and at a distance of 30 cm from the tank.

After assembling the furnace, we proceed to its installation.

For this:

- The base is completely laid out with bricks completely from brick;

- The second row begins with the masonry pondered;

Note!

Usually thoughtfully open before melting the furnace, while its length should be slightly less than the very mine of the combustion

- Next, the door is installed and the next row is stacked on top;

- In the top of the mine pissed by putting a grace;

- We proceed to laying the furnace, after the grace, lay out two rows of bricks, leaving the place under the door of the furnace;

- After that, we laure the door, and put the last two rows;

- After laying for two weeks, the furnace should dry.

Note! The top of the metal chimney is strengthened by two reinforcements for rigidity, for this, fittings weld to the pipe and fixed on both sides.

Additional furnace collection options

It is worth noting that homemade stoves for the bath from the pipe are of various forms.

There are many embodiments of the design, for example, a bathing stove from the pipe with your own hands with a built-in heater during self-assembly of the design you need to carry out the following actions:

- Bottom cutting hole for a grace with a length of 335 mm wide 180 mm;

- Next, rods or an iron strip are brewed at a distance of about 1 cm;

- Separately, a box of 3 mm of leaf iron is 600x140 mm in size.;

- After welding, the box is covered slag;

- Door welded to the slag;

- In the pipe 525, the plugs are cut out, that is, the sidewalls on both sides for this pipe diameter is divided into two and with the help of a circulation, two circles are drawn.

Another option is the homemade stoves for a bath from a metal trumper by a large stone.

For this:

- At the top cut holes for chimney round shape with a diameter of 110 mm., Other square under the heater of 300 mm in size is 250 mm.;

- To control the symmetry of the design, the level is used;

- Next is made niche for stones. To do this, cut out of 5 mm of iron sheets of the size of 2-pass in size of 270x300 mm., 2 hours of 270x250 mm. And one part of 250x300 mm.;

- All items are welded into a square box;

- the seams are abundantly disappeared by kerosene;

- From the sheet of iron in 5 mm, the partition for the furnace mine is cut;

- The next step is to install the bottom pondered below;

- Then close and becoming the cooler;

- At the end to the furnace and the doors are welded to the chimney hole;

- The legs are welded, and the furnace is installed on a pre-prepared place prepared for her;

Tip! The floor under the infancy should be made of non-flammable material.

Finally

Many country houses Today is simply unthinkable without a bath building. Each newly suitable owner of private ownership is sooner or later thinking over the construction of his own bathhouse and the manufacture of stoves for it with their own hands.

According to the advice of specialists, the perfect option is the self-made furnace for the bath from the pipe.

To do this, it is necessary to carefully observe all the nuances, the instruction described in our article will help in the process of assembling and installing such a stove. In conclusion, we wish you - with a slight steam!

Do with your own hands - it is half an end. After all, for a good pair you need a good oven. It turns out that it is not necessary to spend big money on the purchase of fire. After reading the simple drawings and video instructions, you can make it with your own hands. As a material, you can use the simplest tube.

Stoves-benches: We make equipment for the bath yourself

It turns out to make a bath oven, it is necessary very little time and resources. The main desire. In the middle of the craftsmen, fireboxs made from trimming are becoming increasingly popular steel pipe.

If you go to the case with the mind and keep all the instructions, you can achieve all the advantages from such a stove:

- full security for lovers shake;

- the ability to make the stove without helpers, quickly and from the girlfriend;

- reasonable use of the place in the steam room (after all, the pipe can be placed both horizontally and vertically);

- minimum welds (i.e., simplicity, strength and resistance to exercise);

- the ability to protrude a bath to 20 cubic meters.

The diameter of the pipe that is used by the bathhouses varies from 0.5 to 0.6 m. But the wall thickness should not be less than 8 mm. At the same time, the pipe thicker 1 cm will warm too much. And for the chimney you need another pipe for 120-150 mm.

Council. With all these advantages, the bath furnace from the pipe has one significant drawback. When using it, air in the steam room heats up unevenly. If it bothers you, you can set up metal design A brick screen. The laying will perform two tasks at once. With him heated air will spread more evenly. In addition, contact with heated brick will not cause strong burns, while the fascinated metal furnace is a serious source of danger.

Vertical tube

The vertical design is chosen by those who are important savings in the pair room. If you choose this option, you will not need to take care of the external placement of the tank with water and heaters. The basis of this stove is a half-meter trim pipe. The manufacturing technology is quite simple if you are familiar with the welded business.

Horizontal tube

The advantage of the horizontal stove is that here you can arrange a more spacious furnace. Firewood here will burn longer, and your bath will be drunk. The door of the firebox at such a stove is easier to bring to the pre-banner. But to arrange a heater with a tank right in the pipe with such a design it is impossible. This will require attachments. The stove itself is made from trimming a pipe long 0.8 m.

Horizontal Bath furnace: drawing

Attention! So that the furnace has not turned into a fire-hazard element must be observed elementary rules security. The pipe must be displayed on the roof through the overlaps using the peaks from non-combustible materials. Well, if you can easily equip the furnace with a movable damper at the entrance to the smoke pipe. It will protect the oven from excessive traction. In addition, the furnace needs to be periodically brushed from soot, because it can also catch fire.

So, the bath oven is not such a difficult task. If you are familiar with welding, she will be on your shoulder. All that is needed - trim pipes, sheet metal, a few hours of free time and golden hands.

Bath furnace do it yourself: video

Bath furnaces do it yourself: photo

The bath is a place to relax, the main element of which is the oven. Heat and timely supply of moisture depends on what fuel construction in the steam room you build. Experienced cooks recommend building a furnace for a bath of 530 pipes. A simple and economical option will provide high temperature and will require a minimum of effort.

Bath is a place to stay

Put the bath - the task is responsible and important. It is necessary to create a reliable and convenient design to use. It depends on the safety and comfort of holidaymakers in the Parik.

Before you make a stove for a bath with your own hands from the pipe, you should study to the smallest detail, choose a pipe with the desired diameter and prepare the necessary tools. The furnace in the steam can be horizontal and vertical. For the manufacture of any kind, there will be a sheet iron, a welding machine, a bulgarian, chimney, pieces of fittings and the main element - a pipe with a diameter of 500-530 mm. The desired tube segment can be purchased at the point of receiving scrap metal, which will save your cash.

Before making a stove for a bath, you should study to the smallest detail drawing

Horizontal Furnace Production Technology

The horizontal firebox is considered more successful than the vertical. W. vertical furnace The size of the fuel compartment is greater, it allows you to quickly warm the room. Fire rules also placed more. In this case, the device does not take up much space in a limited space, as it differs compactness. For the construction of the furnace, follow these steps.

Horizontal firebox allows you to quickly warm the room

- Spill pipe cut, approximately 80 cm long, and align the edges.

- Install a grate grid. If there is no finished part, you can make it yourself. In the metal sheet, cut the hole and breed a piece of reinforcement.

- Welcome to the trumper grate.

- Cover the stove on top of a metal sheet.

- Cut a pair of rectangular holes with doors. One thing - to load firewood, the other - for pushed.

- We weld the smoke tube to the back of the furnace.

- At the end of the welding work, the finished furnace must be covered with a thick layer of heat-resistant paint, having previously cleaned the metal from rust. This will prolong the service life of the furnace. Paint protects the design from destruction and corrosion.

Important! Horizontal stoves for a bath from the pipe are installed on the foundation, the base of which consists of concrete from below and several rows of bricks on top.

Production of vertical stove

Making a vertical oven is not difficult. This option is not the most practical, but in some cases you need this model. It all depends on the preferences of the owner of the bath and place in a steam room intended for the furnace. The process is not difficult and consists of several stages.

In some cases, the design is suitable for the vertical stove

- Make formwork and put fittings on them. Fill everything concrete solution, thus prepare the foundation.

- Concrete foundation Cover in several rows brick masonry through clay solution. Leave the foundation to stick.

- Take the pipe and align one of her edge. In the future, it will be used as a basis.

- Slide fine holes for fastening the grate and one big for pond.

- If you came up for a homemade stove for a bath from a pipe, then you will not be difficult for you to make chariot with your own hands. To do this, you will need several metal rods.

- Over the furnace, weld the cutter. Use metal sheet cut in the corners.

- Ten centimeters above the Cutter Make a chamber.

- Prepare another sheet of metal with a hole, and cover the heater.

Installing design indoors

When a self-made furnace for a bath from a pipe is ready, it is installed in the room. During the installation, follow the technological rules. Observe the size of the site where you will install the furnace. It should be in the shape of a square of 70 by 70 centimeters. Height - no more than 20 centimeters.

The design is placed with bricks for its own safety.

The furnace is installed in 20 centimeters from the wall to the foundation prepared in advance. The design is attached using clay. In a place where the pipe output will take place, make a brick-thickened brickwork by 10-12 centimeters.

Wooden overlaps Cover the felt pre-impregnated with clay solution. Instead of felt, you can use asbestos or cardboard. Impregnation of clay - mandatory procedure. It is necessary for refractory. The gap of the pipe, which is located between the ceiling and the roof, attach and turn the lime. Outdoor pipe laying out more than 50 centimeters above the roof level. Otherwise, windy weather will not be thrust. The door of the Kamenka must be sent to the corner of the bath (diagonally), and the fuel doors direct in the direction of exit.

The shelves in the steam room are located at the same wall where the heating design is installed. So as not to touch the head of the hot ceiling, the height of the shelves must be calculated before making the stove for the bath from the pipe.

Observe fireproof rules. AT wooden bath The metal stove is necessarily plated by brick or cobblestones. The second use more for beauty. Facing is performed on both sides of the structure, the height of its at least 120 centimeters. Next, you can build the wall and start to heat the bath. Test spend without guests.

Now that you know how to make a stove from the tube for a bath, you can apply your knowledge and in other buildings. Heating in the greenhouse, at a time or in the garage is carried out according to the same principle. Pipes for this can be taken with a smaller diameter. Good luck in all endeavors!

Video: Pipe oven