Best price On slab foundation!

Slab foundation under cottage - prices

The slab foundation is the most reliable basis for the construction of the cottage. It is suitable for almost any soils (weak, sediments, bunched, with a high level of groundwater) and allows you to build houses of large floors from heavy materials - full-time brick, reinforced concrete structures, natural stone, as well as monolithic structures. There is the only reason why it is undesirable to build a house on the stove - significant height differences on the construction site. But it can be eliminated by performing the required volume. earthworksaimed at leveling relief.

It is clear that the fill of the slab foundation is impossible without the use of special equipment, as it is necessary to ride and distribute a significant amount of concrete. Literate preliminary preparation of the site is very important: calculation, markup, creation of "pillows", high-quality reinforcement, proper installation Formwork. The company "Cottage-expert" has its own solute concrete node, powerful equipment and crews of experienced concreteers, which allows us to build reliable slab foundations for cottages in Moscow and Moscow region. Construction on a monolithic concrete slab is considered the most expensive, but in some cases the use of another type of foundation is simply impossible. We are trying to keep prices at an acceptable level for our customers and never exceed the agreed estimate cost of work.

The cost of the plane foundation turnkey. Price per m2.

| Plate height | Plate area | ||

|---|---|---|---|

| 25-100 m2. |

101-150 m2. |

more than 150 m2 |

|

| 200 mm | 4200 rub. / M2 |

4100 rub. / M2 |

4000 rub. / M2 |

| 250 mm | 4500 rub. / M2 |

4200 rub. / M2 |

4100 rub. / M2 |

| 300 mm | 4800 rub. / M2 |

4500 rub. / M2 |

4400 rubles / m2 |

| 350 mm | 5100 rub. / M2 |

5000 rub. / M2 |

4900 rub. / M2 |

| 400 mm | 5700 rub. / M2 |

5600 rub. / M2 |

5500 rub. / M2 |

| Composition of the work: Preparation of the area, crawling axles, geotextile excavation, geotextile installation, device of sand pillow (300mm) with a seal of vibropilet, formwork device, device of engineering communications, installation of waterproofing, two-tier reinforcement (cell 250x250mm), fill with concrete (Magam M300 ) With vibration. * Prices are subject to materials. | |||

Plate foundations: varieties and features

Classic slab foundation - monolithic, finely opened. The choice of the basis of this type makes it possible to minimize earthworks and reduce the cost of construction. The stove withstands the weight of a multi-storey cottage, stealingly tolerates the horizontal and vertical effect of frosty powder, is not subject to uneven deformations, which has a positive effect on the integrity of the above-ground construction of the building. The service life of the monolithic finely swelled foundation reaches 150 years.

Many developers choose a plane outlook, which allows the device underground garage, swimming pool, gym in the basement. In this case, first boiled, at the bottom of which the pillow is satisfied under the subsequent fill of the foundation. The stove serves as a rough floor of the basement and reliably protects it from the flooding of groundwater. Next, using the slab as a base, you can build a similarity belt Fundamentwhere the ribbon will simultaneously perform the functions of the walls of the basement or basement. This option has become possible with the advent of new waterproofing materials and modern technologies.

The third type of slab foundation is the basis consisting of several plates of various shapes and areas having an equal thickness. The option of such a foundation device is used for the cottages of complex shape. So that the stove worked as a monolith, the deformation seams are arranged between its individual fragments. The carrying capacity of the base of this design is preserved even in the case of uneven drawdown, since the formation of cracks due to the presence of seams is excluded.

The thickness of the plate is calculated depending on the peculiarities of the soil, configuration and weight of the built building.

Construction of slab foundation

In the device of the monolithic slab foundation, several main steps are isolated, each of which is extremely important to achieve the desired result - durable and reliable base for the future at home.

Preparation of "Pillows"

The slab foundation requires careful surface preparation: the pad under the fill must be aligned (if necessary, digging the boiler and compact its bottom). Next arranges a multi-layered "pillow":

- Sand (10-15 cm);

- Geotextile;

- Crushed stone;

- Concrete M100 (liquid consistency, layer 5 cm);

- Waterproofing (along the edges with a margin of 30-40cm);

- EPPS;

- Polyethylene film.

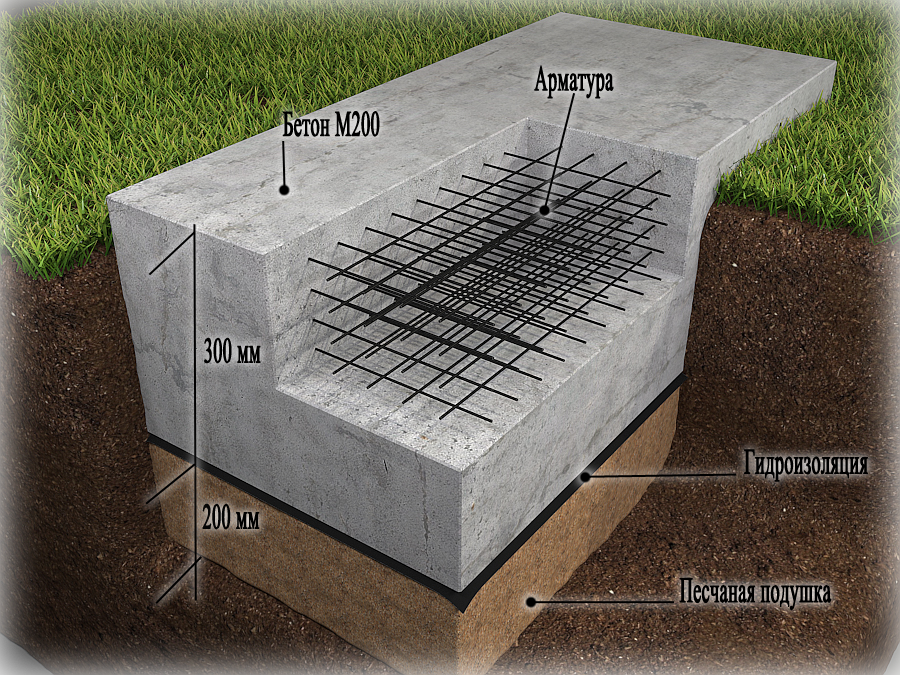

First, there is a subference with a thickness of 20-40cm, the first layer of which consists of sand, the second of the rubble. Sand must be shedding with water and tamper. To eliminate the casing of rubbank, between it and sand is placed geotextile layer. On top of the submetock lay a small layer of low-stage concrete, then the waterproofing material. On bunched soils, the insulation of the slab foundation is recommended in order to prevent the soil freezing. In the insulation, the extruded polystyrene was used (the density of the material is 50kg / m2 or more). It has sufficient strength not to deform under the weight of the plate, does not absorb moisture and is not subject to rotting. Upper layer "Pillows" - protective polyethylene film.

Reinforcement of the foundation and installation of formwork

For reinforcement, the plate form a double-circuit frame using reinforcing rods with a diameter of 12-16 mm. The top and bottom frame of the frame is bonded by vertical jumpers. When fixing the rods by means of knitting wire, the hot-rolled reinforcement A2 or A3 is chosen, with a welded connection - the reinforcement is weldable (for example, A3C). The magnitude of the cells of the formable reinforcement grid - up to 25 x 25 cm. On both sides, the finished frame should be "drowning" into the thickness of the plate for 5 cm.

The formwork is installed along the contours of the future plate. So that when filling under the influence of mass of concrete, the formwork was not deformed, it is necessarily strengthened. Specialists of the company "Cottage Expert" work with a professional fine and large-scale formwork made from smooth front panels with a metal frame. In the desired configuration, shields are installed with the help of internal and external hinged corner frames, metal tie screws and locks - spring, wedge, elongated. So that concrete does not stick to the shields, they are lubricated by Angrelet or emulsol. Using professional formwork provides perfect geometry foundation Plate.

Concreting

Concrete Pouring is simultaneously. The intermediate frosting of the layers is not allowed, so concreting is continuously carried out. To do this, you need to calculate the required volume. concrete solution M300 or M400 brands and organize its planned deliverance on construction site. Concrete hydrophobic coefficient - W8, mobility index - P3, frost resistance - 200 cycles. To eliminate the formation of empty and cavities in the concrete plate at the end of the fill, it is compacted, applying concrete vibrators for this. Holding the foundation takes 20-25 days. So that concrete frozen evenly and acquired the maximum strength, it is covered with a film or watered with water 1-2 times a day.

According to the standards, the fill of concrete is recommended to produce at air temperature from 5 to 25 degrees ( optimal temperature 15-25 degrees). Our company performs a device plate foundations For cottages and residential buildings at any temperatures using concrete of own production with special additives. "Cottage expert" is a reliable foundation at any time of the year.

Monolithic foundation plate - One of the most popular and common types. It is used mainly on floating and inhomogeneous soils. It is a solid monolithic design that no changes are scared in the soil. The stove of the foundation will move with the construction, thereby protecting it from the devastating effects. Experts consider this kind of foundation the most sustainable and reliable. Construction company Western House for the construction of cottages in Moscow and St. PetersburgIn 70% of cases, applies a monolithic foundation plate, and therefore we are excellent specialists in the construction of this type of foundation.

The varieties of the monolithic foundation plate:

- without paintwork

- with Russian

- foundation plate for the basement

The main advantages of a monolithic foundation plate:

- universality, as suitable for a cottage from any materials (aerated concrete, brick, wood and d.R.)

- construction almost on all soils

- reliability (the most reliable view of the foundation at proper operation)

- not necessarily make geological tests

- not susceptible to the beading of soils (when performing insulation of the plate and scene)

|  | |

The main criteria of a monolithic foundation plate:

The subfolder under the foundation plate (pillow) can be thick of from 400 mm to 1000 mm, and depends on the complexity of the soils, the worse the soil, the thicker should be a swing. Used for submail: sand is coarse-grained wicked, PGS, crushed stone (fraction 20-40 mm). Every 10-20 cm will be taught, with vibrotambovka and spill with water. Under the sandy pillow, geotextiles should be shaved to prevent its groundwater blur.

After the subfolder, the sub-preparation of 70-100 mm from the "skinny concrete" B7.5 is performed, for the proper application of rolled waterproofing, which is performed in 2 layers and will be filled gas burner. It is necessary to prevent moisture from entering the land in the foundation slab, which can lead to its destruction.

The insulation of the foundation plate is carried out on top of the waterproofing by extruded polystyolmine (EPPS) with a thickness of 50 mm. The need for this is determined by the fact that when it is used under the foundation there will always be a plus temperature required to prevent . Also necessary insulated breakdown and drainage system. This is very important in the 1st and 2nd winter after the construction of the house while there is no heating, since the ground under the house will freeze and can have an impact on the foundation.

The thickness of the plate can be from 200 mm to 500 mm, the width of the grill is from 300 to 650 mm (depending on the thickness of the bearing wall), the height of the frame from 100 mm to 1000 mm (with greater height, it is advisable to do the ground floor). All these indicators are determined before the construction started on the basis of geology and future structure.

The valve is used in a diameter of 12-16 mm (most often 12 mm), cell 200 * 200 mm. Reinforced the plate of such a foundation with two grids: upper and, accordingly, lower. Moreover, the lower grid is put on the clamps. This is done to comply with the size of the protective concrete layer. To comply with the design dimensions between the grids themselves, special frameworks are used. In addition, reinforced grids are associated with each other with spills. Up and down reinforcement carcass A protective layer of concrete is made of at least 40 mm.

To calculate the foundation you can leave an application for calculating the construction of a monolithic foundation On our site or call us to the office.

The slab foundation is a solid concrete or reinforced concrete slabOutlook in the ground. It is also called solid. The walls of the house, external and internal, are erected on the stove. Due to the uniform distribution of the load throughout the plane, the pressure on the soil is minimized, and the stability to load loads increases. The slab foundation is resistant to uneven movement of the soil due to precipitation, freezing or thawing. Its construction is possible on any type of soil, including brunch and sandy, with a high level of groundwater. The solid plate is actually moving along with the soil, preventing the deformation of the erected structure, so it is also called the floating foundation.

The stove is the optimal version of the support when building buildings on the worst soils: weak, swamp, loose, sandy, watery, destroyed, etc. It is also used in the regions with a great depth of ground freezing. Complete options are very common in private construction. With the advent of Swedish technologies and modern hydro and heat-insulating materials, a warmed stove acquired greater popularity.

Fundam USP.

The insulated stove has high energy-saving properties with a relatively small thickness and small construction periods. With its device, advanced technologies and the latest building materials are used. In such a foundation, all communications, sewage and system are integrated warm floors. Large costs during construction are justified during the operation of the house on the UCP. The technology has been worked out in Europe in the past century, first appeared in Sweden. In Russia, the popularity of Swedish technology for the construction of a slab foundation is constantly growing, but often arise with search construction companiesWith sufficient experience in this area.

Solid slab foundations have a number of benefits:

- maximum reliability;

- the possibility of construction in places with unstable and poor soil;

- high resistance to the pressure of the soil;

- the possibility of building a house from any materials;

- good waterproofing;

- relatively simple installation;

- the elimination of the likelihood of groundwater penetration.

Features of the device

The technological feature of a solid foundation is the construction monolithic plate from concrete or reinforced concrete. The formwork is together with the stove of a single design. Since the plates are constructed most often on problem soils, they are presented the most stringent requirements. When planning and construction, construction technologies should be clearly observed, high-quality building materials are used.

The device of a solid foundation depends, first of all, from its variety. The stove can be solid and lattice, smooth and ribbed, simple (only concrete) and reinforced (reinforced concrete). The base of the UCP requires the creation of a spatial reinforcement frame. The brand of concrete and the type of fittings are always selected in accordance with the features of the project. Depending on the project, a continuous foundation may be finely and deeply swallowed. In the second case, it is advisable to build a basement.

The slab foundation is erected on the rammed sandy-gravel pillow. Under it, the drainage system is satisfied. With a deep blowing, the base is pre-rotated, in other cases, the fertile soil is only removed. Waterproofing is arranged before the fill of the concrete, if necessary, the insulation of the base of the structure is carried out, the fitting is carried out. After that, an embedding of sewage and communications systems is carried out, the floor heating system is attached to a special grid. The feature of the Swedish plate is that after drying and grouting concrete base Fully ready for finishing.

Scope of slaughter foundation

The monolithic base is solidity and constructive simplicity. That is why it is used in cases where there are high demands on the reliability of the future object. The design is resistant to deformations, soil movements and groundwater impacts. That is why the slab foundation is used when erecting objects of any destination on different types of soil. Most often, such grounds are arranged in the construction of low-rise private houses (1-2 floors) and cottages. However, it is allowed to use the designs and in the construction of other purposes, subject to preliminary strength calculations.

Stages of work

| Stage name | Deadlines | Features of work |

|---|---|---|

| 1. Preparation | From 3 to 7 days. | During this time, earthworks are produced, it is equal to the relief, the soil is rambling, placed the grid of the base and prepare a shot for the device of the slab foundation. |

| 2. Bookmark fittings | Several days. | Promotion of the reinforcement grid with cells 20x20 cm over the entire area of \u200b\u200bthe future base. |

| 3. Final part | From 10 to 21 days. | Filling a slab foundation concrete solution. After a day is performed moisturizing the surface. Set of calculated strength to the base will depend on temperature mode. |

The monolithic plate under the foundation is a powerful cast base of a certain thickness, made of reinforced concrete and laid on a sandy-crushed pillow.

The reliability of the monolithic plate under the foundation is determined by the high degree of construction reinforcement throughout the volume.

Subject to the use of high-quality concrete and the correct mating of the reinforcement from the monolithic slab will serve for a very long time, not deforming and without losing strength.

Such a basis is able to withstand very large loads.

Being monolithic, such a foundation evenly distributes the weight of the building across the area of \u200b\u200bthe soil, and being laid on a sandy-chump base - reliably "extinguishes" any movement of the soil, "floating" with it, which eliminates the deformation and destruction of the walls.

It is the "floating" factor allows you to build buildings using a monolithic slab foundation on the soils of any types, even weak, bunched (subject to seasonal movement as a result of freezing and thawing) and with a high level of groundwater. Moreover, for some "problematic" types of soil (for example, peat, monolithic iron concrete plate is the only possible basis under.

To the main lack of a foundation of the type, the monolithic reinforced concrete plate can be attributed to the high cost of the structure. This is caused by a large consumption of both concrete and fittings. In addition, to obtain the desired design parameters, these components must be high quality.

First stage of construction of a monolithic foundation: Determination of the form and parameters of the plate

The first construction stage of the foundation involves the conduct of the necessary geological and geodesic surveys of the construction site. Based on the results of the study of the soil and construction of the building, the form of the future monolithic plate is determined, and its parameters are calculated.

The area of \u200b\u200bthe future foundation of the slab is equal: the area of \u200b\u200bthe construction itself plus the scene.

The thickness of the reinforced concrete foundation monolith depends on the severity of the building and may have a spool from 0.15 to 1 m.

According to the degree of blend into the ground, the foundation with a monolithic slab can be unwinted (floating), low-boiled and bellped.

The last version of the foundation is being built under the heavy buildings of the cottage type and is located below the level of primerization of the soil. As a rule, it serves as the basis for the basement or basement.

Back to the category

The second stage of construction

The second stage of construction of a monolithic slab is earthworks.

The markup of the base is made. If the foundation is illuminated, then the markings are rotated.

The device of the bellows under the foundation-slab is a rather time-consuming process that requires the performance of a large amount of earthworks. This requires a special technique.

Back to the category

Third Stage: Arrangement of depreciation drainage pillow

The base of the pit is thoroughly tamped and is paved with geotextile tissue.

The sand, a thickness of at least 0.2 m is scattered by geocanies, watering and tamped.

After drying, the sand is covered with a layer of rubble 0.2-0.4 m, also tram.

And one more layer of sand, on top of the rubble, a thickness of at least 0.2 m, watering with water and tightly tight.

The thickness of the sand and chump layer should not exceed half the thickness of the entire foundation.

The resulting layer of rubble with sand is poured by a thin layer of concrete. Concrete is withstanding until a complete set.

A layer of waterproofing material is stacked on the resulting sand-gravel cushion.

If it is necessary, the insulation of the base for waterproofing can be laid insulating material, whose sheets are fastened with each other with a special scotch.

The surface of the waterproofing or heat-insulating material is poured by a thin layer of concrete reinforced with a grid (sweeping).

Back to the category

Stage Fourth: Formwork

A formwork from the board is installed on the perimeter of the submersion. The construction of the formwork begins with the corner, the boards are attached to each other at right angles, with the help of self-tapping screws.

The entire formwork box is sprinkled with rubble or soil, is strengthened by backups from boards or fittings. The reinforcement bars are driven into the ground at a distance of at least 1 m from each other in order to prevent squeezing formwork under the weight of the fill.

Back to the category

Fifth stage: armature framework

Armature, forming the reinforcement framework, fit onto the sweet.

Construction of a house on a monolithic plate

When building a house, the question of choosing the foundation will be asked. It is necessary to approach this question very seriously. After all, it is the foundation that gives the stability and strength of any building. The most durable and practical is the foundation in the form of a monolithic reinforced concrete plate.

What a foundation to choose

| A type | Purpose | Benefits | Price | Timing |

| |

Home without basement, greenhouses, baths, fences | Construction of houses in difficult areas | from 775 r. / m 2 | 1-2 days |

| Tape |

Houses of stone, logs, aerated concrete, foam block | Strong pile, building house with basement | from 2600 r. / p. | 1-7 days |

| Columnar |

One-storey wooden, bar and frame objects, fences | Cheaper than ribbon 1.5-2 times | from 1000 r. / m 2 | 1-3 days |

| Slab |

For two-storey brick houses | Monolithic design - the durable | from 3200 r. / m 2 | 3-10 days |

The design of the tiled foundation is one solid reinforced concrete slab. It stacked in the pit for a certain depth.

Advantages of a monolithic plate:

- The monolithic foundation has the highest carrying capacity in comparison with the rest of the foundations

- The monolithic plate has a property to resist the sweatshirt of the soil

- Based on the monolithic plate, you can build a house of any design, complexity and massiveness.

- Monolithic foundation can be mounted almost on any soil

- The monolithic plate has a simple design

The only disadvantage of the foundation in the form of a monolithic slab is the complexity of installation, as well as the cost of the foundation for the house can reach 50% of the construction costs of the whole house.

Classification:

- The monolithic tiled foundation can be made with additional rigidity ribs (ribbed) and without them

- The tile foundation may not be covered - mounted on the surface of the soil or by a swallowed - mounted in the pitted depth

Monolithic plate. Foundation with your own hands

The construction of the foundation is made in several stages. Compliance with all norms guarantees to obtain an excellent result.

Design

First of all, you need to create a sketch of the future at home. Then to calculate the carrying capacity of the soil, choose the thickness of the foundation and the depth of its laying.

The calculation of the carrying capacity of the soil includes the calculation of the load, which will create a building on the ground area. The resulting value should be less than the calculated resistance. Each type of soil has its own resistance. Its value can be found in regulatory documents.

The calculation of the load created by the house is to determine the weight of all elements of the house, including furniture and even snow clusters on its roof. To determine the weight, you need to multiply the volume of the element on its proportion (specific weight value can be found in the directory for each material).

Thickness is chosen in accordance with SNiP the foundations of monolithic and directly depends on the size, massiveness and dimensions of the construction. Typically, the stove thickness is taken from 150 to 350 mm. For block or brick houses, the optimal thickness will be 200 mm.

The depth of laying a monolithic plate depends on the characteristics of the soil. Namely from the depths of the freezing and depth of groundwater.

Mounting work

Any step of installation work must be carried out in accordance with the requirements, as well as follow safety.

Marking

First of all, it is necessary to prepare the area on which the foundation will be located. To do this, remove unnecessary objects and remove thick vegetation. Then make markup in accordance with the project of the house. For convenience, you can drive the pegs and pull the tape throughout the perimeter.

Digger Kotlovana

We produce land work on the chickens of the calculation depth. It is best to do with special equipment, but the last 200 mm. The soil is better to shoot manually, for greater evenness. The bottom of the pit is reported and tamped.

If an excessive deepening happened in any place, it cannot be aligned with sand or land. You need to deepen the entire surface of the pit to this level.

The size of the pit is selected slightly more than the foundation itself, for the convenience of work.

Laying pillows

As a pillow under the tile foundation, sand or gravel is used. To do this, we fall asleep material on the bottom of the pit, align and tamper. The thickness of the pillow depends on the characteristics of the soil, usually it is 150-200 mm.

Installation of formwork

At the bottom of the pitted wooden boards or special blocks mounted formwork for the fill of concrete. Its design should be strong enough to withstand heavy loads that concrete creates. Installation of the formwork should be carried out using the level so that the foundation turns out to be smooth.

Waterproofing foundation

Waterproofing material is spread across the area of \u200b\u200brecovery. To do this, use runner or ordinary film.

Reinforcement of foundation

To obtain a solid foundation in its design, a metal frame must be included. As a material, you can use the ribbed fittings. The optimal diameter of the reinforcement is 8 mm. The valve binds to the grid with cells of 200 per 200 mm. Then these grids are stacked in several layers, depending on the calculated foundation thickness.

The distance is height between nets 100 mm. All layers of reinforcement are bonded by P-shaped metal elements. The frame must be shrouded with concrete from all sides with a layer of at least 50 mm.

In order to reduce the reinforcement grids into layers, special supports can be used.

Foundation solution: composition of proportion

Concrete for fill monolithic foundation There must be at least M250 with water resistance W6. It is best to order ready-made concrete.

The proportions of various brands of concrete:

Pouring concrete

Manufactured with a tray or a special pump. To equalize the surface, you can use a deep vibrator, which will ensure a uniform distribution of concrete in all layers of the plate and air removal.

Drying concrete

The drying of the concrete should occur gradually. The longer the concrete will dry, the stronger it will be. To do this, you need to pull the film above the surface of the foundation and periodically produce abundant wetting with water surface of the concrete. Concrete drying time can reach 30 days.

But he will recruit its strength for a few more months.

The foundation in the form of a monolithic plate will provide maximum strength for your home. And its operation will exceed 100 years.