A private house is an oasis of comfort and coziness. But even in the blissful silence of the garden plot, it is necessary to leave room for the comforts of civilization. Plumbing is something without which one can hardly imagine the life of a modern person. The installation can be entrusted to professionals, however, almost any owner of the house will be able to cope with this work on their own.

Beginning of work

Any work on laying pipes begins with a preliminary drawing up of a diagram. It is important to indicate the following points in it:

- The main characteristics of the existing soil: looseness, softness, and so on;

- Total area of \u200b\u200bthe site;

- Water intake source;

- Pumping system;

- Hydroaccumulator.

What do you need to purchase?

The first and most important thing you need to buy at the store is water pipes. It is better if they are made from low pressure polyethylene. It is also necessary to pay attention to the fact that the products are suitable for organizing a water supply system for transporting drinking water.

Why polyethylene? Products made from it have a lot of advantages: resistance to corrosion, high pressure, low temperatures, strength, ductility, ease of installation, low price fittings. You should not buy too cheap products, as they can cause a lot of problems during operation, which will lead to additional waste. However, you can purchase products from other materials. It all depends on the requirements and preferences of the home owner.

How to determine the depth of the installation?

The depth to which it is necessary to lay the water supply system is determined by the SNIP (a document serving to determine the optimal technical aspects when installing various communications). SNIP standards indicate that pipes should be laid to a depth of at least 1.6 meters. This item directly depends on the depth of soil freezing.

The average depth of soil freezing is 1.4 meters. It is clear where the figure of 1.6 meters came from, because if you lay the water supply above this level, it will freeze, and its further operation will be impossible. But the depth of soil freezing is still different, because there are areas with different temperature climates.

If you do not want to use the average indicators, we recommend that you contact the nearest construction organization for advice regarding specific indicators of soil freezing in this area.

But in any case, you will not lose anything if you lay the water supply system according to the standard. Regardless of the terrain (unless, of course, your dacha is located in remote Siberia), at a depth of 1.6 meters, the positive temperature remains even in the harsh winter season. This means that the water supply system will delight you with its smooth operation.

What to remember when laying water pipes in the ground?

Often, owners of summer cottages or private houses are faced with the problem of the impossibility of laying the pipeline to the desired level due to the structure of the soil. This difficulty can be solved relatively simply. The trench breaks as deep as possible, to the level that the ground allows. Then the water pipes are laid. However, you should first arrange thermal insulation. It is required to be built in all the way plumbing system heating cable, which will make it possible for its uninterrupted operation in winter.

Of course, it is still better to lay pipes in a trench dug on the right level... The heating cable, its installation - all this is expensive, time consuming, and can cause some inconvenience. However, if a trench with the required parameters does not work out, then a measure with a cable is required when laying an autonomous water supply system.

After laying the plumbing system in the country or in the area adjacent to a private house, before filling the water supply system with earth, you need to check if everything has been done correctly. For this, a trial run of water is carried out. Just turn on the water and wait until it passes through the entire water supply. When doing this, carefully observe the entire path of the liquid. It is important for you to see if there is water pipesah leaks, whether the components are tight.

Small addition: Even if your private house or the cottage is located in the south, you still should not significantly violate the norm for the depth of laying the system into the ground, equal to 1.6 meters. Otherwise, if the water supply was laid too close to the surface, it may deform due to various kinds of mechanical influences. If it is laid too far from the surface, the water supply can burst, unable to withstand high pressure.

Add to bookmarks

Gasket polyethylene pipes in the ground

Having learned that the abbreviation HDPE refers to low-pressure polyethylene pipes, one can erroneously assume that we are talking about a material through which liquids and gases under low pressure can be transported. However, the laying of polyethylene pipes with this name is carried out both in sewer systems and in pipelines of hot and cold water supply systems. Polyethylene pipes can also be used to protect underground cables.

HDPE pipes are laid both in sewer systems and in pipelines of hot and cold water supply systems.

Distinctive features of HDPE pipes

The difference between HDPE pipes and other types is in their production technology, and the concept of "low pressure" means that the polymerization of ethylene is carried out under low pressure conditions.

This immediately changed the performance of HDPE pipes. And their main difference from ordinary polyethylene pipes is that they begin to melt 20 ° C higher, and this has significantly expanded the scope of this type, for example, they can be used in hot water supply systems at any water temperature.

Diagram of an extrusion line for the production of plastic pipes: 1 - loading device; 2 - extruder; 3 - forming head; 4 - calibrating sleeve; 5 - water vacuum baths (vacuum calibrators); b - thickness gauge; 7 - water cooling baths; 8 - counting and marking device; 9 - pulling device; 10 - cutting device; 11 - receiving device; 12 - winding device.

These pipes are elastic, and it is easy to give them a complex shape, that is, they "work" well both in tension and compression, because when bent, one side of it, without collapsing, experiences a tensile load, and the opposite is a compressive load. They also have good impact resistance and, when in the ground, can withstand significant shock loads, which is why they are called high strength. In winter conditions, with HDPE pipes, it is possible to work outdoors even in the northern regions.

HDPE pipes cannot be used to transport liquids and gases with which they can enter into chemical reaction... If this condition is met, the service life of HDPE pipes without losing their inherent properties even in the ground is 50 years.

They are designed for internal pressure, which has the following range of values: 0.5 0.63 0.8 1.0 1.25 and 1.6 MPa; you can pick up pipes of almost any diameter in the range from 16 to 1200 mm and lengths from 5 to 12 m with a multiplicity of 0.25 m.

HDPE pipes are much cheaper than steel and, moreover, copper pipes. They can reasonably be considered the material of the future.

Preparing a trench for sewerage

Smooth orange polyethylene pipes are usually used for sewage. Since the drain can be drained and hot water, up to boiling water, it is advisable to use HDPE pipes. Their diameter must be at least 110 mm. The device in the ground of a sewer in private housing construction is not difficult, and this work can be done independently. But it is necessary to treat the construction of this system with all responsibility and knowledge of the basic rules for laying pipes in the ground will not hurt.

Depending on the terrain, the depth of pipe laying in the ground may differ, but in any case it should not be less than 0.5 m.

- The burial depth in the ground should not exceed 3-3.5 m. This depth may be required in the northern regions, where the ground freezes to a considerable depth. In the middle lane, 2.5-3.0 m is enough, and in the south - 1.25-2 m.Depending on the terrain, the depth of pipe laying in the ground may differ from the indicated values, but in any case it should not be less than 0.5 m.

- In places where dynamic impact on pipes is possible (under footpaths and driveways for transport), inserts of corrugated polyethylene pipes must be made.

- The pipes are connected to each other with fittings.

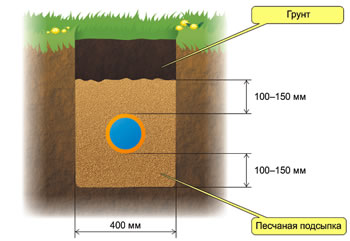

- For pipes with a diameter of 110 mm, a depression of 50 mm is made relative to the bottom of the trench, with a width of 600 mm.

- The slope of the pipe in the horizontal section for each m should be about 1-2 cm. It is advisable to control it as you dig a trench along its length. This means that the slope, for example, of a pipe 5 m long, should be such that the difference between its beginning and end (without the height of the socket) is 5-10 cm, which is easy to check with an ordinary level.

- Along the entire length of the trench, it is necessary to lay a cushion of gravel or sand so that after tamping its thickness is 10-15 cm. The cushion should be rammed at a distance of 2 m from the manhole and at the junction of the pipeline with the inlet pipe. Pits are made in the places where the socket is located.

Sewer pipe laying technology

The pipes are laid so that the socket is in the direction of the slope.

- The pipes are laid so that the socket is in the direction of the slope. Further work consists in checking the cleanliness of the inner surface. Before joining, the inside of the socket and the outer surface of the next pipe must be thoroughly cleaned of dirt and greased with a special grease that is usually supplied with the pipes. Only silicone grease is permitted. No oils can be used.

- Before applying the lubricant, the pipe is inserted into the socket until it stops and a mark is made on the outer surface. After applying the grease, it should enter the flare up to the mark.

- For the device of turns from the sewer outlet in the foundation, bends with rotation angles of 15, 30 and 45 degrees are used. Every 15 m of the length of the pipeline, in case of cleaning it is necessary to install revisions.

Insulation of sewer pipes and trench closure

When leaving the house, be sure to sewer pipes insulate. Insulation work may also be required for its underground part, if they are laid above the depth of soil freezing. Energoflex or stenoflex are used as heaters. The pipeline is wrapped with insulation along its entire length and the insulation is securely fixed.

Before backfilling, it is advisable to make sure once again that during the process of warming and joining pipes, the slope of the pipeline has not changed and meets the requirements along the entire length. For backfilling, it is allowed to use the soil obtained when the work on digging a trench was carried out, only before backfilling it is necessary to remove stones from it and loosen large and dense blocks. The size of large formations in the ground should not exceed 30 cm. The trench is covered with 5 cm thick layers and tamped well. Tamping is done only between the pipe and the walls of the trench. The best will be backfill, in which the first layer will consist of sand 10-15 cm thick. It is forbidden to ram over the pipe. A mound of soil with a height of 0.3 m should form above the trench.

We lay the water supply on our own

The biggest difficulty, after you have received permission from the relevant organizations to connect to the central cold water supply network, may arise if the pipeline needs to be laid under the sidewalk or roadway is expensive. Here you cannot do without horizontal drilling, and with a large distance to be drilled, you cannot do without special equipment. In any case, it is necessary to take into account physical properties the soil and the scheme according to which the water supply will be laid. The characteristics of the soil must be known, since the choice of material for the water supply depends on this, and the diagram is necessary in order to know the number of inputs (outputs) and branches.

Diagram of trenchless laying of HDPE pipes using a drilling machine

The most suitable are HDPE pipes of the PN10 brand. These are special pipes for laying drinking water supply. They, of course, do not rust, withstand pressure up to 10 atmospheres, that is, about 1 MPa, bend easily, do not burst when freezing and do not lose strength after defrosting. When purchasing, do not be tempted by the cheapness of PN6 pipes, they are, of course, cheaper, but problems will surely arise with them during operation and, perhaps, all the work done will be in vain.

A trench for laying the pipeline should be dug to a depth that is greater than the freezing depth of the soil, by about 20 cm. Data on the freezing depth can be obtained from any construction organization that performs work all year round. In any case, the burial depth should not be less than 1.6 m. If the soil does not allow digging a trench to the required depth, then the pipes must be insulated.

Heat insulating materials

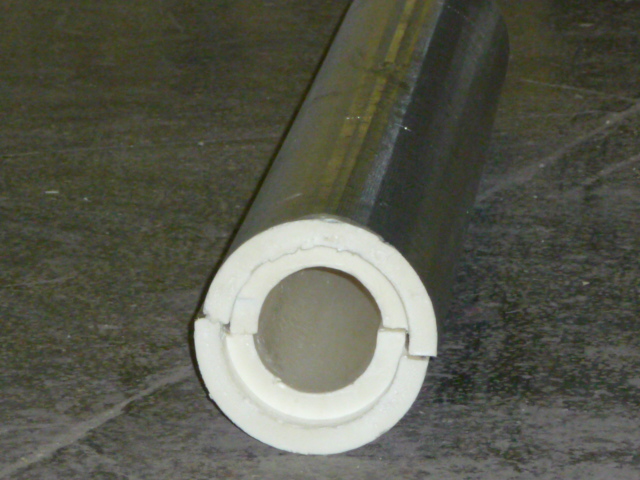

Polyurethane foam shell is a lightweight heat-insulating material, when assembled it is a cylinder 1 m long.

It is necessary to choose a heat-insulating material based on the ease of installation and location of the pipeline. All thermal insulation materials use one principle based on the thermal insulation properties of the air that is inside the material. For application, some must be laid on concrete trays.

Shell of polyurethane foam (PPU)

This lightweight heat-insulating material, when assembled, is a cylinder 1 m long. The walls of the cylinder can have different thicknesses. This material practically does not absorb moisture, which is facilitated by its fine-mesh structure with a closed cell. To increase moisture resistance, the shell can be covered with plastic wrap, moisture-resistant paper or foil. Pipeline insulation works can be carried out in any weather. The inner diameter of the shell is selected according to the diameter of the water conduit pipe. When two halves of the shell are connected at the beginning of the pipeline, they are shifted by about 10-20 cm. On the pipeline, the shell is fixed with ties. Twists can also be used. Provides easy access to the pipeline. The material can be reused. There is no need to use trays.

Fiberglass or glass wool is mainly used for insulating metal-plastic pipes.

Insulation, better known as glass wool. They are used for insulating metal-plastic pipes. It has a low material density, which is its advantage over other heaters, but it necessarily requires insulation with roofing felt or glass cloth.

Expanded polystyrene (otherwise, foam)

Most often they are used to insulate an independently created water supply system. The design of this insulation and its installation is similar to the PPU shell.

Basalt insulation

Made in the same form as PPU. No additional trays are required. They require additional protection with roofing material, parchment or foil. The most expensive material at cost.

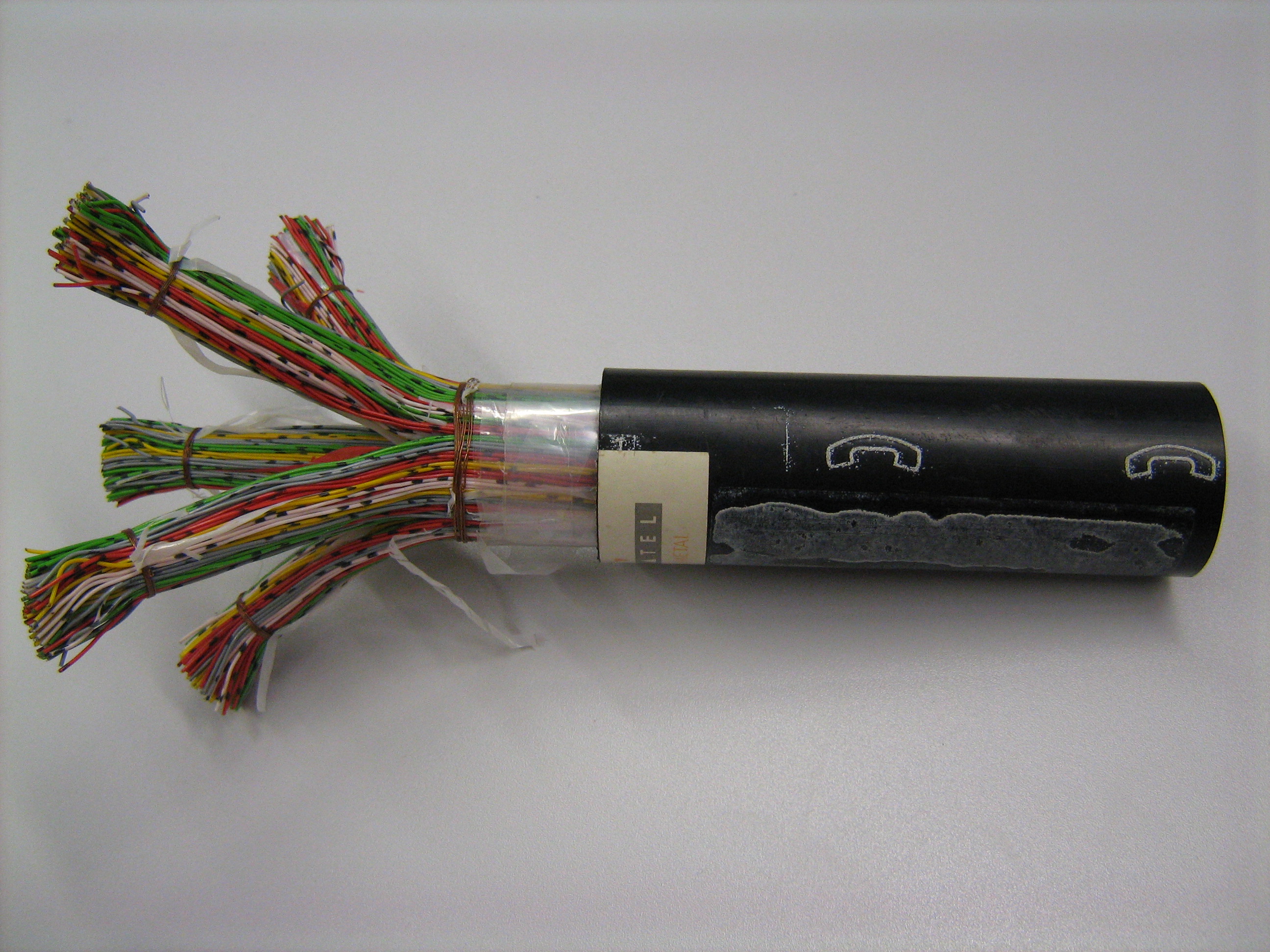

Laying of HDPE pipes for a communication cable

One of the requirements normative documents on the laying of underground communication lines, there is a requirement to lay a 32T communication cable. The outer of this brand is 32 mm, the inner is 25 mm. They must be trenched in advance. Polyethylene pipe allows you to stretch a significant length of the cable and reduce the number of cable joints. During operation, it will protect the communication cable from damage if preparatory work on laying a cable for a new communication line, when laying a massive cable not in pipes, during repair work and when removing a previously laid cable.

The outer diameter of the polyethylene pipe for underground communication lines is 32 mm, the inner diameter is 25 mm.

A polyethylene pipe, coiled into a coil, is installed on a movable vestibule and immediately unwound to the maximum possible span length. In this case, it should be taken into account that will be performed in each transit well available on this span. The length of the cuttings is considered as the sum of the distance between the channels plus 400-450 mm. As a result, its length should be such that trimming in the last well is minimal. If it is impossible to stretch the entire length of the span, it is measured with a tape measure, and then the polyethylene pipe is cut off in accessible places. In wells where there is a change in the direction of the route (corner wells), it must end in each of them.

The pipe is fitted with a ferrule and pushed along the entire span. If there are transit wells inside the span, then the cablemen help push it into the next well. If it bumped into an obstacle somewhere with a tip, and its further advance was impossible, then the cablemen should by joint efforts, turning the pipe clockwise, try to continue its movement along the span.

After the pipe has been pulled along the span, it is cut at a distance of 200-250 mm from the channels and metal plates (anti-theft) are installed on the protruding parts with recesses equal to its outer radius. The plates are bolted together so that they do not move along the pipe. These stops should prevent them from moving when the cable is pulled through them.

In order to save HDPE pipes, it is allowed to join small-sized residues in order to use them on spans, the length of which does not exceed 70-80 m. Their joints are connected using a metal cuff 150 mm long and 1.5-2.0 mm thick. From the inside of the pipes, before joining, chamfers are removed at an angle of 30 °. On both sides of the cuff next to it, one belt (in two layers) of sevilen is applied to the pipes or a layer of GIPK-14-13 glue is applied. A heat-shrinkable pipe with a length of 250 mm is installed on top of the belts. In the wells, they are protected from debris from entering them by wrapping the joints with layers of plastic adhesive tape.

High-quality laying of a water supply system in the ground - low cost of one meter of work

If you live outside the city, running water in your home is a must. What kind of comfort can we talk about if you need to go outside every time to wash your hands or dishes? And if it can be winter outside, and you don't want to leave the cozy room? That is why laying water pipes in the ground is the solution to the problem. Pipes under sufficient soil all year round provide uninterrupted water supply to the house and make life comfortable. The company "Chisto Honest" has been successfully providing services for laying water pipes in the ground at affordable prices for many years.

The cost of laying a water supply system - price per meter

Depending on the type of pipes (PP, metal-plastic) and the relief of the site, our specialists use equipment for digging trenches, or carry out excavation using the entrenching tool. The pipeline is laid in compliance with modern technologies, and the pipes are laid below the level of soil freezing. As a result, we guarantee uninterrupted water supply to the house all year round. At the same time, the underground laying of the water supply system will hide communications from the eyes, they will not occupy the useful area of \u200b\u200bthe site and spoil the appearance.

Low prices and excellent quality of work

The average cost of laying a water supply system in the ground per meter is below the market price in the Moscow region. At the same time, we follow the technology at every stage of work so that the quality is higher. Therefore, we are not ashamed of the final result, which is confirmed by numerous satisfied customers who have contacted us earlier.

You can contact us at the design stage of the building, or in the case when the house has already been built, but there is a desire to conduct a water supply to it. Each case has its specifics (the number of residents, the relief of the site, the location of the water source), therefore, before concluding the contract, we go to the place of work on the laying of the water supply system. As a result, on the spot, we draw up a plan for laying pipes, and you get the opportunity to ask your questions and to see lively the competence of our specialists.

The company "Chisto Honestly" provides professional services for laying a water supply system under the ground in Moscow and the region on affordable prices per meter.