All preparatory work is made, you can begin the connection of plastic pipes.

There are two ways to connect:

- Connect connection.

This method is divided into flange and coupling.

With the flange connection, fasteners of cast iron with a rubber gasket are used. The edges of the pipe are smoothly trimmed at the connection site, then a free flange is put on, a rubber gasket is inserted, the flange is still superimposed, it is still fastened with bolts.

With a coupling compound, the ends of the pipe are trimmed at an angle of 90◦; The coupling is put on (the center should coincide with the junction of pipes); markers on pipes corresponding to the position of the coupling; The ends of the pipes and the coupling (from the inside) are processed by a special lubricant; One end of the pipe is inserted into the coupling and comes onto the second, according to the mark.

Also for connecting non-pressure sewerage use fittings from a corrugated pipe.

The above methods of connecting plastic pipes are characterized by a low price, simplicity of installation and dismantling of the sewer system, do not require the use of expensive equipment and a special tool.

- Low connected connection.

This method is divided into "into the socket" connection, compound with welding, adhesive connection, connection with fittings.

Welding jack is carried out by special equipment. The continuous connection is formed due to heating the edges of the pipes and their docking.

Electric welded clutches are also used, the edge of the pipe and the coupling on the welding parameters specified on the equipment are used.

Connection on glue (cold welding technology) is carried out using a special glue.

The described methods for mounting plastic pipes provide a durable, hermetic, reliable connection to long years. One drawback can be called - the need to acquire expensive welding equipment.

Note!

No need to buy a welding machine for mounting a small sewer system. In this case, it is better to choose the connection of plastic pipes without welding, with the help of fittings (fittings).

Everyone sooner or later have to deal with the need to install pipes. Depending on whether you have chosen pipes from what material, the technology of installation will depend on. About which connection is better to choose - welded, threaded or commercial - when working with pipes from different materials We will talk in this article.

Types of sewer pipes and connections

If earlier the sewer pipes were made mainly from the metal, today in the market you can find not only steel cast iron pipes, but also ceramic or plastic.

Ceramic sewer pipes are produced by a dimieter of 150-600 mm and are more often used when installing outdoor sewage. The main advantage of such pipes is the resistance of ceramics to the effects of aggressive groundwater. In the domestic construction, the use of ceramic pipes is extremely rare. As for the connection of sewage pipes from ceramics, it is similar to the compound of cast iron pipes.

The most applied plastic pipes are made of polypropylene, high and low density polyethylene, as well as polyvinyl chloride. Such pipes are characterized by simplicity of installation, ease, and still mechanical strength and resistance to corrosion. There are plastic pipes for outdoor and internal installation and differ not only with a diameter, but also in color. The first painted in orange color, the second - in gray.

And finally, the traditional material for the manufacture of sewer pipes - cast iron. Such pipes have excellent indicators of mechanical strength and resistance to corrosion.

Also on the market are steel sewer pipes, but they are quite rarely used when laying sewage, as they are subject to indebid exposure corrosion and unstable to aggressive soil waters.

As for the method of connecting pipes, it can be done by welding or gluing. If you plan to create a collapsible sewage system, the pipe connection can be carried out on a thread with fittings or on the flanges. In this case, flange compounds are used on the pipes of large diameter, since they will simply inconveniently connect with the help of a thread. Which of these types of compounds is most suitable for PVC pipes or cast iron pipes, as well as how to connect these pipes, we will tell below.

Cealing angle

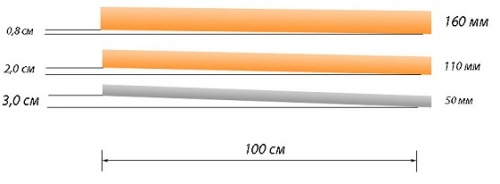

When arranging the sewer system in the house, you need to remember that for normal operation, the pipes should be laid under a slight inclination. In general, the bias should not be less than "0.02", which means that with the total length of the water supply in one meter, the height difference at the ends of the pipe should be equal to two centimeters.

At the same time, if the volume of the scraping is small, then the inclination of the tilt must be more and draw up "0.03".

In general, the angle of connecting sewer pipes can be calculated independently with the help of the formula:

![]()

Or simply use ready-made solutions.

Preparatory work

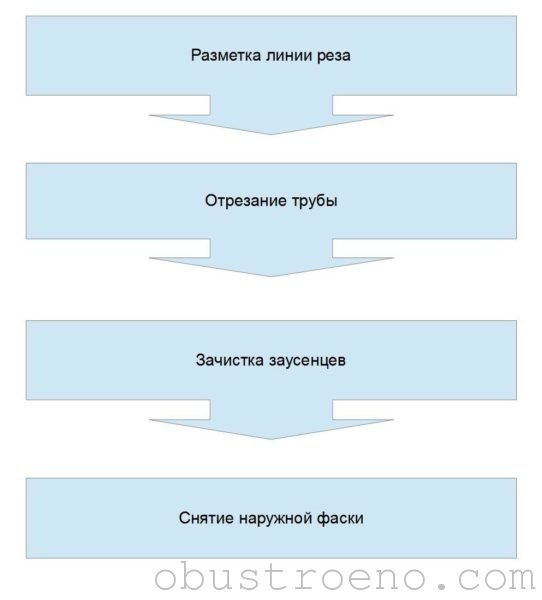

Before proceeding directly to the connection of sewer pipes, it is necessary to carry out some preparatory work:

- Make sure that the entire spectrum of accompanying goods has been purchased and during installation of pipes suddenly will not be found, which lacks special glue or, for example, heat-resistant mittens.

- Note the location of the Communications, prepare a plot for work and create a pipe placement plan.

- Carefully referring to the plan for placing pipes, mark the blanks and proceed to the cutting of the material. To avoid material recalculation, it is recommended to color from large sizes to the smaller.

- To connect the pipes, it was convenient, the locations of the marbles must be cleaned from the burr, wipe from pollution and degrease the special composition.

- If installation is assumed metal pipeThe external or internal thread is applied to them.

Connection of metal sewer pipes

The compound of metal sewer pipes can be carried out in one of two ways: mounting on welding and mounting into a piece. At the same time, the installation in the nest, as a rule, is carried out when the cast iron pipe is connected, while the welding is mainly used when the steel pipe is connected.

Cast iron pipe connection

As mentioned above, the compound of cast-iron sewer tubes is carried out with the help of seven. This installation is made according to the following scheme:

- Cast-iron pipe (that side that without a termination) insert into the fool already installed.

- We take the linen pass and seal the gap between the pipe installed by the pipe and the inner edges of the socket. To do this, we take a special wooden blade and, causing shock on it with a hammer, clog the first wound layer of the packley into the socket. At the same time, you must ensure that when driving a package does not get inside the pipe, as this can lead to the formation of blockages. By the end, the seal must be filled 2/3 of the crop.

- The remaining third of the crusher will need to fill in the seal without impregnation.

- After the slur, it is filled with cement mortar prepared in proportion of 9 cement volumes to 1 water. The solution should also be carefully tumped in a circulation, after which it is covered with a damp cloth. This is done so that cracks are not formed when drying on the cement. In addition to cement mortar, you can also use asbestos-cement mixture, bituminous mastic or silicone sealant.

This method is used to connect cast-iron pipes among themselves, but there are also situations when it is required to connect the cast-iron pipe with plastic. In this case, it is recommended to use special adapters and couplings. They are suitable for connecting sewage pipes of different diameters, as well as from different materials.

In order to qualitatively, perform the transition from the cast-iron pipe to the plastic, it is necessary to make a silicone sealant on a clean and dry inner surface of the crusher of the cast-iron pipe. Also we apply it to the adapter itself, after which we insert the adapter into the socket. A fully sealed connection will become immediately after the silicone sealant is polymerized.

Connection of metal sewage tubes video:

Docking steel pipes

Welding is used to connect steel pipes. And then the main thing is to fulfill everything professionally and taking into account all the nuances of the process. However, even having spent on the welding machine and correctly welded steel pipesWe get as a result of a rather unreliable design. Since the steel pipes themselves are not entirely ideal for sewage, and the welding seam, compared with the rest of the metal, will be more prone to corrosion. That is, only entering the sewer system, we already know that it has weaknesses that, over time, can cause water leakage.

Of course, in addition to welding, steel pipes can be connected using detachable threaded connections. Thus, the fitting-American woman is the most popular of such connectors and is two trumps, which are interconnected by a cape nut.

Connection of sewer plastic pipes

When connecting sewer plastic pipes can be carried out by one of three ways: on a threaded coupling, on welding and in a fool. Each of the technologies requires the use of certain skills and equipment, because we will look at each of them more in detail.

Installation on the coupling

First you need to decide on the view of the clutch on the plastic tube. However, before proceeding directly to the design of the installation process on the coupling, it should be noted that this method of docking the sewage pipes is allowed only if their diameter does not exceed 63 mm. In the same case, if the diameter of the pipe allows you to install on the coupling, you can get a completely collapsible water removal system.

The process of connecting pipes by means of a compression or threaded coupling is quite simple. It is enough easy to disassemble the fastener, wear a lock nut and sealing ring. Next, you need to insert the pipe into the coupling fitting and turn the lock nut on the threads of the cover, which will fix the connection location.

Threaded installation is considered the fastest way to connect sewage pipes, as the system can be operated immediately after tightening the lock nut. However, it is necessary to understand what quickly does not mean reliably. Also, in the case of threaded couplings - a threaded pair can overreight to unleash and the water will begin to seize the water.

Installation on welding

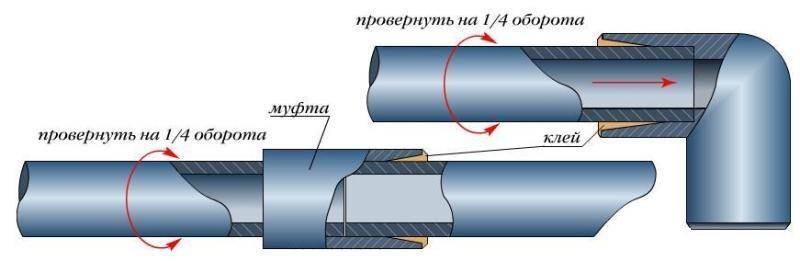

Depending on the material from which the sewage pipes are made practicing cold welding technology, or as it is also called gluing, as well as diffusion welding technology. Cold welding is used when mounting pipes from polypropylene, and diffusion - when connecting pipes from PVC. At the same time, both methods of welding are used when fixing the pipe in a termination or when installed in the coupling.

Installation polypropylene pipes Welding is done as follows:

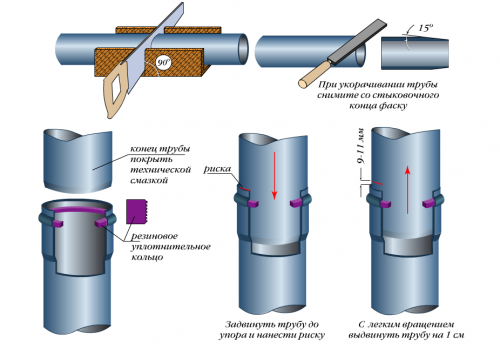

1. Cut the tube's end and measure the depth of placing the pipe in the coupling. Pruning and labeling depth must be preceded by welding, since otherwise you are significantly risking the installation quality, and therefore the reliability of the entire system.

2. With the help of a special soldering iron heating the coupling and pipe. To do this, both products must be put on a nozzle and warm up to 260 degrees.

3. Heated parts are removed from the guides, after which the pipe is inserted into the clutch on the labeled depth.

With this embodiment, the installation of polypropylene pipes is considered to be ready for operation immediately after the coils of the seams to room temperature.

The connection of the sewer pipe PVC is as follows:

1. Implement the end of the end and labeling the depth of dive.

2. On the inside of the coupling and the external part of the pipe we apply special glue, after which we insert the pipe into the clutch on the marked depth. Rotate a bit around the axis. We note, when choosing glue, it is better to give preference to that product that the manufacturers of fittings and pipes themselves are recommended.

Installation in the pattern

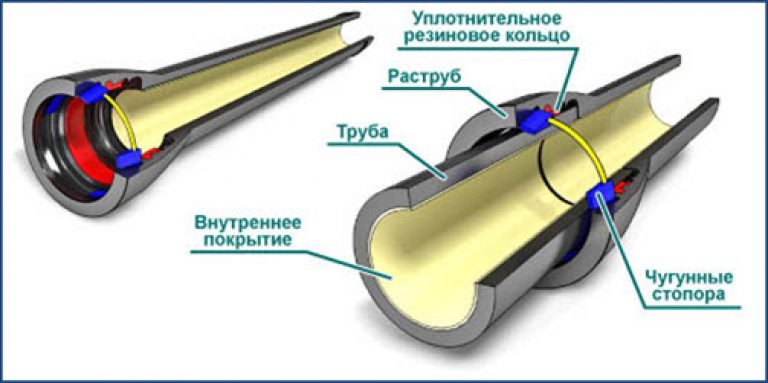

Installation in fallen can only be carried out if it comes to connecting pipes that will subsequently become part of non-pressure networks. Also, the pipes themselves for mounting in the fool must have special thickening on the end.

The pipe compound is as follows:

1. The pipe is installed on the support surface. The slur is mounted to the opposite flow movement.

2. Insert the sealing ring into the slotting of the receiving pipe.

3. When the sealing ring is installed, we enter the sleek end of the second pipe.

4. After assembling the connection, it is necessary to fix the second pipe on the reference surface.

In this article, I will write about how the compound of plastic sewer tubes is performed, with cast-iron pipes, as well as from the fasonial of different types. Some decisions may seem unusual, but they are quite capable of helping you when installing complex suturing system configurations.

General rules

A number of rules are relevant for installation of any sewage regardless of the type of pipe and the fasonine used.

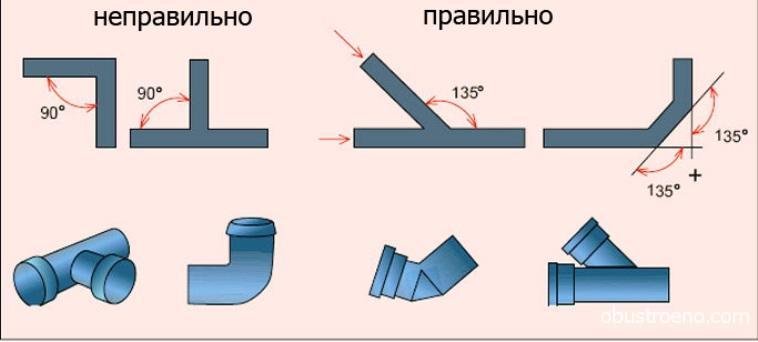

- Popular compounds of self-sequalization are always assembled so that the crops are directed against the flow of effluent. In this case, the inner surface of the pipeline will be as smooth, devoid of irregularities that can cause blockages;

- Pipe is laid with a constant slope in the course of stock. The optimal value of the slope is determined by diameter:

- Pipes are not mounted with bend or lant. Turns are carried out only due to the shaped elements;

A polyethylene sewer pipe due to the elasticity of the polymer is still minor bends.

For PVC, polypropylene and especially cast iron internal stresses are contraindicated: in combination with temperature drops, they often lead to cracks.

- Compounds on the turns and branches are performed by oblique tees and deposits at an angles of 30 - 45 degrees. Thus, the overflow of the pipe is excluded at a volunteer discharge and simplifies the cleaning of the clouds: the cable or sewer wire pass the smooth bending with minimal resistance. In addition, on the tee they always move along, without flexing in the opposite direction;

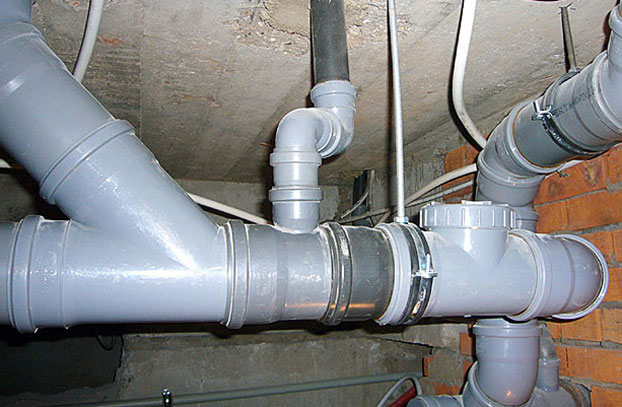

- Complex builds with several shaped elements are necessarily fixed by clamps. This instruction will exclude spontaneous diversion of fuse-tubes;

- Horizontal sections collected from plastic pipes are fixed by clamps, clips, supports or suspensions every 8-10 diameters of the pipe. Otherwise, after 1 to 2 years, the pipes are saved, forming areas with contorlaons, each of which is a potential location of the ground;

- When assembling pipe risers are attached on each raster. The cast iron link (horizontal sewage) is similarly mounted;

- The compound of cast-iron and plastic sewer tubes is performed with a number of restrictions associated with the difference in strength and ring rigidity. In particular, the plastic tube cannot be chipped into the cast-iron raster and use the cast-iron fireplace or the pipe to replace the plastic riser. In the first case, plastic doubts, in the second plastic rasters, over time, collapse under the weight of the cast iron.

Bypass the last problem is still possible. To do this, it is enough to ensure a rigid fastening of all cast-iron shaped elements and pipes to the capital wall.

The chasing of the plastic tube in the cast iron is a rapid idea.

Plastic with plastic

How to combine sewer plastic pipes when assembling samotane domestic sewage? For the connection and pipe, and the fasonine are equipped with rubber ring sealing conversion. A pipe with some force is inserted into the socket - and you can mount the following joint.

Unlike cast-iron patterns, requiring chasing, plastic sewage, if necessary, is just as easily dismantled or disassembled for cleaning.

How do you cut off the plastic pipe along the place and prepare it for docking with a socle?

I do this as follows:

- I place the position of the cut, taking into account the depth of the termination;

- Wrap a pipe with a piece of paper, aligning its edge, and spend a circle around the edge of the leaf. It will accurately perpendicular to the longitudinal axis;

- I cut off the pipe on the marking of the grinder with the abrasive circle. On metal or stone - anyway;

It is the abrasive circle that gives the perfect sharp res with a minimum amount of burrs.

Disk saw, manual hacksaw and even a diamond circle cut plastic much more coarse.

Abrasive cutting is not applicable only for polyethylene pipes: the polymer is lower than that of PVC and polypropylene, the melting point and begins to flow.

- With the same abrasive circle, I remove the outdoor chamfer. It will greatly simplify the salt compound assembly;

- A sharp knife cleaning the inner surface from burrs.

How to collect fool if the pipe does not want to enter the ring seal?

- Make sure that the sealing ring is not twisted and across the circumference is laid in the ring groove in the termination;

- Apply a slightly liquid soap or any other water-based lubrication on the inner surface. In no case do not use machine oil for lubrication and other fuel: they will force the rubber of the sealing tires.

Is it possible to connect together two fastening plastic pipes together? Of course. A sewer coupling is served for this purpose - a short pipe with two sockets.

Installation is performed in the same way as in the case of docking of fuse-tube pipes.

When installing horizontal sections of the sewage, which is not supposed to be disassembled for, the assembly on silicone sealant is practiced.

It will not be worse from this: Silicone will provide tightness even if with a debt of simple rubber seals they will lose elasticity and will give leaks. However, I highly recommend the reader to refrain from saving on sealant: Cheap silicone does not hold onto smooth plastic, depriving additional sealing of any meaning.

Compensating pipe

What to do if additional shaped element (Tee, Cross, revision, etc.) Do you need to cut into a straight pipe?

A compensating nozzle will come to the revenue, equipped with an elongated socket.

The insert is performed like this:

- A plot of pipe is cut. It is desirable - near the termination. If the nearest socket is far away, the sewage coupling is worn to the smooth end of the bottom in the course of the drain pipe;

- A compensator is tightened to the top pipe until it stops;

- In the slot, the lower pipe or coupling is inserted with a sleek end of the Fasonin, which we want to mounted;

- The compensating nozzle is lowered along the pipe into the fool of the shaped element;

- The neck of the latter is fixed by a clamp or clip to prevent its offset and dusting of the connection.

Plastic with cast iron

How to combine the cast-iron sewer pipe with plastic when replacing the area of \u200b\u200bthe old sewage?

- The plastic tube is inserted into the cast-iron fool of the corresponding diameter through the rubber cuff - the seal. The skin must be pre-cleaned from rust, sediments and residues of old sealing (cement mortar and cabels). It does not hurt to apply a silicone sealant between the socket and cuff: the inner surface of the termination almost always has significant irregularities;

Sealing cuff - adapter.

- The cast iron pipe with a nominal diameter of 100 mm is included in the fuel of plastic 110 mm sewage after stripping the surface from the layers of paint and rust. And in this case, from the end of the pipe, it is desirable to remove the chamfer (with the help of a grinder with a circle for metal or a conventional file);

The above-mentioned compensating nozzle is also perfect on the cleaned cast-iron pipe.

I was used to use it for the punching in the cast-iron riser of additional taps. The compensator with the coupling can be used to repair the destroyed cast-iron termination.

- Those who are too lazy to bother with cast iron stripping, can connect the sewer pipe - plastic with cast iron using a special adapter, equipped with a wide fracture and a thick sealing cuff. The price of the product is about 200 rubles.

Adapter with cast iron on plastic. Its distinctive feature is an extended fallen with a thick sealing cuff.

A special case

A separate paragraph, I mention the connection of the knee of the siphon under the sink with the socket of the old cast-iron comb (intra-ordinary sewage). Theoretically, this connection must be sealed. The gap between the field and the knee often leads to the appearance in the bathroom or in the kitchen of the steady smell of sewage.

Most often, this problem occurs in winter, when snow caps that interfere with normal ventilation are formed on the conclusions of the root risers.

The thrust in a closed riser begins to transport the air together with the accompanying aromas from the lower on the rising apartments to the top.

Full sealing of a compound in most sets of strapping for the sink is below any criticism: it is a plastic semicircular plug with a rigid rubber gasket.

The position can save the cuff for the toilet bowl with the top tank, made in the form of two rubber cylinders of different diameters. It is tensioned by a narrow side of the knee, and wide - on a cast-iron socket, after which it can be forgotten about extraneous smells in the apartment.

Pressure sewage

Usually in domestic conditions, the sewage is made in self-either; However, in case of complex terrain or when placing sanitary devices in the basement, individual sections can be equipped with fecal pumps. How are the pressure plots mounted?

- An ordinary non-pressure pipe with a mandatory fastening of all Gorlowins. The strength of the pipes and the beans is quite sufficient to withstand the pressure of 3-5 meters. The rigid fixation of all connections will not suck them;

- Purulent tube under adhesive connections. The glue solvent for PVC is applied to the outer surface of the pipe or on the inner surface of the termination, after which the parts are combined, turn on a quarter of turns and are fixed for a couple of minutes in a fixed position;

- Pressure polyethylene pipe. Its diameters correspond to the diameters of non-pressure sewerage and make it completely compatible with plastic fasonios.

crazy hands

Finally, a couple more recipes that can help you in abnormal situations.

Corrugation

It is a corrugated polyethylene tube with a diameter with a diameter of about 100 mm with a smooth section on one side and equipped with a fular cuff to another. The corrugation is designed to connect a toilet bowl with a displacement relative to the sewer termination.

However, it can be applied for other purposes:

- For mounting the toilet with oblique or horizontal release in the house of Stalin's construction built under vertical editions. In many houses, the construction of 30-50s of the last century, the sewage is removed in the floor toilet; To connect with the rim, the ladder is installed under the ceiling of the lower apartment;

- For reversal of the toilet at right angles to the release. If necessary, two corrugations can be connected to this goal. I was tried to deploy the toilet in my own apartment: its dimensions and the washing machine installed in close bathroom did the use of the bathroom impossible;

- To connect two plastic pipes under an arbitrary angle (in particular, to bypass water supply and other obstacles).

When installing corrugations it is worth remembering a pair of subtleties:

- She should not be saved. I already wrote about the dangers of confurons. In the case of corrugations, the situation is exacerbated by an uneven inner surface;

- Corrugation can not be attached to the box and falseland. The term of its service rarely exceeds 5 years. The typical problem of this fitting is to flow the corrugation fold.

Flavor under the glue

A common PVC patter tube with special requirements for the strength of the compound can be redesamed under a glue fool.

This is done like this:

- The end of the pipe is heated to a plastic state over a gas, an electric stove or with a construction dryer;

- Then the pipe is slightly stretched (with hands in dense gloves or tensioning on a liter glass jar, the diameter of which approximately corresponds to 110 mm sewage);

- The improvised socket is powered by a smooth pipe with a silicone surface applied to its outer surface. The pipe should go to it by about 10 cm; As a rule, it is necessary to warm up two or three times. Silicone performs lubrication function and, after setting, sealing the glue compound.

1.

2.

3.

4.

5.

6.

Plastic pipes are made of thermoplastic materials, and in turn are compositions that include polyethylene, polyvinyl chloride (PVC), polybutylene or polypropylene. They soften in the case of their heating to critical temperatures, and then during cooling without problems restore its structure and their inherent properties.

In the last decade, plastic pipes are increasingly changing metal products. They quickly gained popularity due to the presence of a number of indisputable advantages:

- not exposure to corrosive processes and when laying them into the ground there is no need to isolate the pipeline;

- resistance to the effects of chemicals and aggressive media;

- low weight;

- the smooth surface from the inside, which increases the bandwidth of the pipes;

- the simple installation of plastic sewer tubes is possible due to the use of fittings;

- resistance to mechanical effects;

- high elasticity;

- durability and reliable functioning even up to 100 years.

If necessary, perform the installation of the system, you should consider the pipeline laying circuit and determine how to connect plastic pipes for sewage (read also: "").

Stages of preparation for installation of plastic pipes

Before starting the pipe laying, you need to make a schema of the sewer system, calculate and purchase essential materialsAnd also prepare tools.

Conducting calculations, take into account consumers who use water system.

The shaped products (connecting parts) used when installing the internal system, fastening and branching fluid flows are:

- coupling;

- plug;

- tee;

- transition;

- cross;

- sealing cuffs;

- revision;

- retraction (angle).

At this stage, the pipe is determined and the number of other materials.

The insertion into the main sewering highway is performed using a crossliner having three outputs, with two of them with a diameter of 50 millimeters, and one - 100 millimeters (more: ""). To the 100mm, the toilet is connected to one of the 50-millimeter conclusions - the rest of the plumbing located in the toilet and the bathroom (these are sinks, a bath, washing machine), and the second 50mm conclusion - plumbing devices in the kitchen (washing and dishwasher).

The domestic network is a system operating without pressure. In it, the drains move under a uniform bias in the direction of the riser. As she looks, can be seen in the photo. At the same time, uninterrupted wastewater movement should be ensured.

The optimal dimming size of the pipeline should be 2-3 centimeters per meter. The installation of plastic sewer pipes is starting with their own hands from the long entry point to the waste fluid leads. From this place and you need to calculate the slope.

How to connect plastic pipes

After finishing preparatory work Start the installation of the pipeline.

Coupling connection. The ends of the pipes are trimmed at right angles, put on the coupling so that its center coincides with the junction site. Then the products are made according to the clutch position. From the inside the ends of the elements are lubricated with lubrication. Further in the coupling is inserted one end of the pipe and coming to another, sticking to marks. When creating non-pressure sewage, fittings from corrugated pipes are used.

Both of these methods have low cost and do not require the use of special tools and expensive equipment.

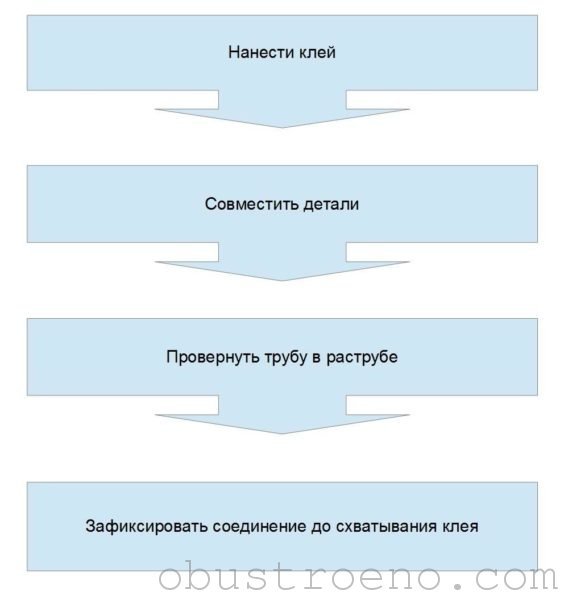

Incomponable connection. For welding jack requires special equipment. Also use electric welded clutches: for this heats the edges of the pipe and couplings, setting the corresponding parameters on the equipment. The adhesive option implies the use of special glue. Before gluing the sewer plastic pipe, carefully study the instructions for glue composition.

The above methods for connecting plastic products into a single design provide reliable, hermetic and durable compound for decades. They have one drawback (except for the adhesive option) is the need to apply equipment that is expensive.

Connecting sewer pipes "in a slurry"

As for the fracture connection, it is considered the most simple way Installation of plastic pipes with the use of shaped products. The tightness is ensured by the compression of the rubber ring on the raster and the smooth end of the pipes (more details: ""). Their edge is lubricated with silicone, then insert into the socket, and the pipe itself is attached to the support surface.

At the same time, we should not forget that the sockets are placed in the opposite direction in relation to the direction of flow flow. Before combining the sewer plastic pipes, their ends can be lubricated with liquid soap. For the processing of the end of the products, the hacksaw with small teeth.

Connection of pipes for sewerage on glue

The strength of this method of compound is based on the mutual penetration of polymers at the molecular level.First of all, a special glue should be purchased, which urged the edges of the pipes.

After that:

- bled surfaces are cleaned of contamination, squeaks and degrease;

- prepared edges are lubricated with glue;

- the ends of the pipes are placed in each other;

- in order to ensure tightness, the place of the junction is missing.

How to glue pipes with welding

When applying welded methods for mounting pipes from plastic, the combined edges of the products are subjected to a small smelting process using special equipment. Heated ends pressed each other, withstand a certain time until the place of the junction cools.It is impossible not to say that this method has a significant drawback: not all types of welding can be carried out at home. So before proceeding to the performance of electrical welding undergo special training.

Connection of pipes fittings

Connect plastic products using fittings due to the presence of an internal sealing ring. Mounting the pipeline by this method can be performed with your own hands (read also: ""). Any newbie is able to connect such a household appliance as a washing machine to the sink with a tee fitting. The connection of pipes without soldering using compression fittings will use for fixing the parts of the pipeline having a small diameter.

One of important elements The sewage system is the cleaner hatches that are located in those places where the formation of a block is most often possible. These need to provide convenient access for the purpose of cleaning and inspection. Clear hatches are of different configurations.

Based on the above information, it can be concluded that plastic pipes are largely superior to metal products.

The term plastic tube is generalized, which includes products from thermoplastic. In turn, this includes pipes from polyethylene, polyvinyl chloride, polybutylene or polypropylene, etc.

Most sewer pipelines are made from, therefore, within the framework of this article, consider the connection of such products. After all, the reliability and durability of the entire system depends on the proper connection.

Connection methods

There are several installation options for plastic pipes:

- in slur;

- with glue;

- welding;

- fittings.

All these methods will provide a durable, hermetical and reliable connection. Now we will analyze them in more detail.

Video: How easy to dock sewer pipes and other tips on sewage laying

In squash

This is the easiest, and therefore the most popular option. Work is divided into several stages:

- Flavor and end of the pipe clean from dust and dirt.

- We check the presence of a rubber seal that provides tightness.

- The pipe is lubricated with silicone lubricant and insert into the fool. On the pipe it is necessary to make a mark in advance indicating the depth of administration.

- Gently pull the pipe back to 1 cm focusing on the mark.

Due to the compression of the end of the pipe with a rubber ring, the tomb of the connection is achieved.

On a note!

Silicone lubricant can be replaced with soap or any detergent. Pipes cut off with a shallow tooth.

With glue

This, no less simple method is used for installation PVC pipes. For such compounds, special glue is used. The work passes as follows:

- Bled surfaces are cleaned and degreased.

- Adhesive glue on the prepared surface.

- Pipes insert each other and hold them in this position 1 minute.

- To increase the tightness of the joint, the tubes are wicked by another layer of glue.

On a note!

The gluing process should not exceed 1 - 2 minutes, as the glue loses its properties in the air.

Welding

The following connection option is welding. To do this, it will be necessary to purchase special equipment with which plastic is heated. Pipes heated to a temperature at which plastic begins to melt, press each other for a few minutes.

After complete cooling, a monolithic compound is obtained, characterized by increased tightness. The disadvantage of such a way is the need to buy special equipment that is quite expensive.

With fittings

Connect plastic pipes with special fittings. This method is often used if you need one - two compounds in a small diameter pipeline. Also, this method is popular and when combined. To carry out the installation on the pipeline, install a clutch with a rubber gasket.

Stages of installation of sewer plastic pipes

The arrangement of the sewage system begins with the preparation, namely from the construction of the sewage scheme, calculating the necessary materials, etc. And for this you need:

- take into account all consumers of water;

- draw the scheme - where turns will be, bends, determine the number of shaped parts;

- calculate the required number of pipes and other materials.

Most often is a non-pressure system, it means that the drains are moved by gravity, due to the uniform slope toward the riser. Provides uninterrupted water flow. Mounting begins with a long wastewater removal point, it is from it that is calculated, which is 2 cm per 1 meter of the pipeline.

The choice of a method for connecting plastic sewer pipes depends on their features, the availability of skills and tools. If you are not sure that you can independently fulfill all the work qualitatively, it is better to entrust it to specialists, which will exclude the appearance of leakage and carrying out repair work.

Video: Installation of plastic sewer pipes