Konopka Any. wooden bath It is necessary to perform in two stages: after the completion of construction and a year shrinkage. For work, use the same insulation that is paving between links during construction. Traditionally, the bath canopate use: moss, felt, pass, hemp. How to make a bath with your own hands, what tools are needed and readers learned, having studied the article to the end.

Crop the bath will have to be in any case. The main thing is to work carefully.

Features of cacopa baths with various materials

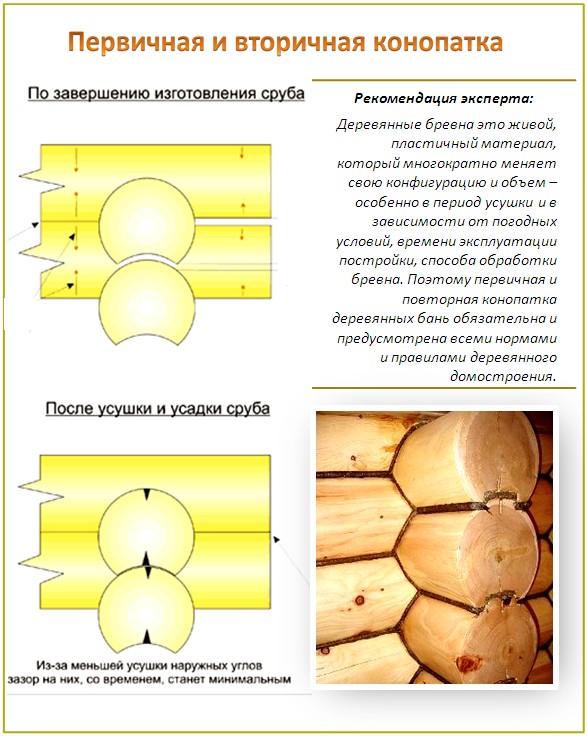

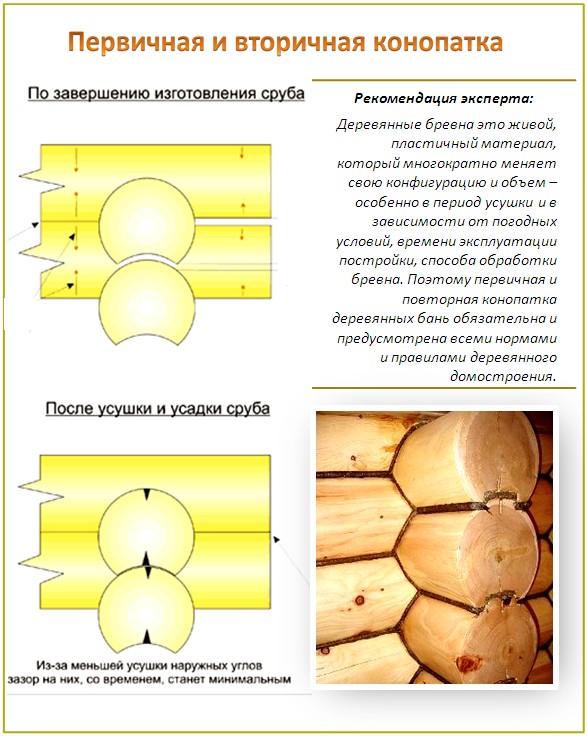

When assembling the bath box, the insulation is paved between each log or timber. But wood gives shrinkage in the independence of chamber drying material or natural humidity. With shrinkage between the logs, space appears, so it is necessary to cross the bath for the first time to compact the seam and the second to eliminate the resulting gaps.

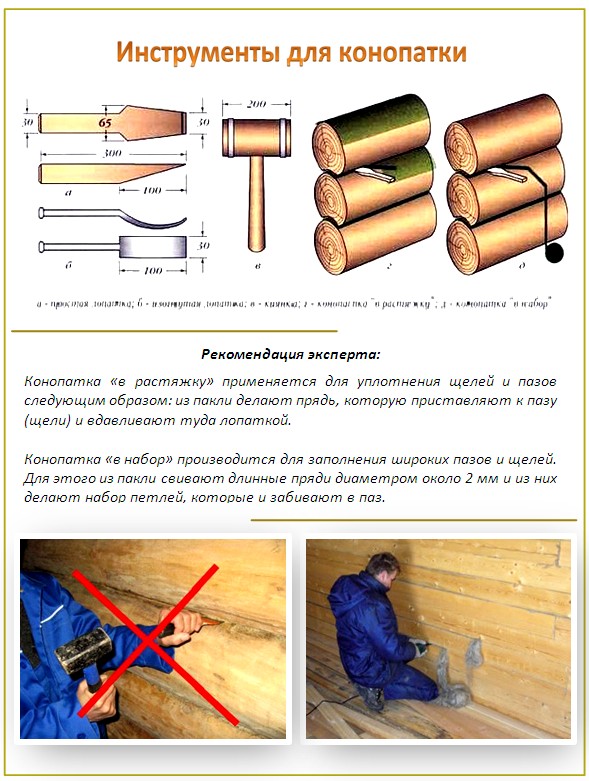

Crop the sack of a bath is easier using special tools: caulking and rubber hammer or a conquer. If there is no cacopa, then you can use the usual chisel.

What material is better to potat a bath?

For cacopa, a steam room is used by natural heaters: moss, hemp, pass, felt. All materials are available, but each must prepare in their own way.

Preparation of moss for caulking

Warming of seams moss traditional waywho used our grandparents. Moss can be scored independently or purchase ready-made in a construction store.

Konopka moss is one of the most eco-friendly materials.

Konopka moss is one of the most eco-friendly materials. Price per moss from 250 r., So cheaper to dial in the forest. The assembled moss is decomposed under the canopy and leave to dry for 1-2 weeks. It is necessary to mix moss once every 2-3 days so that it does not start. The use of wet moss will lead to the formation of mold and the destruction of wood. But it is necessary to follow the drying, as the pushed moss will be fragile and it is difficult to work with it.

Pluses of moss:

- Efficiency (you can type for free in the forest).

- Natural, it means that environmental friendliness is not disturbed.

Minuses have more:

- When drying, becomes fragile.

- It is difficult to careen with a bath.

- It is afraid of moisture and mold.

- Short-lived.

- Good burns.

Choose a moss to cavalize frames only as saving. From the point of view of practicality and durability, it is better to pay attention to something else.

Preparation of felt for canopt

Felt natural material Based on wool. But modern felt can consist of frayed fibers. Moreover, the composition is: 60% wool and 40% artificial fiber, 70% artificial fiber and 30% wool. For the bath choose completely natural or with a large wool content of felt. The fact is that natural material does not burn, but just smolders. Artificial felt is fightered.

The felt for the cacopate bath is suitable natural or with a small addition of artificial fibers.

The felt for the cacopate bath is suitable natural or with a small addition of artificial fibers. Before working felt, it is necessary to treat a solution of formalin, it will not give moths to divorce into wool. After spraying, felt hang out in the sun and carefully dry.

The main advantages of felt are:

- Naturalness.

- Concrete logged simply.

- Natural material is afraid of moisture and rot.

- Mice and birds love to use felt for the construction of their nests, and smear the material from the slots in the Siruba.

- High price of natural insulation.

Preparation of packle to pantry bath

The pass is particularly cooking before work. But mole and other insects love to settle in natural material, so the passage is soaked with any protective composition, for example, formalin.

Pancakes canopate can be baked in bales.

Pancakes canopate can be baked in bales. The main advantages of the use of the packley:

- Low price.

- Natural material.

- Easy work.

- It is afraid of moisture.

- Over time, it can start grew.

- Mice will fall into insulation.

Pacle is an alternative to the MCU, since the price of the material begins from 70 p.

Jute and Flap Bani Bath

Modern variants of the insulation: jute and flabbling can also be used to cavalize the log house. But despite the manufacturer's assurances about the naturalness of the insulation, most of them are artificial additives. They make the jute and flabbing durable, but environmental friendliness decreases.

Jute for yuan is sold in the shape of a ribbon.

Jute for yuan is sold in the shape of a ribbon. Natural jute is made of wood lyps of the family of lime. Jute has high performance, durability and resistance to moisture. Water, falling on the material, is not delayed on jute fibers, but quickly dishes.

Flap fiber is made of flax waste. The material well showed itself on construction sites. Does not rot and does not absorb moisture. But there are pitfalls, the sellers offer the buyer of Fliminatin instead of libolok. Materials are similar in composition, but batting is 40% artificial fiber. You can distinguish one from the other in color, the flanutin has a light, and the fibers of the natural insulation are darker.

Available in the form of a tape, cord. To cavalize the bathhouses apply a ribbon jute or flax fibrel.

Crop the log house is needed insulation, which meets your requirements and opportunities.

Crop the bath is necessary in two stages:

- immediately after installing the box;

- after shrinking the bath.

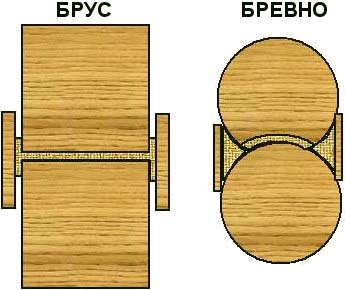

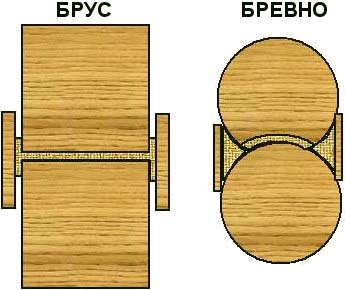

Cropling is difficult to re-frame from a profiled bar, as the castle will not give work to work efficiently. Therefore, the material with the profile is better to take chamber drying or glued. So, the shrinkage will be minimal and the secondary cavity will not have to. All other types: log, simple timber, otlindrovka need to be reheated. It is necessary to work with special tools, as shown in the video:

Tools for work

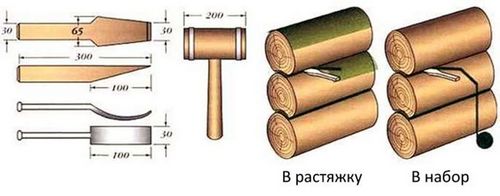

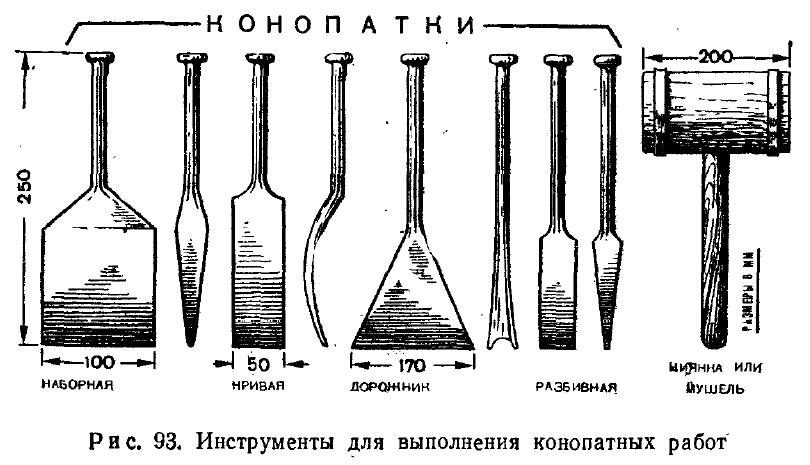

To cavalize the log houses use different kinds Konopkka:

- typical;

- curve;

- broken;

Also necessary kiyanka (Muskel). The tool is used to hit the pantry during work. Cyanka can be replaced by a conventional rubber hammer. Need a roadbreak, the tool helps to align the seam after punching with puzzles.

What subtleties you need to know when the bathroom canopy

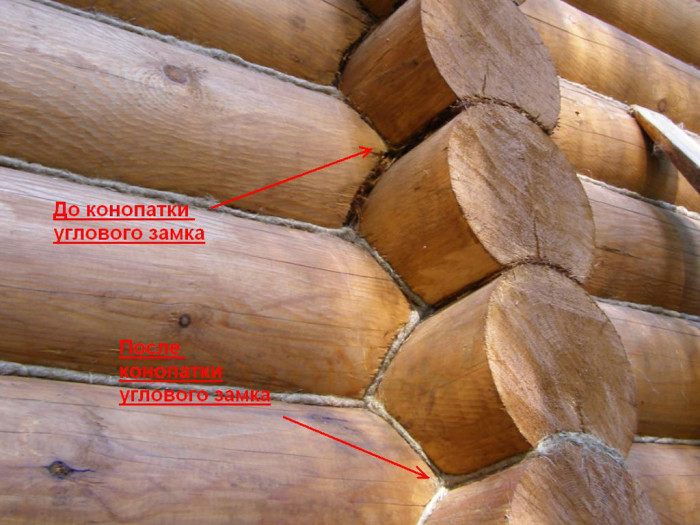

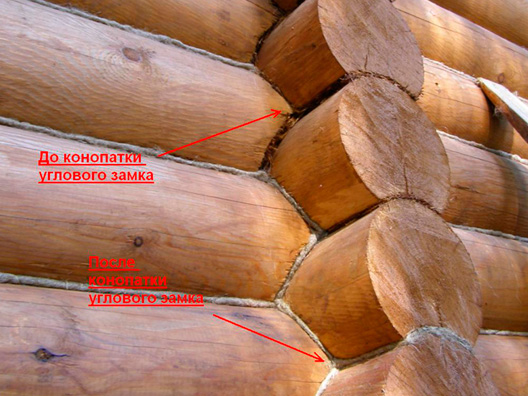

Crop the walls of the bath should be left at the bottom throughout the perimeter. And the work is performed first the crossing of one row from the inside and outside, then the second, etc. The fact is that when the bath is raised by 5-15 cm. If it is not sequentially, the structure will switch. Crop the lower groove on the entire perimeter, outside and inside, then the second, the design of the bath will rise smoothly and evenly.

The bass canopt begins to bottom, throughout the perimeter.

The bass canopt begins to bottom, throughout the perimeter. It is necessary before cauting the log house to take care of the chimney. The pipe is liberated in places of connection with the ceiling and roof or removed for a while not to damage.

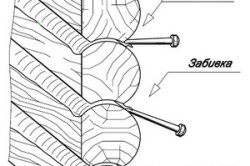

Canopate bath with two methods:

- in the set;

- rotate.

Consider each more.

Canopate bath in a set

Crop in the set is necessary when embelling large slots and grooves. The selected material is twisted into the harness of 15-20 mm and for convenience are cordoned into a small tangle. The harness is substituted to the gap and clog through the helps and the cinema, as in the photo.

Konopka in a set and spinning.

Konopka in a set and spinning. First on top, then below. Align all with the agency.

Canopate Baths Romanovka

The insulation does not need to twist in the harness. It is simply stuffed in the slot between the links, and then punch with the Cyonya. Perform work until the insulation will no longer be called between the log cabins of the bath.

Crop the shed must not rush, thoroughly closeing each gap. Places where it is difficult to get tool just repaid by mounting foam.

We answered the question how to pure a bath various methods. After the bathhouses are finished cavalous, it must be seized and covered with protective compositions. Talk about it next time.

You can build a bath on your own or purchase a ready-made log house and put on the foundation. The first option takes longer, and the second is dangerous in that it is possible to purchase a poor-quality or defective building. If you have chosen a finished design, then you note that it is necessary to close the slots between the logs. What is better to hover the sack of a bath to serve for a long time?

Ban canopate is close up of cracks between the logs.

Bath is a building that is used for washing. It has no permanent heating, and the stove is drowned only when they are going to wash. At the same time, when equipped, the difference between the temperature inside and outside the building is very large, for example, in the bath + 70 degrees Celsius, and on the street - 10. It is wet, a lot of water and steam. Materials used for cutting cutters must comply with the following requirements:

- maintain heat indoors;

- withstand temperature differences;

- do not absorb moisture and steam;

- paste air;

- various high service life.

There are several materials that are well suited for climbing the gaps in the walls of the bath: moss, jute or linen canvas, sealant.

In fact, other materials are used for cacopa, such as palable and felt, but they are not suitable for premises with a high degree of humidity.

Concovery materials Bath

Moss has long been applied to fill the gaps between the logs. He is inexpensive, but it is more difficult to work with him than with modern materials. If you decide to close the junctions between the logs of moss, first smoem it a little, because it crumbly. Only two types of moss are used: Cukushkin Flax and Sfagnum. The first sweep in tapes that are inserted into the gaps into several rows. The second is used in the form of fibers, which, when clogging, hang from the cracks of approximately 5 cm. Then with the help of the tools you need to legittail the material in the junction.

![]()

Jute and linen canvas - tape insulation, that is, the canvas are cut and folded into small shots. The lack of them is that over time moisture resistance decreases and the bath will need to be repaired.

The jointing of the joints between the logs is made in two ways:

- "Stretching" - the material is divided into narrow ribbons and inserted into the gaps;

- "In the set" - divided into the threads.

Most new Material To close the cracks between bars - it is a sealant for wood. It is sold in plastic tubes, in the form of briquettes or cords. This is the only non-natural, but synthetic material. It is distinguished by a high degree of resistance to temperature drops. To fill them with joints, a fairly special construction pistol. The mass is simply extruded into the gaps and fills them. Sealants There are different colors, you can pick up a shade under the color of the bath itself.

Procedure for the Conduct Srub

Credit needs to be caught twice: immediately after installation and after he survive the shrinkage. After a few years, you need to check the condition of the gaps between the bars. It is possible that in some places it will be necessary to replace the insulation.

When using any material for clogging, the cracks will need several wooden blades with a flat tip and a hammer. The material is inserted into the gaps between the bars of the shovel, and it is necessary to knock on it with a hammer so that it penetrates deep into. But you do not need to knock very much, and then the gap will just become more.

After installing a church for the foundation, you need to start closing the gaps. Next should be prepared required tools, choose the material, make the calculation of the right amount. It will take to calculate the perimeter of the building, multiplying it to the number of junctions between the bars and the width of the window and the door. Remember that it is necessary to careen not only from the street, but also from the inside of the room, which means that the obtained number needs to be increased by 2 times.

Konopka cut in any material starts from the lowest joint. You need to close the lowest gap on all the walls around the perimeter of the structure first outside, and then from the inside. Next, close the cracks between the second and third bars of the walls, etc. This is due to the fact that the height of the wall increases with cacapatka. If you do the work unevenly, then the entire log house is bothering.

In order to get the perfect warm log house for permanent residence, correctly mounted it. It is also necessary to quickly fill all the cracks between the logs, so that the heat loss as little as possible has overwhelmed the house. Do not everyone know how to root the loghouse correctly, and therefore the implementation of work on insulation sometimes lead to a doss of the house (in the worst case) or simply to rotting the tree and insulation (at best).

About how to root a log cabin from the moss video and general recommendations According to other types of insulation in our material below.

Materials for cutting cutters

Caulk wooden log can various materials. The benefit of the construction market today offers wide choice of natural to synthetic and semi-synthetic. The most popular are such species:

- Construction Moss.. May be called "SFAGNUM" or "CUKUSHIN LEN". This type of insulation was used by Archors yet in ancient Russia. Moss quality as insulation is priceless and indisputable. Safagnum is highly resistant to moisture. He seemed to get off with a tree in the event of the convergence of the latter and simply takes all the moisture to himself. In addition, Moss does not represent any interest for birds, moths and other insects. And this means that all the material for the cacopa will remain in the place that the master will determine for him. Moss "Sfagnum" and "Kukushkin Lon" does not burn, does not rot and is an excellent natural antiseptic for wood for many years.

Important: Buy construction moss in any volumes can be in specialized points of sale.

- Construction package. This type of material also behaves perfectly in a tandem with a tree with a pant of walls. Produce a pass from the residues of flax and cannabis grass. Pacle is also a natural material that protects the tree from moisture and cold.

- Jute fiberin the form of a ribbon - improved material of natural type for cacopa of walls. Jute is made of shrub, which refers to the family of lime. And Lipa, as is known, copes well with cold and moisture. Jute is able to somewhat moisturize the log when it is over drying, but it does not take moisture at the tree with a moisture content in the house of 80%. Jute's tape is conveniently laid between the crowns, as well as fill in the slot when re-insulation at home.

- Linovatin. They produce insulation of linen fiber in the form of a wide ribbon. According to mine technical characteristics Linovatin is similar to Jute. It is convenient in styling between the crowns and with a pantry "stretching."

- Felt. Unsuccessful type of insulation for wooden house. Felt is inclined to rot between the logs and in the case of an excessive amount of moisture on the wall felt not only will lose its insulation qualities, but also spoil the tree from the inside.

Tool for performing work

![]()

In order to properly finish a chopped home, you need to use special tools. Otherwise, the insulation will fall into the slot surface, which will lead to the formation of cold bridges. Basically, professionals use special steel or metal cacopakes. The first is better. You can also make wooden cacopakes from dense wood - beech, walnut, oak. It is desirable that the tool has a rubberized handle for the convenience of performing work.

Important: The tool for cauldron should not have an acute blade, otherwise the insulation can be damaged during caulking. For the same reason, it is necessary to avoid jar on the surface of the tool. In this case, the insulation is clinging to the teeth and breaks.

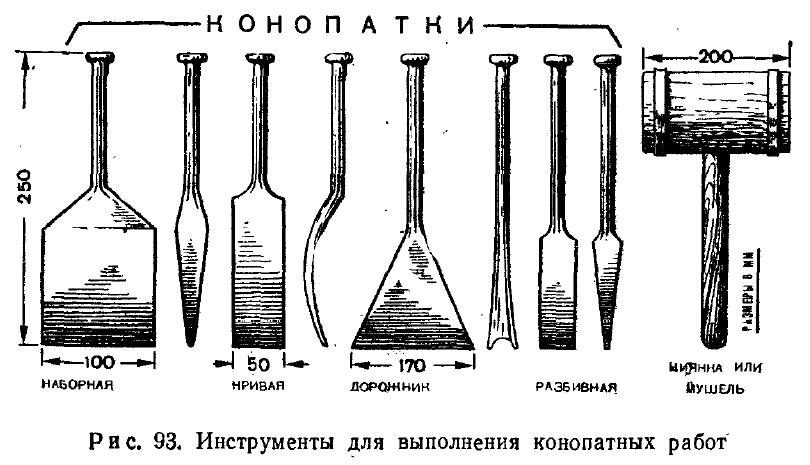

The main type of core tools:

- Set of cacopat. It is a flat peculiar chisel with a blade width of 10x0.6 cm. Used to pack the insulation of seams between the logs.

- COVER COVER. The same chisel, but the curve of the form. Used for root corners of the house and rounded gaps. The width of the blade in this case is twice as smaller than that of a set of cacopa.

- Konopka "Morning". It has a water-shaped form and is used for the cacopa of the slots using the method "in stretching". The blade here has parameters 170x15 mm. Depending on the width of the slit, you can use a wide, medium or narrow panty.

- Konopka is broken. It has a wedge-shaped blade width of 30-35 mm. Such a tool is used to expand narrow slots and filling them with insulation.

- To help all types of tools use Cyans. With the help of such a rubber hammer, the seal in the slot pushed.

Technology performing work

In order for the house from the log, the insulation gasket must be performed in several stages. At first, the rolled insulation or construction moss is laying out between the crowns in such a way as to 5-6 cm he played the edges of the log. In this case, the ribbon insulation of the type of jute or flax fiber fixes to the tree with a construction stapler. By the way, you can do the same with moss.

After the house feels down and sweeps, new gaps are formed. It is through them that the heat loss will occur. In addition, heat, leaving the house, when contact with wood and low temperatures On the street will form an embryo (moisture). That, in turn, is converted to the frost, which will destroy the log. That is why additional caisopate of new gaps is required and putting off the peeking seal between the crowns.

You can perform a third panty in 2-3 years when the house is completely inacted and all possible cracks will be opened by the master.

Ways of Konopkka

Warming "Stretching"

This method involves the filling of narrow slots and gaps. It is good with the caispatic of houses from the rounded log, since the slits are minimal here. It should be attentive with a pantry of such a log. There is a risk to migrate the cracks, which will lead to the skeleton of the crowns, and respectively walls.

So, the insulation "stretching" is performed in this way:

- As soon as the edge of the insulation is 5 cm long, they take a new bundle of the insulation and its edge is spilled with the remaining end.

- The resulting plexus is clogged into the slot and continue to careen all the gaps.

Important: The quality of cacopa can be checked by pulling the remaining end of the insulation. If the material freely comes out of the gap, then the work is incorrect. If the insulation remained in the gap, then everything is performed well.

Konopka "In Set"

This method is used to fill large gaps. Here you need to stop the insulation in the dog. Then the loops are made from the resulting fibers and stuff the gap. And at first Copatyati top The gap with the help of a printed tool, and then clog the loop into the lower part of the gap using the "Roadbreak" tool. It is worth knowing that the thickness of the insulation loop must correspond to the thickness of the existing slot in the litigation.

Important: When working, it should be remembered that one width of the blade should have one hammer blow. Do not dilute much, otherwise there is a risk of overgrinking the gap, which will lead to a break of the house.

There are also a number general requirementsIt should be observed when the log cabin. Observing them, it will be possible to avoid gross mistakes in the work:

- So, to start a reappeat at home lower ventsSince when packing insulation in the slit, the house will rise by 5-15 cm.

- Perform the filling of gaps is necessary alternately outside and from the inside of the house. That is, first fill the slot of the lower crown outside, and then the logs are moving inside and stuff the gaps of the same crown from the inside. Such technology will preserve the evenness of the walls of the house.

- It is best to use natural insulation for cacopa. Synthetics overlaps the flow of the tree.

- If the moss is used for cacopa, it should be treated with a special solution of soap and oil in a 200: 500 ratio, mixed with a bucket of water.

- Warming at home needs to be performed in dry weather at a temperature of + 10- + 20 degrees Celsius.

- In addition, the underworld of the insulation is also bad, like his bust. It is worth strictly monitor the amount of fibers in the hinges so that their width corresponds to the width of the gaps.

Remember, properly performed work is a guarantor of a warm and cozy house even in tall frost.

Correct Sruba causes many questions from newbies. It should be previously declaring when heating the bath with which heat insulator is suitable. Congratulate the gaps in the construction will turn out to be your own hands without the help of specialists. Consider the nuances of this process.

Content:

Warming of the bathroom bath is carried out by the method of cacopa. To do this, the heat insulator is driven into interventic gaps. It is necessary to prevent condensate and as a result of tree rotting. Ban canopate is a long, time-consuming and painstaking process. The first time the construction is caught at the construction stage or immediately after it. The second time - in a year or two, when the logs sit down, and additional slots appear. The third cacker is made 5-6 years after construction. It is such a period that must pass for the final shrinkage of the structure.

Choosing material for cacopki shrub bath

You can choose natural material or artificial. The main thing is, it should differ in low thermal conductivity, not to highlight odor, to be environmentally friendly and resistant to temperature drops. On the selection of the optimal insulation also affects the thickness of the bar.

For cacked, use:

- Linnatin. It has environmental friendliness and high heat protection indicators. Absorbs moisture and gives it. Attach the ribbon by a construction stapler. From the disadvantages you can allocate a short service life (up to three years). In order not to have insects, it is treated with a special chemical solution. At the atmosphere of the steam, this affects a negative way.

- Peng, linen, jute pala. Eco-friendly material. Popted because of its thermal insulation and antiseptic characteristics. However, it absorbs moisture, and therefore its service life is up to three years. After that it is very difficult to remove from the interventional clearance. It is more convenient and faster to lay the laying of the combustible pane.

- Jute. Durable, moisture-resistant, eco-friendly, heat-insulating and resistant to rotting material. It is made in several species. Jute Paklya is not sufficiently tight and hard. Laying takes a lot of time, and it must be done several times. Jute felt is dense and flexible. Before the pantry should be treated with mortar from rotting and the appearance of moth. Len-Jute has all flaws. Therefore, it is not recommended for insulation.

- Forest, white and red swamp moss. It has been applied for several centuries due to its antiseptic and bioactive characteristics. It does not rot, does not contribute to the reproduction of microorganisms, quickly absorbs moisture and is characterized by environmentally friendly. The only disadvantage is the complexity of laying. When choosing moss, pay attention to its humidity. It should not be completely wet or too dry. Before the pantry moss is wetted. The procedure of such insulation needs to be repeated 6 months after construction and after a year and a half.

- Hermetic composition. Work with such material is easy and convenient. It can be chosen in the color of the cut. It is produced by B. different types. Soft sealant squeeze out of the tube in the slot. The cord of foamed polyethylene pushes into the interventory space and operate with varnish. Briquettes are also extruded by a gun-electrichearter in the gap. Of the disadvantages, the transformation of the material into the monolithic substance can be distinguished. When deformed logs, it damages fibers. This can be avoided by applying elastic sealants.

Wall cacked methods Bath

To insulate the log house yourself, you will need a mile, a roadboat and a set of cacopants - a set (with a narrow nap), broken (for extending the seams), curve (curved shape). Tools are better to choose from wood to prevent damage to logs.

There are two methods of cacopa baths:

- Rottozhka. The insulation strand is scored by one side in the gap. The second side bend and tamper inside.

- Vanbor. A strand of thermal insulation material with a thickness of 1.5 cm We score into the loop and scoring a breakdown with a pantry each across the gap. On top of a sealing road.

Bath Bath Technology Moss

You can safely legish a log house using moss (from 16 thousand rubles), vegetable oil, water, soap.

The process of insulation of the bath is carried out in such a sequence:

- Make a solution. We dilute vegetable oil in a bucket of water (0.5 l) and soap (200 grams).

- Welcome in a moss solution.

- Courling the ends of the heat-insulator into a peculiar roller and tightly tamper it into the gap.

- We apply the shovel to the insulation and grab in the image.

- We begin pantry from the bottom seam. We process it around the perimeter of the bath and only after that we begin to pure the second.

Instructions for pantry bath packs

Canopate walls juteThis is the method of cacopa in the Bath. To begin with, it is necessary to decide on the type of jute. Then prepare it for insulation. To legittures the log house as much as possible, we will need a jute (about 6 rubles per stranded meter), resin or bitumen (if you use jute felt), formalin (when using Jute Pakli).

In the process, adhere to such a sequence:

- We prepare material to work. If necessary, soaked it.

- We twist Jute in strands and score them to the Lower Sewage interventic clearance.

- Capatokes tremble edges.

- Align the seam with a roadboat.

- Consistently go to each tier.

Please note that around the chimney pipe before work you need to free 2-3 cm space. The design during insulation rises to a height of about 10 cm. Therefore, it may damage the masonry.

Konopka cut Bath with synthetic sealant

Handling work with sealants are performed operational. The main thing is to choose the optimal version of the material. We will need a sealing cord, sealant (about 200 rubles), a brush or a spatula for smoothing, a mounted pistol.

We warm the log house stages:

- We lay in gaps and cracks sealing cord.

- Irishly fill with the sealant all the slots around the perimeter. To do this, we use the mounting gun.

- Carefully apply a mixture into corner reference.

- Sprinkle with water all interventic seams.

- Smoothing the sealant with a spatula or brush.

- We remove the surplus from the bars using a wet rag.

All finishing works are carried out after thermal insulation. The design rises, and therefore it can damage the facing.

Bathhouse power technology is shown in video:

For high-quality warming of the cut, it is necessary to carry out both an external and inner panty. If you choose the right material and follow step by step instructionsAll work is easy to perform independently even without relevant experience.

Despite the wide range of materials, the construction of houses from a natural tree is still priority to many people. A tree is not only environmentally friendly, durable and reliable material. The houses from the bar "breathe", which allows you to maintain a healthy microclimate in the premises. But so that the housing is warm and drafts are not walking in it, you need to properly comply with all stages of construction.

Warming of a church is a very important step that will help keep warm in the home, prevent moisture penetration and dampness. Since ancient times, log houses were caught moss, at that time it was the only available material for housing insulation. Modern selection of insulation, which can be placed between the logs, much extensive. Corps of gaps between bars provides high-quality thermal insulation.

Stages of Srub insulation

Log cabin gives shrinkage for several years. Despite the fact that the Wenty seal always has a wet seal between the logs, it is not possible to avoid cracks and gaps in the walls.

The first time the log house is caught immediately after or during the construction. The work process itself is quite painstaking and time consuming. The second time the insulation of the walls spend in a year or more. During this time, the logs are exposed to ambientWhat is why the material can deform a little. It is the bug that appeared after shrinkage and need to legally repeatedly.

The third time the walls of the house require to pry after 5 years after the construction of a church. During this period, the house will finally give a shrinkage, the material will acquire the final form.

An important rule! Cutting the log house must be strictly according to the scheme: they begin to close the gaps on the lower crown, along the length of the entire perimeter of the house. Only after one row of logs will be sealed, you can begin the insulation of the second crown. If you do not comply with this rule, the log house can squeeze.

"Varcomk". This method is to push the insulating material into the gaps using a special tool. In this case, the clearance is tightly filled with insulation, the remnants of the material are tightly folded into the roller and pushed into the slot with strength.

"VNabor". This method is suitable for filling out wide gaps. From the insulation, harnesses are folded, which are then twisted in the loop. These loops pushed into the gaps and completely fill free space. In this case, the method of insulation remains of the material does not stick out of the gaps.

Materials for filling gaps between logs

Natural materials

Moss. Despite the fact that the moss was used for the insulation of the walls of many centuries in a row, he now does not lose popularity. This natural material is not only environmentally friendly and safe, but is a long-term antibacterial protection for wood. Moss prevents the occurrence of mold and fungi in gaps between the logs.

Before the caulkit of the walls, high-quality moss must have a certain humidity, not to be reheated or too wet. The only drawback of this material is a high cost.

Tow. This material is also often used for a log insulation. There is not a lot of packle, but working with it requires effort. This material is not the best sealant, as the fibrous package can absorb moisture that after a few seasons can affect wood. A spoiled pass is quite difficult to get from the gaps. It should also be paid to the possibility of eating the insulation of the mole, which will affect the quality of the insulation of the walls.

This material is made by grinding flax and its pressing in the tape. The flanutin is characterized by good heat saving and characteristics, not subject to rotting, does not accumulate moisture. This material is laid between the crowns during the construction of a church. Fastened to logs using a construction stapler for a bracket.

Jute. To date, this is one of the highest quality and durable materials for the cacopa of log cabins. Jute tapes are laid between the crowns in the process of building a log. Mixed on the brackets. Jute is not subject to rotting, not hygroscopic, durable. The only drawback is a fairly high value of the material.

Also, when buying insulation, you should pay attention to the fact that there should be no secondary additives in the material, for example, flax. If there are supplements, the insulation does not differ in durability and resistance to rotting.

Rubber sealants

Working with these insulation is quite simple, does not differ in time and does not require effort. Sealants can be divided into three types.

Soft sealant in special tubes is extruded in the slit, filling all the space. Excess the extruded material are spilled. This sealant can be chosen under the color of wood, which will improve the type of log.

Video - warming cut acrylic sealant

Polyeneetylene in the form of a cord pushes into the slot and aligns. After drying it, it can be covered with varnish or other observing material. Sold in different colors.

Briquettes for cutting cutters require the use of a special pistol-electrovate. In the slit through the nozzle, the liquid mass is soles and fills free space. This method of insulation is perfect for walls with large gaps, since the tool has several nozzles with different nozzle diameters.

Crop's tools cut

If the insulation does not use sealants, it is required to purchase the next set of tools before the cutter.

Kiyanka. Hammer with wooden or rubber base for work with blades.

Set of cacopat. This tool has a narrow nose, with which the material is easy to push into narrow slots.

COVER COVER. This type of tool is distinguished by a curved form. Allows you to quickly fill in the insulating material uneven widths.

Roadman. This is a wide shovel like a spatula. Allows you to work faster with equal widths.

Broof cacopat. With it, it is slightly expanding the gaps between the crowns for better laying of thermal insulation.

What you need to know before starting work

- The process of insulation and sealing walls with natural materials is a rather time consuming. With this procedure, the material with force drives into the slot, which contributes to raising the entire cutting structure by 10 -12 cm.

- Before insulation of the walls, it is impossible to carry out any finishing works inside or outside the house. Due to the raising the crowns, the entire finish may be damaged.

- You need to start work from the lower crowns of the structure. The material is rolling into the slit evenly and sequentially. After the lowest logs are insulated throughout the perimeter, you can enjoy the overlying crown.

- Canopate only one wall can lead to deformation of the entire cutting structure, it is also not recommended to use for insulation of one structure different materials With different hygroscopic performance. When the moisture set, the insulation has an expanding property, which can also lead to a breakdown.

- If independent insulation led to a blockage of the building, do not panic. Experts who are engaged in this type of work can correct defects with repeated cavinc.

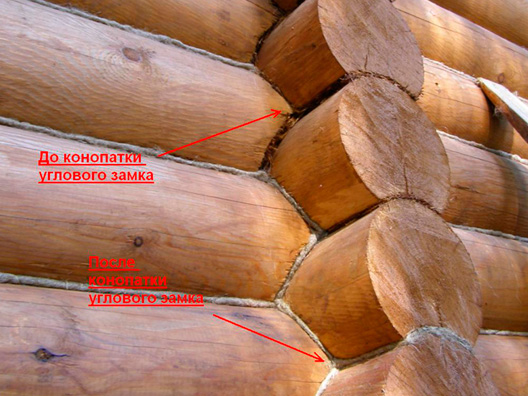

- Special attention should be paid to the pant of the gaps at the corners of the house. Since a lock or a gas fastening system was used to build a chub, the gaps can be different in size.

For the insulation of the walls in the "rotor", a pacular or other fibrous materials is most often used. You need to take a bundle of the insulation, to dissolve it, forming a wide strand. Then the material is applied to the gap. It is important that the fibers are located across the gap.

The insulation is pushed between the logs, the remains of the fibrous material should hang around 5-6 cm from the gap. Then the tight roller shall be folded from the protruding fibers, which, with the help of a tool, pushes into the gap and clogs into a chisel. After this procedure, the material should not perform between logs more than 1 cm. The amount of material from which the strand is formed depends on the width of the gap. Than more gap, the more you need to take the insulation.

For this type of insulation, the material is required to pre-prepare. From the insulation, thin and long strands are formed, which are folded into the ball. Then the resulting harnesses are folded into the loops that are pushed into the gaps between the logs. This method of insulation is suitable in the event that the slits in the firebird are large and different in width.

In case of caulpipe, the hinges are drunk first into the upper part of the gap, then tamper into the bottom. In this way, it is possible to achieve a uniform filling of the space between the logs and the high-quality heat insulation of the walls.

If jute was used as a insulation, then after shrinkage, the house requires additional heat insulation of the cut. When laying the cents, the jute should be located between the logs so that the edges of the insulation performed into the gaps into the gaps into several centimeters. After the log house made a shrinkage, it is necessary to organize the walls. For this, the protruding ends of the jute are touched down and with force driven into the formed clearances. It is also required to comply with insulation technology: to close the gaps should be started with the lower crowns.

In the uppermost crowns, which are highly, it is not necessary to drive the insulation with the help of a queen. It is enough to push the jute into the gaps with the help of a blade.

Video - How to Crop the House with Jute