With the erection of the capital building, the base of the base (foundation) plays an important role. The foundation serves as a support for the entire building, and the longevity of the structure will depend on its reliability and quality. That is why it is necessary to approach with a great responsibility to choosing and.

The main objective of the foundation is concluded in making all loads from the walls of the house and overlying structures, as well as countering the pushing forces of the soil. First of all, the construction of the foundation depends on the type of soil, the depth of freezing and groundwater.

Plate foundation: varieties

Today, solid (slab) foundations are considered the most reliable. The foundations of this type are used in the presence of weak types of soil, high groundwater occurrence, as well as with bunched soils. The slab foundation due to the perfect design allows without disrupting the integrity to accept variable loads that occur during uneven soil displacement.

Constructive slab foundation It is a strongly blurred, laid directly to the soil plate. The stove can be made like from monolithic concreteand from reinforced concrete plates and precast beams with a monolithic coating.

If a monolithic design is performed, ribbed and boiled plates are used. Ribbed plates apply only when it is necessary to ensure high stiffness of the foundation.

The slab foundations in the depth depth are divided into classic and floating, whose depth of which is no more than 80 cm from the surface. A large area of \u200b\u200bthe plate allows to reduce the load on the soil to 0.1 kgf / m², while the transverse reinforcement does not give the structure to deform with an uneven displacement of the base (freezing, thawing, soil drawdown, the presence of floors).

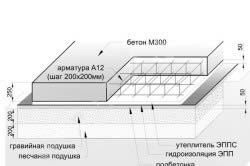

Flat foundations are considered to be the most effective today. Thanks to its simplicity, they are more technological. The stove thickness should be installed on the basis of the calculations. Typically, a slab foundation is made with a thickness of 300 mm to 1000 mm. The class of concrete used should be no less than B20, while reinforcing is at least 0.3% of the total volume of the design and is made from the reinforcement rods 12-25 mm with a diameter. Waterproof of concrete - no less than W6.

Back to the category

Construction of a slab foundation: Stages

The construction of the slab foundation is carried out in several stages, each of which is quite laborious:

- Preparation of the site. The upper layer of soil is removed, there is a breakdown of base contours with the tuning of the axis lines.

- Depending on the depth of the slab, the hob is rotated or a sandy mound is made.

- Conducting drainage work will be necessary only in the case of too closely the arrangement of groundwater.

- After drainage, if it was needed, the formwork is installed.

- On top of a well-tumped base, the first layer of the screed is poured, which should have about 40 mm in thickness. At the first layer of the screed after its complete solidification, the calane waterproofing is stacked. The overheating of the material layers should be at least 50-70 mm. It is necessary to make a release on the edges of the foundation about 1 m long, so that then you can get insulation on the walls.

- The next layer of the screed must have a thickness of 40 mm. It is placed to protect the waterproofing layer from gaps in the implementation of vertical fittings.

- Reinforcement is made in the form of 2 knitted grids with a step of 250-400 mm and cells of 200х200 mm from the AIII fittings. The knitting is conducted with an annealed wire from steel with special hooks.

- Pouring concrete is done very quickly to eliminate the "cold" joints of concrete. It is desirable to use concrete pumps and mixers.

To remove seals and air emptiness in concrete mix, low-frequency vibrators are used.

When pouring a concrete mix in hot weather, watering concrete coating is performed ordinary water. If irrigated, it is impossible to perform, then the slab must be covered with a film for 2-3 days.

Back to the category

Construction of a slab foundation: Benefits and Application

The slab foundation is usually used in low-rise construction (on unfavorable soil), as well as in large-scale construction, when it is necessary to ensure reliability at high loads on the base (multi-storey construction). The construction technology of this type of foundation is quite simple, so its construction can be organized even by non-professional.

With all the modern diversity of the types of foundations and their advantages, many builders of the bath give preference after all the same monolithic. After all, what is worn, always stronger than prefabricated designs. Yes, and the construction process in this case is something easier. And the most popular foundation - monolithic platewhich is so reliable that the skyscrapers are even built on it.

What is good such type of foundation?

Monolithic foundations are always durable and withstand heavy loads. They are not terrible neuronal movement of soil, nor constant abundant precipitation, nor rigid freezing and thawing. The bath will be simply climbing and descended along with the foundation without destroying any supports. After all, it is known that concrete works only on compression - and not on the extension. That is why the foundation in the form of a monolithic plate is almost indispensable for bunched and sandy soils, where high groundwater levels.

Yes, for bruschers, frame and log Ban. Such a foundation in some cases and luxury - if the soil is normal, it is easier to make a ribbon shallow mint. That's just the Russian sauna itself has long ceased to be just a hut - its own overalls bath complexes with pools and whole billiards. And under the massive pair slab monolithic foundation - what is needed.

Varieties of monolithic foundation designs

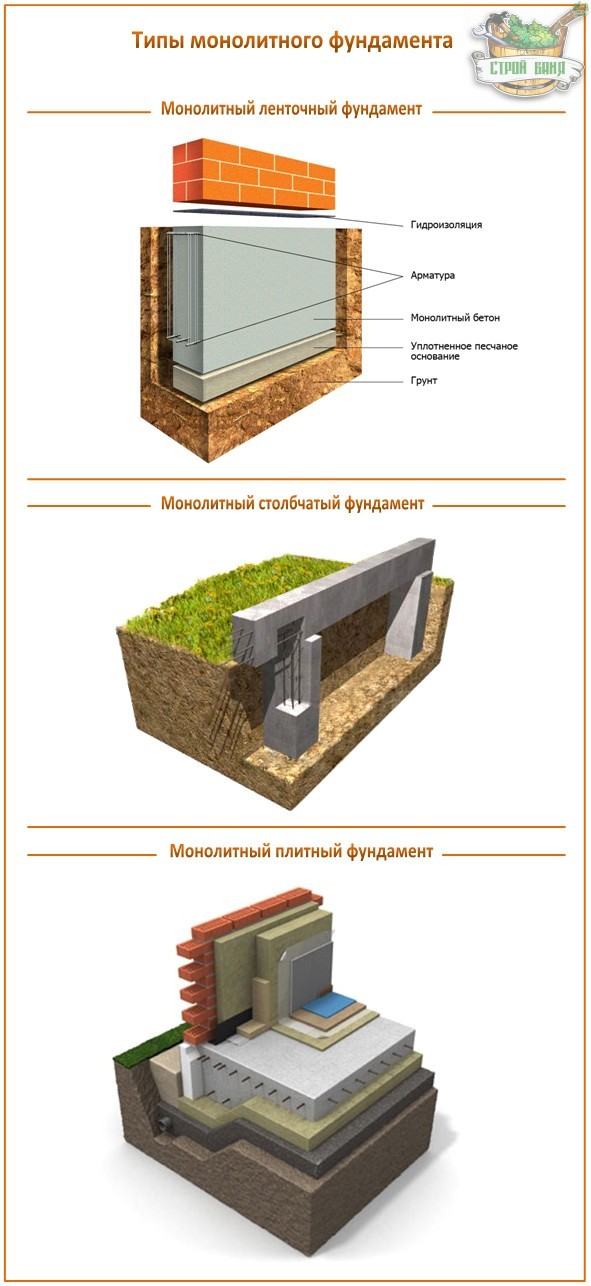

The monolithic foundation has several species. The most popular is a slab, which is also divided into just a plate and a slab on a ribbon, similar to an inverted bowl, which day of day is becoming more and more popular abroad.

But in terms of building a bath, it is best that the monolithic foundation monolithic slab has proven itself. Its main advantage is that there is no need to put it below the depth of the primer of the soil - and this is a significant reduction in the costs of building materials and reliability with sharp air temperature drops.

The slab monolithic foundation is essentially a solid reinforced concrete slab, which is blown into the ground. And external and interior walls Baths are built directly on this stove. And thanks to the even distribution of the entire load on the plate area, the pressure on the soil is minimized - the same physical law works here when a person in the boots falls into the snow, and there is no skiing, because the pressure area is already greater. The design of the slab is so universal, which is suitable even for candid peatlands and even swamps. And most importantly - in the construction of such a foundation, any errors are practically excluded, and therefore for private construction it is suitable as it is impossible. Including - for the bath, because the volume of earthworks in this regard is minimal, and the basement of the steam room is not particularly needed.

Another kind of monolithic foundation is a columnar monolithic, which is built for light baths. In essence, this is a single design of the frame and reported by the columns.

But the ribbon monolithic foundation with the basement is able to withstand quite large loads and feels well in the most unfavorable climatic conditions due to the fact that it perfectly copes with drawdown, thawing and the oscillations of the soil. In fact, it is a reinforced concrete band that goes throughout the perimeter of the building. It can be finely breed and bewitched. The first option is suitable for a bath from a log and a bar, but the second - for brick two-story pairs, which have a considerable weight.

Stages of construction of reinforced concrete slabs

The construction process of the monolithic foundation is much more simple than the structure of the prefabricated. But there is important moment: All materials used should be the highest quality, because monolithic foundation More serious requirements are imposed. But at the same time, the involvement of construction equipment is not necessary!

Stage I. Preparation of the site

First of all, you need to clear the site: remove the top layer of soil with vegetation, for which you can hire a bulldozer.

Thickness of such a foundation, or rather, it is the monolithic plate that can vary from 15 to 40 cm. It depends on the characteristic of the soil, the weight of the future bath and what it is filled.

Stage II. Digger Kotlovana

Usually, the hobban is thrown to a depth of 1.5 meters, from there, the clay is pulled out and is replaced by gravel or sand. An alignment surface should be in a building level - there can be no slopes and speech, otherwise deformation and complete destruction of the future foundation can not be avoided.

Stage III. Installation of formwork

Sometimes such foundations are built from ready-made monolithic reinforced concrete slabs, which can be seen during construction in panel house. They have already clearly designed quality, but for their installation will have to cause a crane and still do on top of the entire concrete tie. And this design will be no longer as tough as an absolutely monolithic plate.

And for its own hands under construction, the formwork is originally needed. For her, there will be boards with a thickness of at least 25 mm plus uksu. It is necessary to put the formwork itself with loosening - and it is desirable to initially check the rigidity of the whole design. It is possible to make it an elementary blow to the foot - if the formwork breaks, it is better at this stage, and not during concreting.

Stage IV. Warming and waterproofing

It is worth mentioning the Swedish construction technology of such a foundation - it involves the use of modern heat and waterproofing materials. This base is called a warmed stove, which has stunning energy-saving properties with small construction periods and low costs. For the Russian bath - the most!

Foundations under modern buildings are different types. Each type is intended for building structures with certain characteristics and placement scheme. Foundations are selected, considering the current GOST, SNiP, technical reference books and the design features of the building.

Meanwhile, there are practically universal base samples that are equally suitable for most buildings.

Features and destination

Reinforced concrete foundation is a construction with which in the absolute majority of cases is starting to build any home. Reinforced concrete builders have elected due to its exceptional strength, it is possible to work perfectly for compression, at a relatively low cost.

The disadvantages of concrete are removed by the reinforcement of the reinforcement grid and the addition of special fillers.

Reinforced concrete foundations can be built over several standard samples. For example, reinforced concrete foundation columnal Collected columns are collected from blurred in the land, which are associated with the help of belts from beams.

A columnar foundation is quite an economomen and is suitable for loose soils, but it does not withstand a serious load.

Ribbon foundation is also extremely popular. It is collected from monolithic blocks, which form the pillow and the body of the foundation. Also often architects prefer the use of prefabricular blocks, or combining concrete blocks with pouring monolith.

If you use GOST and SNIP to reinforced concrete structures, then you can note the fact that ribbon foundations Ideal for working with frameless buildings, in which the entire load is transmitted through the bearing walls.

The silent prefabricated bases are also popular, based on burbilic columns or piles, as the builders are called them. The current GOST and SNiP on the pile foundations gives them preference in the arrangement of relatively light buildings on unstable soils.

But none of the above samples will be compared in its popularity with the creation of flat monolithic plates. The slab foundation is distinguished by an exceptional simplicity in execution, but at the same time, and quite serious complexity.

These two seemingly not combined properties, nevertheless are present in flat slaughter (solid) foundations. And all due to the fact that their device has certain differences.

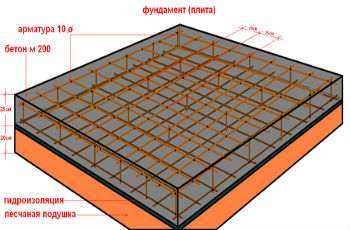

The device of flat monolithic or prefabricated foundations does not provide for use in them blocks, piles or pillars. The whole foundation consists of a single solid plate with a reinforced frame.

As you understand, the usual monolithic reinforced concrete plate is created by fairly simple technology. It is enough to simply appreciate GOST and SNiP, as well as assemble loads from the building. GOST must apply a certain one. It is better to know a specific number.

In this case, GOST 52086-2003 is suitable. However, even the guest of an older sample will also fit. Snip must be used by number 52-01-2003. It is a SNiP with the title "Concrete and reinforced concrete structures", which indicates all the rules on their arrangement, reinforcement, fill, the thickness of the protective layer, etc.

All information that gives you the current SNIP and GOST should be considered in obligatory. Moreover, you can learn almost everything that is required for work. Even the necessary formwork sheet thickness and struts.

You will have to work on the direct execution of the slab. And all because the volume of work on the creation of monolithic foundation plates They are considered the most impressive, especially if you take a column, pile or even tape bases.

The stove itself will have a thickness of 15 to 50 centimeters. Her dimensions cannot be less than the dimensions of the house. And the middle house, if you turn to statistics, has dimensions from 10 × 6 meters. At the same time, all the space of the slab must be reinforced, and very seriously.

Under the foundation itself, the gravel and sand preparation is still arranged by a minimum thickness of 50 cm. From this it follows that under the construction of the slab foundation it is necessary to dug a rattling of rather impressive sizes, and then also half off his pebbles.

It is obvious that removal or pile foundations, time and resources you will have to spend much less.

What is the advantage of the foundations of this type? Everything is very simple. The dense monolithic stove gives the structure of emergency stability.

First, it stabilizes the house and eliminates the possibility of his drawdown. The appearance of cracks or other similar problems is also practically excluded. In Europe, even skyscrapers are often elevated on the foundation pillow of solid slabs.

Secondly, this is the most important point, such a foundation is suitable for absolutely all types of soils. Even the most bulk and harp. In the worst conditions, the house will simply seek in one place or deepen all over the perimeter. But the designs will remain safe and will resist until the latter.

This is possible due to the way the plate is equipped. Due to its huge area and uniformity of the load distribution, the stove is able to keep well on any surface, as the pressure from the house is smeared through a large area. Applied here elementary laws Physics.

Similar properties can observe lovers of skiing. If a person gets his feet to his foot, then there will fail.

But standing on skis, he will be able to fulfill much more serious manipulations without fear to fall. And all because the load from its weight is distributed over the entire ski area, which is 5-8 times more than the area of \u200b\u200bthe human foot.

Types and differences between solid foundations

There are two types of whole foundations. But to start their species in terms of construction technology. According to this parameter, they are divided into:

- Monolithic;

- Prefabricated.

Monolithic foundations are preferable, as they have increased strength. They do not use individual blocks or elements, and the entire stove floats per day. What, it is worth noting, imposes certain inconveniences.

So, if blocks and plates of the team type can be installed gradually and for a long time, then poured over one sitting. It is impossible to divide this process, since such actions are fraught with the appearance of cracks in the places of the solution of solutions of different prescription.

Prefabricated whole foundations are collected from blocks or plates. Most often their combination is used. For example, the faces of the base form blocks, and its body is assembled from finished reinforced concrete slabs. It happens differently. When the blocks do not apply at all, and instead of them, the reinforced belt is poured on the edges.

Out of the plates also often poured a stabilizing frame with a thickness of minimum in 5 centimeters. However, prefabricated whole foundations are weaker than monolithic, and this should be considered.

The device of solid foundations in the form of plates also has its own characteristics. By type of construction they are divided into:

- Standard slab;

- With the lower stabilizing belt from blocks.

In the first case, we are dealing with the simplest foundation, whose device is a conventional plate, which is mounted on gravel preparation.

The second option is already more reminiscent of the tape type of foundation, but only partially. It is from blocks and solid monoliths poured a kind of envelope design. Here the blocks play the role of the stabilizer and the foundation pillow.

If you look at it from the side or in a context, the form will resemble an inverted bowl or a container in which the blinding blocks are edges, and the slab pallet.

This design is popular in Europe, due to an increase in the stability of the building and give it increased strength. But the time to create plates of this type will have to spend more.

Technology arrangement

As we mentioned above, building a slab foundation is more complicated than to create a ribbon of precast blocks or monolith. It is more difficult in terms of consideration, the need to pour the whole design immediately, as well as the need to spend a lot of time on digging a large pit.

Moreover, if the slab foundation uses additional blocks or the faces by directly the slab, then the amount of work will only increase.

Do not forget about the cost of the materials used. It is in the slab bases that the most concrete is used and especially fittings.

However, after his construction you will forget about all the problems and inconveniences. After all, such foundations can be described as you like: columns, walls, beams, etc.

The technique of creating solid slab bases is directly as follows.

Stages of work:

- We choose a place under the foundation, we calculate its parameters, the type of reinforcement, etc.

- We carry out the geological incision of the soil, we determine the exact dimensions of the design.

- They roll up the pit.

- We take out the bulk of clay and soil, replace its gravel pillow and sandy bedding.

- If necessary, and in coordination with the project, stool on the pillow or layer of waterproofing.

- We form formwork from boards and.

- We collect and mount the reinforcement frame.

- Fill the design of concrete.

- We are waiting for a week until the concrete is grabbed, and it will be possible to walk. Another about 20 days is recommended to wait until the construction of bearing structures.

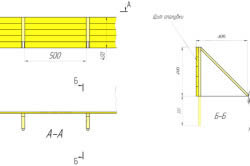

If the foundation is used with the bottom strapping. That for its construction can take prefabricated concrete blocks or pour monolith. In this case, first will make the frame of the belt, and digging the pita. Then they will fill all with concrete, and after that it will be created by the creation of the slab itself.

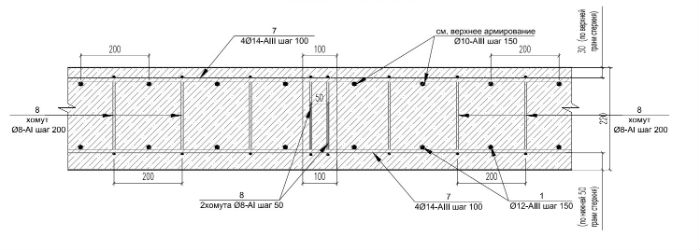

Armature carcass Plates are created according to the standard scheme. From below, we have an armature with a diameter of 15 mm. We put it with a cross-closer with increments of 15-20 cm. The more step, the weaker the stove will be.

The upper grid, in contrast to the technology of forming slabs of floors, is done solid and in its diagram almost completely repeats the lower circuit. Only here a step can be slightly larger, and the diameter of the working rods will be 8-14 mm.

The upper mesh is mounted on special holder clamps and stands. Lower stands on locks for reinforcement frames. Under the bottom grid should be at least 3-5 cm of the protective layer of concrete. This will prevent possible cases of corrosion of metals.

Creating a monolithic foundation plate (video)

No similar entries.

This type of foundation is considered one of the most reliable and practical. It is a solid monolithic plate of reinforced concrete, which is erected under the entire area of \u200b\u200bthe future structure. The monolithic slab base is almost universal, it is distinguished by a high bearing capacity, uniform load distribution and the ability to withstand without deformation, the soil shift.

Characteristics

- Priming: Any, including with weak carrier characteristics.

Contraindication - a pronounced slope. - Material (weight) of walls: Any.

- Load bearing capacity: 6.0 MPa.

- Waterproofing: Imparably bituminous and double-tired rolled. If the water is not aggressive to concrete, then only the cut-off double waterproofing on top of the foundation plate is allowed.

- Armature carcass: Armature AIII (D10-D20), step 150x150 -: - 200х200 mm.

- Class concrete B25, thickness 300 mm.

Application

Stop your choice on such a foundation is, in the case of:

- Swampy terrain, presence in the immediate vicinity of the reservoir or river bed, high level of groundwater.

- Big weight of the structure. For example, if the house is built from full-time brick Using monolithic w / w overlaps.

- Complex geometry of the building with uneven load distribution. For example, the presence of separate "wings" of the building for the garage, the pool.

Important. The foundation of the type "stove" can not be arranged on areas with a pronounced slope and plastic soils. This can bring the building to "fascination".

Benefits

High bearing ability - The main advantage of the design of this type. Thanks to the large area of \u200b\u200bsupport, the foundation is capable of providing stability of even very heavy structure on weak and bunched soils. With soil oscillations, the monolithic railway plate smoothly "drifts" on a sandy-gravel pillow, providing high reliability and integrity of the structure.

Resistance To strong deformations and deflection.

Configuration variability at home - This foundation can be erected for cottages of any geometric shape.

Stages of editing foundation

1. Excavation . Excavator or manually developed by the pit. In the case of the presence of water in it, work on the drainage (drainage) of the pit is carried out. The development depth depends on the relief of the site, the thickness of sand and crushed stone preparations, the floor level of the first floor relative to the Earth.

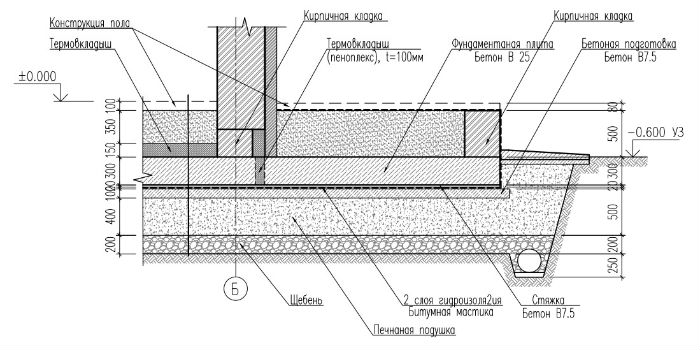

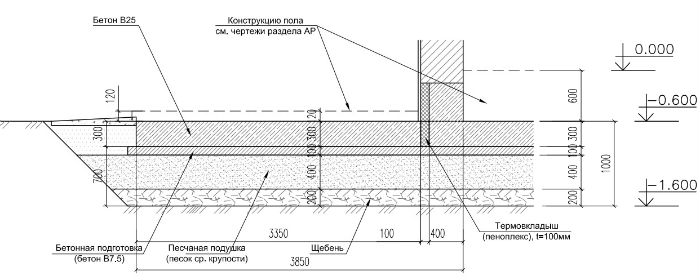

Typically, the depth of the pit is about 1 m: 150-200 mm - rubbed preparation, 250-400 mm sand preparation, 100 mm - sweet, 30 mm - protective screed of waterproofing, 100 mm - insulation (it can also be top plate), 300 mm - The foundation plate itself.

2. Sand-gravel cushion device With mandatory traam. The lower layer on the entire perimeter of the pit is stacked by gravel crushed stone, as a rule, fractions 20-40. From above sandy layer. Tamping is performed by vibratory. In "home" conditions, it can be replaced with a homemade "T-shaped" inverted design in the form of a wooden board with a handle. Additionally, sand can be shedding with water. This will make it time to the density of 96-98%.

3. Solid concrete non-reinforced preparation (sweeping). Thickness 80-100 mm. It is an unarmed screed. It is performed from low grades concrete (B7.5-B.15). The perimeter of the submersible should be 0.5-1m to exit the perimeter of the foundation plate.

4. Waterproofing device. Rolled material (Hydrosteclozol) type Tehneelast EPP is laid with an overlap at least 10 cm in two layers. After installing the foundation plate of the edge of the hydrohotelloisol, they wrapped on the plate with an adhesive no change of 0.5 m. The side surfaces of the future foundation plate and the adolescents of hydrochloxycol are processed by coating waterproofing (hot bitumen).

5. Protective screed waterproofing. In order to protect the waterproofing during the reinforcement of the slab, it is protected cement-sand tie 30 mm.

6. Reinforcement of the plate It is performed from the rebel reinforcement (A3) of various sections, (most often 12-14 mm), which is associated with a spatial frame. The reinforcement frame is two layers (lower reinforcement and upper reinforcement) with a grid step 15-20 cm. The frame amplification is performed due to a more frequent mesh step or an increase in the diameter of the reinforcement. The protective layer of concrete (the distance between the reinforcement and the surface of the concrete) should be at least 2 cm. To comply with this requirement, the lower layer of reinforcement is set on special plastic stands (clamps). The nesting of the rods of the reinforcement is at least 40 diameters.

7. Installing formwork. It is made of a thickness of at least 30 mm thick, an additional approximately every 1.5 meters are exhibited (one end to the ground, the other in the formwork). The height of the formwork should be 7-10 cm exceeding the top mark of the foundation plate.

8. Concretion. It is performed from the brand concrete not lower than M300 (B22.5). In the process of laying concrete, it will be trambed using vibrotambovka or in the "home" conditions using a manual "blasting", for example, reinforcement. If the temperature on the street exceeds 25c, recommends the spill of concrete with water during the day.

Features

When the monolithic w / b device should be remembered that:

- it is impossible to carry out work on carpented soils;

- the pouring of concrete should be carried out at a time (the break between the fills of concrete "car services" is not more than 2 hours) - otherwise the bearing capacity of the foundation is reduced.

Under all the conditions, it turns out a reliable monolithic foundation.

disadvantages

One of the cons of such foundation is quite high cost. However, it is necessary to take into account that, despite higher costs, the device of monolithic foundation plates does not require highly specialized equipment, and due to the simplicity of the design less likely an error in the work of work.

The construction of the foundation is the responsible business, and not everyone will decide to implement it independently without experience in this area. However, in fact, if you know what and how to do, the installation of the base for the house may seem simple and affordable option to save money.

This will be discussed in our article, after reading which you will learn how to use the tools and fill the foundation of the house.

Acquaintance with the monolithic slab

Externally, this product is a solid product from cement, filled in one plane. Unlike ribbon grounds The monolithic reinforced concrete foundation is located under the entire structure, ranging from the bearing external walls and ending with interroom partitions.

Of course, it may seem wasteful, pour so much cement mortarBut each building element has its advantages and advantages. In this case, this is the fact that the foundation of the plate monolithic is the reinforced concrete plate, may be rightfully called one of the most durable options submitted today.

Specifications

- Let's start with one of the main factors - the price of manufacture. Nevertheless, it will cost you much lower in price, but there is another side of the medal - saving funds. If you decide on the device of a monolithic plate, then provide your future house with a durable and reliable base that does not require additional investments. This is another plus in the Fundament Piggy Bank.

- Affordable installation, which can be done with your own hands is among the advantages of the monolithic plate. There are only a few features to pay attention to: the quality of the cement mortar, correctly reinforcement and high-quality heat and waterproofing. Installation itself is pretty simple, we will tell about it in more detail in the following sections.

- The advantages include both increased resistance to weak soils (displacement and swelling of individual sections). It is achieved due to the size of the product, which are significantly superior to all other options for foundations. Therefore, there is no need for a deep trench in digging, as the stove evenly distributes the entire load on the ground.

For your information! In this case, the depth of the primer of the soil and the presence of melting and groundwater is not terrible, of course, if at the base the insulating materials are properly laid.

There are negative sides at the slab foundation:

- For example, the base installation work should be carried out in a warm time, at temperatures below -15 degrees, the solution will not give the expected effect. Such a product can not be called durable.

- We have already talked about the cost of building such a foundation and revealed that you spend on its construction, you will save in the future. But it is worth considering the factors that the initial value platular base It can cost 30-50% more expensive than when laying tape foundations.

In the end - we do not make you choose a monolithic device reinforced concrete foundations For your country houses, but we give you the right to choose what can be called durable, and what is impossible.

Where better to use slab base

- First, such a foundation is ideal for sites with weak soil, plus to everything if the building will create significant loads.

- Secondly, in places where uneven compressibility of the soil is possible.

- Thirdly, as we have already spoken, in areas with a high level of ground and melting water.

- Fourth, for areas with a strongly movable primer base.

Monolithic plate installation process

And now let's talk about how the foundations of monolithic reinforced concrete should be correctly erected independently, without resorting to the help of qualified specialists.

Note! If you want to achieve positive resultthen you should not save on building materials. For example, the M200 brand cement is not suitable, as the rusty reinforcement and major sand is suitable.

Preparatory process

- It is necessary to start with clearing a land plot: remove all vegetation, garbage and other elements that can interfere during the workflow.

- The next step is to post a plot for future foundation.

- Easy manually or with the equipment of the equipment, the depth of it depends on the thickness of the foundation, which can be from 15 to 70 cm. Usually, the recovery is rotated by 1.2-1.5 meters.

For your information! The platform is better to dug a little more than the foundation is planned, this will allow you to install formwork without unnecessary problems, and after - to make a break of the house.

- At the same time using the measuring instruments, it is necessary to smoke a deepening. The slopes should be eliminated to the cement fill stage, what will happen with the soil after the construction of the foundation will not affect the integrity of the structure.

- For smoking materials, use gravel or sand, the thickness of such a "pillow" should be at least 20 cm.

When the bottom of the pit is aligned with sand (gravel) and thoroughly tamped, you can proceed to the mounting of the formwork:

- Using boards with a thickness of at least 30 cm, they should be installed on the perimeter of the site, without forgetting to check their construction level.

- In places docking boards, use nails or self-tapping screws.

- Additional supporting elements can serve wooden bars, driven into the ground from the outer side of the formwork. This will help to avoid irregularities when pouring cement.

- The strength of the formwork can be checked by a simple foot of the foot on it, if the design does not flinch, then everything is performed qualitatively.

- First you need to put the waterproofing material at the bottom of the site. Can be used different materialsBut the most cheapest is the polyethylene film.

The working process

- When the waterproofing is fixed on the walls of the formwork, you can start laying the insulation. This process is considered optional, as it depends on how low the temperature is lowered in winter timeIf you have such a case, it is better to protect yourself. Polystyrene is suitable as a thermal insulation material - affordable and practical material.

- The next step is reinforcing. This stage is considered the most important, since Armokarkas is responsible for the strength and durability of the foundation. It is better to purchase a rod with a diameter of 12 mm, and use a soft wire for a ligament.

Try to fix the corners of the products and lay the bars with a crosswise method in two rows. Between the rows should be a lumen at 10-20 cm, depending on the thickness of the foundation.

Note! In this case, only horizontal Armokarkas is used, which looks like a metal mesh. By the way, such products are already sold in finished videoIf you want to save time on the mating of metal rods, you can purchase several rolls.

The last stage is the fill of the cement mortar. There are several features that you should remember:

- First, it is necessary to pour concrete only at a time, it is impossible to allow the foundation to turn out to be two-layer.

- Secondly, during the fill, using any durable pole, a solution of the area should be evenly distributed.

- Thirdly, after the cement fully fills the formwork, it is necessary to wait a few hours before the initial setting and cover the base film. So you protect the material from ultraviolet rays and precipitation.

Important! Do not forget that only high-quality components are used for the solution, allowing you to count on a positive result.

The monolithic reinforced concrete plate and the foundation is not always the same, in some cases it can play the role of overlapping in the house or serve as a basis for car parking.