The monolithic plate is the most reliable type of foundation. The design is selected if the future building will stand on a plot with a complex soil. In practice, the monolithic stove is being built in the following cases:

- close location of groundwater;

- wetlands;

- peatlands.

Also, this type of foundation in construction is called floating. This name has received the design due to the fact that the foundation is floating or beaming the foundation as a wave. The base is reinforced concrete slab. The monolithic stove reliably protects the walls of the construction of the deformation, since any soil changes diverge on the surface of the foundation plate.

Tip!The foundation plate will be the perfect solution for the house with two or more floors. Also, the masters recommend choosing this type of construction for brick or block buildings.

The lack of design include the fact that with such a reason it will be problematic to build a basement. This minus can be circumvented in the event that choose a deep-shaped foundation. IN this material We will analyze the base device in detail, as well as consider the process of preparation and installation of the monolithic plate.

The construction of any type of foundation begins with the preparatory operations, the monolithic plate is no exception. When a suitable scheme is selected, you can start preparatory work:

- Selection of "Pie". Under this definition is the composition and number of layers from which the stove will consist. In addition to concrete, the "Pie" includes a sand pillow, as well as insulating layers.

- Selection of the method of reinforcement. To choose a suitable design, you need to analyze the soil, landscape, and also know an approximate load from the future building.

- The choice of suitable thermal insulation materials. The house will stand on a solid concrete Plate, Therefore, it is worth considering thermal insulation in advance.

- Waterproofing for walls. We are talking about structures that will rely on the edges of the foundation after the construction is completed.

- Calculation of fortifications from armolations, which are a mandatory requirement in building a building from brick masonry or blocks. Otherwise at the base and carrier structures Cracks are formed.

The readers probably had a question: "Is it possible to build such a type of foundation with your own hands?". In theory, it is possible, but many people should participate when pouring concrete, as it is necessary to fill the foundation quickly and evenly. As for the preparatory stages, they must be involved in them.

The process of building a monolithic foundation

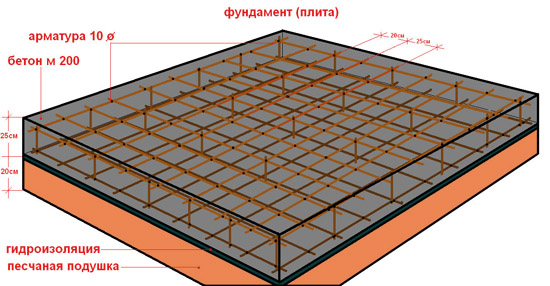

Base laying scheme. Here, "Pie" is shown in detail, from which the foundation is.

Base laying scheme. Here, "Pie" is shown in detail, from which the foundation is. It cannot be said that the monolithic plate is the most complex design, but there will be more work here than with a tape, columnar or pile type of foundation. Starting construction and calculations are only after consulting with professionals that will make a project for you. It is also recommended to take care of the special equipment, it will noticeably speed up the construction process.

Having studied the device can be started:

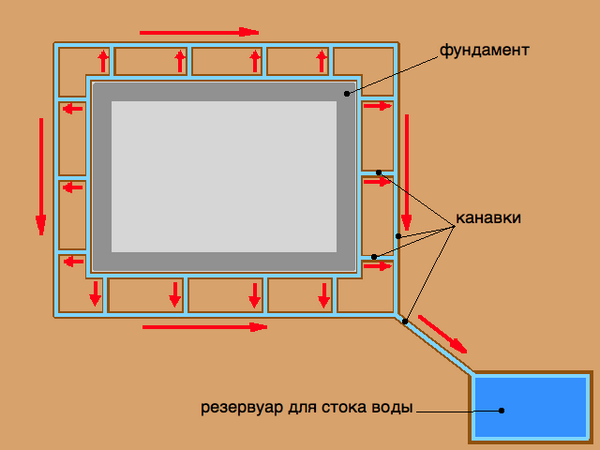

The scheme of waterproofing the foundation plate - the material is selected depending on the type of soil, climate and landscape. This will tell you about this in detail, which will be a project for future buildings.

The scheme of waterproofing the foundation plate - the material is selected depending on the type of soil, climate and landscape. This will tell you about this in detail, which will be a project for future buildings. Positive and negative sides of the monolithic plate

If the foundation plate was the best solution, it would be used absolutely for all buildings. Like any type of foundation, the monolith has its own minuses and advantages.

Start stands with pluses. These include maximum strength among other structures, durability (construction on the stove can stand up to 150 years). Apply Monolith can be used to different types of structures. If a deep-shamed basement device is selected, the plate becomes the floor for the first, basement or basement in the house.

The scheme demonstrates that the monolith can be made in ribbon base at home.

The scheme demonstrates that the monolith can be made in ribbon base at home. The disadvantages include the high cost of the work, because the material for the foundation plate need much more than for a standard belt or bar base. Also to push the complicated calculation, which simply obliges to contact the construction bureau. And the latter is the laboriousness of the process, because the workers have to perform a large amount of earthworks.

In order for the construction of a new home with their own hands in a couple of years, it has not turned into overhaul, you need to take care of the right foundation. It takes not only to withstand the weight of the construction - it usually does not occur with this problems. It is much more difficult to compensate for the effect of unnecessarily moving soil on the walls. On complex areas with a weak soil with this task, only the foundation of the monolithic plate can cope.

In essence, it is just a reinforced concrete "pillow" on which the house is worth. Due to the maximum area of \u200b\u200bsupport, the load from the structure is transmitted to the soil in the distributed form, and the pressure decreases several times. And the wider there will be a "contact" in the diagram, the lower. This property allows you to apply slab foundation Where the weight of the building exceeds the bearing ability of the soil.

Another case, when without a solid reason it is not necessary - bunched soils (sands, sandy, all clay types). This can also include wetlands and wetlands. The use on such a plot of the monolithic tape will lead to the fact that one part of the house will rise in the season, the other is descended, and the bearing walls will simply work for a break. And if the elastic tree, such loads are still able to transfer, then brick or block buildings from such an appeal will quickly go cracked.

The output is the same monolithic stove. Remember the picture from the textbook of physics, where the matchbox swings on the waves, but not moving? Flat foundation will work on the same principle. The soil can lift or lower it, and the house will remain beaten relative to the concrete plane.

These are two exceptional cases when the use of the monolithic base is economically justified. In any other situation, it is better to refuse to refuse cheaper metal piles or concrete tapes. However, this is only a question of money - there are no other restrictions. The price of a turnkey foundation even a small thickness of 25 cm begins from 3600 rubles / m 2, a more powerful stove will pull on 4000-5200. And even the device of a monolithic base will be released only by twice as cheaper, as the main cost of expenses is a purchase and delivery of building materials. And they just need a lot.

Phased construction technology

If the plot just got under the definition of exceptions or the builder is not so sorry for money as its own forces, it's time to get acquainted with monolithic technology and study the guide on the device plate. Step-by-step instruction Shares the construction of the foundation into separate stages. Each step is a new layer of a kind of "cake", and no one can miss. Works traditionally begin with marking, preparation and leveling of the pit. Building materials will be gradually stacked. Usually under the small-breeding slab foundation, it suffices to remove the fertile soil reservoir and pull out a flat area at a depth of 0.5 to 0.7 m.

1. Device drain pillow.

Fall asleep the first layer of sand, moisturize and tram it until it obtained a smooth surface. Depending on the weight of the future building (taking into account the fondament plate itself), the thickness of the finished pillow is selected from 20 to 30 cm. From top of the geotextile, and re-smells to a height of 20 cm, but already from rubble.

At this stage, concrete preparation from the M100 liquid solution can be performed. If there is a gravel pillow, this item is optional, although the cost of fill is small, but a lot of use. The thickness of the protective concrete layer is only 1 cm, but provides greater stability of the foundation on the ground and its best protection against excess moisture. At the same stage, you can take care of the insulation of a monolithic base and partially implement the technology of the Swedish plate. For this throughout the area, a solid pillow of foam or high-density polystyrene is formed. But, again, everything is at the discretion of the owner.

2. Waterproofing foundation.

The most inexpensive and important stage of work, after which the monolithic plate acquires "immunity" to the destructive influence of moisture. After all, unshauncated base in any case will be higher than the level of primerization of the soil, and in winter, the water will start tearing it from the inside. Inaccessibility of concrete for water will be the key to its long service.

In fact, the dense membrane provides protection for fine insulation from damage. On Geeckin, two layers are placed by a film with a thickness of 0.2 mm and solder joints with double seam. Sometimes the rubberoid is used as a hydrobrilever, but its service life is not long enough - after 10 years it rotates, and it will be impossible to replace. Isolation takes such a width so that the slab foundation can be wrapped to it from the ends at the end of work. This is how an indifferent waterproof layer is created, which will protect the concrete from moisture and subsequent destruction with the arrival of frosts.

3. Installation of formwork and frame.

The slab foundation has a small height - from 15 to 40 cm, so that the deck will be enough ordinary boards. The main thing is to strengthen them well, putting the side ships and struts, as well as check the parallelism of opposing walls. The reinforcement is placed in two horizontal belts with transverse dressings. The size of the cells is selected from 200 to 300 mm - such a scheme of reinforcement of a monolithic foundation plate is considered optimal in terms of strength, although it requires a large consumption of rods and knitting wire. The distance from the ends of the rod to the outer walls of the monolith should be about 50 mm. This will provide metal reliable protection against corrosion in the body of concrete.

If it is planned to reinforce the foundation of fiberglass reinforcement, the difference can be reduced twice, since the composite is completely not afraid of moisture. In the rest of the laying scheme, the rods remains the same. A similar replacement of the traditional metal is performed by rods of a smaller diameter and gives good saving of funds, while the durability of the frame is preserved. Plus - on the rupture resistance in fiberglass reinforcement is much higher than that of the same AII.

4. Laying concrete.

The entire volume of the formwork of the foundation must be poured into one reception. Manually prepare such a number of solution will be difficult, so it's easier to order its delivery from the nearest RBU. The brand of concrete is chosen on the basis of a strength calculation, but usually grabs M250-M350. The main thing is that the mobility of the mixture is sufficient - the class P3 or higher, if the work is performed in hot weather.

The freshly plated monolithic plate is compacted and aligned with vibrator either aligned by a wide range. The quality of the concrete surface at this stage is of great importance, since the cluttered solution is seriously processed. It is better to do everything right away right than then grind cement stone. The stove is covered with a film, but after a day it will have to be saved. At all concrete works It is advisable to put on raw and cloudy weather so that hydration flows in normal mode.

According to the technology, the monolith must recruit the strength of 4 weeks, but the foundation can be rapped before. To continue construction, concrete is enough and 70% of the declared brand - they will reach them in the second week. So it is not necessary to wait full time. After the platform, the left edges of the waterproofing are raised from the ground and solder to the ends of the plate.

The technology of the monolithic base device is indeed the easiest and does not require much experience from builders. That is why it often choose those who are forced to do their own. After all, if the instructions are followed, serious errors are practically excluded, and with expenses at first no one is considered.

But on the construction of monolith, it is possible, and sometimes you need to save. To do this, make calculation of the thickness of the slab foundation based on the construction scheme. The monolith must be powerful enough to resist the bending loads between the walls. Partially "lever" can be reduced by forming rigidity on the stove.

At the same time, the foundation of too much thickness will be not only material intensive and expensive, but also will increase the pressure on the ground due to its weight. So it is worth spending half an hour of time and independently understand the technology of design of w / b-plates.

It is widely used in the construction of both multi-storey and private houses, cottages. The high popularity of such a design is explained by the fact that it is very reliable and in its supporting abilities exceeds other types of foundations.

This design is reinforced concrete monolithic slab, reinforced with metal rods throughout the area. This design allows the foundation to form a whole whole, so that with minor movements of the soil, the building does not threaten the risk of destruction. To ensure high stability of the design throughout the operational period, it is necessary to properly prepare the basis for the future foundation Plate..

The main stages of training under the foundation slab

The initial stage of the fabrication of the slaughter foundation is excavation - digging the corresponding sizes. Initially, the recovery is rotated using an excavator, and the lower layers with a thickness of 10-15 cm It is advisable to remove manually. The total depth of the pit is about 40-50 cm. If a building is planned to build a building with a basement, then the depth of the pit may be greater.

After the completion of land and aligning the surface of the pit, the creation of a special cushion from rubble, gravel and sand is carried out. The pillow thickness is about 20-25 cm. Its main purpose is to protect the monolithic slab from the possible aggressive impact of moisture, if the soils in the construction zone are saturated with moisture or groundwater level highly.

To save concrete mixUsed when pouring, from dehydration by absorbing the liquid with sand, when preparing for a gravel-sand pillow, it is recommended to fit one or two layers of the film or a bowl of reference.

Sometimes in the preparation of the buffer cushion of the foundation plate instead of sand, such a material is used as polystyrene foam with a thickness of about 15 cm and a density of at least 20 kg / m 3. Extruded expanded polystyrene can also be used, having a higher resistance to compression. In this case, you can do without moisture protection layers from the film or runnerdoor.

The next step in the preparation of the foundation plate is the installation of a steel frame of fittings. For this, the reinforcement bar is chosen with a thickness of 10 to 15 mm. To ensure the desired carcass strength, steel rods are welded - it will save the structure from destruction when moving from earthy layers. To add the strengths of the concrete plate, the frame is additionally installed metal pipes or iron scrap.

After carrying out preparatory work It can be started to immediately fill the foundation plate itself.

What you need to know before preparing the foundation under the foundation plate?

Before the start of work on preparations for the construction of a slab foundation, geological and intelligence work must be carried out, in the process of which the condition of the soils should be found at the place of development and the presence of nearby soil waves. It is from this that the desired depth of the pit and a suitable brand of concrete will depend on it.

Before the start of work on preparations for the construction of a slab foundation, geological and intelligence work must be carried out, in the process of which the condition of the soils should be found at the place of development and the presence of nearby soil waves. It is from this that the desired depth of the pit and a suitable brand of concrete will depend on it.

Positive aspects of the use of foundation plates:

- increased bearing capacity;

- resistance to displacements and swelling of ground layers;

- uncomplicated design;

- resistance to the effects of soil and melting water;

- the possibility of building a basement;

Negative sides:

- high price;

- large labor costs.

Order Preparation of the foundation and subsequent fill of the foundation plate in Moscow, and the Moscow region can be in construction company "Project". We have many years of experience in creating any foundations and are ready to perform in a compressed time. professional level everything necessary work. Contact our company, and we will execute your order qualified and at an optimal price.