The foundation is the most important component good house, His fortresses and durability. The choice of foundation for the future house is unrestrained and is due to quite definite factors. What will be the foundation depends on the climatic zone, the characteristics of soils and the characteristics of the future structure (dimensions, floors, the presence of a basement or basement). The choice for the home of the collecting-monolithic belt foundation in many cases will be the right solution. It is perfect for any relatively sustainable soils and most climatic zones, will freely carry the structure of an individual residential building to three floors. This article describes the stages of the construction of the foundation with photos and video of construction at the end of the article.

We will fulfill all types of concrete works! Call: 8 938 10 44 002

What is a collection-monolithic belt foundation

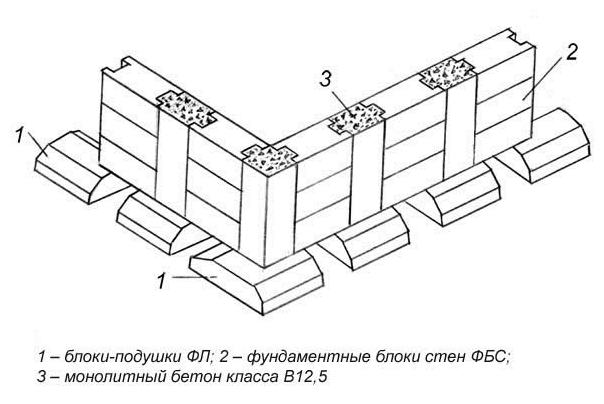

Collected-monolithic belt foundation is a design of monolithic concrete parts and precast concrete parts. Monolithic concrete sites are the foundation tape and armoo - and the teams are the foundation blocks of the walls (FBS). The design of the collection-monolithic belt foundation is schematically as follows:

Before starting construction work, you must fulfill and hold (according to the links, the relevant articles do how to do this).

Stages of building a collection and monolithic belt foundation

- The construction of a collecting and monolithic belt foundation is carried out in several stages:

- Shooting, layout and marking of the land

- Copper trench

- Sand cushion or sweeping device

- Foundation tape device

- Installation of FBS blocks

- Device of monolithic belt

- Waterproofing foundation

- Backflow and rambling

The shooting of the site is necessary to determine the heights of the future foundation and is carried out by experts with the appropriate equipment (level, theodolite). After setting the marks, the site layout according to the project documentation. During the planning and markup, the location of the future structure is determined.

The location of the foundation tape is wakewicked with sand for an excavator, and stakes and ropes are removed.

A trench digit manually too long and labor costs, so it is better to use the services of the excavator. But manually adjusts the trench with the reconciliation of diagonals, since the excavator is not able to dig it perfectly clearly. The width of the trench is made sufficient to get the ability to install formwork and subsequently fill the foundation waterproofing.

The bottom of the trench is leveled and checked heights again. Preparation under the foundation ribbon is performed from the B-7.5 brand concrete or the rammed sand.

The construction of the foundation tape begins with mating and installation of the reinforcement frame. Its dimensions, ligaments and geometry are reflected in the project documentation. When the frame is ready and installed, the assembly and installation of the removable formwork of their wooden board is made. The formwork is installed in the trench, creating dimensions of the future foundation tape. The reinforcement frame is raised by 50 mm on a bit of broken brick. Broadcasting shields must be securely bonded, otherwise the concrete can squeeze it or relax. For an additional fortress outside the formwork, struts are installed and reinforcement stakes are driven.

After receiving and frozen the concrete, the formwork is removed.

Installation of the FBS of the Ribbon Fundament and Monolithic Belt

The next step is the foundation blocks of walls. There is a crane and brigade of builders. Blocks are installed according to the sizes according to the layout in the project documentation on cement-sandy solution. The joints between the blocks are also closed with a solution.

After installing the FBS, we proceed to the mating of the rebar of the monolithic belt, which is installed on the blocks. Armopoyas formwork is attached to blocks with screws on concrete and firmly fastens with each other. When installing the formwork, it is necessary to "shoot" the level height, so that the monolithic belt brings the foundation for the desired mark and was smooth in the horizon.

After accepting concrete, we leave the monolithic belt for drying for several days, and then remove the formwork. In complete, we produce waterproofing the foundation in two layers of bitumen mastic.

After drying, the waterproofing is made of reverse fusion and the ground of the soil under the monolithic slab and the breakfast.

Video construction of a collecting-monolithic belt foundation

Important rules for the construction of a collecting-monolithic belt foundation:

- At each stage, check the heights of the level and the diagonal, the geometry of the future house depends on it.

- Use construction equipment that facilitates and speeds up

- Carefully strengthen the formwork, its gap and pouring concrete will cost large cash losses

- In hot dry weather, shed fresh concrete with water, as it quickly loses moisture, which leads to the formation of cracks

- When accepting concrete, no mee should work

- When pouring the foundation tape, it is recommended to use a deep vibrator.

- In the next article you will learn how monolithic plate (draft floor)

Construction is unthinkable without special equipment and equipment, which in small objects is usually taken to rent. But if we talk about large and long-term contracts, the question of the benefit of the acquisition of equipment is raised. Now the market offers services such as shipping construction equipment from China favorable prices With full accompaniment of cargo and elaboration of the route. In addition, the design of all the necessary documentation, insurance, customsization and maintenance of cargo will be ensured.

Collected monolithic type of foundation combines high performance, spatial rigidity, resource. At the same time, standard FBS blocks are used, filling technology into a reinforcement formwork. The foundation can be enhanced by Armopois under blocks, on top of the last row, between them in each row of masonry.

Foundation Technology with Monolithic Armopoyas

Collected monolithic type of foundation provides a high construction budget. In the building stain, it will be necessary to order a lifting technique for installation FL, FBS, then mixers for filling the reinforced concrete. Monolithic sections enhance the national foundation, allowing you to achieve a high operational resource.

The collectively monolithic type of foundation is a belllee (PSF) or a low-tender (MZLF) tape, the angles of which are assembled from the FBS blocks resting on the FL plates, the intervals between them, the top ring of the Armopoyais is filled into the formwork. Therefore, pickups are needed for the axes of the bearing walls, the perimeter of trenche or pit. According to the joint venture 70.13330 (construction geodesy), the technicallylamant TR 94.03.1 (railway designs underground) the foundation should be located:

The hoist has a horizontal board design (the length is slightly larger than the width of the foundation tape), nailed to two pegs (8 - 12 cm diameter). Mounted pickups of 1.5 - 2 m from the walls of the pit, trenches, strings, cords, wire stretch over the wooden plank. Thanks to these devices, the cord can be shifted on the axis, external, inner edges of the walls.

Before the beginning earthworks It is necessary to clearly represent their consequences:

- trenches cut down the formed underground layers, which can change the movement of groundwater

- soil can rise from flooding or settle down during drainage

To ensure a high resource of concrete structures below the surface of the Earth, the foundation is protected from groundwater with a ring drainage system. The technology of building drainage sewage has the form:

When removing the soil from the tape base trench, the excavator is hovering, the bottom must be touched by manually. The density is dropped by half the bucket fangs, shovels cleaned the trench profile to get to the formation with the untouched structure.

Base

The collectively monolithic type of concrete structures is traditionally reliable on the pillow of a nonmetric material. There are design solutions of several species:

In any of these options, layer-by-layer seal with vibrating plates is a prerequisite.

The sharp edges of the rubble are pierced, disturb the integrity of the waterproofing carpet. Therefore, the collection of the monolithic type of foundation is based on a 5 - 10 cm tie with a low brand of skinny concrete.

Smooth plane is convenient for rolling rolled material, sealing joints. The sub-concret is poured without arms in the formwork.

The foundation has hygroscopicity, there are moisture in the soil of several types. Therefore, the waterproofing of the soles actually extends the resource of the base of the dwelling. The coolements, paints, impregnations are useless here, 2-3 layers of rolled material (Česospan, TechnoNikol, bikrost) with 10 cm overlap.

The edges of the insulating carpet are produced outside so that after the platforms to start them on the side walls, ensuring the continuity of the layer.

Laying plate FL.

To stabilize the verticality of the tape, the foundation is interrupted in the sole of FL plates. The layout scheme is as follows:

- corners - Mounted Long Plates for Supporting Two Blocks

- filling in direct areas - aimsmaker to save budget either close to each other to increase the reference plane

- monolithic works - plates have a trapezoidal shape, when they dock them at a right angle there are emptiness that need to pour concrete

If you do not deposit the joints of the plates, with the backfill of the voids are filled with bunchy soil, providing pushing the effort to the FBS block located above it.

The national foundation is large-format laying of concrete blocks by analogy with brick walls. For installation, cement-sandy solution is needed (consumption of 1.5 - 3.5 buckets per unit depending on the width), lifting equipment. There are two schemes of monolithic national foundation:

In the first case, the stiffness of the structure is provided with the dressing of the angles, intensifying the long blocks into the array of the tape. In the second embodiment, a complex block configuration is used. At the ends, they have a groove, which when pouring is filled with concrete. After the mixture is frozen, it turns out a robust design. Installation with corners in the first diagram has the form:

In the second case, the technology is somewhat different from the previous method:

- two FBS blocks are mounted in one corner on the total plate of FL to contact inland ribs, a blank square remains in the corner.

- the operation is repeated in all angles, the overall horizontal is controlled, the vertical of the exterior edges of each block

- then the new row is displayed on the same blocks without dressing vertical seams.

- the operation is repeated until the design mark is reached.

The last technology has almost copied foundation columnalHowever, the foundation blocks are located here between the columns.

At this stage, the concrete remained in the ribbon of emptiness. If the FBS blocks are used in the corners, pairing, mount the formwork is much simpler:

The foundation will receive spatial rigidity due to the high quality of the FBS blocks installed in the responsible places of construction. If the blocks are mounted on each other without dressing, outer angles when assembling the formwork will have to be measured by tools. On direct sections, the shield installation scheme is similar to the previous method. With the discharged installation plates of the FL, they must have a length:

- the width of the piled post (usually 1 - 1.5 m)

- opporting FBS block (0.5 - 0.7 m)

- opportuning the second block (0.5 - 0.7 m)

In monolith, it is necessary to leave the technological holes by installing the sleeves through the shields of the formwork:

- for nodes input communications below ground level

- for the production of ventilation in 40 cm above the cabin minimum

Door openings need to be covered with jumpers, windows can be made in monolithic ribbons without them. Pluts adjacent to the window to the window, are enhanced by rods by analogy with beams, rods are mounted near the corners diagonally. The hollow-formator (rectangular box) is placed in formwork, fastened through the shield by self-draws.

The foundation collected from unarmed blocks does not have spatial stiffness. The large area of \u200b\u200bthe side walls is experiencing serious tangent efforts from the soil. Therefore, to stabilize the structure, the ring armoomas is applied to the top of the blocks. Technology has the form:

When viscating the reinforcement is better to use the wire, bending the rod to the next side, and not to poison their flashes right in the corners.

The foundation is operated in aggressive media, so waterproofing of porous structural material is necessary - concrete. If the waterproofing components are entered into concrete in the manufacture of the mixture, the material gets the default water-repellent ability. To do this, you can use the admi alex penetron manufacturer powder, which is adding 100 cycles of minor resistance, inertness to alkalis / acids, petroleum products. The waterproof mark rises by 3 units.

The same manufacturer produces a dry mixture of penetron, which is used for external treatment. When applied to the surface of the solution, the components of the waterproofing react with cement stone, the structure of the material is changed over the entire thickness of the concrete structure, giving the same properties as the Admix with the addition of compression strength by 5%.

In other cases, the secondary protection of concrete from moisture is used:

- causes, paints - have a different consistency, bituminous or epoxy basis

- roll materials - for foundations used waterproofing on fiberglass, polymer base with two-layer bitumen coating

- impregnations, primers - are usually used before staining, salary, fractive concrete surfaces, increasing the resource one and a half times

Combined protection with the use of penetrating mixtures can provide 80 - 120 year resource. In projects with an exploited basement, the outer surface of the tape walls is additionally insulated. In cottages without cellars, only the cabin is insulated at the level of the soles with a horizontal layer.

In the first case, the walls are flown by XPS expanded in one layer on top of waterproofing, additionally fixed dowels with umbrella caps. The design is covered with geotextiles before the inverse filling of the sinuses. Nonmetallic materials (PGS, sand) with layered vibration absorption are used to prevent swelling in the backfill. Laying the insulation under the cabinet is necessary at the level of the sole of the foundation over the drainage sewage.

The backstage is made after styling drainage, hydro, heat insulation of the walls, protect the insulation geotextile. If some of these operations is not completed, it is impossible to float the sinuses.

Varieties of the national foundation with monolithic elements

Collected monolithic type of dwelling has several options. The most popular among individual developers are as follows:

Each variant allows you to significantly increase the stability of the structure, the stability of the geometry, spatial rigidity. The minuses are switching from one construction technology to another, an increase in the budget due to the rental of special equipment, a decrease in the pace in comparison with the national technology team.

The above technology allows you to use the advantages of both the monolithic and the prefabricated method. When maintaining the pace of construction, the tape becomes more durable, but additional costs are required. Subject to the recommendations, the foundation will receive the highest possible resource.

Under the monolithic foundation, the basis of the construction, made of a solid reinforced concrete element, is most often understood. Depending on the design, slab, ribbon and pile types are distinguished. Each of them is used everywhere not only in individual construction, but also when the majority of major objects are erected. It is the monolith of reinforced concrete that allows you to guarantee reliability and durability, and the relative ease of construction work - A good help in order to implement a "zero cycle" with your own hands, without using the services of respected guest workers.

Device

The main role is assigned concrete mix and fittings. Frozen concrete solution Forms a solid stone mass, which is characterized by increased resistance to compressive loads. In turn, the reinforcement is its skeleton, thanks to which the uniform distribution of loads throughout the monolith is achieved. Steel fittings B. more than It is responsible for the perception of stretching loads, it is for this reason that the reinforcement grids or belts are placed closer to the grains of monolith. Such a simple device contributes to the protection of the above-ground construction from local deformations.

Depending on which the depth is the monolith, distinguish:

- foundation or unduned (usually slab or tape);

- outlook, in which the base sole is below the drainage depth (tape or pile).

Important information

The most difficult in the manufacture of the type under consideration is to calculate. At the same time, it is necessary to take into account the nature of the soil, the level of groundwater, the depth of the primer of the soil, which is determined by climatic conditions, the project of the house and much more. Of course, it is better to entrust all these professionals, but the cost of such work can spoil all the impulses to the construction country house. Therefore, they are carried out independently, and this makes them very approximate - only an impressive margin of strength allows you to be confident in the reliability of this approach. It is also important to competently approach the decision of the reinforcement, the choice of concrete mix, the devices of the formwork, waterproofing and insulation - all this will have a positive effect on the quality of operation of the constructed structure and its durability.

Sole parameters

- if the soil is poured and susceptible to significant seasonal changes, and the depth of its freezing (GPG) is sufficiently high, most often give preference to the slab, which in any other situations is considered economically inappropriate. In this case, the base sole is characterized by the maximum area, which allows you to evenly distribute the load on the ground, securing the house from the impact of local changes occurring in the soil;

- provided that the soil is poured, but the GPG is small, you can make a bet on the foundation shrouded below the drainage depth. This approach is suitable subject to the use of a limited amount of supports and a relatively small load from the house;

- if the soil at the construction site pleases medium and low bunchiness, then depending on the project (with or without basement or without), it is possible to lay either beugoned or undue type.

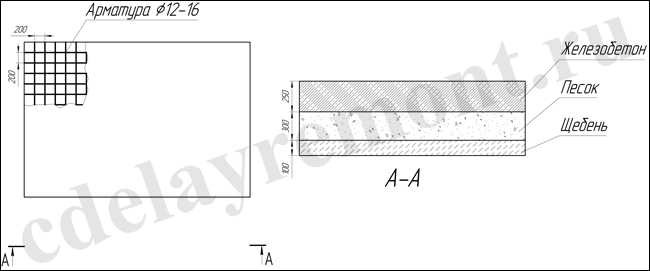

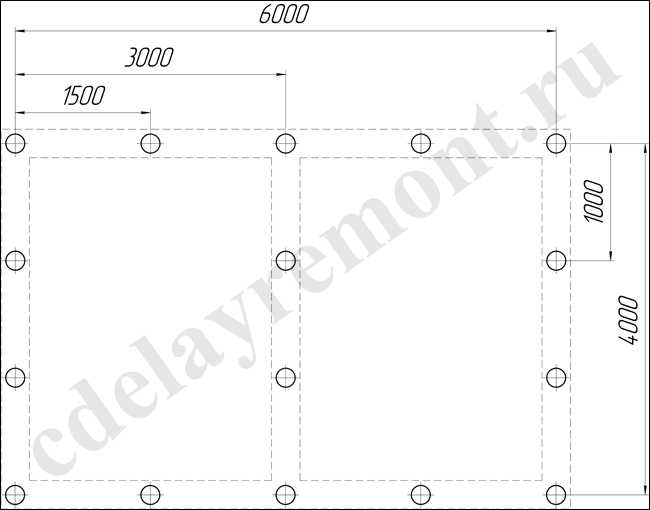

Blueprints

The simplest drawing can be made by themselves. This requires only the calculated data obtained earlier. So, for the plane under the house 8x6 m, the drawing may look like this:

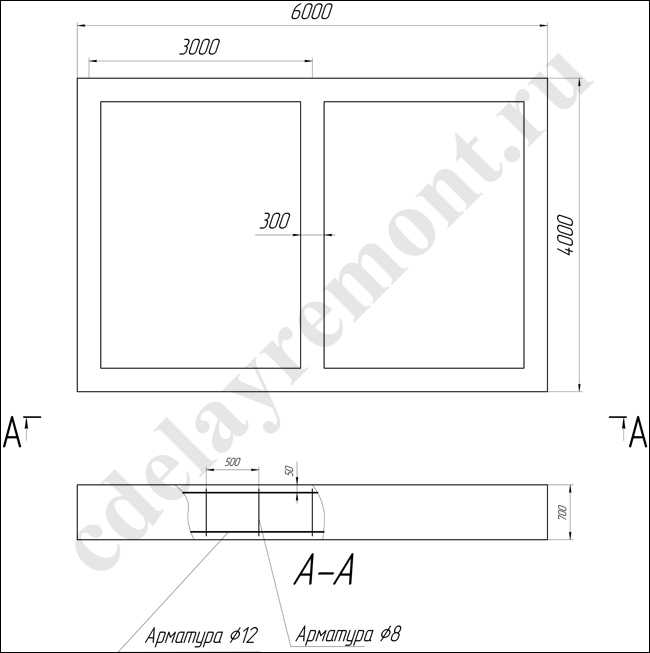

If we are talking about ribbon foundationIt can be constructed as follows, given the location of the bearing walls (under which, actually, the base tape should be located):

In some cases, it is preferable to build a pile form, and it must be borne in mind that the supports must be located at the place of crossing the walls, and where the load is maximum, it will be necessary to reduce the step between pile:

Important! Analyze the soil on your site! It is not necessary to spend money on professional services of geological intelligence: Make several wells in a conventional garden brown at different points of the site and see how the composition of the soil is changed as the gluke. Again, you can estimate the level of groundwater and predict the behavior of one or another type of foundation.

Reinforcement

As we said, armature carcass It is an indispensable component. It is thanks to him that all the load is evenly distributed throughout the volume of monolith. Depending on the construction conditions apply different types steel reinforcement. You can read more about the reinforcement.

Choose concrete

Depending on the magnitude of the load, the concrete mixture is determined with the class (brand). At the same time, the nature of the soil and climatic conditions is also taken into account, are determined with the optimal values \u200b\u200bof F, W coefficients, P. what do they mean and how to choose the right concrete? We recommend that you recommend reading in our article about.

The formwork serves as a temporary form or structural element. It is on it that the confonna mixture is assigned during its curing. Waterproofing, as well as thermal insulation, contributes to the preservation of the qualitative characteristics of the monolith. With all the stages of the construction of specific types, you can get acquainted on the pages of our site in individual articles.

Read also

|

How to make a bath procedure for truly cool? For this, it is important to comply with three conditions: a successful company, a good chandelier and a really cozy bath interior. In this article, we will not be able to help you with the Council regarding the first two conditions, but we will talk about the basic rules for the design of the steam room, a washing and rest room. Enjoy Your Bath! |

|

Reliable and durable foundation can be only when all necessary calculations were carried out before its device. First of all, it concerns the determination of the size of the sole area. This indicator Directly associated with the ground conditions on the site. We tried to describe in detail the methodology for calculating the foundation. |