The complexity of arched forms requires sufficient skill for the manufacture of such architectural structures at home. Interroom Oak Arch, the manufacture of which we will look at today, looks very beautiful. At first glance, such a design of the interior arch may seem too difficult, however, dividing it with an experimental view to the components, the master will be able to determine that each of the parts can be made independently in the presence of required tools and work skills.

Construction of interroom arch.

Pilastres - Boxed designs of the P-shaped section, imitating the support columns of the arches. Each pilaster is going out of three details. The curly design of the pilastry column is provided by the following elements: a figured base (lower part of the structure), the protrusion (middle part) and the capper (upper part).

Arch - arcuate design, "arch" opening.

Archives - Framing platbands Arch.

The width of the door or interroom opening, in which it is intended to install the arch, determines the form of the structure. So, a fairly wide opening in one and a half or two meters allows you to install the arch in which the upper sector is a part of a circle, a narrower space limits the structural capabilities of the ellipsis form.

Production of an arched arch template

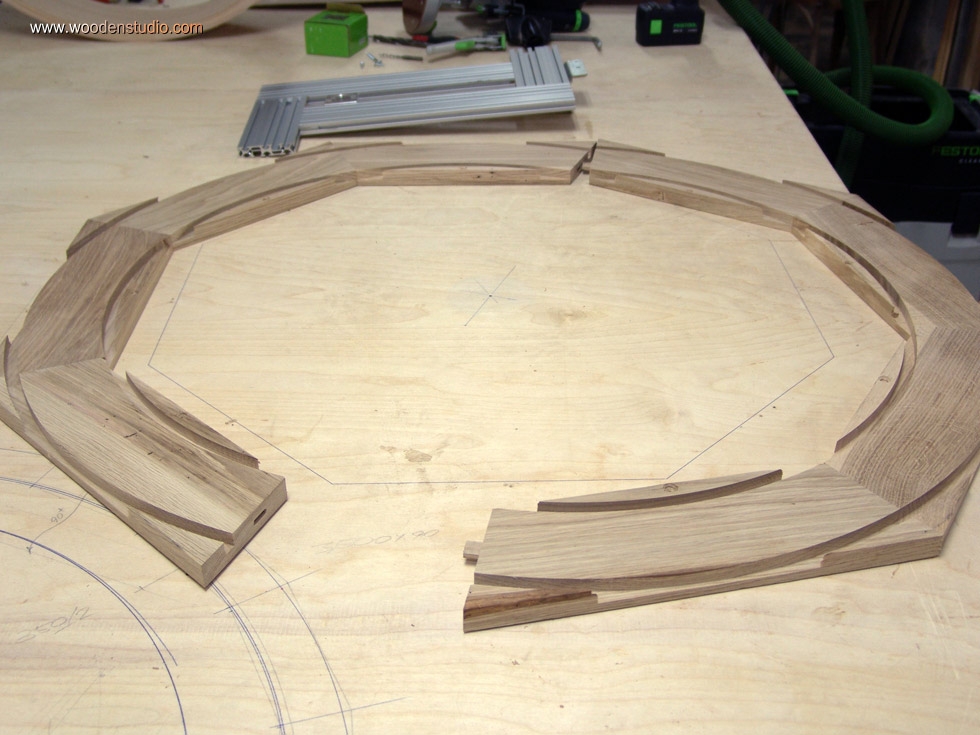

In any case, for the manufacture of an arched arch requires a special form (in the form of a ring or ellipse). The template is made of 20 mm thick plywood, drinking it with a pubsy. For the inner circle (ellipse), a hole is drilled in a sheet of plywood, which is then inserted into the pill.

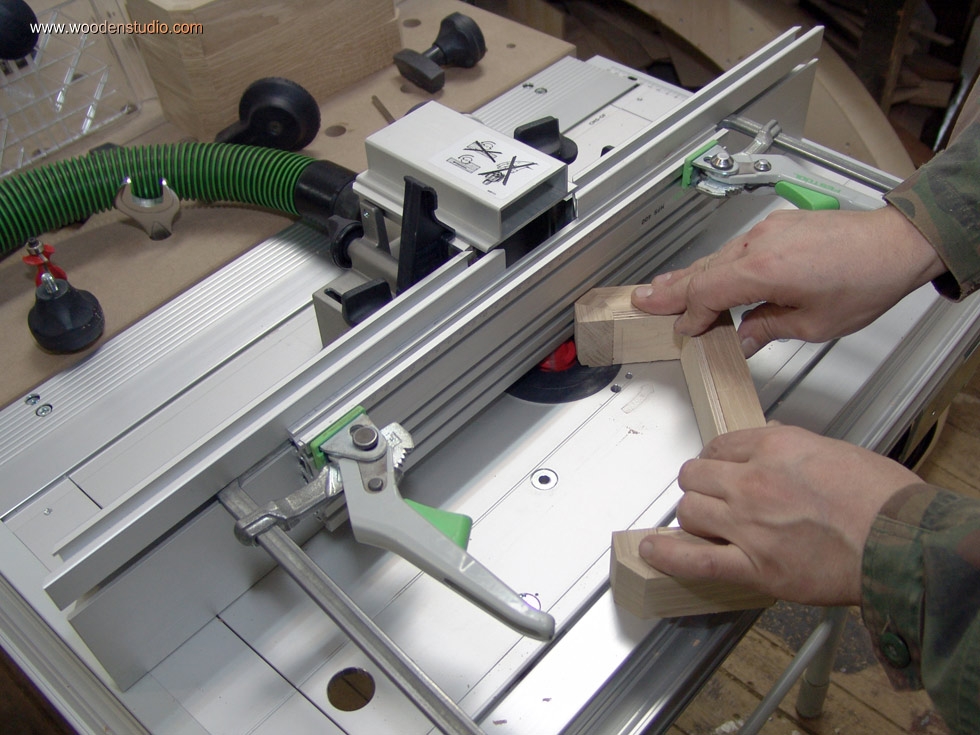

The cut-off plywood ring is treated with edges, it is easy to make on the milling table using a fit cutter with a lower support bearing.

For the manufacture of an ellipsis shape, the pattern is first drawn on paper, subsequently carrying the drawing on the phaneer. You can use a computer printout on several standard sheets (A3 or A4), however, in this case it is necessary to carefully combine parts of the pattern. To transfer images, you can use the usual copy paper. The ellipseed or round jumper is collected into two equal parts, fastening them with each other with jumpers in such a way that the width of the resulting shape with the jumpers was about equal to the wall thickness (permissible error 3-5 mm).

Almost finished form are strengthened with DVP, plywood or thin sheet metal. It is important to find a compromise solution here, since more solid materials are more difficult to process, but it is precisely the hardness of the form determines the quality of the part.

On the finished form, you can start the discharge of the part. Material for manufacture can be chosen to your taste, a good option can be a combination of plywood and a veneer with a thickness of 2.5 mm. After completing the work, the workpiece is fixed using clamps until complete drying. Waving the time required to clarify the glue (according to the instructions), go to the processing of the part.

Production and processing of arched arch

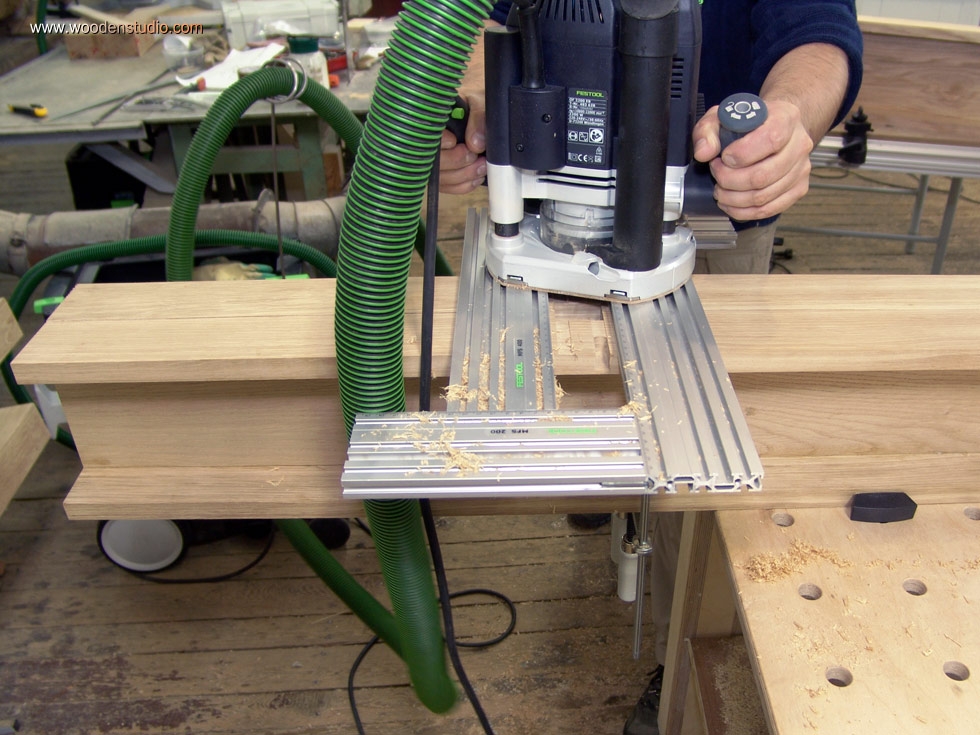

Initially, cut the protruding parts by the jigsaw, then with a grinding machine with a solid plate, small irregularities are treated.

The processing of eccentric grinding

machine

The sequence of the operation is as follows:

- The form is raised above the table in such a way that the blank remains on the surface and is fixed by clamps.

- Available for processing edge is processed by a belt grinding machine.

- To process the second edge from under the form, the plates and the billet turn over is removed.

- Finishing includes the removal of glue residues and grinding the surface of the part.

From the accuracy of processing and accuracy of the assembly of parts depends on the appearance of the finished product. Thus, before gluing the components of the upper part, it is necessary not only to crop the inner side of the archival of the viscosity, but also to fix the parts using the stops of the part, not allowing their offset. The inner edge is processed only after complete drying of the glued parts. At the same time, the inner surface of the future arch of the arch is polished.

|

|

|

|

It is worth considering that the outer edge of the archived is processed into the required size, and the inner edge is processed with a 2-3 mm intake for further processing. Milling grooves in the manufacture of archived may be carried out not completely. From half the depths, they can be cut through the jigsaw, not forgetting to leave a small allowance for a paddown.

In the manufacture of an ellipseed arch, the manufacture of archives has characteristic features:

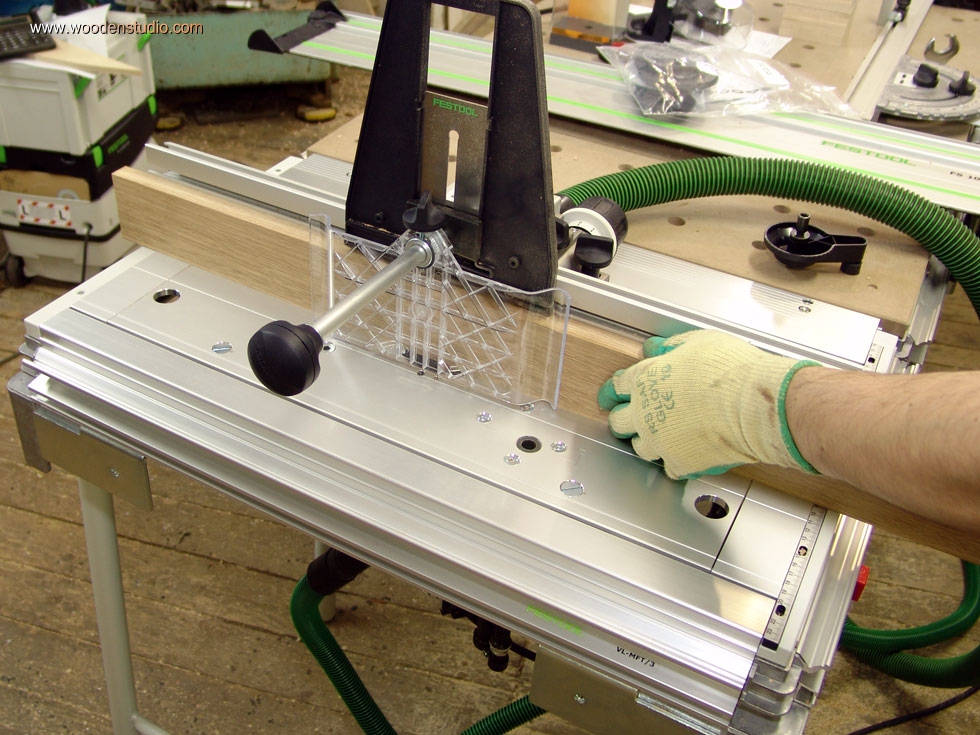

- The workpiece is attached to the shape for shouting the army with screws, after which the groove is molded.

- The second billet of the archival is applied to the professional, it marks the edge line.

- Over the line edge is cut with an allowance.

- Using one (first) item as a copier, you can achieve the identity of the blanks during the manufacture of external edges.

- The last barcode is grinding the details.

|

In the fixed billet, a manual milling is selected grooves |

The edge of the second workpiece is clipped with an electric bison with an allowance |

|

Processing the second billet. The first part is used as a copier. |

The final grinding of previously performed parts is performed. |

|

Glue and parts are clamping clamps to complete drying |

After drying the adhesive, the internal edge is performed. |

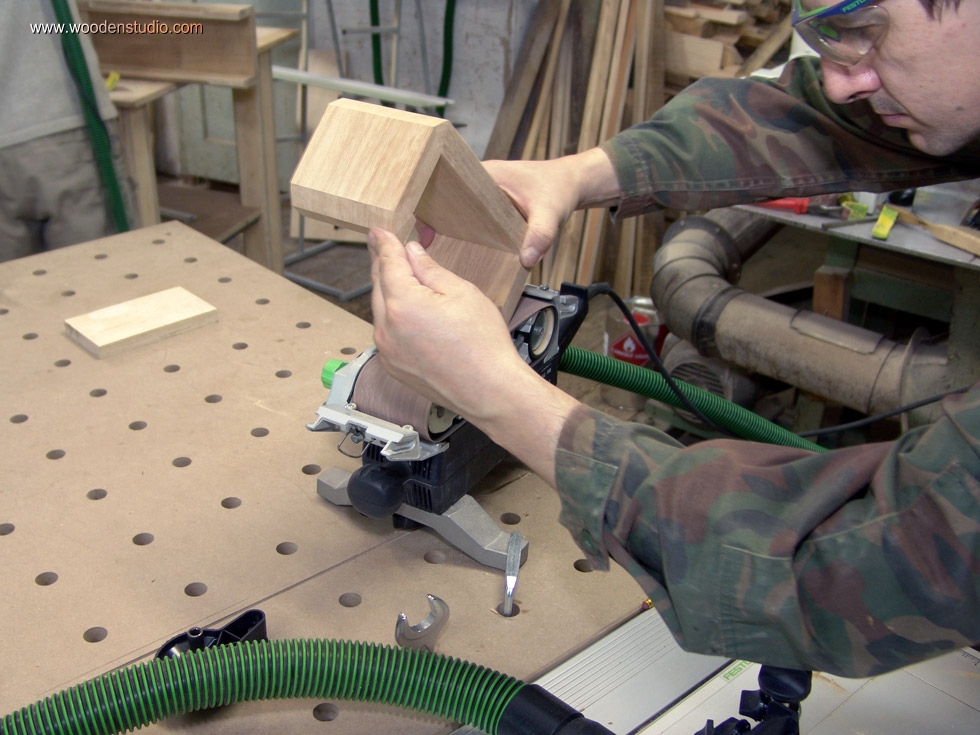

Making a pilaster

Pilasters in the design of this interroom arch are divided into two zones. The grooves needed for fastening the decorative strapping (belt), if necessary, it is necessary to apply for mounting the arches to the wall.

|

|

|

|

Making capitals, belts and figured bases

|

|

|

|

Final assembly and coating by varnish

Before applying a varnish coating on the arch elements, you can apply a pattern or ornament. Depending on the selected style, colors and other characteristics external view The future arch is chosen by colorless, colorful varnish or other types of coating, as well as their combinations. When choosing a multilayer coating, it is necessary not to hurry and withstand each item after applying one of the layers the necessary time before proceeding.

|

|

|

|

Lacted and well-dried parts are collected again and carried out installation in the opening in two stages: preparatory, which includes fitting in size, and final with capital reliable fastening. In the process of final installation, the hollow parts of the arch elements are filled with by mounting foam, taking into account its expansion.

Application interroom Arch The interior design has not only decorative character. With such structures, it is possible to divide the excessively elongated room (for example, a long and narrow corridor). The proposed manufacturing technology of arched structures can serve as a kind of template, based on which, applying other materials and forms of design, will easily create an arc for any purpose.

According to the materials of the site of the Lab Dmitry Dovzhenko.

When creating the interior, you need to pay great attention to every detail. Even the most insignificant work element can carry a huge feature in space. For example, engraving the opening, you can bind together individual zones of space, giving it accuracy and completion.

Evaluate the possibilities of Leskvantta

Interior decoration by wood It was relevant at all times. According to experts in such a space, a person feels significantly better - it is easier to breathe, a calmer sleep and the likelihood of depression is reduced. In addition to well-being, the wooden interior creates a special comfort and comfort in the house.

The company specializes in large-scale woodwork and offers its customers a variety of services in this area. By individual order, our craftsmen are manufactured wooden arches, interior doors and cut various patterns on wooden surfaces.