As you know, you can watch the fire forever. Actually, for this, during the construction of country houses, their owners love to establish fireplaces. Nowadays, it is rather a luxury element than heating.

But there are some features that must be taken into account in order to further avoid trouble with its operation.

The fireplace can not just buy and put it. For him, special conditions are needed, such as compliance with proportions, the right chimney.

Make chimney correct

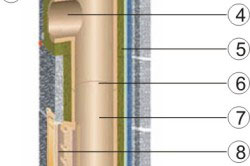

Diagram of the chimney pipe device: 1 - channels for the installation of reinforcing rods; 2 - ventilation channels; 3 - stone shell; 4 - a tee for connecting the consumer; 5 - contour thermal insulation; 6 - chamotte tube of round section; 7 - a tee for connecting the door; 8 - sealed door shutter; 9 - Door for inspection and purification; 10 - Condensate Capacity; 11 - condensate removal; 12 - ventilation grille air; 13 - base chimney.

- The first thing we pay attention to, the material. IN lately Increasingly began to make chimneys from stainless steel, but if the flue gases from your fireplace are not with increased acidity, you can do and the usual material is brick.

- The most suitable shape is cylindrical. The fact is that the greater the chimney of the corners, the more soot accumulates in them, so the shape of the cylinder ensures the unimpeded passage of smoke through it.

- Chimney can not be done in the outer walls. Surely you met on the Internet pictures of beautiful houses, where the pipe was located in the outer wall. In our harsh climatic conditions, it is categorically prohibited. Young designers, after seeing foreign magazines, embody these ideas into life, without even thinking that the pipe was freezing and give a reverse craving. Of course, if you are still convinced of the need to make a chimney outward, it is possible to make it a thickness of 2.5 bricks. It is such a thickness of the walls to ensure reliable protection.

- Place the pipe close to the skate. The smaller portion of the pipe will stick out of the roof and be on the street - the better. The risk of reverse thrust is great.

- The diameter of the chimney depends on the size of the furnace. Most often there are chimneys with diameters of 180 mm, 200 mm, 300 mm and even 500 mm. For low temperaturesEven through the smallest pipe, it takes a huge amount of heat, therefore, the wider she is, the more air is destroyed.

- Deflectors and umbrellas. They are installed to improve thrust, but their action applies only to windy weather. It turns out when there is no wind, these materials make it difficult to make a free yield of smoke into the pipe.

Clear adherence to these rules will allow you to make the right chimney without obstacles and problems.

Possible errors in construction

The oversights made by the negligence of builders or the owners themselves may cause serious harm not only to your home, but also health. Therefore, it is imperative to comply with all the rules. But still, it does not work out without mistakes.

- The use of absinthe or aluminum is not recommended, since these materials are intended for other purposes. In the event that we are talking about the construction of a gas boiler, then the brick is not the best option. It can collapse under the influence of an alkaline medium. And remake of the chimney is a very unpleasant lesson.

- Changing the diameter during the operation of the fireplace can significantly reduce the efficiency. Therefore, if you need to change the width of the pipe, it is better to resort to the help of specialists.

- Insufficient thermal insulation of materials can lead to their fire.

- Arbitrary change in the shape of the pipe do not spend without prior calculations.

Consider the stages of the chimney

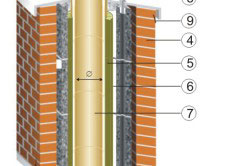

Smokery of the chimney brick: 1 - sealant; 2 - stainless steel cone; 3 - light covering stove under the stencil; 4 - masonry from facial brick; 5 - contour thermal insulation of the chimney; 6 - ventilation channels; 7 - chamotte tube; 8 - Console stove; 9, 10 - ventilating hole in the seam of brick masonry.

- Design and calculation of parameters. It takes into account the individual features of the aggregates and premises, which are undergoing chimney. The diameter of the pipe should not decrease or increase. According to GOST 9817-95, 1 kW power accounts for a section of at least 8 square cm.

- Installation on the heat generating unit. There are 2 installation schemes: "Light" and "Trim". Light is a chimney collected from single-circuit elements. "Trim" assembly of two contour elements.

- Assembling vertical part. All links are installed very tightly to each other without gaps. Fall must be at least 0.5 diameter. If there is a need to make a pipe with a discharge to the other side, use special knees.

- Installation through overlaps. As a rule, specially trained people are engaged in this, since the withdrawal of the pipe through the wall is a rather difficult job. To do this, the passing nozzles are used that isolate the pipe from the walls of the house. Consider that the opening in the ceiling must be somewhat larger than the passing nozzle. Gaps launch a high-quality insulation.

- . To perform this stage there is a specially developed scheme. If the overlap is made of easily flammable materials, then at the point of passing, install the same pipe as when the passage through the floors. Sealing the place of the junction is performed, based on the diameter of the pipe and the angle of inclination.

So, to make the right chimney, consider all the features and do not repeat the errors. Qualitative materials and neat work will provide you with your loved ones in the house and safe stay in it.

For the manufacture of chimneys apply various materialsSome of which have been used for several centuries, while others have become actively used only a few years ago. Any type of removal for smoke has its own characteristics, so it is important to have an idea of \u200b\u200beach of them.

Materials for chimney

The considered structural element of the heating system can be built from traditional building materials, but wealthy hosts can afford and materials created by the latest technologies. The choice of solutions for a particular house primarily depends on the economic feasibility, the requirements of fire safety and the aesthetic views of the owner of the housing. We advise you to explore more information about in addition to this article.

Metal chimneys

As already mentioned above, metal pipes for the removal of smoke are divided into single-layer and two-layer. Single-layer are a cylinder, which, as a rule, is installed inside the brick or ceramic chimney. Two-layer consists of two cylinders of different radius, between which the layer of the heat insulating material is placed, the role of which most often serves basalt minvat.

Tip! If the external design of your home is decorated under ancient, then to maintain the stylistic uniformity, the metallic chimney can be covered with copper casing.

Black metal

High-quality chims from this material from above are covered with a layer of enamel, which reduces their exposure to priora and corrosion. As a result, such a product may last time at a temperature of up to 500 ° C, while admissible are short-term differences to 700 ° C.

The key advantage of pipes for drowning smoke from black metal is the most low pricebut operational characteristics do not allow them to be an effective solution for chimney heatingoperating in intensive mode.

Stainless steel

This material is ideal for chimensions of any types. Alloy stainless steel tolerates the temperature to 850 ° C well, and also withstands peaks up to 1200 ° C. Earlier, we have already written about and recommended adding an article to bookmarks.

The best brand for the designs of this type is considered to be AISI 321 (there are molybdenum impurities), but widespread also have AISI 316 and AISI 304. It is worth noting that many unscrupulous manufacturers produce products from less heat-resistant brands, as a result of which they can be lit through 10-15 years of non-intensive use.

Tip! Choosing a stainless steel chimney, be sure to ask the quality of the steel. You can independently evaluate this parameter using a magnet: good steel has a large number of alloying additives, as a result of which it does not make a magnetic.

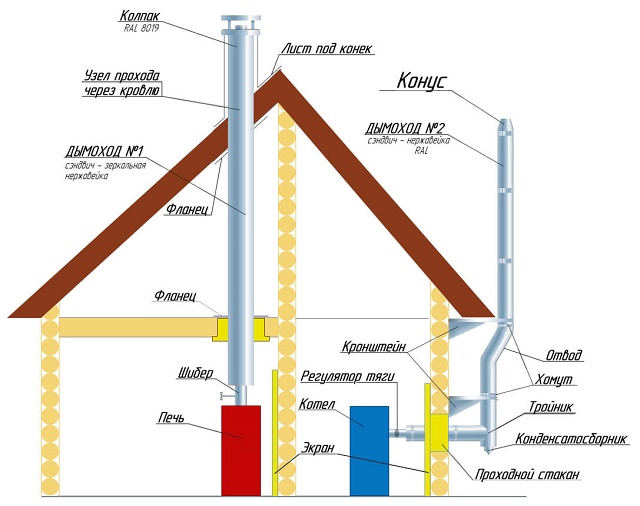

Sandwich chimney for the furnace with their own hands

Best option For mounting a chimney, with their own hands there will be a stainless steel sandwich system. It looks good and answers all modern fire safety standards. An important advantage is the fact that it is most simply assembled alone, without having experience and special knowledge. Enough to adhere to the following recommendations:

- The installation process should begin with the lower elements.

- In the contact places of pipes with wooden and other fire-hazardous materials (in the attic or roof area), it is necessary to use isolation, for example, stone cotton wool.

- In order to protect the surface of the ceiling in the region of the passage, the steel platform must be mounted.

- In case of creation outdoor pipe It is necessary to include in the system of tees designed for condensate.

- The above-mentioned elements are inserted into the following.

- It is advisable to protect the upper yield of the chimney with the help of thermogrybla, weather, a deflector or a sparky.

The convenience, comfort and safety of operation and gas boiler depends on the correctness of the project and the correctness of the surveillance of the smoke wood stove Bath. In today's article, we will talk about how the chimney installation scheme looks like for different types of heating devices.

General rules Installations and installation of chimney:

- Fire safety. It is achieved by laying insulation between chimney and combustible flooring materials, as well as thickening of the chimney walls. It is also necessary to observe minimum distance between the wall and the chimney pipe. A favorable solution is to use a pipe sandwich.

- Availability of good traction. The first rule of thrust: the longer the channel for removing smoke, the better the thrust. The optimal length is 500-600 cm.

- Tightness of the exterior of the pipe. This will ensure the correct and long smoke performance.

- The smallest resistance for the passage of smoke in the exhaust canal. The walls of the channel must be as much as possible.

- Compliance of the material for the manufacture of chimgoda temperature regime and chemical composition Reference gases. When using a different type of fuel should be used different chimneys.

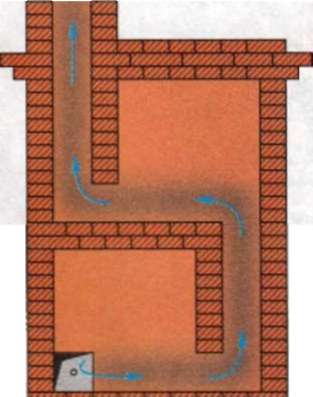

- High smoke temperature in the exhaust channel. If this rule fails, condensate will be formed on the walls of the chimney, which contributes to the destruction of the inner surface of the chimney. And less vertical partitions in the smoke removal system, the better. This is especially true for large stoves.

Competent float mounting for wood fireplace and stove

A feature of firewood, like fuel, is a big heat from them. It follows from this that the temperature of the smoke in the bathing furnace bath or fireplace will be high but uneven. Not every chimney will be able to withstand such a long impact.

Most often for mounting a chimney for heating devices such as a stove for a bath or a fireplace with a wood firebox, a heat-resistant brick is used (see chimney with your own hands).

Making brick chimney

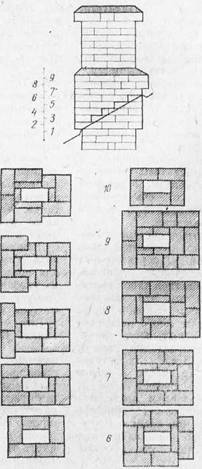

The correct scheme of the chimney of the brick in general may look like this:

- Most often, a housing tube is used for a wood-burning furnace. That is, it continues the exhaust hole of the oven itself or fireplace. It should be known that the masonry of the inside (indoors) is best done on the clay and sandy solution.

It should be known: all the work on the masonry from the outside of the building must be performed with the addition of cement and water to the solution!

You should know! In order for the protrusion of the otter to be forceding water, it is necessary to make angular slopes from cement plaster from all four sides.

- After external expansion, the main riser is made, as in the attic room. For beauty, a brick head is usually laid out.

- Completes the brick chimney of the cap protecting against exposure ambient: Wind, precipitation. By form, the protective umbrella can be different. The best option is the deflector.

A graphic scheme of the chimney of a brick furnace for home or bath is presented in the figure below.

It is the two-column smoke removal system that is optimal for use in large furnaces and fireplaces with considerable foci on firewood. It provides more or less uniform heating in the room, and also has a minimum of the obstacles to the movement of smoke to the exhaust channel.

Features of double chimney for fireplace

Another of the variants of the chimney is a double tube. Outside, it is made of brick, and a metal cylindrical part passes inside it. If the pipe is made of stainless steel, then this variant of the chimney is suitable for installing a gas boiler.

Combined double decays for fireplaces have several advantages over bricks:

- The channel for the movement of the smoke has a smooth surface, without obstacles.

- The fire safety of the building is increasing.

- The laying of the outer part can be done without a roller.

- Increases the life of the chimney.

- It improves the tightness of the whole chimney.

The figure below shows the scheme of the chimney of a fireplace or a gas boiler having a combined structure.

A feature of such a design is that it is usually done in a radical performance, and not an atmosphere. That is, the chimney itself is located directly next to the heating unit.

- When installing the combined chimney, the foundation is first made, which has a minimum height 30 cm.

- The laying of a mine of the brick is made in accordance with the same conditions as when installing a conventional brick chimney.

- Due to the design features of the double channel, the outer mine is placed vertically without mandatory thickening of the walls in place ceiling overlap.

- Below, immediately after the foundation, a niche is made with a doors for cleaning.

- Metal pipe From the stainless steel is assembled from top to bottom in such a way that each subsequent knee is inserted inside the previous one.

- All joints of the inner part of the combined chimney are processed with a sealant with a contained heat resistance to the manufacturer at least 1000 ° C.

Right installation of chimneys for gas equipment

Features of waste generated during the operation of the gas boiler, imply certain design requirements for chimneys for this type of heating devices (see installation of chimneys of various types).

We collect chimney for a boiler with a natural burden

The overall chimney mounting scheme for a floor gas boiler with a hole for removing the combustion products from the back of the case is as follows.:

- Since in the smoke formed during the operation of the gas boiler, acid-containing substances appear, chimney should be made from an acid-resistant stainless steel. Such systems are sold in the store and the process of their assembly is not particularly difficult. The optimal option is a two-channel chimney type "Sandwich".

- The main part of the pipe is on the street. To give stiffness, it is fastened in one or two places on a wall bracket.

It should be known: since the allocated combustion products in gas equipment have a low temperature, then the formation of condensation is possible. To protect the boiler from water from getting inside when using a single-channel chimney, a condensate collection should be mounted into the system, as well as warm the pipe that takes place on the street. A more rational solution is to use a sandwich chimney.

The sandwich tube of three layers is consisting:

- The inner layer of the tube sandwich is experiencing serious chemical and thermal loads, it is used for its manufacture, stainless heat-resistant steel;

- The middle layer of the tube sandwich is a heater (basalt fiber);

- Outer circuit Sandwich pipes - galvanized or stainless steel.

The cross section of the sandwich pipe is oval, since this form is optimal for the chimney mounting for the gas boiler.

You should know! All contacts with combustible substances in the walls and overlaps should be isolated with non-flammable materials.

- When the roof is released, the pipe has a discovering part (skirt), which performs the same function as the otter in the brick tube.

- For better protection against the penetration of precipitation under the roof, the pipe is inserted into the hole of a peculiar apron having a square shape.

You should know! Before buying the roofing knot, the chimney (apron) be sure to measure the angle of the roofing surface of the surface! This will allow you to make a smoking pipe as accurately as possible through the node hole and ensure the highest tightness of this design.

- Completes the chimney of the conical or fungal headpoint.

Mount the hood for the wall boiler

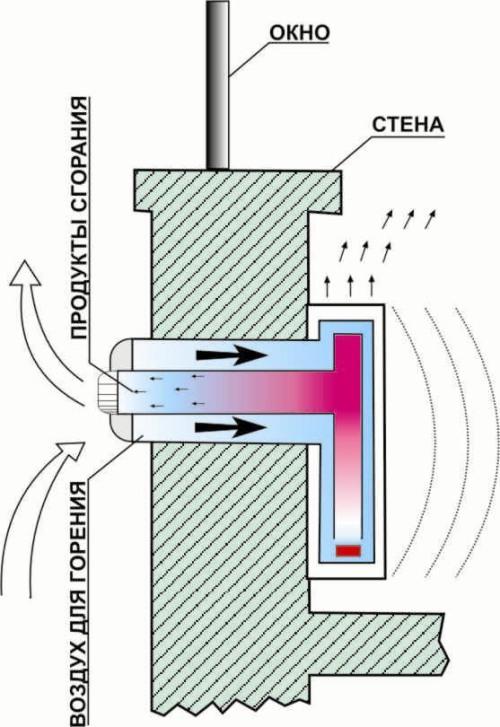

There is a type of gas boilers with forced exhaust combustion products. Inside the exhaust camera, such devices are "Duich" - fan.

Chimneys such boilers are characterized by minimal size in length and the smallest complexity in montage. They consist of two channels, isolated high quality stone wool. The inner channel serves as an exhaust, and the outer-fear of the air from the street.

The chimney scheme for the boiler with coaxial output is simple, installation is carried out as follows:

- On the boiler puts on a removal with an angle in 87 degrees.

- Next is the hole in the wall under the pipe. Then the boiler is removed from the anchors and hosted on the markup (pumped) through a hole, taking into account the gasket of non-combustible isolation in 30-100 mm along the entire length of the circumference of the pipe.

- Now I wake the pipe into the hole and insert it into the removal, which is already attached by special screws to the boiler body.

You should know! To seal all compounds in the coaxial chimney, a special sealant and a wide clamp are included.

One of the important parts of the heating system in the house is chimney. It is used to display outward fuel combustion products. That is, if there is a furnace or fireplace in the house, then this device will simply need. Therefore, you will have to take care of how to make it right.

It may seem that combustion products from the furnace can be outwarded with a pipe of any design. However, in practice everything is different.

The whole reason is that inside the chimney, sooner or later, but the soot begins to accumulate, which at one perfect moment takes and lights up. Moreover, the exhaust pipe does not make directly from the furnace, but should have a number of branches and knees. And of course, any properly equipped discharge system must be responsible for both sanitary standards and fire safety measures.

What should be the height and diameter of the chimney?

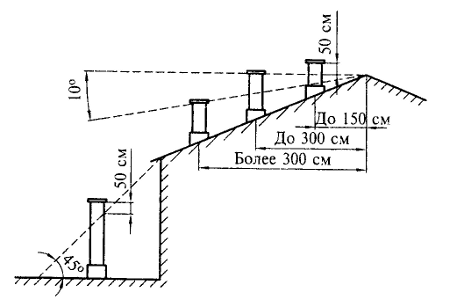

- If the smoke system is mounted on flat roofthen its height from the roof plane is at least 50 cm

- If the pipe is located at a distance of less than 1.5 meters from the ridge of the roof, then it must be made above the skate of at least 50 cm

- If the pipe is located at a distance of 1.5-3 m from the skate, then in height, it must be at the level of the skate itself

It is notable to also pay attention to the length of the pipe. It is from the combustion chamber of the boiler to the headband should be at least 5 m.

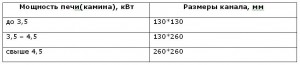

As for the diameter of the pipe, it should be calculated at the calculation of the power of the boiler itself. If the latter power is less than 3.5 kW, then pipes with a diameter of up to 80 cm are used. At a boiler power at 3.5-5.2 kW, diameter - 95 mm and more.

Material for modern chimney

As a material for the smoke system, the stainless steel resistant to the effects are increasingly begin. Although, if there is a furnace or fireplace in the house, then you can make it from ordinary brick. By the way, the chimney must try to make a cylinder. If smoke on his path meets obstacles in the form of angular or turns, then in these places and is going to soot.

If there was an oven or a fireplace in the house with a smoke output system, then for the new installed boiler, you can use such an old chimney, but it is pre-made its sleeve. That is, to invest in an old tube a sleeve made from an acid-resistant steel, but with such a condition that the sleeve is a gap between the inner wall of the old pipe and the outer wall.

In addition, the part of the chimney, which goes outside, is recommended to protect from the wind and make additional clamps. You can install the sparkium on top of the pipe. And it is right!

True, such a flasher is established only on those systems that are intended to derive the products of combustion of the furnace or fireplace fuel, but not gas.

Requirements for work on the stack of chimney

Without a doubt, without complying with certain rules to make a chimney properly with their own hands does not seem possible. If all work is performed correctly, then such chimney, and in general, the heating system will work properly long years. So, the basic requirements:

- The pipe passing through the heated room may not be isolated. But half the meter before the overlap it is recommended thoroughly isolate

- For proper design and further installation, it is necessary to calculate all the main characteristics. Namely: make the calculation of the diameter, the height of the pipe and the force of traction

- The pipe deployed through the same intervals of 1.5-2 m attached clamps. Exactly the same clamps should be consolidated and angular taps. If a portion of the pipe will perform over the roof more than 1.2 m - it is additionally attached to the roof

- So that the smoke system does not cause a fire if it has constructive joints, then they must all be located so that they are not at the level of jumpers between the floors. But they must be visible

- When performing work on chimney equipment, measures should be observed fire safety. If he passes through wooden designs at home or close to them, but they should be treated with special compositions preventing combustion

- As for external design, some specific rules do not exist. It follows from this that it is possible to issue an external part of the chimney system. For example, the surface of the wall that is closest to the pipes can be decorated with a special tile and other

Country house cannot be submitted without a fireplace or oven, which means that the chimney will be mounted on the roof. Ancientized ancient device for removing combustion products is a complex engineering design. For the safe and successful functioning of the chimney channel in the house, first of all, it is necessary to accommodate the pipe, to make the chimney properly with their own hands and in the future periodically check its work and clean.

Design of chimney

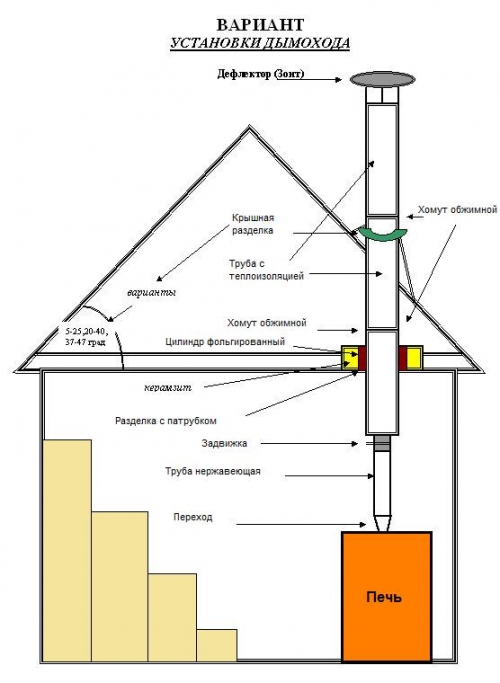

Chimneys are arranged in this way to effectively remove the combustion products from the room. The main part of the design is a straight vertical channel. The chimney begins directly from the boiler. After the vertical part of the pipe, the channel passes the cutting and overlapping, which leads to the attic, and then enters the chill, turning 90 degrees. The china is ends vertical pipeWhat is located above the ridge of the roof.

Due to the drops of temperature and pressure in the chimney, a constant movement of air is formed in the direction of "bottom up", which is called the burden. The presence of thrust acts as a major factor for the proper operation of the chimney. The chimney tube must have good aerodynamic characteristics, so the advantage of designs with round cross section. In pipes with smooth walls, smoke raises freely up, without forming twists. To prevent condensate falling out, it is customary to warm the external parts of the pipe.

Selection of material for chimney

Solving what to install chimney, you will have to navigate to the stove: you need to know the type of heating device, the temperature of the exhaust gases, location, the efficiency coefficient. The discharge gases are strongly heated during the operation of the instruments, which operate on solid fuel, because the temperature of the smoke during its incomplete combustion can reach it easier to 600 degrees Celsius.

Since the brick can withstand such a high heat, the most popular until recently were brick chims. This type of relevant and today for house furnaces and classical varieties of masonry fireplaces. Also temperature loads are well transferred ceramics, heat-resistant and enameled steel.

A new generation of heat generators on natural gas or liquid fuel has a high efficiency, which reaches 90%, due to the low temperature of the combustion product (less than 160 degrees). However, in this case, an aggressive-sour condensate appears on the walls of the chimney, which quickly destroys the material of the porous - asbestoscent and brick. You can prevent this process using additional waterproofing. But it is easier to make chimney from chamot, steel, polymeric materials, special grades of glass and ceramics.

The smooth mirror surface and simple installation are the main positive qualities of modern chimneys made of steel. The brilliant surface provides minimal friction of exhaust gas on the chimney wall, and the compilations that are included in the package of modular systems, condensate output beyond the chimney. If there is a brick mine in the house, then the steel channel can be paved inside it.

Table fans of the style of "High-tech" can establish special reflective screens. The wall inside the room, along which the chimney is located, can be bred using a patterned ceramic tile. And the outside of the pipe for removing smoke can be covered with galvanized iron, which is painted in any painted color.

How to make high-quality chimney

Workable, high-quality and reliable chimney is the key to lack of smoke and good reverse thrust, and also acts an important element Cottage comfort systems. The optimal option for the price / quality is recognized by the chimney A la Sandwich - the heat-insulated channel with an impressive service life, a minor indicator of soot deposition and a reduced level of condensate formation.

Calculation of the basic characteristics of the chimney - diameter and forces of thrust is performed in compliance with the main requirement: the thrust must simultaneously increase with an increase in the height of the pipe. Otherwise, the effect of the "illuminated" smoke smoke in the form of a decrease in thrust will arise with an increase in height and a large cross section of the pipe. Lastly discussed appearance and the harmonious proportions of the chimney with other elements of the construction - the ridge of the roof, the height of the pipe, ventilation channels. First of all, the efficiency of the heating system and its functionality.

Options for structural execution of the channel for removal of smoke depend on the installation site of the boiler and the features of the room. Internal chimney is customary to be installed inside the structure and carry out with additional work: a device of support, cutting and protective casing. It is not necessary to warm the internal chimney. But not less than 60 centimeters before the overlap you need to arrange insulation of the typewich type. According to construction standards, it is strictly forbidden to lay through the overlaps of uninsulated channels. And the pipes that pass through not heated attic must be insulated.

The outer adhesive dynamic channel consists of a connecting gas, sections, revision and carrier wall bracket. For the outer chimney, it is imperative to carry out insulation of pipes. The usual cylinder is the most efficient form of chimney, providing easy operation of the product. When choosing a form of chimney, specialists recommend choosing the simplest schemes, because intricate forms serve as the main cause of clusters of a large amount of soot. The height of the elevated chimney channel should not be less than 5 meters.

When the chimney is needed, it is necessary to envisage that all the joints of the design are placed below or above the inter-storey jumpers and were open to visual inspection. Before installing the chimney, it is worth studying fireproof norms and joints of the joints to isolate with non-combustible materials, as well as special attention to pay the place of way out of the roof of Sandwich.

Installation of chimney

The process of installation of the chimney is taken in the direction of "bottom-up", other words - ranging from the object of heating. Pipe links must be collected sequentially: each subsequent segment is inserted into the preceding link. A similar sequence of chimney installation with their own hands protects the product from the moisture in the insulation. In order to better protect the design from moisture, it is recommended to use a special sealant, which has a working temperature of about 1000 degrees.

All working joints in the heating system must be fixed using special clamps and along the laying line to install with a step of 1.5-2 meters of brackets that serve for fasteners of the structure to elements of the structure. It is necessary to monitor horizontally laid areas and eliminate contact with various communications - gas pipes and electrical wiring, as well as to limit one meter the length of each site.

For the convenience of cleaning the chimney channel during operation, install the door or removable part in the bottom of the design. Working channels must be installed along the internal partitions and walls, designs must be made exclusively from non-combustible material. If it is impossible for technical reasons, the installation is made along the walls, it is necessary to apply oven flue pipes.

High-quality chimney isolation is the key to rapidize the room and the formation of a minor amount of condensate. Having pipes near the flammable finish, an additional fire protection protrusion is insulation. Part of the chimney pipe, which goes outside, should be protected from wind and fix. Protection against garbage and atmospheric precipitation provide deflectors, flugers and grids. But such protection is not in all cases to suit. If for the furnace and the fireplace, the cap is the norm, then for gas equipment Speakers the stricter security violation of the system.

Care for manufactured by the chimney is not too burdensome. For its organization, it is only a few times a year (upon completion and at the beginning of the heating period) to check the quality of traction in it, as well as the tightness of the seams and the integrity of the joints of its individual elements. When conducting such inspections, you can simply carry out the cleaning of the inner surface of the chimney from soot.

Laying brick chimney

The masonry of the brick chimney is considered not an easy work, so required to view the video about the chimney with their own hands. But if the brick canal passes inside the wall, then no special qualifications are required for its organization. Enough to leave in carrier brick wall An unfailed mine, the cross section of which is equal to the size of the lying brick.

Bricks are approximately 25 to 12 centimeters. According to construction standards, per 1 kW of the power of the installed boiler should have about 8 square centimeters of the smoke cross section. Hurrying the area of \u200b\u200bthe majority of standard bricks, it turns out 300 square centimeters. You can connect boilers with a capacity of up to 38 kW to the smoke channel with a similar section, which are suitable for heating houses with an area of \u200b\u200bup to 350 square meters.

If planned to spread separately brick construction, then it is necessary to approach its construction carefully. The chimney masonry in this case needs more accurate design - the angles should be straight, and the walls are smooth. If the chimney to the wall does not adjoin, then it should be done strictly vertical. The channel, which is adjacent to the wall, should be attached to the vertical surface with anchors located every 4-5 rows. It is recommended to provide in the masonry technological and revision holes, as well as to arrange a hatch for exhausting soot at the bottom.

The walls of the chimney on the inside should be smooth. There are many recommendations for the design of the surface of the smoke mine - one option offers plastering the channel from the inside "under the verge of". The cross-section of the channel is approaching the round form, also smoothed irregularities. Another option does not require the coating, because with the poor performance of the work of the pieces of plaster, they are crumbling in the channel and make it difficult to move the air. The outer part of the chimney is customary facing brick Or decorate with roofing material.

Cleaning chimney

The combustion of any fuel is accompanied by the release of carbon compounds and carbon dioxide. When burning gas, combustion products stands out less, and when burned solid fuel - a large number of. Substances that contain carbon, on the walls of the chimney are settled in the form of soot, which periodically needs to be removed from the chimney.

They carry out the cleaning and repair of the chimney with their own hands using chemical, mechanical and physical methods. For chemical treatment, funds are used, which contains substance corrosive soot. Most. simple way It is burning in a furnace or a fireplace of aspen lanes, the combustion temperature of which is about 1,100 degrees Celsius. The soot burns at such a temperature, but this method is dangerous, and it can be practicing it if the smoke canal has no damage and made of refractory materials.

If the chimney has not been cleaned long ago, and on its walls, the soot layer exceeds 3 millimeters, then preliminary mechanical cleaning should be made. For this purpose, a long time is used on the rope with the hero, which throws on top into the chimney. He pushes a plug down. If this manipulation did not bring results, then nothing remains another, how to disassemble the part of the chimney channel in which clogging was formed.

Experts produce professional cleaning with the help of reagents and sprayers, after processing which the soot is separated from the chimney walls and crept in the furnace. The effect of such a procedure lasts for 3-4 months. You can also clean the chimney with the help of a special vacuum cleaner, which sucks soot from the channel through the furnace. But it does not save at large ash sediments.

Now you know what should be the perfect chimney from the position of functionality, efficiency and safety. Follow carefully instructions before making a chimney with your own hands, and the heating system of your home will work more than a dozen years.