The procedure for selecting pipes requires a particularly attentive relationship, where many nuances should be taken into account. Among them are important physico-chemical properties. The list should include the length and diameter of the selected products. Maybe someone does not know, but this characteristic, as the diameter, has a direct impact on the hydrodynamics of the entire heating system. The greatest distribution among pipe products used for private houses was obtained designs, the diameter of which reaches about 16-40 mm.

The peculiarity of the pipes of such dimensions is that they can cope with pressure in the heating system. In addition to this they demonstrate simplicity during operation. This can be noted in relation to the execution of installation works. With their help, it is possible to effectively solve the problem on the organization of pipeline wiring open.

Which inner diameter of polypropylene pipes is used for heating

To determine the appropriate size, you can use the table or calculate the internal diameter of pipes using the following formula:

To determine the appropriate size, you can use the table or calculate the internal diameter of pipes using the following formula:

d \u003d √ (4-U-1000 / πl)where

U is a parameter that is defined as the total rate water consumption in the house that the water supply must be provided,

π - 3,14.,

L - water flow rateIf the large diameter tube products are used, this parameter is determined by the index 1.5-2 m / s, and for products with a small diameter - 0.7-1.2 m / s.

Most often, polypropylene-based pipes have an inner diameter equal to about 20-32 mm. If it is planned to install a warm floor, then the choice is usually stopped on plastic structures, the diameter of which reaches 16 mm. At the same time, it is still necessary until the installation understand how difficult work will be, and considering this to choose a material that all loads can withstand. When determining the pipe cross section, many factors are necessary to take into account that are characteristic of the operation of heating systems.

Among the set features, the most significant is considered:

- the temperature of the carrier;

- flow rate;

- pipeline length;

- pipe diameter;

- pressure hot water.

The view is common that only under the condition of the competently performed calculation of the inner diameter polypropylene pipesUsed in the heating system, you can provide the most efficient and reliable operation of the system. When performing miscalculations with the determination of the size of the polypropylene tube, the likelihood is high that during operation of the system there will be certain problems.

Let's say, picking up a diameter, a slightly larger required, you can face the situation when the pressure in the heating system will not reach the optimal level, the consequence of this will become insufficient water circulation for all apartments in an apartment building. To ensure the proper operation of the system, it is necessary to competently perform repair work, the essence of which is reduced to the installation of pipes that have a suitable diameter.

How to choose the right diameter of the polypropylene tube for heating

If the task of organizing the heating system arose in a private house or cottage, then it is necessary to solve this question, taking into account the fact that the diameter will be permanent only under the condition that it will be produced direct connection to the central heating system. If we are talking about use autonomous SystemIn this case, it is allowed to apply pipes of any size. Here the final decision must be taken by the owner of the house.

If the task of organizing the heating system arose in a private house or cottage, then it is necessary to solve this question, taking into account the fact that the diameter will be permanent only under the condition that it will be produced direct connection to the central heating system. If we are talking about use autonomous SystemIn this case, it is allowed to apply pipes of any size. Here the final decision must be taken by the owner of the house.

When selecting billets with suitable characteristics, all the nuances should be taken into account. First of all, this concerns the situation when a natural heating system is used in the house, in which the specifying role will not be given to the cross section and power of the pump. This feature is considered one of the advantages of this heating system.

Of the minuses of this system should be allocated a small radius of action, as well as high costs for the purchase of elements of larger diameter, which will have to be used in a similar situation.

In order for the system to work most effectively, the owner should take care of maintaining the optimal level of pressure. Only when performing this condition, it can be achieved that circulating heat carrier will be able to calmly accomplish any obstacles on his way. Speaking about such barriers, first of all, the situation with the friction of the liquid on the wall of the removal or the tap of the heating device is implied.

It should be noted that the length and diameter of the elements of pipelines directly affect the resistance and the speed of moving the fluid. If the coolant will flow pretty quickly, and the pipes will be different with a small cross section and considerable length, it will lead to an increase in resistance on the water path.

What pipes are suitable for heating systems

The installation procedure of each heating system requires a mandatory execution of such work as the development of the project scheme. Next, already begin to cook all necessary materials and tools that will be required to perform installation work:

- pipes;

- armature;

- required tools.

After solving this issue, you can already think directly about the installation of polypropylene pipes.

When the question of choosing suitable elements will be resolved, it is necessary to take into account the features of the room, not forgetting about the type of heating. Engaged in conducting preparatory events, it is necessary immediately appreciate the complexity of work And relate them to their capabilities to understand how to realize this idea.

The fact is that the owner is not able to fulfill the owner in all situations. Sometimes some owners are not solved to take on such responsibility and simply invite qualified professionals.

When organizing heating systems, the owner has the opportunity to choose the following types of pipeline designs:

Each of the listed products is inherent in its pros and cons, due to the features of materials used for them. About this moment necessarily need to remember when the issue will be resolved with the choice of a suitable option for its system.

Among the proposed structures best are products from propylene. Metal pipes have enough shortcomings, among which should be noted the high cost and the availability of difficulties in operation. An equally important disadvantage is susceptibility to corrosion processes, which negatively affects their life.

As for the metal-plastic products, they they differ more affordable price

, do not create problems in use. However, in terms of reliability and strength, they lose counterparts from polypropylene. For this reason, you immediately need to abandon this design of the design for the device based on the heating systems.

As for the metal-plastic products, they they differ more affordable price

, do not create problems in use. However, in terms of reliability and strength, they lose counterparts from polypropylene. For this reason, you immediately need to abandon this design of the design for the device based on the heating systems.

Based on this, the output comes down to the following: the best solution for the system of the system is polypropylene, since it is ideal for assembling pipes for which water will circulate.

It should be remembered that polypropylene designs are different species: Some are intended to ensure hot water circulationAnd others are cold. For this reason, and choose the material is needed, taking into account the specific type of planned work.

Let's say if it is planned to lay pipes for heating, which will flow hot water, it should immediately refuse to use the designs for them designed for cold water. The fact is that in this case will prevail a different temperature regimethat, ultimately, will lead to impairment of operational conditions, and this may end the emergence of problems in the system.

The advantages of polypropylene

If the owner solves the task on the device in the house of a warm floor or heating system, then he, no doubt, can stop the choice on polypropylene pipes. In many ways, a similar solution is preferable due to the presence of many positive characteristics in these structures. Among the most significant are the following:

- reliability;

- long service life that can reach 100 years;

- high resistance to corrosion processes;

- lack of mineral precipitation;

- impotence of influence from chemicals;

- lack of problems when assembling;

- design features allow repair work when a malfunction occurs or breakage;

- low cost.

Disadvantages of polypropylene

If we talk about minuses that are characteristic of such a type of materials, then the first to mention the ignition and exposure to high temperatures.

If we talk about minuses that are characteristic of such a type of materials, then the first to mention the ignition and exposure to high temperatures.

Starting an organization in the house of the heating system, it is very important to choose the diameterwhich will have a pipeline design. Moreover, you should not choose too large diameter of polypropylene pipes, as it will negatively affect the operation of the system.

Installation of heating systems using polypropylene pipes

One of the important stages of the installation of the heating system is to resolve the issue with the scheme that will have to adhere to when performing work. And if we talk about the use of polypropylene structures, then the following options can be involved here:

- Movement of fluid in the heating system of gravity. This option allows the owner to abandon the use of the circulation pump, since the fluid in the system will flow naturally. This scheme can be implemented in rooms that are distinguished by the instability of the electricity supply, which is why it is very difficult to maintain the operation of the pump in continuous mode.

- Lower filling system in heating. A feature of such a scheme is the use of a radial layout, which is based on the use of a pump provided by an increase in water pressure, which is achieved due to the smaller diameter.

- A permissible scheme in which one- and two-pipe systems Connected to the radiator, which is implemented by the side or lower connection type.

Installation of systems of heating from polypropylene pipes

If you wish, it is possible to install propylene components of the pipeline system and do it yourself without resorting to the services of professionals. The procedure itself is performed using welding. Moreover, it is unacceptable to use threaded compounds to combine elements from polypropylene among themselves.

Even before the soldering, it is necessary to prepare assembly components, cut them into fragments of the desired length, for which special scissors use. It must be done particularly carefully to give cuts smooth edges and exclude the formation of burrs. This work outlines a rather small amount of time.

Even before the soldering, it is necessary to prepare assembly components, cut them into fragments of the desired length, for which special scissors use. It must be done particularly carefully to give cuts smooth edges and exclude the formation of burrs. This work outlines a rather small amount of time.

Welding works are performed using the appropriate equipment, which is designed to carry out such operations. To connect the pipeline elements in such a way, it should be placed the pipe into the nozzle of the suitable diameter, after which it is heated, around to a temperature of 260 degrees. The heating procedure of the pipe can occupy different timeThe diameter of the product is influenced first. Let's say if the size of the pipe is 20 mm, then it is enough to heat the length of 5 seconds. With the greater diameter of the design, which, let's say, has a value of 50 mm, it will be necessary to spend 18 seconds for heating.

Conclusion

Device of heating in the apartment or country house Requires a large number of characteristics, among which the choice of diameter for polypropylene pipes plays an important role. This moment is necessary to pay great attention, remembering that this will affect not only the simplicity of work on the installation of the heating system, but also the quality of its work.

Therefore, if you decide to fulfill this work with your own hands, you must first prepare the necessary materials. Pipes must be selected only with the future conditions of their operation, as well as the need to ensure sufficient circulation. Otherwise, water will not come to all consumers in sufficient quantities.

Poly propylene pipes, mufti and fittings

In this article, we consider polypropylene pipes for heating and their specificationswhich are indicated in the marking. Let us fill a little on the materials that are used for production and reinforcement.

Materials and characteristics

Know the diameter is just half an end, but coming to the store, you will come across a variety of materials. Polypropylene pipes for heating correspond to GOST R 52134-2003. They are made of three types of plastic, two of which can be used for hot water systems and:

- consisting of identical structural units. Them molecular ties Do not withstand heating, respectively, are not applicable to systems with high operating temperatures;

- consisting of different structural units. The heterogeneity of the links between molecules makes them resistant to heating, while the material does not lose its natural elasticity;

- consisting of crystals. Have the most durable and resistant temperature structure, the structure is losing in elasticity.

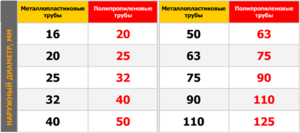

In the labeling of polypropylene pipes for heating, their outer diameter is indicated. Pay attention to this when you need to connect the contour of the apartment with a central riser. With an equal outer cross section, metal and polypropylene pipes have a different internal conditional passage, it has a wider metal.

Be sure to choose reinforced products. Aluminum and fiberglass are used as reinforcement material. It is better to give preference to the latter, since when installing does not need to remove the reinforcement layer to the depth of the contour with couplings and fittings. Armification by aluminum is carried out:

- monolithic layer;

- layer with multiple holes.

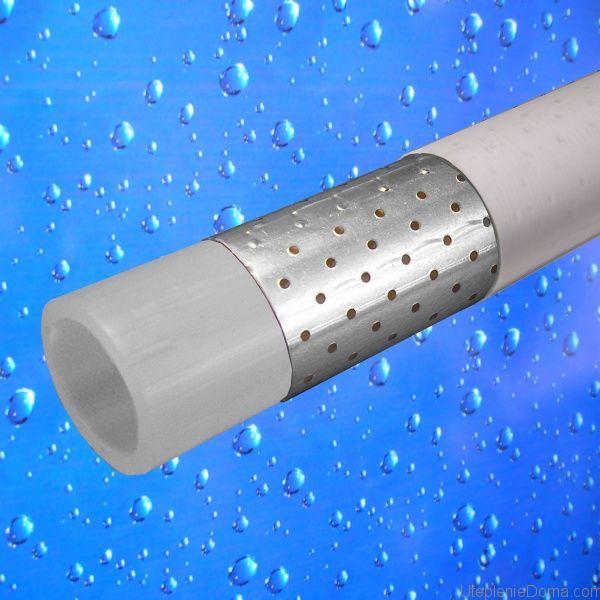

Polypropylene reinforcement with perforation

And aluminum, and fiberglass layers of reinforcement are between two layers of plastic. Reinforcement is only needed to compensate for an increase in the contour in length when heated. About the strengthening of the product of speech does not go, as plastic and without it is very durable. Unnamed products are not suitable, since they have a too high linear expansion coefficient, which is 0.15 mm / m. For comparison, the reinforced products, it is 0.02 mm / m. Polypropylene pipes for heating have standard dimensions. They are sold by segments, the length of which is four meters.

For clarity, we will calculate. Take one meter of the contour, in which the water circulates, heat up to 80 degrees. Multiply the temperature on the linear extension coefficient and get the following values:

- for reinforced products - 1.6 mm lengthening;

- for unarmed products - lengthening by 12 mm.

Also in the marking indicated nominal. Marked with Latin letters pn. For example, the product with the RN16 marking is withstanding 16 atmospheres, but this is not a maximum of its capabilities. It can withstand and greater short-term increase. Nominal pressure is an indicator in which the service life of polypropylene pipes will be the substitute. The calculation is made using special programs where the water temperature is laid in equal to 20 degrees. This is important, with an increase in temperature, the service life will naturally, less, since, heating, plastic changes its mechanical characteristics.

Calculation of diameter for central heating

In search of calculations, a lot of material was studied, often at a particular answer to the question of how polypropylene pipes for heating should be. How to choose a diameter so that the system is balanced. In principle, to make accurate calculations, taking into account all factors, you need to be a realistic specialist and get a profile education. The calculation of the diameter of the pipe is included in the hydraulic calculation of heating, which is carried out using special specialized programs. All other calculation methods will be approximate.

The thickness of polypropylene pipes for heating in private homes and central heating apartments usually does not exceed 25 mm. Also use products 20 and 16 mm.

It's simple when you need to determine the diameter of the polypropylene tube for heating in central heating apartments. From the riser passing through all the floors, the nozzle comes out into each apartment. Its cross section, naturally, less than the riser itself. In order to correctly determine which diameter of polypropylene pipes is needed for central heating, you just need to choose the size of the section to the nozzle. Make sure that there is no contour. That's all, it's about the choice of materials. Please note that the internal section should match, and not outdoor.

Calculation of diameter for autonomous heating

Questions about how to choose the diameter of polypropylene pipes for heating appear when mounting

![]()

Calculation of the diameter of the polypropylene tube for heating

contours in private houses. Immediately note - the calculations are approximate, but this does not mean that they are not correct. You can also apply for contours of apartments with central heating. Determining parameters of the diameter of the polypropylene tube for the heating of a private house:

- the area of \u200b\u200bheated premises.

It depends on how much heat will need for heating to the required level. In order not to delve into the Debresions of the formulas, you can follow a general example and take into account 0.1 kW of energy per meter square, with standard height Ceiling 2.5 m. Of course, it is necessary to take into account the degree of insulation of the room, based on which the coefficient of heat loss is calculated. But in order not to get confused, simply add 20% to the required number of kilowatts;

- the speed of the coolant.

This indicator varies from 0.2 to 1.5 m / s. The greater the flow rate, the pressure in the circuit is higher. Often, this leads to the appearance of noise in the system, due to the friction of the coolant about the wall. To calculate the diameter of the pipes, it is customary to use a value up to 0.6 m / s - optimally for autonomous contours of private houses. Because the diameters of polypropylene pipes for heating are chosen, the rate of circulation depends. The thicker contour, the water flows slower;

- the difference in the flow temperature and returns.

The indicator is quite individual. It depends on the power, and on the material of the pipes, their insulation, as well as on the speed of the coolant. The standards identified that the feed is carried out at a temperature of 80 degrees, and about 60 degrees will be on the reverse stream. The coolant cools on 20 degrees, usually this value and takes into account.

What diameter polypropylene pipes are used for heating a single-storey house with an area of \u200b\u200b80 sq. M:

- in the formula there are two permanent values, moving which we obtain the value of 304.44;

- then this number must be multiplied by 9.6 (80 sq. M x 0.1 kW of energy + 20% of the stock), comes out 2100,636;

- the resulting result is divided by 20 (temperature difference) and 0.6 (m / s, coolant flow rate);

- at the end, calculate the root square from the value obtained and obtain a value of 13.23 mm.

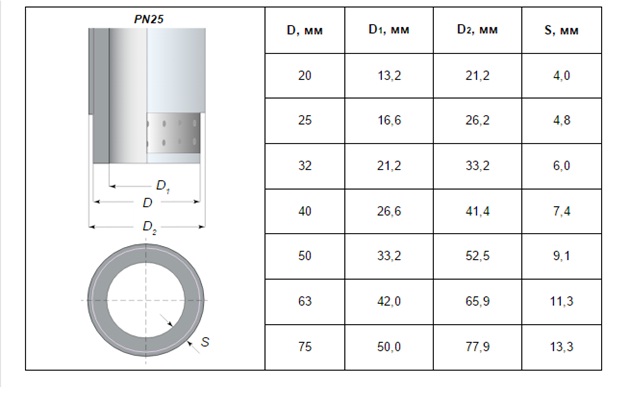

The thickness of the walls of polypropylene pipes of different diameters

It turns out that the inner diameter of polypropylene pipes for heating at home with an area of \u200b\u200b80 m 2 is 13.23 mm. Once again, pay attention to the fact that polypropylene tubes are marked by outdoor. Also in the labeling present information about the wall thickness. Calculate the conditional passage can be in one action, easier than the paired turnip. You can also use the table of the ratio of the pipe walls to their diameter.

Based on this, it can be concluded that in this case the pipe is suitable with a diameter of 25 mm, since the twenty is slightly pronounced. To calculate, we took the flow rate of the coolant 0.6 m / s, although a value from 0.2 m / s is allowed. Accordingly, by choosing a pipe with a cross section, we reduce the circulation rate, while it remains within the framework of the standard.

Calculation based on the coolant flow rate

The diameter of polypropylene pipes for heating Table:

The ratio of pipe diameter to heating thermal power

There is a simple way how to calculate the diameter of polypropylene pipes for heating is a table. Let them take advantage and make calculations for the entire same single-storey house 80 sq.m. For its heating, 8 kW of energy is needed, which is 8000 W. We find in the table this value and we drive to pink cells in which the optimal coolant speed is indicated. In our case, this is 0.5 and 0.3 m / s. Start your choice on the first value, which corresponds to a pipe with a diameter of 25 mm.

Now compare with the results of the calculations performed above. As you can see, they coincide, it means that both methods for determining the diameter of pipes for heating are consistent and can be used to carry out calculations. As a result, you should pay attention to the fact that it is better to adhere to standards. The use of too narrow and too wide pipes has a negative impact on the functional characteristics of the system.

The inner diameter of polypropylene pipes (the table will be shown below) allows you to correctly calculate the load on the product during operation.

So, for example, with outer diameter 20, the inner diameter may be 16.2 or 13.2, that is, the thickness of the pipe wall, in the first case there will be 1.9 and in the second case - 3.4.

This indicator in the table makes it possible to choose products that are able to withstand the operating temperature and the alleged pressure.

Characteristic features of polypropylene products

Why choices fell on polypropylene? Polyethylene or polypropylene, what's the difference?

Why choices fell on polypropylene? Polyethylene or polypropylene, what's the difference?

Both materials are similar, a lot of common physical qualities. But it turns out, polyethylene is significantly inferior to polypropylene in hardness!

Production process itself:

- does not harm ecology,

- no high power consumption,

- not time consuming

- does not occupy large areas.

Polypropylene pipes are made by extrusion (journaling). Fittings and connecting devices are manufactured by injection press. Only for pipes - PN20 are used universal complete fittings.

It's important to know: Polypropylene pipelines are able to withstand the temperature range from - 10 to + 90 ° C. Water in them can turn into ice, but the structure of the pipes will not break, because polypropylene elastic material.

Very often used secondary raw materials. This approach allows you to hold relatively not high cost per final product. .

Advantages of use

Advantages of polypropylene products:

Advantages of polypropylene products:

- Long use. It is believed that with a hot tube carrier, the pipes will serve within 50 years, with cold within 100.

- The smooth inner surface on which the liquid is moving, does not contribute to sticking the deposits.

- Polypropylene absorbs noise.

- Condensate is not formed.

- Resistance to temperature changes.

- The heat exchange is low.

- Easier metal is 9 times.

- Not difficult installation.

- Does not need further maintenance.

- High elasticity of polypropylene products.

High qualities of polypropylene highways allow it to apply it for:

- supply of houses with water;

- connections to the boiler;

- water supply;

- installation of the heating network, etc.

Compliance with GOST

The only standard for which the quality is determined is GOST R 52134-2003. It requires the characteristics of all products that are used for the installation of heating systems and water supply.

The only standard for which the quality is determined is GOST R 52134-2003. It requires the characteristics of all products that are used for the installation of heating systems and water supply.

The document contains all the quality standards of thermoplastic pipes. It takes into account the size parameters of the product, for which operating conditions it is intended, and the allowed useful life.

Note: The quality of the thermoplastic pipeline is suitable for transporting drinking water, and meets the standards of Russia. The shelf life of the thermoplastic pipeline for contact with liquid food products is confirmed by the national certificates of the European Union.

This GOST is used to determine the thickness of the wall wall. When calculating the need for the number of pipes, take into account all operating conditions, as well as the desired operational period. In the calculation, take into account not only any parameters should take pipes and from what material.

Classification

When choosing pipes, you must take into account their ability to withstand working pressure and temperature!

When choosing pipes, you must take into account their ability to withstand working pressure and temperature!

Suitable for the production of installation work, both in residential and industrial premises.

- PN 10 This brand is manufactured in a thin-walled version, suitable for cold water to + 20 ° C, as well as can be used to install heated floors, where water is up to + 45 ° C, withstands 1 MPa, 10.2 kg / cm².

- PN 20 This brand is considered universal, applicable to water + 80 ° C, permissible 2 MPa, 20.4 kg / cm².

- PN 25 Brand of pipes with aluminum layer, suitable carrier transportation up to + 95 ° C, and 2.5 MPa, 25.49 kg / cm².

- PN 16 This brand can be used where the liquid carrier temperature is not higher than + 60 ° C, at 1.6 MPa, 16.32 kg / cm².

Differences in polypropylene pipes for used raw materials

Ppr.. If there are this marking on products, the polypropylene randomsopolymer has been used for their production, which provides thermal stability. Products with this marking can be used for highways intended for transportation hot liquid, and for cold. Mostly this brand is used for the installation of warm floors.

Ppr.. If there are this marking on products, the polypropylene randomsopolymer has been used for their production, which provides thermal stability. Products with this marking can be used for highways intended for transportation hot liquid, and for cold. Mostly this brand is used for the installation of warm floors.

PPH. The raw materials add additives that provide higher strength products. This brand of simple polypropylene products is used mainly for installation of cold water systems.

Ppb.. This marking indicates that a complex polypropylene block is used for production. From this brand, fittings are made, characterized by high strength.

PPS. Products with similar notations are used to supply hot liquid. Excellent option for mounting heating highways.

Selection by size

In principle, the length of the products can be made anything, but usually they are made by four-meter. Distinguish them in diameter. The diameter determines the purpose of the product.

In principle, the length of the products can be made anything, but usually they are made by four-meter. Distinguish them in diameter. The diameter determines the purpose of the product.

For example, products with a diameter:

- 110 mm applied to technical needs.

- 200 mm are used in constructions where there are large streams of water, like hotels, hospitals, etc.

Take note: The choice is made taking into account the internal diameter, allowable pressure and maximum allowable temperature indicators. The choice is made by special tables where all parameters are indicated.

If the liquid medium contains some number of aggressive chemicals, then pipes are suitable for transportation, Ø 63-mm. They are used to mount the systems transporting compressed air.

Ø 63 and 25 mm are used to connect radiators, distribution through apartments, installation of floors with heating, etc. For individual construction, Ø 20-32 mm is better suited. They have good bandwidth and they can easily bend.

Installation

Installation methods depend on what purpose the pipeline is intended. If water supply is to be produced, in this case, it is necessary to use all-in-mail connections that are made by the welding machine.

Installation methods depend on what purpose the pipeline is intended. If water supply is to be produced, in this case, it is necessary to use all-in-mail connections that are made by the welding machine.

There are other options for connecting pipes:

- when Ø is less than 63 mm, it is possible to use fuse-free welding.

- for large diameter, the welding of jack is used.

- coupling welding, that is, the device is used - coupling.

Good to know: Such pipes have a high degree of weldability. Therefore, the collection of the system is made by thermal welding. Maintaining the highway is made only once.

See the following video about the ratio of diameters of various pipes:

In modern building technologies We are more and less observing the application for mounting pipes of pipes from the familiar metals. Today we are increasingly moving to the use of polymeric materials. For example, it is used to lay the sewage from PVC, and for heating systems - propylene. They are much better, more durable and more efficient than metal products.

Propylene tubes are used in the following areas:

- Central heating systems;

- Cold water supply;

- Hot water supply;

- Boiler rooms;

- Water floor heated;

- Risers;

- Irrigation systems in agriculture;

- Transportation of compressed oxygen and chimberities.

Classification of polypropylene pipes

The classification of polypropylene pipes allocates the following varieties:

- aluminum reinforced. Aluminum can be in the form of a solid sheet, unpaid, can be corrugated. Reinforcement can be performed both by the outer edge and in the middle of the product. Connection with aluminum significantly increases their stability and strength;

- fiberglass reinforced. Reinforcement is performed on the middle layer;

- composite reinforced. Reinforcement is performed by a composite comprising propylene components and fiberglass. It helps to make the best properties of these products for use in heating systems.

This classification is already in itself gives an idea of \u200b\u200bwhat the propylene products are better than steel.

The main characteristics of polypropylene pipes

Propylene products have become so popular and in demand in the installation of heating systems in modern construction, thanks to the totality of its operational characteristics. Consider details these features:

- Excellent wear resistance of products, due to their multi-layered structure;

- They are not corrosion, which makes it possible not to spend the resources on their staining;

- High resistance to rotting and destruction;

- Little mass that simplifies their transportation;

- Lack of vibration when moving fluid in them and small hydraulic resistance;

- Tightness;

- Protected from wandering currents;

- Resistance to high and low temperatures;

- Resistance to chemical and mechanical destruction;

- Non-toxicity and environmental friendliness;

- Lack of favorable conditions for the occurrence of bacteria, microorganisms, as well as scale and mineral deposits;

- Simplicity and convenience in montage and operation;

- Affordable price;

- Versatility;

- Durability and warranty at least 50 years of service.

Thanks to all the above properties of propylene, are widely used in modern construction technologies of gaskets of highways and water supply systems. Due to the declared durability and guaranteed long service life, they can be carried out in the form of both open and closed gasket, as well as strips on the walls.

It should be noted that the long-term service provisions declared by manufacturers can significantly be reduced if the temperature and pressure of the fluid do not comply with the standards. They can withstand a large pressure, but at low temperatures. Or vice versa - high temperature at low pressure. High temperatures at high pressure will lead to a significant decrease in the life of the product.

Sizes of polypropylene pipes for heating

Propylene pipes have different sizes depending on those areas where they are used. The main characteristic is the diameter. Distinguish the inner diameter and external. The outer diameter depends on the hydrodynamic calculations of the site where the use of this product is planned.

Consider which diameters are applied to solve various tasks in construction:

- Large diameters Over 200 mm are used in the construction of large shopping facilities, hotels, shopping centers, hospitals, where a large number of people are planned;

- The diameters in the range from 20 to 32 mm are used to build a small building or partner. They are convenient to lay, giving the necessary form;

- For hot water, a diameter of 20 mm is applied, and for mounting the risers - 25 mm;

- To mount the water floor heated, products are used, the diameter of which is 16-18 mm. They are easily bent, taking the necessary form of laying the system;

Below, the table will show the interdependence of various parameters in such products:

Sizes of polypropylene pipes for the heating of a private house

Calculate the size of the polypropylene tube for any home will help a special table. Considering the pressure drops and temperatures using a lot of different complex formulas, to delve into which I do not want and there is no need, the table will give an opportunity depending on the water consumption per unit of time determine which product diameter is needed for heating this particular home.

We see, the dependence on the flow of water, heat flux and velocity to determine which diameter is suitable for the heating.

However, as practice has shown, for St. Petersburg, calculations do not need to be carried out - in this case, it is simply recommended to use propylene pipes with a diameter of 20 mm. This eliminates us from the need to check with the sizes' tables, dive into complex technical formulas and makes it possible to determine how much What size pipe for heating is best for our house.

In this article we will understand in detail how to choose the inner diameter of polypropylene pipes for water supply, where large diameters of pipes are used and how they are classified.

Nevertheless, first one should briefly describe common concepts.

Where polypropylene tubes are used

On sale polypropylene pipes appeared not so long ago, nevertheless, already enjoy greatly popular.

You can select a number of advantages that allocate them on the background of analogues:

- the material is not subject to oxidation;

- can be used in environments with aggressive conditions;

- low cost;

- do not conduct electricity;

- pipes are easy to lay;

- excellent look outdoor.

It is worth noting that PP pipes can be used not only as an internal water supply.

Additionally, they can be used for arrangement:

- Ventilation systems. Even the large outer diameter of polypropylene pipes leaves them light, without creating large loads on partitions from wooden carcass And drywall sheats, for example.

- Sewer. The material is not afraid of aggressive substances.

- External water pipes with cold water supply.

Since polypropylene is not as durable as cast iron, in some places it needs to be protected. If the pipes are packed under the roads, it is better to build a reinforced concrete box.

The advantages include the fact that there are no deposits on the inner walls of pipes from polypropylene. Due to its elasticity, such pipes will not be injured under the influence of frosts.

Classification of pipes

There are tables of diameters of polypropylene pipes. Several varieties of PP pipes should be distinguished.

Ppb.

This marking corresponds to shockproof pipes. Most often, they are used to arrange floor heating and cold water transportation systems.

PPH

Traditionally, they include PP pipe diameters of which have greater values. They are used in ventilation systems and for transporting cold water, as they are sensitive to high temperatures.

Ppr.

Such pipes are considered the most popular, because they differ in their versatility. They are not afraid of high temperatures, so they can be used even in hot water systems and for heating.

![]()

It is worth noting that all the above pipes are a variety. polyethylene pipes. Depending on the additives, the polypropylene may differ flexibility and thermal resistance.

Use of reinforcement

Reinforcement is one of the ways of giving the pipes of special mechanical properties.

Reinforcement is as follows:

- Aluminum foil layer. It can be both external and placed inside.

- Fiberglass layer. As a rule, has an internally location.

Thanks to the reinforcement of the pipe, the magnitude of their thermal expansion becomes less.

Such a type of pipes never loses its mechanical strength and is not stratified, and it does not need stripping for their installation.

Classification by passability

Additionally, the pipes are classified for passability. The internal size of polypropylene pipes indicates how much water they can skip for a certain period of time. The external sizes of the PP pipe in this case do not matter. This suggests that the wall thickness can be any - from this parameter only the way the pipes will be durable.

How to calculate pipe patency

D \u003d √ (4 - q total - 1000 / π ∙ v), where:

Q total - limiting the total water consumption;

V is the speed of water movement.

If the pipes are thick, then the speeds are assigned a value of 1.5-2 m / s, for thin pipes, this value, as a rule, is 1.2 m / s. That is, than the cross section of the pipe is less, the higher the surface / lumen ratio. In other words, in a thin pipe, almost the entire volume of water will slow down the wall.

PP tubes with sections of 10-25 mm are selected if the speed of water movement is small. But if V values \u200b\u200bare large, then the cross sections should be at least 32 mm.

In any case, it is desirable to proceed from the highest speeds, since polypropylene has very smooth walls. If the water supply system is installed, then in this case the friction of water about the inner surface of the pipes will be minimal.

The exact values \u200b\u200bof the patency and pipe cross sections are of great importance only in the case of design. plumbing system in high-rise buildings. If you do not use the table of the size of polypropylene pipes, and choose a pipe with a section less laid, then in periods with peak water consumption, the tenants will simply remain without water.

However, it may be desire to take a pipe with a margin in cross section. In this case, it is worth paying attention to the feasibility of such a solution from an economic point of view. Tubes with a large diameter will need more expensive fittings. As a result, expenses can grow largely. If desired, you can not allow this, the main thing is to use a rational approach.

PP tube of large sections is inappropriate to use in such places where enough thin pipes will be, again for the purpose of saving. The fact is that when you drag cold water from the crane for a long time, with a large cross section of the pipe and water it will be more accounted for before the water becomes hot. If there is no water intake, then a significant part of heat from hot water is simply scattered without a case.

It is recommended to organize the circulation system of water supply, so it will not be necessary to drain the water every time until it becomes hot. If this a private houseYou will only need to establish an uncomplicated circulation pump, as well as buy and equip the system with an additional pipe along which the water will return to the boiler.

There is a huge range of polypropylene pipes for heating and not only. If you are making a water supply, then polypropylene pipes are suitable with a cross section of 25 mm, if it is a five-storey house, and 32 mm - for homes from nine to sixteen floors. In this case, by defining with a diameter, it is worth considering the exact number of sanitary devices that will be operated in this system.

Polypropylene pipes of large sections are most often used to supply cold water to one or several homes. For laying pipes in heating areas, polypropylene is not used, as it does not like hot water. In addition, it is such a place where a large load will be affected on the pipes, from which soft polypropylene can simply be damaged.

With cold water, everything is much simpler - due to its low temperature and small pressure in the system, increasingly, with the equipment of water pipes, refuse the cast iron in favor of polypropylene. Quite often, you can meet systems with a conditional diameter of polypropylene pipes in 500 mm and more, which feed the whole small areas.

If a house or apartment is equipped

When creating a project for a standard private house or apartment there is no need for accurate calculations. The number of sanitary devices will be minimal, while the difference in the price of pipes of various diameters will be different as minimal that it will not differ in the budget.

If you look at the mixer hose, then you can see what they have a small diameter, that is, for what minimal holes water enters the sink. Taking into account the fact that the cross section of the polypropylene tube will be much larger, it will always be enough, since this hose will be in this case in this case. That is, the passability of the entire system will rest in the most narrow place.

That is why the owners of private houses and apartments do not conduct complex calculations, and simply acquire a polypropylene tube with a cross section of 20 mm, while saving their precious time. In the overwhelming number of cases, with a standard amount of washbasins, shells, baths and other plumbing devices, such a pipe is enough with a large margin.

conclusions

We hope everyone figured out with what diameter polypropylene tubes are measured. The selection will not be much difficulty. As practice shows, it is often possible to just buy the most simple and cheap pipe - as a result, it will be high-quality and properly functioning water.