Many dacms or people having a house outside the city in the winter period of time have difficulty exploiting an ordinary oven. The fact is that its design involves a fairly long period of heating to an acceptable temperature, and its cooling process is also prohibitively large, which makes it difficult to use the device in short intervals.

That is why many dacms create ovens long burning With your hands out of the brick, so as not to spend a lot of time to heat the room and reduce fuel consumption.

Types of devices

At the moment, two types of furnaces with a long-term combustion function are considered the most popular. The first one implies an independent manufacture of all elements, including firebox and chimney.

The second view is a finished product of factory production, which can be used independently or as an element of a brick furnace.

Choosing a project

Before choosing a challenge plan for the manufacture of the whole design, it is necessary to understand that brick stove Long burning has significant differences from standard-type devices and slow raids.

They provide separate air supply systems and sealed locking systems. This allows you to adjust the power of the fire and fulfill the total combustion of the gases secreted.

That is why it is necessary to select the project especially carefully, focusing on the presence of data of elements in the design or a clear description of the principle of action, which would correspond to the functions of long burning.

At the same time, do not forget that the furnace should fit into the dimensions of the room in compliance with all fire standards and safety regulations.

Foundation

One of the main features that the stove has a durable burning of brick is the speed of its heating and surface temperature. This is due to the fact that it should go to the operating mode in the minimum time, having warmed the entire room.

That is why the foundation, milking such an oven, it is necessary to place at least 70 cm from the base of the house itself and in the space between them satisfy the sand:

- First, it is necessary to dug a divestic depth of about 70 cm, the dimensions of which would be 10 cm on each side more than the oven dimensions.

- Next, it is placed on its bottom, waterproofing on a bituminous basis and fall asleep with sand by 5-10 cm.

- On top of it, it is possible to lay a small layer of rubble or broken bricks, on which the foundation can be laying out, taking the ranks between sidour.

- As a solution for a brick foundation, cement with sand in a ratio of 1 to 3 is used.

- After the base is ready, it is also possible to lay a layer of waterproofing and asbestos onto its surface.

Tip!

For the manufacture of the foundation you need to use only a rotary brick, which is well tolerate moisture.

Silicate construction material For these purposes, it is not suitable because it is not resistant to the aquatic environment and temperature drops.

Masonry

For the manufacture of furnaces of this type it is worth using a rotable brick, and the fireboxes should be made from heat-resistant and fireproof materials. The usual and double silicate brick M 150 is not suitable for this.

However, some masters use ceramic materials that have shown themselves from a positive side when working with high temperatures.

- The masonry must be carried out in strict accordance with the referee plan.

- For this use cement mortar, with sand divorced 1 to 3.

- For the manufacture of furnaces only. The usual heat-resistant material, which is used in the devices using a tree as a fuel, in this case does not fit.

- It is best to use clay with sand as a binder material. It needs to be breeding in proportion 1 to 1 and it follows the day before use.

Tip!

When installing, you need to use accurate measuring instruments and plumb. They will help to avoid the occurrence of irregularities in the form of a depression or bulges.

Additional elements

In contrast to standard heating devices of this type, the ovens of long combustion of bricks have a number of additional elements that are made of metal and serve to organize proper functioning and control. These include valves, dampers, hermetic doors, grate, etc.

The installation of these elements must be produced into the seats, which are made for several mm more real dimensions. At the same time, spaces from asbestos should be installed between the brick and metal. Also for these purposes, special mixtures are suitable based on sintering materials and industrial compositions.

Tip!

As seating for metal elements, silicone for fireplaces or shaft can be used.

These materials are not only well tolerated the temperature, but also provide tightness.

Chimney

For the manufacture of the ventilation system and chimney, you can use even the usual building brick. This is not affected by the quality of the combustion process in the design, but will significantly reduce its life and make it difficult. That is why professionals are recommended to acquire composite elements.

They are special brick blocks inside which a ceramic tube is placed in the winding from the insulation. At the same time, there is a special instruction on specific types of similar products, which provides recommendations on the installation of products of specific manufacturers.

Tip!

Choosing composite elements for the manufacture of chimney, it is necessary to consult the seller about what mixture it is better to use to connect.

This will greatly facilitate the installation process and the degree of reliability of the whole design.

Finished structures

Furnaces of the factory production should be used in accordance with the technical documentation, which is attached to the specific model. If you need to make a firmware with a brick, then it is necessary to first shift it asbestos or refractory insulation.

Some masters use refractory brickBut then the meaning is lost in the principle of long burning.

Safety technique

It is worth noting that the furnaces with long-burning systems are considered much more dangerous than ordinary heating devices. This is due to their rapid heating and high sheatheel temperature.

They are often compared with the baths for the bath and use similar security measures.

- First of all, it is necessary to protect the device from other designs or interior items that are easily flammable.

- Also in all places of contact of the furnace with other objects (if this cannot be avoided) should be installed gaskets from asbestos. In the market, the price of this material is low, but it provides protection against fire, it provides almost perfect.

- Separately, it is worth noting the right organization and exhaust. This system must be constantly checking on the absence of blockages and conduct its periodic cleansing.

Mandatory requirements of the rules and rules of fire safety in the device of furnaces in residential buildings

Output

In the video presented in this article you will find additional information on this topic. We hope that you can clarify the existing differences between conventional crops and long-burning structures.

The problem of gas supply exists in many corners of our country. Therefore, to this day is the relevant ability to install the furnace.

One of the varieties of furnaces for a private house is convection productswho have long been used in the West, and we have more known as an upgraded - oven on solid fuel for long burning.

Design features

A distinctive feature of the domestic furnace was its form: not cylindrical, like a western counterpart, and rectangularThe upper corners are slightly truncated. This design Promotes an increase in heat transfer indicators. In addition, the heat exchanger was also modified: the intake holes of the pipes are located as low as possible (the distance from the floor level does not exceed 100 mm). The protective casing covers the entire oven. Due to this element, the heating temperature in the heat exchanger increases. And the surface of the housing itself, due to its flat form, can be used as varochnaya - Preheating and disintegration of food is now available on the ovens of long burning.

Benefits

Furnaces on solid fuel have important advantages compared to analogs on liquid fuel, the first of which is the easiest of their manufacturer. Furnaces on liquid fuel need a special design element - a burner with a dropper for liquid fuel. List the rest pros of solid fuel structures:

- efficiency: heating solid fuel Russia is much more efficient and more profitable than electricity or diesel;

- in the absence of gasification - the ability to install do it yourself;

- renewability of solid fuel as a source of energy, makes this option reasonably beneficial; Moreover, in addition to wood, the unit can work on granular fuel - wood waste (pellets);

- there is no need for permanent combustion control: long-burning products provide the process of heating the premises with almost no human involvement.

Principle of operation

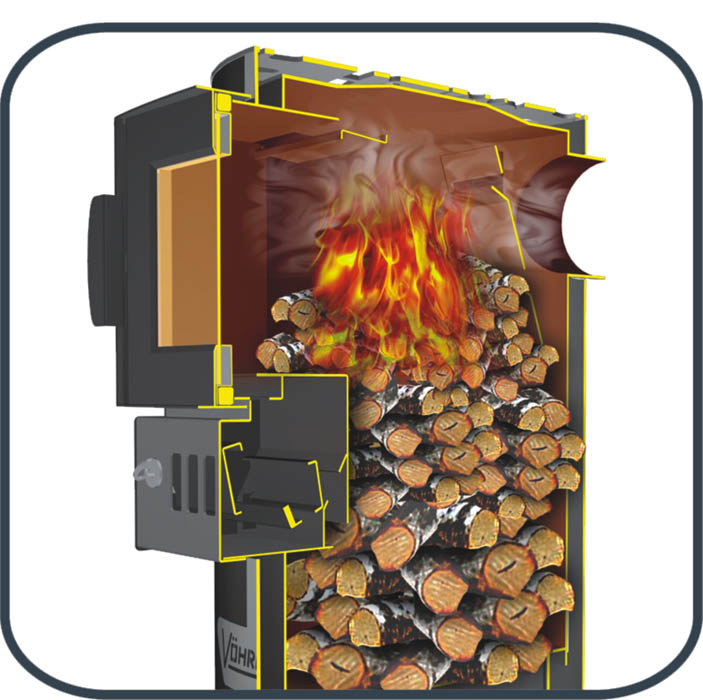

The usual solid fuel oven has a fairly well-known principle of work. To start firewood or other solid type of fuel is loaded into the flue chamber, below which is located standing camera. The oxygen required for the combustion process comes from a subpend chamber. The intensity of combustion is completely dependent on the volume of incoming oxygen, so this process can be adjusted.

Combustion products come into the chimney, the bends and the so-called knee of which improve heat transfer, and, in part, increase the efficiency of the heating system. The process of combustion of fuel occurs extremely speedlessly, throwing into the atmosphere unreasonably excessive heat.

Therefore, for heating systems it is desirable to minimize the combustion process and ensure maximum selection pyrolysis Gazawhich will be the main source of heat. Such a principle is the basis for the functioning of long-burning furnaces.

Making a furnace

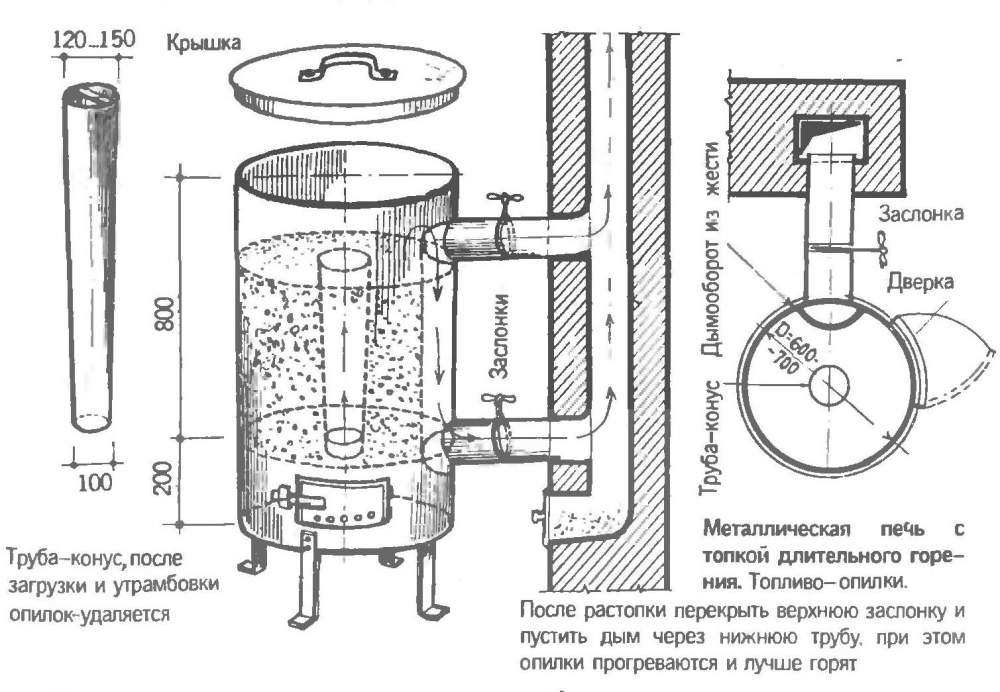

Consider one of the options for the manufacture of a long-burning oven for a private house with your own hands.

The cylindrical oven is perfect for the manufacture, it has a compact size, and it looks attractive and aesthetic design. The design of solid fuel products of long burning, as we have already considered quite simple. For the formation, you will need accessible materials and an easy tool. The main task in the crust of long burning - Hold heated air From direct exit to the chimney pipe. To do this, inside the design, a peculiar labyrinth of pipes and plates welded to each other is constructed, which will be an obstacle to the movement of heated air.

Necessary materials

A solid fuel bust of long burning, made with their own hands, will require:

- metal sheet (thickness of at least 3 mm),

- barrel ,;

- steel corner and cover for firebox

- materials for the structure of the chimney pipe or the finished chimney pipe of the appropriate length and diameter.

To begin the process of manufacturing an aggregate, it is necessary to cut out all the details, it is better to use harvested drawings, diagrams or do it, relying on video instructions. Prepared details need to be cut and polished their edges.

Now we have stood the following steps:

- The top of the barrel is cut, and its edges are aligned. For a cut, you can use a grinder, and bending uneven edges - a conventional hammer.

- From the steel sheet, the circle is cut with a diameter of less than a barrel of 1.5-2 cm.

- a hole is made in the cut circle, the diameter of which is 10 cm. It is welded to this hole steel pipe The same diameter.

- To the bottom of the circle with the pipe are welded segments of a chapellor, this is done in such a way as to ensure the free movement of these segments inside the barrel space. Channels in the design are recognized as fuel to provide a long-burning process.

- A damper is installed on the top of the pipe, carved from the steel sheet (diameter similar as the pipe). Inside the pipe must be fixed with a threaded pin. From one of the edges of the flap, the hole is cut out to the flap mounted on the heel, closes the pipe. The flap is screwed with the nut. This design will allow you to control the volume of air entering the furnace, i.e. Adjust the burning intensity.

- In the case of needing the hammer lines the side of the cover.

- A hole is made in the lid with a diameter of 10.3 cm, this can be done with a chisel. Through this hole will pass the pipe made on the previous steps. Then the drain hole is brewed in the lid.

- At this stage, it is necessary to prepare the base for a solid fuel furnace. It can be a brick platform, for example.

- In the upper part of the case, the hole is cut (to pass the chimney) with a diameter of 15 cm. The length of the chimney must be about 1.5 of the housing length. In the upper part of the housing to the hole, the cutting pipe is welded.

- Now at the bottom of the unit, the opening of the square shape for the door is cut. Then the door itself is welded to it, through which the ash and soot will be removed. Directly in the hatch can be installed in advance of the prepared box (ashnik) so that it is possible to conveniently clean the furnace, putting kicking the box.

- The lower part of the chimney is hermetically brewed, and the pipe itself is installed on the legs.

- The knee is welded to the chimney tube. Then the stove is connected to the knee. The design is better to fix with the help of a clamp, under which it is necessary to arrange glass gamble to ensure fire safety and tightness of the connection.

Important! The device must be installed at a distance of more than 30-40 cm from flammable items.

Solid fuel design, made with their own hands, ready. Now it is necessary to test the furnace of long burning to determine the most optimal mode of operation.

Solid fuel design, made with their own hands, ready. Now it is necessary to test the furnace of long burning to determine the most optimal mode of operation.

Launch of the furnace

- The cover is removed;

- it is getting an element with a welded pipe (for air supply);

- then the solid fuel is loaded; Here it is necessary to trace so that the loaded fuel does not blocked the chimney of the knee; If firewood is used as fuel, - they should be placed vertically, tightly to each other;

- on top of the wood, small twigs or sins are stacked, and then paper that can be coined pre-kerosene;

- damn tube is installed in place, and the design is covered with an upper lid;

- in the hole of the air suppression tube, a lit paper or a piece of material is rushed (matches in this case will not help);

- then it is necessary to wait for a complete ignition of fuel, and overlap the flap of the air supplied pipe.

Everything. It is necessary to periodically check the operation of a long-term combustion furnace for private home ownership.

For most regions, gas or electrical equipment is still inaccessible at the moment. The first is due to the lack of gas distribution networks, and the second is due to too high electricity tariffs. And the question of the use of solar energy or geothermal sources for the purpose of heating in the Russian outback is not even worth it.

Convection equipment in the West appeared for a long time, and there it is actively used, but in Russia it is seriously serious. Only after the brilliant professor and engineer of Butakov created an oven on solid fuel of long burning, such devices began to appear in Russian homes. As a basis, a similar design of imported furnaces was taken, in which he made some changes so that the results of work became much more efficient.

Design features and distinctive features

First of all, the shape of the furnace was changed. Domestic devices were not cylindrical, as in foreign fellows, and rectangular with truncated upper corners. Thanks to this form, it was possible to significantly increase the heat transfer indicators in the process of burning pyrolysis gas. There was a whole set of changes in the furnace on a solid fuel for a long burning of Professor Buttakov. The main transformation was the premises of the elevation holes of the pipes as low as possible, at an altitude of no more than 100 millimeters from the floor level.

The next practical and visual difference made by the inventor was the protective casing, which is located above the heat exchanger and closed the entire oven completely. Due to this supplement, it was possible not only to increase the heating temperature in the heat exchanger itself, but also to increase the diameter of the pipes used, and this makes it possible to increase the volume of heated air. The surface of the protective casing in the top of the furnace is flat, which allows it to be used as a cooking, on which heated food and heating water for economic needs. Furnaces on solid fuel for long burning with maximum heating allow not only heating, but also prepare food.

The equipment got a rectangular shape, due to which it can now be easy to enter into any interior of a modern or rustic style.

Principle of operation

Furnaces on solid fuel for long burning, regardless of the model, can work on one of the types of natural fuel: wood, pellets, eurodrov, chips and sawdust, borants and stone coal. If we consider that the pyrolysis method is used in their device, in which the wood gas is burning in the secondary furnace, the natural wood turns out to be the most suitable version of fuel. Than better tree It will be dried, the greater the amount of gas it can work out, that is, give more heat as a result of the operation of the entire system. The fact is that from a wet tree it turns out a wet smoke, connecting with gas particles, because of which they become harder and not burned completely.

The process of burning wood fuel occurs in the main combustion chamber, located at the top - there is a small burner. Through it, the resulting pyrolysis gas enters the secondary furnace, where it is surrounded by giving heat passing inside the pipes of the heat exchanger. Long burning furnaces are not used forced air inflow system. The intake of oxygen is carried out through the adjustable damper, which is quite enough to saturate the secondary chamber.

The lower part of the furnace is equipped with a small container in which the ash is assembled. Residual combustion products are referred to in it through the serving bottom of the furnaces. The ash tick in the design of the furnace is used to clean the heater from the slags accumulated in it.

Chim response

The nozzle for connecting the chimney in this equipment is also different in its location from convection ovens of foreign production. It is not accidental vertically. Due to this, the fast-circulating condensate flows back into the combustion chamber. This became relevant due to the fact that in the condensate such boilers there is up to 35-40% of incompeated pyrolysis gas, evaporating from moisture, and then spent. Vertical location Pipes makes it possible to install the furnace as close as possible to the walls of the room. For smoke removal in this design, the use of any chimneys, starting with a simple metal pipeending with glass, ceramic or sandwich tubes, so now popular.

Installation

The feature of the design and characteristics made very popular solid fuel boilers Long burning. The installation scheme is selected depending on the room where the equipment will be installed. The place is recommended to equip heat insulating screens. Free space should remain at least 150-200 millimeters from the furnace housing to the walls, which allows to protect decoration Materials from overheating and ignition. It is possible to store wood near the furnace, thereby partially dry it before use in direct intended.

Their appearance allowed not only to make accommodation in homes more comfortable, but also solve issues related to energy saving, protection ambient, as well as savings on buying fuel. In addition, it should be noted the improvement of the operational capabilities of the equipment, as it does not need a constant supervision as previous models. The heating systems operating on solid fuel today have great prospects.

Automatic solid fuel boilers for long-burning at the moment were widespread to organize heating houses, cottages, greenhouses, offices, shops, industrial and production buildings, car wash, service station and other objects. Many Russians refused to gas boilers in favor of solid fuel devices.

Benefits

The best solid fuel boilers of long burning have a number of undeniable advantages:

The highest degree of economy is ensured due to the fact that in Russia it is much more efficient to dump solid fuel than electricity or diesel;

Opportunities for installation in areas where there is no gasification;

Solid fuel is a renewable source of energy, which makes it a rather advantageous option for use;

The combustion mode does not need constant control - the best solid fuel boilers of long combustion provide combustion of fuel without human participation of the week and longer.

Device working conditions

The device requires creating certain working conditions that will ensure the greatest efficiency. First of all, this is a boiler room in which the boiler itself turns on, an expansion tank, a circulation pump, a security group and other elements. The chimney must be required, which should be selected according to the results of the calculations carried out, which does not allow an insufficient or excessive thrust. Heating in the house will be organized by using a heating line consisting of radiators and pipelines.

Of all the variety of boilers, which can be performed independently, rectangular will be the most aesthetic and compact. They are suitable for heating the premises of small sizes, and if you refine them, you can warm and more. The design of solid fuel boilers of long burning is quite simple, and for its implementation, quite affordable materials will be required, the number of which is completely dependent on the size of the future unit. The whole point here consists in holding heated air from direct yield into the chimney. To do this, inside accommodations that consist of pipes and plates welded to each other in a special way, which allows you to create a kind of labyrinth between them, providing a slow passage along it of heated air. With properly organized supply of additional gas, the upper compartments will serve as cameras. If desired, the unit from the inside can be chopped by a brick or you can also make a brickwork from the outside.

Materials

Homemade solid fuel boilers of long burning require the use of certain components: a metal sheet with a thickness of at least 3 millimeters, a steel corner and a cover for the hole in the furnace, the chimney pipe of the appropriate configuration, diameter and length. To begin with, all items required to cut out in accordance with the pre-drawn plan. Next, neatly cut, clean or polish the edges. Only with the full compliance of the plan, you can get high-quality solid fuel boilers for long burning. The scheme of such devices should contain the names of all components and the location of their exact location.