In a number of existing ways of heating country houses, cottages, baths special place long burning. The maximum effect of their use is achieved where there is no possibility to use the main gas or connect to central heating. Conventional boilers require a large amount of fuel, and heat generated by them is very quickly spent. Installation of long-burning furnaces is a great solution to the problem.

Long burning furnace device

The furnace is arranged as follows:

- the combustion chamber (fuel) having two compartments: one for burning fuel, the other - for combustion of combustion products. The latter is performed in the form of a dome;

- chimneys (optimal diameter within 80 - 150 mm) through which occurs through the removal of combustion products;

- some models are aggregated by an air convection system or a water heat exchanger;

- the design may include plates; wind cabinets and etc.

How does a long burning furnace functions

A distinctive feature is the ability to work in two modes:

- fast room heating (fully open Sewber and extended ashp);

- long burning mode (temperature supported at a constant level).

Principle of work of long-burning furnaces

The principle of operation of long-burning furnaces is radically different from the functioning of a conventional heating device. The effect of long-burning furnace is based on the spread of fire from top to bottom. Fuel is mounted in the upper part, thanks to the use of the air-powered pipe. When burning gases, sucking through the chimney. Air supply control is carried out by the damper: the combustion process is transformed into depression. Such a functionality allows heat dissipation for many hours and even a day.

The processes in the furnace are carried out as follows:

- drying fuel (energy carrier);

- pyrolysis (decomposition); Mandatory conditions are the lack of oxygen, the temperature is about 450ºC;

- combustion of bats (lungs) fractions with parallel carbenization (saturation of carbon dioxide) of fuel;

- decay of solid fractions of fuel and their transition of a volatile state;

- oxidation reaction (production of hydrogen and carbon monoxide) at 400ºC.

The result of oxidation (recovery) is the yield of a large amount of heat. Prerequisite: Temperature should not fall below 250 ºC. Otherwise, hydrogen and carbon monoxide will come out. Heat will not be transferred.

Working hours of long-burning furnaces

Modern devices do not require constant fuel replenishment. The time of their continuous operation depends on the volume of the furnace chamber. One bookmark is enough to 20 hours. The work of some stove models last up to 3 days.

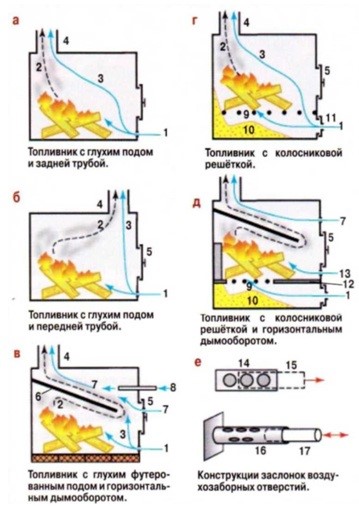

Scheme of long burning furnaces

Schemes of furnaces are slightly different depending on the model (manufacturer, type of fuel). You can submit a design as follows:

- combustion chamber (fifth);

- secondary air receipt system;

- grille (grate);

- doors to replenish fuel;

- doors through which the camera cleaning occurs;

- the doors through which the primary air is supplied, adjustment is adjusted;

- solnik;

- the exit system of combustion products into the chimney.

Construction of long-burning furniture with water contour

If the design provides the use of a water circuit, then the following elements are included in the composition:

- water boiler;

- boiler cleaning doors;

- returnable system system;

- system that provides a ledge of the heating fluid from the boiler;

- thermal insulation of the water boiler;

- cleaning capacity;

- cooling circuit.

Operation of long-burning furnaces

Operation does not depend much on the shape and type of equipment, its size and place of use (residential building, bath, household premises). The algorithm of action is the same. The process begins with the boot of firebox fuel. In the lower half of the fuel, the primary air is entered, fuel is set on fire. In such a long-burning mode, the oven acts until the temperature in the chamber reaches the required value (usually 400ºC). After that, there is an overlap of primary air.

There is cracking fuel. Gas generated as a result of this process rise to the upper half of the chamber. Here is the serve of the secondary air necessary for the survival of combustion products. The result of the process is to allocate a significant amount of heat. The task of a long-burning furnace with high efficiency - effectively with a minimum of losses to transfer the produced thermal energy The surrounding air or liquid water circuit.

How to turn the oven for long burning

First, the furnace is performed as usual. The smoke thrust is increased, the flue chamber is filled with half. If the furnace has a big chamber, then the fuel is laid in it gradually. The full tab is carried out after the temperature stabilization.

Efficiency of long-burning furnaces

The nature and method of heat removal depends on the design. The housing of the heating unit can be equipped with protective screen. Such a device prevents fires located near the materials and significantly improves heat exchange. The result is excellent performance indicators. So, the bubzhuyka bake Pyrolysis long burning has an efficiency of 90%.

In some cases, the installation of a long-burning furnace house is conjugate with water strapping, which is directly attached to the liquid circuit of the heating of the house. When installing a long-term combustion oven, it is required to take into account that in contact with the cold liquid, the housing will inevitably cool. Such contact adversely affects the process of pyrolysis occurring inside.

To avoid heat loss, it is necessary to increase the performance of the heating element (which is technically difficult to perform), or have a water jacket at some distance from the case.

Installing Long burning furnaces

The correct installation of a long-burning furnace is associated with its correct operation and compliance with the requirements. fire safety. To properly install the furnace, the following rules must be observed:

- the distance to any flammable and combustible materials should not be less than 1 m;

- the location of the heating device must be as close as possible to the stationary chimney;

- free space in front of the fuel should be more than 1.25 m;

How to install long burning furnaces in the house

There are several ways to increase installation safety:

- applying plaster (layer to 25 mm) to nearby objects, which will reduce the distance to them to 0.7 m;

- installing a protective metal sheet with a thickness of up to 1 mm, or protection from light insulating materials with a thickness of up to 7 mm;

- installing brick masonry up to 55 mm thick;

- the surface under the furnace is protected either brick masonry (minimum in one brick) or a metal sheet laid on refractory material: The list should be in terms of entering the oven dimensions from all sides.

Installing fireplaces of long-burning fireplaces

Installation of fireplaces of long-burning fireplaces in the house is considered the most fire-hazard, due to the presence of an open fire. At the same time, the design fits perfectly into any interior. A modern furnace-fireplace can be equipped with a stove for cooking.

Installation of long-burning furnaces

Prior to the start of installation, you should choose a set of pipes for chimney. There are two main types of installation: outdoor and vertical.

With vertical mounting, the plots are mounted inside the building, the output is carried out through the roof. The pipe is aggregated in the available brick channel. With an outdoor method, the chimney leads along the outside of the building. Conclusion to the street is carried out through lateral output. In this embodiment, the hence of the chimney.

Installation of a long-burning furnace in a wooden house should be carried out when the main door and window openings are equipped, i.e. After a clear understanding of the direction of cold air flows in the room. If the furnace should dump several rooms, the air duct system should be designed.

In order to properly stir the furnace of long burning, it is necessary to take care of the place of fuel storage. It is required to plan the workspace in front of the heating device, think through the fuel tray paths.

Comparison of long-burning furnaces

It does not matter in principle, whether the furnace of long burning is installed in the house or its own hands. Any device must respond to a number of mandatory requirements. Fundamentally the following:

- fire safety design;

- the burning time of the oven long burning should be at least 5-7 hours.

Comparison of long-burning furnaces shows that in the design there must be a download channels (jetters), which ensure the flow of fuel. The location of the channels is not fundamentally. May be at the bottom, in the middle or above the furnace. Some manufacturers hide the location of the jackers.

The next comparison parameter: the volume of the furnace and the dimensions of the furnace door. What they are more, the more fuel fit in one bookmark. An important glass is in the door. Always nice to look at the fire.

It is necessary to take care of the presence of constructive solutions that extend the service life and increase the efficiency of long-burning furnaces (for example, a shame of a flame that protects chimney).

Liquid fuel structures

Considering the various design options, it is worth remembering about the oven long-term combustion, working on working out technical oils. Functioning oven on the burning of the oil vapor. The combustion time is comparable to solid fuel structures and ranges from 12 to 20 hours at one refueling. It is economically beneficial to use such aggregates where there is a large amount of working out. The minuses include the need for frequent cleaning of chimneys, or the need to pre-clean oil.

Long burning furnace

Any ovens of long burning really make yourself. To this end, it is necessary to stock up the drawings of the selected design and the necessary materials. The factory oven will look outwardly looks attractive, but it costs much more expensive.

With the arrival of colds, the owners of those rooms that are not connected to the general system of central heat supply are forced to think about how they will heat these rooms with cold winter evenings. In order to maintain a normal temperature in the heating season you can make a long burning furnace with your own hands.

Long burning furnace: where to start

Starting is from purchasing all the necessary materials. To do this, we need:

- 1 metal barrel 200 liters (size is not sufficient, and depends on your preferences); (See also: )

- two small cuts steel pipe, one is a bit longer and one shorter;

- metal schweller

- Hacksaw for working on metal, ax, hammer steel and cizyanka;

- Such measuring devices like a roulette, plumbing and building level

- Ordinary red brick for masonry device, about 50 pieces

- Reflector;

- small piece of sheet steel

- welder

- electrodes

- Building mixture or materials for the preparation of the solution on the masonry.

How long burning oven

The main principle of the work of a long-burning oven was borrowed from Lithuanian producers of the strap boiler. The firewood is burning in them, not as in conventional furnaces, from the bottom up, on the contrary, thereby achieving the most economical fuel consumption and its longer burning.

In the ordinary oven there is more intensive combustion solid fuelAs a result, it leads to a very rapid warming of the room during the work of the furnaces, and to the same rapid cooling, after the completion of the process. Such a design causes the need to regularly add fuel every 2-3 hours, especially this refers to the furnaces that work on wood.

During such intensive combustion in such furnaces, fuel allocates not all the energy immediately, which is due to the large oxygen inflow, and more selected calories goes directly into the chimney, which does not lead to empty energy consumption.

In addition, the supply of oxygen for burning in printers of long combustion occurs directly from the room itself, which, as a result, lowers its temperature.

Principle of operation of the furnace of long burning on firewood.

The main principle of the work of the wood-burning ovens is a decrease in the inflow of oxygen into the combustion chamber, and the sort of oxygen is not from the bottom, as in conventional furnaces, but the opposite from the upper side of the loaded fuel. (See also: )

A similar method ensures a sufficient reduction in the intensity of combustion, thus translating it into the active heating mode, thereby keeping the fuel and making the interval of its bookmark is not so frequent.

The next distinctive feature of a long-burning furnace is the ability to carry out oxygen supply, which is necessary for its operation, directly from the street, and not heated air from the room.

What you need to know about the mounting of a long burning oven

Now let's talk about how the installation of a long burning oven is your own hands.

The foundation must be capital, since in the process of operation of the furnace, the metal will be greatly generated.

The mass of the structure itself is minimal, and even taking into account the plated brick, its installation on a fragile or not a refractory base is simply excluded.

Step-by-step instruction mounting oven

Now let's follow the following manual installation instructions for long burning:

- Selected in advance of the tank give the form of the cylinder, on one side of the open, the second side will serve the bottom of the furnace. After that, in the upper edge of the barrel you need to cut hole in accordance with the diameter of the chimney pipe.

- We are taken for making a metal piston. For which from the metal sheet 2-4 mm height, it is necessary to cut the disk, the external diameter of which will coincide with the inner diameter of the furnace case, considering the gap, which is designed to compensate for the expansion of the material during heating. And in the center of the disk, cut the hole with a diameter that will coincide with the pipe diameter through which oxygen is supplied. After that, connect the resulting structures by resorting to the help of welding. You can also put the extension cord on the oxygen supply pipe and remove it beyond the placement in which heating will be held.

- Cover the whole design with a common lid of sheet metalwhich will have sealing and protective functions.

- To increase the efficiency of the design inside the chimney pipe, you can install the blades that will create turbulence of the air flow, or use other heat exchanger equipment. This will significantly increase the KPD of the furnace, while maintaining the entire temperature in the room.

- Adjusting the combustion process can be performed using a damper that is installed in chimney for furnaces. It should be remembered that when it is complete closed, the combustion process is practically stopped.

- Any connections and seams on the pipes must be carefully sealing. This is done to eliminate the unauthorized inflow of air and facilitate regulation.

Where to use long burning furnace

Place of application of homemade ovens of long combustion:

Of course, self-made ovens of long burning due to them, directly say, low aestheticism, are practically not used in residential premises, but higher efficiency and ease of maintenance made it almost indispensable in the conditions of using a variety of utility rooms.

In the absence of power supply or central heating, the furnaces of such a plan are almost the only sources of heat that any person can independently make a couple of hours from the primary materials.

A fuel for a long-burning oven usually serve various waste from woodworking industries, and for ignition, chips and sawdust are actively used. When trash, you simply load the mass into the furnace housing and produce it arson, then cover the design with a special piston with the air supply pipe (the damper on the pipe is always kept open) and close the lid. After complete root, the remaining ashes from the furnace housing.

Features of mounting the furnace

What is worth paying special attention when installing homemade oven Long burning:

- When the smoke pipe device, connect all its individual sections between them in the direction, completely inverse the movement of gases.

- During the installation of a long burning furnace, select a certain space around it, taking into account its periodic maximum heating to very high temperatures. It can not be placed near such a furnace, not only flammable and combustible objects, as well as any products and structures that cannot withstand the effects of very high temperature.

- Provide chimney with the possibility of its analysis for periodic cleaning, at any time.

- Before running the equipment, you must try several possible modes of operation. As a result, you can decide on the most suitable temperature and fuel combustion mode.

Advantages and disadvantages of the furnace of long burning

Positive aspects of the use of long-burning furnaces:

- Using economical furnaces long burning, you can save ourselves from extra expenses, since all necessary materials You can find in my yard or cheap to buy in the store.

- Easy design that does not take up a lot of space in your room.

- You do not have to, like with conventional furnaces, to throw firewood every 3 hours, or other heating materials.

- It is convenient to use in small utility rooms

The negative sides are only two:

- Appearance, to put it mildly, leaves much to be desired, so, most likely, you do not want to establish a similar design at home.

- A long burning furnace is necessary to isolate from all the light-sensible objects, since during operation, the metal from which the furnace is made greatly becoming.

The use of materials is allowed only if there is an indexed reference to the material page.

Although the progress gradually reached almost all the corners of our planet, the wood furnaces did not touch the scene. They still well serve for the benefit of mankind. Of course, a lot has changed in the design of furnaces, and in the way of maintaining burning firewood, and in terms of an economical approach to the fuel used. The ovens of the old sample quickly slept the room, but had a number of sufficiently serious flaws: a low efficiency, a frequent decomposition of firewood, the inability to track modes of operation. That is why they gradually began to move the wood-burning furnaces of long burning.

What it is? This is a completely unique design in which the firewood is practically not lit. The burning occurs, but with a small amount of oxygen, so the fuel in the stove is just tweet. To create such conditions, it is necessary to make such a flue chamber so that it is gradually with a decrease in the amount of fuel during combustion, also decreased.

With long-term burning of firewood, some positive positions of the device appear:

- An increase in the combustion time of firewood, and accordingly increases the time between their bookmarks.

- The effectiveness of heat isolate.

- Increase the efficiency.

In principle, all these figures are characterized today with modern heating units. Therefore, it became necessary to deal with heating furnaces Long burning.

Variety of long burning stove

Variety of long burning stove

Constructive features

To the peculiarities of such a stove should be attributed to the entire design, which includes:

- Case made of metal.

- Two combustion chambers, sealed apart and from the casing.

- The flaps with which you can adjust the air supply to the combustion zone.

The principle of operation of this furnace is the following:

- Firing laid in the firewood set fire, open the flaps completely. That is, the furnace works like ordinary burzhuyka.

- As soon as the temperature inside the chamber reached + 200 ° C, the dampers are covered. That is, the supply of fresh air decreases.

- Now it is necessary to adjust the dampers so that the firewood in the furnace is not burning with a "blue flame". They should, as already mentioned above, smoldering.

- In the design of a long-burning furnace for the cottage, the casing from the furnace is separated by an air shirt. That is, there is a gap between two walls. Heat into the room is transmitted through the air inside the unit. This partially reduces the efficiency, but increases the life of the heating device itself.

See also:

How to choose the right brick for stoves

![]() Stove on long burning firewood

Stove on long burning firewood

Although it should be noted that the double walls are not a prerequisite design. So you can make such an aggregate without an air layer. But in any case, such stoves are high heat transfer and minimal fuel consumption. It should be noted that the market can be purchased in the market, the wood laying in which will smooth up to two days. And at the same time it is noted that the size of the installation is sufficiently small.

There is one very interesting point in the whole situation. If the oxygen in the furnace is to act in the improper quantity, then condensate will be formed on the walls of the device and in the chimney. If the oxygen supply is increased, it will be for large quantities to form soot. So this is a stick about two ends. Therefore, it is necessary to carry out accurate adjustment of the dampers. This is all the salt of the furnace furnace technology for the giving distance.

Booleryan.

Booleryan.

Disadvantages of construction

With advantages of this type of furnace, we got acquainted. But she has four drawbacks. True, some of them do not seem to be attributed to the shortcomings, because this is the design of the device. But still:

- In such a stove, it is very difficult to install a water circuit. This is due to the fact that this model is pure convection. Although on the market such options have long appeared.

- Very high demands on the humidity of the fuel used. Firewood should be very dry. Increased humidity reduces thermal selection, so the furnace begins to work incorrectly. In any case, do not expect a high efficiency from it.

- The chimney is imposed very stringent requirements. There is not only an accurate calculation of its diameter, but also correct installation. Some models require vertical installation, some inclined or partially horizontal. Therefore, this issue will have to be understood in accordance with the selected model.

- Customize such an aggregate is not easy. Better this process is trusted by a specialist. The thing is that the change in some operating factors can lead to a decrease in the efficiency. For example, the same damp of firewood, changes in the circulation of air indoors and the house as a whole.

See also:

Pros and Cons of the Russian Furnace with Lena

The shortcomings are essential. But all this is compensated by the high efficiency of the heat transfer of the device, saving fuel consumption and other positive aspects of a latter combustion fireplace.

Slopowa

Slopowa

How to make it yourself

Make a bourgeitogon of long burning with your own hands is easy if you know the principle of installation of installation and design features. We have already written about this above, so it is worth staying on the issue of manufacturing.

First of all, you need to choose a model. Let's consider the simplest, which exactly resembles a burgundy. In essence, it is she. Only it has some constructive changes.

- The grate grille is cleaned. Firewood will lie on the lean, so this element is recommended to make or out of a thick sheet of iron, or enhance it with another sheet.

- Install the door of the furnace by the type of door of the "Buleryan" model. In the door itself you need to make holes that will open and closed using a special round damper.

Constructive row of bourgearies of long burning

Constructive row of bourgearies of long burning

What is these constructive changes? First, the absence of a piping zone makes it possible to reduce air intake. After all, under the wood there is no space and no pissed. So, the intensity of burning is reduced. Secondly, the hot gas that is formed in the process of decay of firewood immediately does not leave the furnace, it is in it for a long time, thereby well heats the stove wall. Thirdly, with a circular flap, it is easy to adjust the supply of oxygen.

Can this design A little change, but at the same time increase the efficiency of its work. To do this, the combustion chamber of fuel should be divided by a horizontal or inclined partition. But this element should not reach the front wall of the chamber for several centimeters. Between the lower chamber and the top should form a gap through which the hot fluxes of the flue gases should rush into the upper chamber. This increases the area of \u200b\u200bheat exchange, plus the possibility of using a pyrolysis process appears.

See also:

How to build a mini oven yourself

What does it mean? You can additionally create conditions under which the boiler gases will be burned in the second chamber. To do this, it is necessary to simply supplement the design of the side tubes through which oxygen will flow into the second chamber. The gases themselves will not burn, but the air-gas mixture is perfectly burning, highlighting a huge amount of thermal energy. By the way, such furnaces are the owners of a large efficiency, reaching up to 95%.

Bath oven for long burning

Bath oven for long burning

Long burning furnaces

In fact, models of this type of heating installations have a huge amount. We only reviewed ordinary bourgeities, and there are not only horizontal installations in this category, but also vertical. For example, known to many of us the stoves "Bunch" and "Stropor". Do not forget about the Canadian version of "Buleryan". By the way, about all these designs on our site you will find more information.

Approaching the selection question, each consumer comes from those operating conditions that they are put forward as the most basic. But in any case, it should be noted that the ovens of long combustion can be used as heating devices, for small buildings and buildings. For example, for cottages, country cottages, garages, workshops and baths. IN large houses They can also be installed, but only as an additional heat source.