Wooden floors arrange not only in wood houses, but also in brick buildings. Such a floor looks great and helps to create a good microclimate indoors. It is easy to perform with your own hands even if there are minimal carpentry skills. But at the same time it will be necessary to prepare in theoretical plan and consider the most important moments upcoming work.

There are many options for wooden flooring. Choose them depending on certain conditions of construction, where the flooring has to be done. Most often stop at such versions:

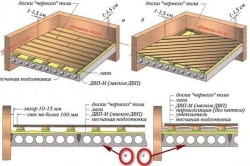

- The floor with the installation of rough and insulating layers, which is located on the ground or beams of overlapping.

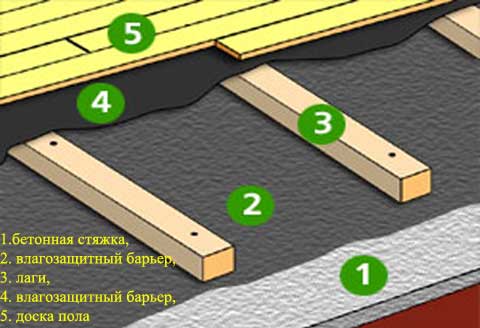

- Wood floor on a concrete basis with a warming layer.

Number one option is commonly used by owners of own homes. In this way, you can arrange the floor as a ground-based basis in the basement or on the first floor and on other floors in the form of overlapping on the beams.

Option The second implies the manufacturer concrete screed As the basis for the floor. It can also serve as the slabs of overlapping from reinforced concrete. The design of the floor can be significantly changed and improved that not only facilitate installation, but also make it cheaper.

General Wood Floor Arrangement Terms

Work on the construction of sex is better to exercise better when the heating season ends. During this period, it is less likely that wooden materials are absorbed by moisture, which will later be harmful to affect their quality. If work is decided to spend in the summer, it is necessary to try to wait for the moment when over the past tenfig days is good, dry and sunny weather.

Like another wood, intended for use in construction, lumber should be treated with antiseptics, antipirens.

Materials for wood flooring:

- board of glued timber;

- sheet material - for example, plywood, chipboard;

- uncircumcised board;

- folded board.

Of the uncircumcised boards and sheet materials make flooring for roughing. Later will be laid out the flooring. The folded board and glued timber material are used to form a pure layer, which will need to be painted or varnished.

Preparation of the foundation

If the wooden floor is planned to be laid on the ground, a reliable strengthening of lags should be ensured.

There is a device for waterproofing space under the floor, it is necessary to take care of both insulation.

The basis is prepared - for this, the ground is removed on the entire perimeter of the room, so that the thickness can be inserted into 20 cm below the ground level. A layer of rubble and a layer of river sand are poured on the prepared foundation, wet water and tram.

On this basis, several brick columnswho serve as a support for lags. The width of this column must be - two bricks, height - 20-40 cm. Bricks are fastening with the help of ordinary cement mortar, they are built on top. It is necessary to take into account that each of the lags should have the smaller two pillars, which will be located at the edges.

For long lags add pillars in the middle. The distance between them is calculated depending on the size of the boards for lags and the planned settlement load. To compile calculations, it is better to turn to professional designers.

When laying building materials on beams located between floors, it will not be necessary to prepare. On this basis, you can immediately begin to distribute lags.

Over the beams or pillars put the rolled waterproofing material. After that, they are put on special woods made of wood prepared by lags and anchors fasten them to columns. The upper face of the lags with the help of a plane is derived in a single plane. The extreme lags are built up with the help of a level, between them stretch the fishing line, after which the rest are stacked.

The details for the construction of the draft floor are attached to the bottom of the lags. For the base in the form of soil and lags on the pods, the bars are fixed across, along the entire length of the room. When laying on the beams, to nail the bars to the sidewalls of lags on both parties. For insulation take vapor-permeable materials - for example, minvatu, plates from basalt. They are inserted into the gaps between the lags so that no gaps remain.

Before laying a wooden floor lay a vapor-hydro insulation membrane. It must be stacked with the allen 20 cm, the joints of the material are well cleaned with scotch. Fastening will depend on what the finish coating is selected. For example, under the boards made specifically for the floor, with the presence of a ventilation gutter, the rails for fasteners are not necessary.

Concrete floor base

Far simply mount wooden floors Based on concrete. Lags can be installed with a greater frequency, which will reduce the bending load. Align such lags are much more convenient. Permissible step for lags with a thickness of 20 mm when installing on concrete base It is considered 30 cm. For boards with a thickness of 25 mm, a step must be withstanding 40 cm. To fix them, they will need construction studs with a diameter of 8-10 cm. The holes for them are drilled in the bars.

After the lags are aligned and secured, starting laying boards. For fixing it is better to use selflessness.

At the end of the work when all the boards are posted on the floor, finishing finish. It can be grinding, cycloying, paint and varnish coating.

Most private and. They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

In this article we will tell you the technology of the black floor assembly on the lags.

They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

In this article we will tell you the technology of the black floor assembly on the lags.

Wooden floor in the apartment: installation features, sequence of work and subsequent processing "href \u003d" http://shkolapola.ru/derevyannie/457-derevyannyj-pol-v-kvartire "\u003e Apartment houses are used by floors from wood. They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

In this article we will tell you the technology of the black floor assembly on the lags.

I \u003d ""\u003e what are lag

Lags are bars who lie perpendicularly to the floor, and serve as a reason for him. Most often they are made of wood.

Their use gives a number of advantages:

- Noise insulation is increasing;

- It is observed correct ventilation of the tree below;

- The ability to put inside communication;

- An increase in thermal insulation and the ability to use additional insulation;

- The strength of the structure increases;

- Ease of repair and replacement of defective elements with their own hands.

Selection and purchase of material

Inexpensive wood (pine, spruce, fir) can be used as a lag. Sometimes a larch is used, since the price is high. Wood 2-3 varieties with humidity of about 20 percent.

The cross section of the bar must have a rectangular shape so that the height is more than 1.5-2 times. Dimensions will depend on the width of the spans and the thickness of the insulation. The photo shows an example of calculations if the lags will be laid in 70 cm increments.

As a flooring, cedar, aspen, pines are used. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

Distance between lagami

Cedar, Osin, Pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

The most elite materials are the array of oak and pine, they will be very durable. Larch does not rot in wet conditions, so it can be used in the bathroom, bath.

With these materials, it is even possible not to use the finish coating, but simply sprawling well, cover them with varnish, versal. However, in this case, you will have to buy a first-grade gender board.

Aspen and alder is well suitable for the bedroom and children, as it is good for health.

It is advisable to buy dry wood so that it will not be deformed after drying. Take into account the stock of about 15 percent for marriage and trimming.

Tip! Before stacking, it is desirable to handle wood with antiseptics and antipirens to counteract fungus, mold, fire. You can also use treatment with hydrophobic fluid so that the surface has water-repellent properties.

Distance between lagami

The lag of the floor allows them to be located at different distances, depending on the thickness of the genital board.

- If thin boards are used, the step becomes small to avoid bending (from 30 cm).

- If thick is used massive boardsThe step can be increased, up to 100 cm.

- The most commonly applied step 50-70 cm.

- Also consider such a distance so that it is convenient to lay insulation inside.

flooring board from larch, cedar, aspen, pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

flooring board from larch, cedar, aspen, pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

The most elite materials are the array of oak and pine, they will be very durable. Larch does not rot in wet conditions, so it can be used in the bathroom, bath.

With these materials, it is even possible not to use the finish coating, but simply sprawling well, cover them with varnish, versal. However, in this case, you will have to buy a first-grade gender board.

Aspen and alder is well suitable for the bedroom and children, as it is good for health.

It is advisable to buy dry wood so that it will not be deformed after drying. Take into account the stock of about 15 percent for marriage and trimming.

Tip! Before stacking, it is desirable to handle wood with antiseptics and antipirens to counteract fungus, mold, fire. You can also use treatment with hydrophobic fluid so that the surface has water-repellent properties.

Distance between lagami

The lag of the floor allows them to be located at different distances, depending on the thickness of the genital board.

- If thin boards are used, the step becomes small to avoid bending (from 30 cm).

- If thick massive boards are used, the step can be increased, up to 100 cm.

- The most commonly applied step 50-70 cm.

- Also consider such a distance so that it is convenient to lay insulation inside.

Batten From larch and other lumber "href \u003d" http://shkolapola.ru/derevyannie/427-polovaya-doska-iz-listvennicy "\u003e Flooring of larch, cedar, aspen, pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

The most elite materials are the array of oak and pine, they will be very durable. Larch does not rot in wet conditions, so it can be used in the bathroom, bath.

With these materials, it is even possible not to use the finish coating, but simply sprawling well, cover them with varnish, versal. However, in this case, you will have to buy a first-grade gender board.

Aspen and alder is well suitable for the bedroom and children, as it is good for health.

It is advisable to buy dry wood so that it will not be deformed after drying. Take into account the stock of about 15 percent for marriage and trimming.

Tip! Before stacking, it is desirable to handle wood with antiseptics and antipirens to counteract fungus, mold, fire. You can also use treatment with hydrophobic fluid so that the surface has water-repellent properties.

Distance between lagami

The lag of the floor allows them to be located at different distances, depending on the thickness of the genital board.

- If thin boards are used, the step becomes small to avoid bending (from 30 cm).

- If thick massive boards are used, the step can be increased, up to 100 cm.

- The most commonly applied step 50-70 cm.

- Also consider such a distance so that it is convenient to lay insulation inside.

I-7 \u003d ""\u003e Installing Lag

The device of the wooden floor by lags can be done along a concrete or earth ground, overlapping or beams. The main rule that should be observed, regardless of the selected method, lagows should be thoroughly and in the same plane. This will give you a guarantee of the strength and durability of your floors without the appearance of a screens.

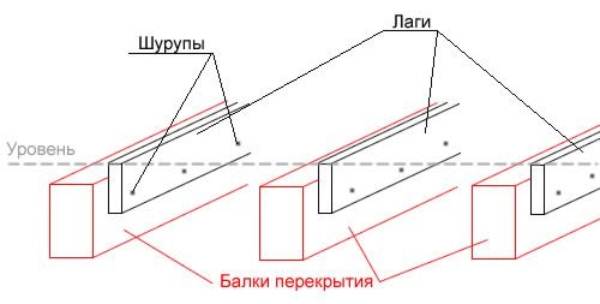

Installation on wooden beams

If in the house of the overlap is made of wooden beams, Lags are attached to them. Considering the fact that the beams are usually not perfectly even, it is best to mount them to the side part, exposing the level.

If simply fixes them, laying on overlappings, it will be necessary to put the gaskets to align the same level. It is better to do so if the distance between the overlaps is large. In this case, it will be necessary to mount the lags perpendicular to beams with a smaller step.

It is necessary to use clocks 6 mm and a length of 2.5 times the width of the lag. For bars do not crack during screwing, it is previously necessary to drill holes for smaller diameter.

Concrete flooring

There are several ways to make a smooth wooden floor device on lags on a concrete base.

- The first method is most popular - the use of linings for bars, to level the level. Over time, they can fly, dry, deform, and the floor will begin to creak, so this option is not the best.

- The next way is more expensive, but effective - preliminary leveling of the base. This may be a self-leveling mixture, sand, depending on its condition.

Laying Lag on the soil

And self-leveling mixture, sand, depending on its condition.

Before laying, you need to sash on concrete waterproofing from a plastic film. It is also extremely desirable to put on the lags and from their ends with soundproofing substrates to reduce the transmission of vibration noise.

It is advisable to use bars to the entire width of the room so that you do not have to dock them. The insulation is laid between the lags installed.

Many ask a question whether it is necessary to hardly fix the lags to the base? The device of floors on the lags on a concrete base allows them to be fixed with the cement-sand mixture.

However, it will be necessary to protect the boards with bitumen insulation or hydrokhotloxole. The coating is placed only after drying the solution. In this case, you can set the lags into one plane, by saving the solution to them.

However, it should be borne in mind that the rigid fastening of the lag to the overlaps will strengthen the transmission of noise to the neighbors below. That is why it is more likely to make a floating mount with an anti-vibration substrate.

Tip! To enhance the strength and rigidity of the frame, it is recommended to bore the bars between themselves with crossings by cropping boards and corners of 4 * 4 cm.

Laying Lag on the soil

Paul B Floor wooden house By lags on the first floor can be installed directly on the ground.

- First of all, you need to align and tamme the soil. This can be done manually, building a device for thrombling from a large log and a wide board from below.

- Then you need to mark the columns that will support lags. At the edges, they will have to rely on the foundation. The extreme lags must be installed almost at the wall, with a gap of 5-20 cm.

filling of floor screeds in lighthouses, and self-leveling mixture, sand, depending on its condition.

filling of floor screeds in lighthouses, and self-leveling mixture, sand, depending on its condition.

Before laying, you need to sash on concrete waterproofing from a plastic film. It is also extremely desirable to put on the lags and from their ends with soundproofing substrates to reduce the transmission of vibration noise.

It is advisable to use bars to the entire width of the room so that you do not have to dock them. The insulation is laid between the lags installed.

Many ask a question whether it is necessary to hardly fix the lags to the base? The device of floors on the lags on a concrete base allows them to be fixed with the cement-sand mixture.

However, it will be necessary to protect the boards with bitumen insulation or hydrokhotloxole. The coating is placed only after drying the solution. In this case, you can set the lags into one plane, by saving the solution to them.

However, it should be borne in mind that the rigid fastening of the lag to the overlaps will strengthen the transmission of noise to the neighbors below. That is why it is more likely to make a floating mount with an anti-vibration substrate.

Tip! To enhance the strength and rigidity of the frame, it is recommended to bore the bars between themselves with crossings by cropping boards and corners of 4 * 4 cm.

Laying Lag on the soil

The flooring device in a wooden house on lags on the first floor can be installed directly to the ground.

- First of all, you need to align and tamme the soil. This can be done manually, building a device for thrombling from a large log and a wide board from below.

- Then you need to mark the columns that will support lags. At the edges, they will have to rely on the foundation. The extreme lags must be installed almost at the wall, with a gap of 5-20 cm.

Filling a tie of the floor - how to qualitatively make a reliable basis "href \u003d" http://shkolapola.ru/ustroystvo/styazhka/560-zalivka-styazhki-pola "\u003e Filling of floor screed in lighthouses, and self-leveling mixture, sand, depending on his status.

Before laying, you need to sash on concrete waterproofing from a plastic film. It is also extremely desirable to put on the lags and from their ends with soundproofing substrates to reduce the transmission of vibration noise.

It is advisable to use bars to the entire width of the room so that you do not have to dock them. The insulation is laid between the lags installed.

Many ask a question whether it is necessary to hardly fix the lags to the base? The device of floors on the lags on a concrete base allows them to be fixed with the cement-sand mixture.

However, it will be necessary to protect the boards with bitumen insulation or hydrokhotloxole. The coating is placed only after drying the solution. In this case, you can set the lags into one plane, by saving the solution to them.

However, it should be borne in mind that the rigid fastening of the lag to the overlaps will strengthen the transmission of noise to the neighbors below. That is why it is more likely to make a floating mount with an anti-vibration substrate.

Tip! To enhance the strength and rigidity of the frame, it is recommended to bore the bars between themselves with crossings by cropping boards and corners of 4 * 4 cm.

Laying Lag on the soil

The flooring device in a wooden house on lags on the first floor can be installed directly to the ground.

- First of all, you need to align and tamme the soil. This can be done manually, building a device for thrombling from a large log and a wide board from below.

- Then you need to mark the columns that will support lags. At the edges, they will have to rely on the foundation. The extreme lags must be installed almost at the wall, with a gap of 5-20 cm.

I-14 \u003d ""\u003e insulation

Since the lag laying device allows insulation inside the design, at this stage you can fill the cells between lags insulation. Most often for this use mineral wool, extruded polystyrene foam, foamizol, sawdust. If the lags are installed on the soil, the insulation must be laid on the draft floor.

For the isolation of a wooden coating from evaporation and condensates, you can fix on the lags before the covering sheets of vapor insulation (pergamine) on the stapler. If at the bottom is dry and warm, you can do without it.

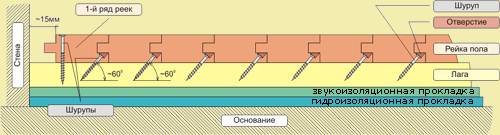

Sheathing floorboard

The floor cover is starting from the far from the corner. It is important to leave the temperature gap of 10 mm around the perimeter of the walls, which then hobs the plinth.

The casing is placed perpendicular to lagas.

- Flooring has a spike on one side, and with another groove. We put the first row with a spike to the wall and secure it on top of the self-tapping screw to the lag. Additionally, fasten this board on the side of the groove, screwing down the self-tapping screw at an angle of about 60 degrees. Boards need to be shorted so that their joints are in the center of lag.

Note! It is very important to put the first row to put exactly, as it will set the direction of all others. At the same time, it is impossible to repel from the walls (they can be curves).

- The second and the subsequent row is joined with the previous one. For dense docking, they need to be hammer through the gasket. Unlike the first row, it is necessary to fasten them only on the side of the groove so that the screws are not visible.

- Thus, the device of the adhesive floor is made along the lags throughout the rest of the area. The last row will need, most likely to cut off.

Note! Sevective rings on the boards should be alternating. In one row, they should look in one direction, and in the other - in the opposite.

- The length of the self-tapping screws should be the thickness of the genital board 2-2.5 times. For example, for a 27 mm boards, the screws of 3.8 * 55 mm will be optimally used.

- If the finish will be used to be used on top of the boards, the screws can be screwed into the usual way - on top, and not at an angle. So it will be faster, but the hats will be visible.

- Pre-drilling holes will save the splitting boards and allow them to close them.

- It's better not to use nails for this business, as they overwhelm it over time, and the boards will begin to creak. If you still decided to mount the boards with nails, then take them with a length of 70-100 mm.

Tip! During the boost of the boards, one edge will fly out of the groove. For temporary fixation, you can use the clamp, which will attract the board through the gasket, as shown in the photo.

The use of this technology will allow you to correct the significant irregularities of the overlap and will evenly distribute the load, but you will have to sacrifice 7-10 cm of the ceiling height. Instructions on the video in this article will show you in practice, how the device of the black floor is done on lags:

"width \u003d" 640 "height \u003d" 360 "frameborder \u003d" 0 "allowfullscreen \u003d" allowfullscreen "\u003e

The dignity of the wooden floors is a lot: they are distinguished by elasticity, silent, heat. They are attractive in appearance, non-slip and easily repaired, which is very important, as a considerable number of seams and the risk of cracking - their constant "travelers". The key to durability, strength and evenness is competent and qualitative preparation of the foundation.

The technology of the wooden floor device is primarily determined carrier design. With all the variety, they can be classified into two types: on screeds (monolithic or prefabricated) or separate on lags.

Concrete base flooring

The wooden flooring device in concrete involves performing a certain type of work.

Determining moisture tie

The concrete base should be sufficient dry - the regulatory humidity is less than 3%.

Mounting on a fresh screed board can be the earller in three months.

To assess the degree of moisture content of concrete there are special portable devices. However, check the status of the tie, albeit with some error, can be very simple way. The polyethylene film (1x1 m) or a square of transparent plastic (30x30 cm) is tightly glued with a scotch to its surface and after 24-48 hours are verified for the presence of condensate on the inside or a dark wet spot on concrete. An insignificant condensate or its absence, like stains, allow you to start laying the floor.

Basic Alignment

Overlooking the surface can cause a violet or sediment of the flooring. To check the level of inclination and evenness, use a 2-meter rail and the construction level, which are applied to the surface of concrete in several places. The level will indicate a bias, and the lumens under the rail are low.

Small defects, elevations and depressions are eliminated very simply:

- low - align in bulk mixtures;

- high sections are removed by grinding.

Pair and waterproofing device

The finished tie is treated with a primer. It performs at the same time two functions: impresses and envelops the surface, creates a pair-hydro insulation. If the cement-sand layer is well succounted, then a single-component primer mixture of polyurethane is used as a primer, and for new or insufficiently dried - 2-component epoxy, which is applied to several layers. Works continue after drying the primer.

Some prefer more traditional way Waterproofing with rubberoid or polyethylene. Isolation sheets are placed on a concrete with an overlap at least 10-20 cm and glued together with a construction scotch or mastic. If the floors below have increased humidity, it is better to lay insulation in two layers using bitumen mastic.

It is also recommended to perform a wooden flooring device with insulation and sound insulation. Additional advantages are pleasant to the touch, warm and prevents the spread of outsiders. Perform thermal insulation is simple enough:

- if the floor is laid on the paneur, then use materials such as foamed polyethylene;

- mounting lags, between them laid the insulation, say, the plates of mineral wool.

What will the next step be determined, based on the selected mounting option.

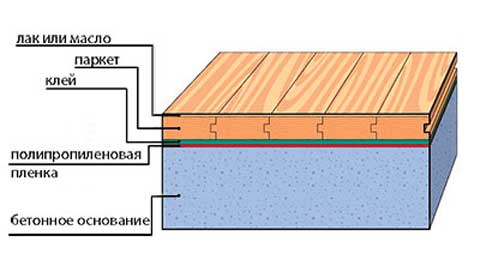

Technology gluing Halp

It involves laying boards directly on the screed. Perhaps this is the easiest and most common technology in the world today. This technique is perfect for the buildings of the private sector, new buildings or any other, where there is no need to raise or align the base.

Among the advantages of such a design should be noted:

- this technology costs significantly cheaper than any other way;

- no loss in the height of the room, since the floor rises only on the thickness of the wooden coating;

- to gather for anyone, so simple installation;

- the design of this type is ideal for mounting "warm floors".

A glue is applied to the concrete surface, for example, one-component elastic polyurethane glue modified by silane.

The second layer is placed polypropylene or polyethylene film, not less than 10 mm in thickness. To ensure the required thickness in the case of a thin film, it is dismissed into several layers, which each other must overlap. On the perimeter it is necessary to ensure a small occasion of the film on the walls.

The film is covered on top of glue, on which the floor is outdoor material. The wooden floor is opened with varnish, oil, paint, etc.

What to pay attention to the installation

- the base should be varied smoothness and durability, without crack; The magnitude of the permissible deviation is 3 mm for every 2 kV. m;

- it is not recommended for alignment, since their incompatibility with glue is not excluded, which can shake the reliability of the structure;

- for better fixation on the coating area, the load is used;

- between the coating I. doorways, walls, thresholds and columns require compensation gaps in 1.0-1.5 cm, fill them with a cork compensator.

To ensure sound and thermal insulation, it is necessary to pave an additional layer of insulation - most often it is a technical cork or isolon. It is located directly under outdoor coating On a polypropylene film covered with glue.

Laying on Faneru

To equalize the base, use 12-18 mm moisture resistant fane or OSB plates. Standard sheets are cut into stripes (width 40-80 cm) along the smaller side and laid diagonally to the future direction of the coating, leaving the gaps of about 4 mm. Fragments are glued, after which it is fixed to the screed: either with the help of self-tapping screws, or targeted by dowels. The plywood canvas before laying the wooden floor is roughly grinding and cleaned from dust.

Advantages and features of technology

- used to equalize deviations at an altitude of up to 10 mm;

- this method of alignment is much cheaper than the use of aligning mixtures;

- thus, you can align the height of the floor in different rooms.

When installing, you must adhere to the following instructions:

- the thickness of the plywood or OSB plates should be at least equal to the thickness of the boards on top of the boards;

- to increase the adhesion, the surface of the sheets grind and ground.

Laying on lags

In cases where the horizontal deviation is more than 1 cm, use a more complex technology - laying on lags, which are assembled with increasing income than 50-60 cm.

Fastening the lag to the base can be performed in several ways:

- with the help of screws and dowels - their heads need to be "drown" lower than the surface level by 3-4 mm;

- by gluing - for this use glue or bitumen-containing mastic.

- on sound insulation pads, preferably from Feds.

Thanks to this design it becomes possible

- an additional heat insulation device with insulation laying between lag;

- alignment of the base with a significant difference in heights;

- avoid the level of alignment of the concrete surface itself.

This design, however, reduces, and significantly, the height of the room.

A more advanced technology is considered to use in the design of the floor of the adjustable lag, in which the height of the installation varies with a simple rotation of the bolt.