Economic furnace, economical furnace

When in 1994 I put a hop of 6 6 meters, the question arose about choosing a stove for heating, quick drying of winter clothes (especially boots), cooking food in terms of frequent power outage and, finally, in order to constantly be warm water . BUT  my wife wanted to have an oven.

my wife wanted to have an oven.

It was assumed that I would live in this house. The furnace was needed small and economical to manage a small amount of firewood and tram it once a day.

When describing its furnaces, the authors usually do not talk about the consumption of firewood, modes and duration of the furnace and other important issues of their operation, carried away by the description of the design and laying technology. This is understandable, because many contradictions concluded in the operational requirements for the furnace. It is difficult at small dimensions and a small mass of the furnace masonry to ensure its multifunctionality, greater heat capacity and a small consumption of firewood.

By that time, I had already had experience in operating spinning, including a water tank for water heating. And I had an idea to accumulate warmly not in brick masonry, and in a tank with water. Water compared to the brick has a greater heat capacity, as a result of convection, it heats up faster and gives accumulated heat into the room for a long time. These properties are characteristic of water with a temperature below the boiling point. When boiling, all heat supplied to water is spent on vaporization. The heating mode of the tank without boiling liquids in it allows to save not only on firewood, but also on the water.

In addition, pairs indoors are harmful for both the log cabin and the health of people. Therefore, for the tank it was necessary to find not  good is the optimal location of it in the body of the furnace, but also the form.

good is the optimal location of it in the body of the furnace, but also the form.

By profession, I am not a cook and experimenting with masonry on the eve of winter did not, but found a master with whom we discussed the idea and details of the design. Soon we built such a furnace.

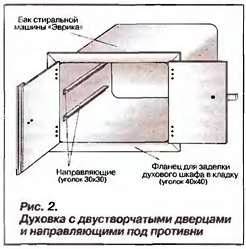

For the water tank and for the oven, I used the drums in size with sizes 350x350x390 mm from stainless steel from Eureka washing machines. For the smoke tube there was an asbetic pipe 0175 mm. In the drums brewed holes at the bottom. The drum, which was intended for the water tank, brewed most of the top and made a folding lid, and the crane turned on the side (Fig. 1).

The water tank fastened so that a third of the volume beyond the oven dimensions. This allowed conveniently filling the tank with water and provided heat exchange heated water with air room.

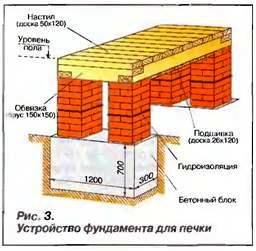

The live shop with whom we worked, insisted on the device under the furnace monolithic foundation and a solid base of bricks. I considered the load and found that the entire stove with a pipe, firewood in the furnace and water in the tank will weigh no more than 400 kg, while one laying of a continuous base under the furnace would have weighed more tons. I note that for 10 years of operation of this furnace, the level of wooden flooring, removed to the floor level of the room (Fig. 3)not changed per millimeter.

Foundation for the furnace I set, retreating from the wall by 350 mm. Bottom cavity  under the flooring was made by a pergamin, completely filled with glass gamble and top covered with polyethylene. The gaps between the foundation flooring and the floor I stole a mixture of PVA glue with sawdust.

under the flooring was made by a pergamin, completely filled with glass gamble and top covered with polyethylene. The gaps between the foundation flooring and the floor I stole a mixture of PVA glue with sawdust.

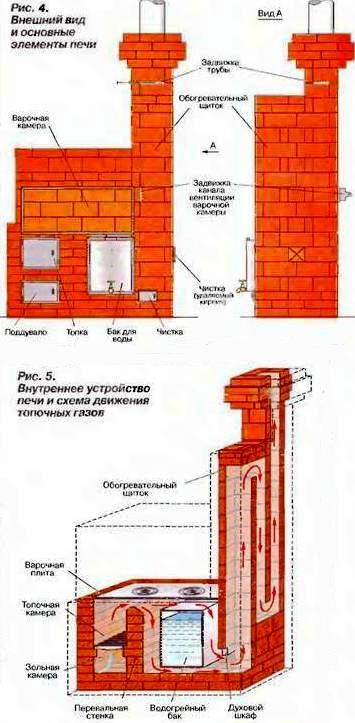

The furnace is simple (Fig. 4.5). The oven is located opposite the water tank. The space between the tanks is laid by brick. The cooking cam is posted in a quarter of a brick and has a vault that relies on the strip iron. Next to the cooking chamber, the cook on his own initiative made a small attack on which the boots can be dried. The mouth of the camera around the perimeter is framed by steel corners 35x35 mm. It was planned to attach the doors to close the chamber during the cooking of the sawarer for goats having a specific smell. But the goats had to "part", and the doors did not put the doors.

When firefed, the air out of the room through the pensive door enters the ash chamber with dimensions of 270x200x550 mm, the rear of which has a rise. Then it rises through a grid through a grate to the fiber chamber with dimensions of 270x350x550 mm, where firewood is burning. Having passed above the transferred wall in the Pollipich, through the slot 75x500 mm, the hot gases are overpowered from above and below the tank with water and placed the oven. The passes above the tanks have a height of 70 mm, on the left and right - 80 mm, and below - also 70 mm. The width of the passages is 500 mm. In the area of \u200b\u200bgases in the heating pad channels installed doors for cleaning.

The cooking chamber is reported to opening with the output channel closed by the valve. This opening is necessary for the withdrawal of vapors and odors in smoky pipe. It is also used to warm the pipe when the temperature in the house is lower than on the street, and there is no traction in the furnace or it is reverse. This fact can be easily established by deflection aside by  camping flame raysin or candles in front of the opening door of the furnace. To have a normal thrust, one or two lit newspapers should be lowered in the output channel. The output channel is heated in this way - a guarantee that the furnace will turn around without smoke.

camping flame raysin or candles in front of the opening door of the furnace. To have a normal thrust, one or two lit newspapers should be lowered in the output channel. The output channel is heated in this way - a guarantee that the furnace will turn around without smoke.

The heating shield is posted in a quarter of a brick and has three channels (turnover). In the laying of the passage between the second and third channels there is no brick half - this opening is needed to clean the second channel and the exhausting of soot when cleaning the chimney and the third channel. When laying the furnace, this half is inserted on the outer coating and, if necessary, it is easy to remove it. I do not give a laying order, as it depends on the size of the available furnaces and tanks. At the end of the third channel, an output valve is delivered.

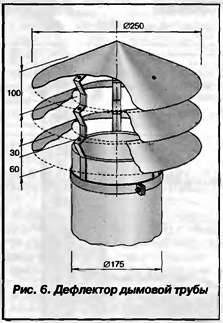

The chimney is removed 200 mm above the roof skate. Three-tier deflector installed on the pipe (Fig. 6)which significantly increases the thrust and prevents sediment in the pipe.

Channel cross sections in the shield - half of the brick. To clean the chimney in the zone between the second and third channels, the brick is inserted easily. In the third channel, a window is done in the cooking chamber, which overlaps the valve. Before the disadvantage, the valve is installed, which overlaps the smoke canal at the entrance to the pipe.

This small furnace of 1500x640 mm has been serviced for 10 years. In winter, when frosts up to 20 °, it is enough to protrud it once a day. However, in strong winds (the house is in the open space), as well as in very coldy, it accounts for twice, but every time only one wood laying.

Before the crossing, clean the grille and put on the far end of the carbon chamber, chips and setting together. I closes the door to the furnace, and the door pissed the outdoors to open. When the extracts grow up, laying the full fuel chamber of firewood. And when they spoil, I almost completely close the door pissed and gradually, as the flame decreases, I begin to cover the output valve.

Firewood I use only dry, mostly pine! Birch is too strongly split bricks in the flood chamber, which must be protected. Prepared firewood folding  on the closed veranda. Behind the stove, I keep the lamp on 34 fireboxes. There they better dry out.

on the closed veranda. Behind the stove, I keep the lamp on 34 fireboxes. There they better dry out.

Length try to chop the same in thickness so that they are roasted at the same time. Puffing wood gives little heat and in the frosts such a furnace have to drown twice.

When the combustion goes into the depression, I leave for about 2 cm in the output valve approximately 2 cm. In this case, it continues to smolder for a very long time (4 ... 5 hours), while carbon monoxide is released, which tramples in a warm heater shield and gives the heat. By the way, it is according to this principle with high efficiency of type "Bulleryan", "Sinel" and others. I close the output valve completely, only when I am convinced that after the movements of coal there is no money.

The temperature of the water in the tank during the furnace reaches 8085 ° C, the temperature of the shield rises to 5060 ° C. The pipe in the attic heats up only to 4045 ° C. In such mode, the stove becomes hot very quickly, after 15 minutes. The temperature in the front of the room is noticeably rising.

It is especially pleasant to quickly melt the furnace and after 1015 minutes he gets heated when you come from the street the extended, and in the room it has long been not fan. Thomart hands can be shoved in the warm water of the tank, and they are immediately warmed.

You can judge the advantage of a zkonny method of firebox by the fact that it accumulates more than 100 kg of ash for the winter - this is the most valuable fertilizer for the garden and the garden.

With this mode of firebox, that is, the decoration of firewood, in the channels of the shield and in the smoke tube there is a lot of soot. For cleaning the chimney, I occasionally flowing in the maximum mode - with a fully open output valve and half the open door pondered. Then the furnace buzzes, the firewood is cracking (that many love) and most of the soot fuses. In the maximum thrust mode, all the ash flies into the pipe, and in winter on such days the snow around the house becomes black.  However, if the channels in the shield and the chimney have time to strongly influence the soot, even with a fully open output gaming and the door pondered the thrust lacking for burning soot and it will accumulate.

However, if the channels in the shield and the chimney have time to strongly influence the soot, even with a fully open output gaming and the door pondered the thrust lacking for burning soot and it will accumulate.

Constantly exploit the furnace at maximum thrust is impractical. Initially, such a furnace temperature in the room drops 24 ° C and only then begins to slowly rise. The decrease in temperature is explained by the fact that with a maximum thrust through the furnace, much more air passes, which is necessary for the combustion process and most of the heat released is spent on its heating and carries into the pipe. Pressure drops in the room, and flowing through all possible cracks cold air from the street, from the sample, from the neighboring rooms, reduces the room temperature where the furnace is worth. When the firewood flared up, the heat released begins to be missed and for heating. But the firewood burns very quickly - for 40 ... 50 min and do not have time to warm up brick and water in the tank. The efficiency of the furnace in the maximum burden mode becomes two times less than in the minimum thrust mode, correspond to

venno and firewood in the first case need more.

For 10 years, we are with a stove as it were "became friends." I am her shore, and she gives me warm. Does it mean that she is  i completely satisfy? Of course not. And I had thoughts on its modernization. Here are some ideas about this.

i completely satisfy? Of course not. And I had thoughts on its modernization. Here are some ideas about this.

- The furnace is made from a high-quality, but ordinary building brick, which in the flood chamber has already burned down and sparkled, especially at maximum thrust. Consistent temperature differences could not go to him. And I already acquired refractory brick. After its installation, it will be possible not to be afraid of sharp temperature jumps.

- The oven in the furnace is practically not used. I have long laid it to increase heat capacity, but this is not the most the best way. The volume of the existing water tank is almost 50 liters. If you replace the oven and the tank per large water containerThe amount of water heated can be brought to 150 liters. That is, you can increase the heat capacity of the furnace. But this container makes only to order, and I have no money yet. Having made such a container, you can think about water heating bathroom and adjacent to the veranda of a warmed room. Calculations confirm this opportunity.

- The chimney slot over the tank is greater than below, and almost all hot gases pass on top, respectively, they are heated more at the top. Beyond this, the water is heated slowly, and the bottom of the furnace is not heated for a long time. That is, 30 bricks are excluded from the heat transfer. To direct the main stream of hot gases down, you need to push the tank slightly and up, make a reflective protrusion and rounding in the top of the wall (Fig. 7).

- The master when laying the furnace for some reason did not bring the second and third channels of the heater to the bottom of the furnace, which means that it does not participate in the heat exchange, because of which the right lower corner of the furnace does not heat up (see Gas Movement Scheme in Figure 5)

- Since the cooking chamber is almost not used, and its overlap is used often (there is an ideal temperature regime for drying herbs, crackers, boots, etc.), then the back wall of the cooking chamber could be removed, lower the camera cap and whip it from the inside For better reflection of thermal rays.

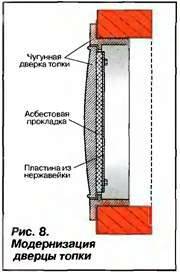

- When choosing a door for a flue chamber, I drew attention to only that it closed tightly. However, during the operation of a powerful overheating, the door was deformed and began to close loosely. Therefore, I decided to replace the door of the flue chamber, putting on it from the inside the screen of stainless steel with a gasket from asbestos (Fig. 8).

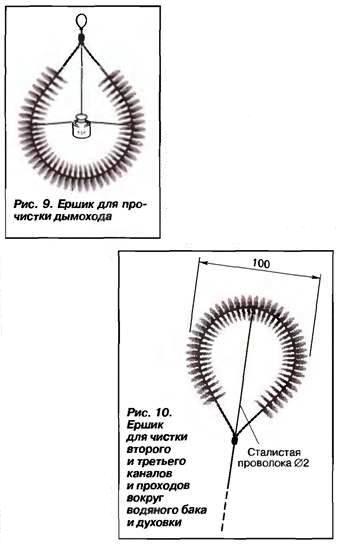

I clean the oven once a year before the start of the heating season. At first, with an open output, I remove the deflector and read the chimney pipe with a rigid piercing brush, bent into the ring. In the middle of the ring strengthening a kilogram weight (Fig. 9).Multiplely pulling the Yers for the rope, the end of which I pre-tie to the pipe, and read the pipe starting below.

After cleaning, we dress the deflector in place. Then we take a brick from the panel between the second and third channels (in the room everything you can, cover a pre-film to protect against soot), and carefully absorb the accumulated soot there.

Houching the ERS to the elastic steel wire 02 mm (Fig. 10), I can read the second and repeated - the third channel of the shield. Through the burners, I can read the passages from above and from the sides of the oven and water tank. Bent a noche

door for cleaning space under the tanks. In completion through the same door, I can read the first channel of the shield on the wire on the wire. Do all this is necessary in the respirator.

Having finished cleaning, I put in place and smear the clay brick cleaning. Carefully examine the oven and silence the place where she cracked or outdated. Mostly it happens near the slab and the door, and outside the furnace did not crack.

Design of barrel

Not everywhere and you can not always take advantage modern methods Heating of their homes, cottages or garages using such heating devices as gas or electric boilers. And then the stoves made by their own hands come to the revenue, called bourgeois. Despite the primitiveness of these devices, the efficiency of the Bourgesics is sufficient for heating a small room. Especially since it can be treated with both firewood and any other fuel - coal, peat, woodworking waste, or just garbage, which is always in excess in any farm.

Types of homemade stoves of long burning

For heating of small rooms, brick furnaces or metal (burzhuyki) can be used, capable of working on both solid and liquid fuel.

Brick stoves long burning It is rarely built, because not everyone is able to lay them out with their own hands, given the special requirements for the material and the device of the chimney.

After all, the incorrectly made chimney tube will turn into solid problems with insufficient and smoke the room. In addition, the purchase of chamotte brick and the same powder for the solution will require decent money. Yes, and my brick ovens itself takes a lot of space that for such premises, like a garage, a small country house or a greenhouse is not acceptable.

In the, called bourgear, can use free fuel in the form of spent oil, which does not require further disposal and brings tangible benefits.

What are the advantages of the bourgeoke?

First of all, such long-burning devices are distinguished by low profitability. Indeed, for their manufacture, as a rule, containers used in use. They can be purchased completely free either for the minimum cost. The same can be said about the price of fuel.

Besides:

- Bourgehinka can be made with their own hands, if you find successful and understandable drawings of its design.

- With small sizes, it has sufficient efficiency.

- For her there is no need to make a powerful foundation.

- No need to make a bunch of permits.

- Simple maintenance and free installation.

- Bourgesic, except for the heating function, can serve as a cooking oven.

Important! The burzhuyka is the most profitable structure when it is necessary to quickly heat the room of a small size, and where it makes no sense to set capital heating. It may be a garage, a cottage with seasonal accommodation, economic buildings or a greenhouse.

Door for firebox

But despite all the advantages of similar furnaces built with their own hands, they have such disadvantages as rapid fuel extensions, as well as rapid cooling due to the inability to accumulate heat. All these disadvantages can be eliminated if applying advanced types of furnaces and build accumulating heat designs.

Requirements for the construction of bourgeoke

The economical furnace of long burning on firewood should meet some requirements and rules of the device:

- In obligatory, such a structure is equipped with a chimney pipe, and the room is equipped with a supply-exhaust ventilation system.

- Given that the design of the burzhuyki when heated is raised to very high temperatures, it is necessary to comply with the requirements of fire safety when it is installed in the room.

The furnace should be located away from the flammable designs of the walls, the ceiling and gender, as well as to have a fence to eliminate the fire and the risk of burning burns during its operation. The bourgeois is fenced with a wall-resistant brick wall not only becomes safe when working, but also creates additional heating areas.

Constructive scheme of the bourgeitake device on firewood

Similar heating devices can be the most different appearance and method of manufacture. But in each of them is a metal thickness of at least 3-4 mm.

Scheme of chimney

Common elements for them serve:

- firebox;

- solnik;

- chimney pipe;

- door;

- copyright.

For the manufacture of the stoves are used:

- former in use metal barrelsif the thickness of their walls is not less than 3 mm;

- gas cylinders;

- iron pipes and just sheet metal;

- metal corner;

- pipe from tin or asbestos-cement;

- grate.

Regardless of the shape of a long-burning stove, be it a barrel or a welded rectangular shape of sheet metal, it is divided into two cameras - combustion and ash bar. The latter is characterized by a smaller size than the furnace. Both branches are supplied with holes and doors.

Colonsets

A grade grille is mounted between the furnace and the ashite, and the door is attached to the opening the chamber, which should have a reliable valve. The grate grille on which firewood is stacked, strengthens the thrust in the furnace and serves simultaneously to sieve ash into the ulter separation. Hence it is cleaned as accumulated.

Standard grate

Depending on the fuel used, the grate can have different extent of longitudinal holes. If coal is used in fine fractions, then the slots in spokesipers should be within 1-1.5 cm, for large fuel, this value must be increased to 4 cm.

For the roller chamber, you can make a small metal box. With it, it is easier to remove accumulated ashes, simply by removing the bin from the hole.

Chimney

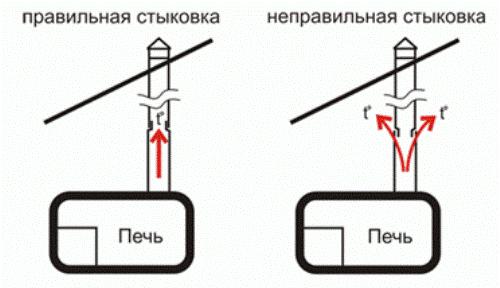

In the upper plane of the furnace, the hole corresponding to the diameter of the chimney pipe is cut. The pipe itself may have a curved shape and be located under a slope, vertically or horizontally. In the case of horizontal location, the speed of movement of hot flue gases will be significantly lower. As a result, the heating of the room will happen better and faster. The pipe is needed with a diameter of at least 100-120 mm. Otherwise, you will get a problem - smoke burgundy, and you have to make a lot of effort to correct the design.

But it must be remembered that horizontal pipes of the pipe should not exceed 1 meter length, their slope must correspond to 30 degrees. A portion of the pipe coming out of the stove should have a wall thickness, as in the bourgeois design itself - at least 3 mm for 1-2 meters. Further, the chimney can be made from a thinnest metal - 0.7 mm, since the temperature of the flue gases is no longer so high here, as at the beginning.

Finished design

It is important to remember that the use of asbestos-cement pipes can be used only on the spin of the chimney, where the temperature of the assigned gases is minimal, that is, outside. If you decide to deliver such a product directly to the furnace, then get ready that it will soon be repaid under the influence of high temperatures or cracks. But asbestos cords can be seen the cracks in the design, if such were formed due to poor-quality welding works. They are quite capable of withstanding high heating.

The outer portion of the pipe should be as high as possible relative to the level of the roof of the heated construction - 1.5-2 meters, which is well affected on the quality of the thrust.

Installing the stove

The whole design is installed on the strapping welded from the corner. For a stable position of the stove, it is necessary to organize a solid base covered with iron sheet. It is necessary to protect the floor from accidentally departing sparks and coals at the time of loading the fuel in the flue chamber.

Podophaling metal sheet should perform for the dimensions of the stove 20 cm on three sides. From the fourth, front, side, it should cover the floor before confused and the furnace at a distance of 55-60 cm. These are the rules of fire safety for all ovens of long burning on firewood and other types of fuel.

All joints should be absolutely hermetic to prevent the release of smoke into the room, which is harmful to health and traction. The outer part of the pipe, which should not be less than one and a half meters, must be fixed with wire stretch marks, and its top is covered with an umbrella-sparking.

Improving the stove to increase the efficiency

Suitable for garage heating

To increase the performance of the bourgear stove, the chimney pipe can not be built without behind, as is done traditionally, but on the front directly above the heat chamber. In this case, the stove walls will begin at first, increasing thermal returns. And if the furnace itself and the pipe hold the brick, the cooling time will increase significantly, which will lead to fuel economy. In addition, if the size of the structure allows, you can make the inner walls in the cooler compartment from chamotte brick, that is, to spend a lining of the furnace.

Another method of increasing the heat capacity stove-bourgear is a device of additional fins. For this purpose, strips of thick metal, located perpendicular to the walls, are welded to the side walls of the furnace outside. It increases the heated area, which hears the surrounding air faster. If you install a water container on the stove, it will also contribute to long-term heat conservation after the cessation of the furnace.

The furnace with woven ribs can be protected by a special metal casing or heat-resistant materials. This will reduce the risk of burning during the furnace firebox.

Another way to increase the efficiency of the Bourzuyki stove is to tear up the hollow metal pipes of large diameter. Their ends at the top of the stove will be directed to the opposite sides on the principle of buleryan furnaces.

Why the bourgeois smoke?

It happens that done with your own hands is badly melted, and smoke instead of going to the pipe, enters the room. It would seem that everything is done according to recommendations and drawings, but the problem remains.

Non-standard chimney

There are several reasons for this:

- raw firewood;

- non-compliance with the diameter of the chimney pipe and the sizes of the heat chamber;

- insufficient smoke length over the roof of the room;

- large sizes pondered (ash bar) and other factors.

The problem with raw wood is solved simply - they need to be stored under a canopy.

If you, for example, the sizes of the furnace within 70 × 70 cm, then the diameter of the chimney must be at least 110 mm. And the size of the ashtar, which regulates the incoming air flow into the flue chamber must be at least 3 times less in volume than the furnace itself.

The height of the chimney pipe is written above.

Conclusion

As you can see, make the stove of long burning on firewood is not so difficult if you comply with all the recommendations and tips. First of all, when building burzhuyki, it is necessary to pay attention to security issues. In this case, the cheap heat will not cause burns or patronage poisoning and smoke gases.

Fuel type: Firewood

Oven with catalyst

Warranty: 3 years on the oven, 6 years on the catalyst

Production: Canada

Characteristics:

Economical stove It may have small sizes, but to fulfill all their functions to the fullest. All this is possible with small heaters from the Vermont Castings brand. These models can exceed the work of large heating devices - fireplaces, but take a little space. Power is also impressive - 10 kW and above.

For country houses and cottages often this option is the right one, as miniature models economical furnaces Very easy and practical in the installation, when planning at home, the design of the furnace does not need to be considered, as it takes a little space. It is very convenient, and the choice for installation is not limited, the main thing is to choose a place for the opening of the chimney pipe.

Vermont Castings ovens are made by english traditionsThis explains the elegant furnace design. Dutchwest Small oven with heat recovery up to 10 kW and efficiency of 70%. One long-lasting firewood of firewood into the furnace is enough for non-stop work up to 8 hours. During this time, the whole house will be able to rush in full. This option is good for country house Also that it has a cooking surface, where you can cook food, warm the water. In economic purposes and heating, this option is a real find. The furnace is made of cast iron, has a side loading of firewood, and a specific known length of 50 centimeters firewood. Long the work of the furnace is provided economicity Fuel consumed, you spend less than firewood, and you get a well-sandy house as a result. A small economical oven will be able to help in heating both small spaces and large enough.

The cast-iron small-sized furnace is a great option for the extract, which can be made once a day, apply it as the only heating element - and that is enough to fully heat the space at home. Comfortable heat provides a special system supplied in English furnaces Vermont Castings.

Such furnaces will also become ideal assistants in creating a colorful situation in the house. An elegant powerful stove of small sizes is gracefully departed accents in any house. Complete the stove with characteristic furniture - the headroom of vintage chairs and the table, and the atmosphere reigning in the English living room will fill the space of your home.

Economical bubzhuyka oven.- This is not always a label of large sizes, modern collections from the brand Vermont Castings will show you a completely new approach in your models of powerful economical miniature stoves.

Homemade Economic Stove for Heat Heating

Today, the greenhouses use a variety of heating devices, differing in both structural features, and by type of fuel. They work on electricity, gas and solid fuel. You can make a good oven for the greenhouse with your own hands, you can buy a ready-made model - here each is already determined by its capabilities and the planned budget. Here are just those who are confident: a greenhouse is not a house, but therefore inserting a lot of money in her heating is no sense - the idea simply will not pay off.

Therefore, consider the most popular options, how to make a good oven with your own hands - they enjoy tremendous success among gardeners and are not practically inferior to expensive industrial models. In this article we will look at the manufacture of the most popular types of ovens for greenhouses.

№1. Brick oven with borov - Anglass

Massive ovens for greenhouses exclusively on firewood is better to build with Borov - this is a horizontal tube with a rise in the flue gases, which provides good traction. For the construction of such a furnace for heating your greenhouse, you must get a pair of old iron pipes And at least two iron plates from old brick stoves, plus approximately four hundred stove bricks - new or used, no matter.

So, the first thing you need to build a foundation for such a furnace - better monolithic, along the entire length. "Walk" he should not - otherwise it is not to avoid cracks in the walls. It is possible to make it from concrete, and it is also possible: to firmly connect two plates with a frame from pipes.

In the upper part of the furnace you need to make two pipes for air passage inside the greenhouse. The thrust will always be created due to the fact that the air in the greenhouse is resolved - goes on the combustion of firewood in the furnace. It is only important that the cleaner door is tightly closed. From the very greenhouse, the air will pass through the side pipes into the confusion chamber, and the pipes themselves are connected to the channels. In the channels, the air will fall through the air intake, and then the soil will warm in lateral beds.

Over the furnace, we have a water tank - early spring will always be warm water for watering, and on hot days - extra humidity for cucumbers and pepper. To the same, this furnace will be from the street. And to clean these channels, there is a special door and a camane at the bottom of the riser where it is possible to rack the South. It is convenient to do this with a rigid brush on a long handle.

№2. Standard greenhouse furnace on sips and firewood

It consists of such a furnace for a greenhouse of long burning from the fuel compartment, over which - the second bottom, then - the hole with the door and pondered. As well as the chimney with the metal valve and the lid - everything is simple.

The fuel can serve chips, sawdust and small firewood, only to load them will be only two-thirds of the volume of the fuel itself. This is how the process itself looks like: the cone-shaped pipe is inserted and the sawdust is pressed around it, then the firewood is put on the lower part of the firewood in the lower part, the pipe is removed and the furnace cover is removed. After that, open the damper on the chimney and ignite the firewood - sawdust will also begin to smooth.

the location of the furnace in the greenhouse is very important! By placing the heating furnace in the pit, the conditions of heating are improved and the possibility of burning is reduced.

So, that's how such homemade stoves For greenhouses:

Step 1. We take a thick-walled pipe segment with a diameter of 40 cm for fuel tank and 10 cm for chimney.

Step 2. Cooking black tin or leaf steel with a thickness of 5 mm.

Step 3. Made the fuel tank: in the upper part of the pipe cut the hole in 10 cm with a diameter.

Step 4. Making a bottom of the furnace: cut out of the sheet steel with the same diameter as the fuel. And for this make marking: we put the pipe onto the sheet and supply the marker, and then we cut the circle with a grinder. In his center - we do a hole at 5-8 cm.

Step 5. About 50 longitudinal lines are needed by the next step in the pipe - with a diameter of 0.8-1 mm.

Step 6. Insert the pipe into the donyshko oven and cook.

Step 7. We make the lid of sheet steel - round or polygonal. In the center of it we make a hole - the same as the diameter of the pipe so that the roof is delighted with the french pipe. Then another hole is closer to the edge, so that oxygen and thrust can fall into the furnace.

Step 8. We make the damper - for this we take the most ordinary metal cover from cans. You can make two more handles in it for convenience, from ordinary metal rods.

Step 9. Mount the chimney - connect the clamp of the nozzle into 10 cm with a diameter and the pipe, then weld the nozzle itself to the upper side of the stove.

Step 10. We wear chimney on the nozzle and compact the connection location with heat insulating material. From above - tighten the metal strip.

Step 11. We put the oven on the support from metal profile. To the furnace we weld three or four metal profiles.

That's all! Put only a furnace in a greenhouse away from flammable materials and take into account that the heat near it will still be so - the iron surface is increasing when furnace. Therefore, look so that some gentle plants do not care.

And here is another example:

The oven for the greenhouse. I bring to your attention a homemade oven for the greenhouse.

Super turbo stove for greenhouse and at home.

Number 3. Make the oven on sawdust - profitable!

If you have your own workshop, such a furnace is a real find! And greenhouse plants will grow warm, and there will be where to do all waste from your beloved business. It is also good if there is a woodworking enterprise near you.

Owls After all - excellent fuel: well and burn, eco-friendly and cheap. They can easily get easily or acquired pressed into briquettes and pellets. For heating, greenhouses is an excellent raw material that is absolutely not demanding about the design of the furnace, why it is easy to make it yourself from what is. Often such bourgeities are collected from pipes, steel barrels and spent gas cylinders. That's just about the last version, we will tell you now.

Here is the instruction how to make a furnace from an old gas cylinder. Why of it? For laying in it fuel no longer need a conical tube and clean such a furnace from combustion products is much more convenient.

So, we take a gas cylinder with a wall of 5 mm, a grinder with cutting / credit circles, a welding machine, steel sheet, metal fittings, Studs and pipes for chimney.

Operating procedure:

Step 1. Preparing metal pipe. Cut off the top of the top - from it later we will make the lid.

Step 2. In the upper part, we cut a hole in 10 cm with a diameter where we will mount the nozzle, and in the bottom - with a diameter of 5 cm. It's a drift tube with a drilled perforation. The top is hermetically brewed.

Step 3. The nozzle is welded on the wall of the fuel tank - it is a future chimney.

Step 4. We make the lid from the upper remaining part of the cylinder, fixing its edges.

For the convenience of cleaning the furnace from the ashes to the outer sidewalls, you can breed two studs and make the basis.

4. Furnace with heat exchanger - for warm irrigation!

But how to make a stove immediately from two barrels - burning will happen in the first, and the second will serve as a heat exchanger.

So, the order of work:

Step 1. We take two metal barrels with thick walls - one on two hundred liters, the second is fifty. Ideal for cumshots from square washing machines.

Step 2. Cut off top barrels. From the smaller - we make the lid, fixing the edges of the reinforcement. We weld the handle and from three corners we make a leg length 10-12 cm.

Step 3. From the metal sheet, we cut the bulgarian partition-support for the installation of the chamber. In the center cut a hole with a diameter of 6 cm.

Step 4. Inside insert a little smaller tank with a drilled hole - also 6 cm with a diameter. The partition is placed in the form of a triangle from steel rods. The height of the support should turn out 15 cm, we put this stand on the bottom of the outer barrel.

Step 5. Under the partition we make a box for collecting combustion products. It will have a bottom, walls and knobs-brackets for opening and closing the stove. For this drawer in the wall of an external tank, cut the hole 30x13 cm.

Step 6. To the hole we weld the box of steel with a thickness of 1 mm. In its central part, weld the pipe and with the help of a clamp and thermal insulation connect the pipe to it.

Step 7. In order to protect the metal pieces of the stove from corrosion, cover all the parts of the heat-resistant paint or aluminum crumb and liquid glass.

How to work with such a stove? Layout fuel, use, as in previous versions, a cone-shaped pipe and ram around it sawdust. Then remove it and throw a lit long match in the resulting channel.

№5. Greenhouse buleryan - nothing complicated!

Making such a furnace, take a large piece of pipe with walls of at least 10 mm and "Improve" to it everything else.

Step 1. Cut the slot to the chimney - under the asbestos cord. Step 2. We provide the regulation of thrust.

Step 3. We connect two nozzles of download.

Step 4. I will brew oven and check its tightness.

Step 5. We weld the side sheets of convection cannons and deflectors from the rear.

Step 6. We weld the front carrier door frame and cut the window.

Step 7. We make doors with seal and reflective plate. Make sure that the pressure of the door handle on the doors came out not to the edge, but at its center.

Step 8. Put an intrinsic box with a regulator pondered. What is the advantage of such a stove for greenhouses in front of other models?

It's all about its heat screens - infrared radiation is not so tough, because it is transformed into thermal convection flows, and such a furnace can calmly be in a greenhouse even at a distance of just 20 cm from the walls. Those., Speaking by a simple language, from such a furnace goes to the heat, namely hot air, which is very valuable for the plants grown in the greenhouse. The front and rear wall of the furnace should be made of metal, not less than 4 mm. So, a little diligence - and a whole year you can raise anything in the greenhouse. But the oven plays and the second important role: it is hot in summer, it is well accumulating sunny heat, and at night it gives it - and the daily temperature differences are not so noticeable for the plants themselves.