Table of contents:

The furnace is the main element of the bath. The wood version is a classic for a Russian person. It is on it that all the basic functions in the steam room are assigned: heat the air and water, warm the walls, send pairs to washing. A good furnace is obliged to comply with a specific number of criteria:

- She should not take too much space in the bath

- Must be economical

- A good furnace ensures air heating in the steam room below at least to + 400s, upstairs - at least + 800c

- It should not be released gas or smoke

- If the furnace meets the requirements, then steam is formed when the water is applied to the stones

Vintage clay recipes for furnaces, which are known from the long time, exist today. It is they who help modern owners of country houses create truly Russian baths that are characterized by their quality and strength. Properly prepared clay - the best construction materialcapable of withstanding large thermal loads.

Galled oven.

The earliest prototype of the modern Russian furnace is the global modification, which was completely flattered from clay. She was sculpted in the same way as the cook loose dishes before the manufacture of a pottery circle. In certain areas of our country, such furnaces were still manufactured in the middle of the twentieth century.

And this is not surprising at all, because many builders of today's similar designs can envy their strengths, which are almost twice as old. In those days, clay with minimal moisture content was used. It was exactly so much that the composition did not lose his plasticity.

Such furnaces were manufactured in the summer when the material had time to quickly dry, without losing forms. The process was carried out by a large number of people at the same time. One or two men, it was not possible for one or two men. All tools are usually wooden. Beat the oven was taken under the leadership of the Master-Heboy.

Check quality clay

As historical practice shows, a Russian clay oven can easily replace more modern brick analogs. Brick before was needed only for the floor and laying pipes. And today the clay is used only for mounting bricks among themselves. No one is already solved to make a furnace completely from this composition.

Clay - Earthy soft rock, which, when adding water, turns into plastic mass capable of easy to create any forms. When firing, such a composition turns into a campaneous body. Depending on the plasticity, fat, middle and skinny clay are isolated. Ideally, she should be drunk with their hands, but do not adhere to them. One of the oldest methods of checking the plasticity of clay is the manufacture of a flagella of it. At the same time, the smaller the radius of the arc, in which it bends, the better.

There are several methods for determining the quality of clay:

There are several methods for determining the quality of clay:

- In 0.5 liters of clay, they add slightly water and stirred to completely dissolve it in the composition. One of the important indicators may be the fact that the material should not pester hands. A piece of prepared "test" rolled into a ball with a diameter of about 5 cm. Next, it is necessary to make a cake with a diameter of 10 cm from a similar piece and leave both products to dry for 2 or 3 days. After the specified time expires, inspect your billets. If there are cracks on them, this suggests that the solution is too fat and requires an increase in the amount of sand in it. If there is no crack, you can spend another experience: throw the ball from a height of about 1 m. If it crumble, then the composition is suitable for making a furnace. If the ball remained the whole, it indicates that you used to use the cylinder clay, and it is not considered sufficiently strong for a bath furnace. Therefore, in this case, it is necessary to add more fatty material. Sand and clay should be made in several techniques in small parts, and after each addition, it is worth checking the quality of the resulting solution. Sand can be from 1/2 to 5 parts of the total.

- 2 liters of clays are poured with water in some kind of dishes. Stirring the composition of the stick, please note whether the clay sticks to it. If it is completely covered with clay mortar, then you are dealing with a fatty rock, and sand should be added to it. Ideally, only separate clots should remain on the stick. And there is another third option when it remains covered with a thin layer material. This is an indication that you have a skinny clay in which you need to add fat.

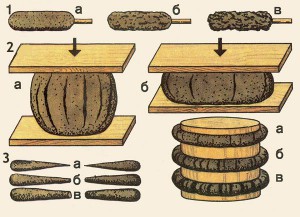

- In 0.5 liters, clays are poured some water and mixed up to the consistency of the steep dough, as was done in the first method. Of the prepared composition, the ball is formed with a diameter of about 5 cm and placed it between two powders, while smoothly pressing the hand to the upper one. The ball will gradually begin to shrink. It is necessary to continue to press until cracks appear on the clay product. To determine the quality of the solution, it is necessary to thoroughly examine the degree of flatness of the ball and the nature of the resulting cracks. Thin cracks appear on the ball made of fatty clay when it is compressed by half a diameter. The product rolled out of skinny clay disintegrates into pieces even with a slight click on it. The ball from normal clay cracks when it is compressed somewhere on 1/3 diameter.

Preparation of clay solution

Preparation of the clay solution is considered the most difficult process of the chimney. The proportions of clay in the furnaces must be selected individually, based on the characteristics of its fatness and grain of sand, if its addition is necessary. But there is a common ratio of solid components in a solution: 1: 1 or 1: 2, where the first figure is the clay content, and the second is sand. To obtain the required consistency, the amount of water equal to 1/4 of the clay is usually sufficient. Before you begin to breed a solution, you need to determine exactly what amount of composition you will need. The norms found that for masonry of the mid-size furnace, 3.5 m3 of the clay solution will be required. There are several ways to properly prepare the composition, which will then be used when laying bricks. In order for your efforts to be gone in vain, we immediately note that the prepared solution should be stored in a closed container.

For the first method, you will need to install a wooden box, a hint of tin, or iron container and soak there clay for 2-3 days. After the specified time, it is necessary to pour sand there, while mixing such a volume of the solution will have to be legs, having prepared high rubber boots in advance. It is necessary to interfere until you get a homogeneous mass without clay lumps. If it is too difficult to break large fragments of your feet, you can use any healthy tool. The remaining dense bunches must be removed by hand from the tank. At this stage, you can already check the correctness of the proportion of sand and clay you have chosen. Immersing the shovel into the composition, slowly get it. If the material slowly slides and does not stick, it means that the solution is successful.

For the first method, you will need to install a wooden box, a hint of tin, or iron container and soak there clay for 2-3 days. After the specified time, it is necessary to pour sand there, while mixing such a volume of the solution will have to be legs, having prepared high rubber boots in advance. It is necessary to interfere until you get a homogeneous mass without clay lumps. If it is too difficult to break large fragments of your feet, you can use any healthy tool. The remaining dense bunches must be removed by hand from the tank. At this stage, you can already check the correctness of the proportion of sand and clay you have chosen. Immersing the shovel into the composition, slowly get it. If the material slowly slides and does not stick, it means that the solution is successful.

An easier option is to use medium fat clay, which does not require the addition of sand. In this case, the solution can be prepared on a special shield, which is called the battle. It is poured by clay with thin layers, each of which is wetted with water. As soon as the material softens slightly, it is stirred: they are collected in small rows of 30-35 cm high, and then on this ridge they beat the edge of the shovel. Thus, it turns out that one row seems to be cut into separate pieces, thereby we achieve a complete mixing of the composition and breaking individual pieces of clay. With this method, unauthorized impurities and stones are very simply detected, which in the process of kneading must be deleted. Similar mixing should be repeated about 5 times.

Tip from Master!This method can be used with the addition of sand, if it comes to fatty clay.

The first layer on the battle is embanked by sand in the form of a wide ridge, with small deepening. The clay is on top and it is poured by water, such a mass is topped with a layer of sand. Waiting until the clay is softened, the composition begin to mix with the help of shovel in the same way as described above. It is necessary to interfere before the formation of a homogeneous composition, which slides from the shovel, and does not spread through it. Such a solution has explicit cons: it remains large sandy particles that do not allow treating thin seams. The only option to correct the situation is to filter the composition through the sieve.

The last method is perhaps the fastest. Middle fat clay must be placed in a barrel layers, each of which is wetted with water. From above, everything is also poured with water. For several hours, the material snaps sufficiently, so that you can proceed to stirring. All solution must be skipped through a sieve with cells 3 * 3 mm. If necessary, water can be additionally added in the process of preparing the solution to achieve the necessary thickness of the composition. If you need to add sand, then with this method, all components are better sifted to mix them. Sand passes through a sieve with cells of 1.5 * 1.5 mm. At the same time, it is added not to dry clay, but to already spacious and sifted. The composition is stirred and filled with a sieve again.

It is believed that the quality of the clay solution can be improved using all sorts of additional additives. For example, some assume that the addition of 100 g of the cooking salt by 10 kg of clay will significantly change the strength characteristics of the composition. But here you can argue here: our ancestors did not use any additives, and the baths served as decades. It means that the main thing is not to find all sorts of tricks, but in proper preparation of the material.

Clap-based solutions are traditional materials when equipping a home furnace. They are used both for masonry bricks and to shock the folded stove. In this article, we will consider the rules for the preparation of a clay solution - its composition and proportion, as well as how to make it properly .

Clay mortar for masonry oven

When erecting the furnace, the cement mixture prone to cracking with strong heating is used only when it is masoning its base (foundation) and the chimney head board. For masonry, only clay-based solutions are used for stucco.

For laying the base of the furnace, it is allowed to use the usual red clay, which can be found in any career. In the furnace and chimney, the bricks are fasten with heat-resistant chamotte clay - white kaolin sedimentary high density breed, which to increase the strength characteristics is burned in furnaces. Under the action of high temperatures, it acquires a cream or gray-brown shade, and after the firing is not inferior in strength even a stone.

The classic composition for masonry furnace consists only of clay and sand. If necessary, they add other ingredients that improve the composition. Manufacturers offer the following refractory chamotte mixtures:

The classic composition for masonry furnace consists only of clay and sand. If necessary, they add other ingredients that improve the composition. Manufacturers offer the following refractory chamotte mixtures:

- "Terracot": manufactured using classic furnace technology.

- "Stovetonit": with reinforcing heat-resistant fibers.

- "Door": in the form of a hammer chamotte powder.

- "Makarov's furnace house": Chamotal (unformed mass), the clay and ground refractory brick are included in the composition.

- "SPO": based on chamot and sand.

In addition to masonry and plastering mixes for furnaces and fireplaces, the construction stores are also implemented and reinforced clay compositions used for chamotte furnaces. There are also special formulations for masonry bath furnacesoperated in high humidity conditions.

Formulations: clay, sand, additives

The following types of solutions are used to perform furnace work:

- Based on red clay: able to withstand midh temperature 1100 ° C, used to masonry the body furnace.

- Fireproof chamotte: for bonding bricks in the furnace or chimney.

- Lime: refractory below average, is able to withstand the temperature only 450-500 °; It is used to masonry the base of the furnace and pipes located above the roof level.

- Sand-cement and cement-lime: Used only for the top of the chimney and laying the foundation. The cement-limestream is stronger than the usual lime, but withstands the temperature only to 200-250 ° C.

- Clay-lime: Used for plastering.

Adding salt into a masonry solution will increase its strength. 1.5-2 kg of salts are added to one bucket of the finished clay solution. The mixture after that dries longer, but it becomes after firing the monolithic and very strong.

Proportions and preparation of a masonry solution

Since clay is pouring for quite a long time, it is possible to prepare the entire volume to work at once. About 20 liters will be needed to bind 50 bricks. For the Russian ovens, the solution will be needed by more 15-20%.

Since clay is pouring for quite a long time, it is possible to prepare the entire volume to work at once. About 20 liters will be needed to bind 50 bricks. For the Russian ovens, the solution will be needed by more 15-20%.

The material is necessarily pre-crushed and soaked at least a day. You can soak it immediately in the container in which the solution will prepare. After that, the required amount of sainted sand is added to it, and everything is thoroughly mixed. You can make it a construction mixer, a drill or a wooden spatula.

The proportions of clay and sand can vary depending on the fat content of the first. On 1 part of the clay can be added from 2 to 5 parts of the sand. To find the right ratio, prepare several samples of the solution with different quantity Sand. From each rolling balls with a diameter of 5 cm and from a height of 1 m throw them on a solid surface. After falling the ball made from the "correct" clay solution, should not change the shape or crack. If he fightened - the mixture turned out too fat. Add sand. If she crashed - we enter more clay.

How to prepare a mixture for masonry is shown on the video.

Clay for stoves

You can quickly bring it in order and smeared with crack time with the same clay. Plastering of the furnace walls make to:

You can quickly bring it in order and smeared with crack time with the same clay. Plastering of the furnace walls make to:

- Reduce the risk of smoke penetration while cracking seams in old furnaces.

- Give a specific style.

- Align inaccurate masonry.

- For longer, save the heat in the stove.

Cooking with your own hands

For plastering, you can use a simple clay composition, lime-clay, lime-gypsum or make it from sand, clay and cement. The process of kneading such a solution is not much different from the preparation of a mixture for masonry. The clay mass is also pre-crushed and soaked, and then mixed with sand and lime or cement.

On 1 part of the clay of medium fat and 2 parts of the sand (it is advisable to find a clean river) added 1 part of the limestone test. When using cement, focus on the amount of sand. Than it is more, the more it is necessary to add cement. On 3 parts of the sand it is necessary to take 1 part.

When any other components are added to the clay solution, they are first mixed with each other, and only then with a pre-closed clay. Asbestos, fiberglass, hemp or straw can be added to the reinforcement and strengthening of plaster in it; 0.1 (clay: Sand: Additives).

How to make a cooler

The surface of the stove is pre-cleaned from the old solution, dust and dirt. If this was not done in the construction of the furnace, the masonry seams are selected between the bricks by 10 mm. Only pre-melted warm oven begin to flash:

- The surface must be rich in rich.

- First applied a layer called spray. For it, a slightly more liquid solution is prepared, which can be easily sprayed on the furnace with a small layer of brush or broom. Make it better twice. The second thin layer is applied after setting the first in order to close small cracks and places where the solution fell too little.

- Before applying each layer, the wall is definitely moistened.

- A reinforcement grid is attached on nails.

- It is covered with a thin layer of a very liquid clay solution. After such a priming, the main layer will stick better.

- The primer dries.

- Now applies the main layer. It should be small - 2-5 mm. If a large layer thickness is required, then it is applied again after drying.

- The last layer is the coverage, leveling surface and filling all small irregularities. Its thickness is 2-5 mm. The solution for it is prepared as liquid as for spray.

So, the preparation of the clay solution is not so complicated. But the masonry itself requires experience and care. An error in the order (masonry scheme) can turn out that the stove will merge merchandise or in the absence of sufficient traction refuses to flare up at all. Therefore, if you start this work for the first time, do it under the guidance of an experienced cook.

We hope that the article was interesting to you. Leave your questions and comments in the comments below.

As perfectly, sometimes get into the bath or just to warm up in the furnace at your own country. But initially this pleasure will be prestundable work on the construction of the furnace. But for the quality of it, it is necessary to know everything about what clay for the furnace you may need. Recall that clay has a large number of additives of different character. This is sand, and mica and lime trace elements. And, accordingly, according to such filling, it can be divided into fatty, normal and skinny compounds.

Since we already know how clay behaves in touch with water, it is worthwhile to ask the question of how it behaves when heated. In this matter, clay acts otherwise, it evaporates this water actively. And if the water has come completely, the structure becomes porous. Well, if in this situation do not stop heating, then the clay is gradually melted and baked. These are very important knowledge if a clay oven is planned, since such construction is used as burnt bricks, so converting solutions.

Features of the clay solution for the furnace

For masonry, the furnace uses a plastic clay solution. Most often, the proportion of one to one one is used to create this solution. This means that one part of the sand will be taken as much clay. As for the water in this solution, it does not take it a lot. The best calculation is a quarter of the volume of clay, which will be applied.

Many builders give a very important advice to which you need to stick if you plan to get a better solution. This advice refers to water that will be applied. It is impossible to use rigid water and it will be a definition of quality. An ideal option for such an application is water from rivers or rainwater. And as practice shows, it is this moment that can affect quality. Therefore, before starting work, you need to test the weight of the clay solution.

Checking the clay solution and its quality

From a long time, it is clay products that were used to build furnaces. And on the story it is known that creating a stove made of clay with their own hands, not only a solution, but also directly bricks was manufactured. They played the role of solid masonry material for chimney. But today they still stopped using only a clay solution to fasten the material among themselves. Ideally, it should be possible to spread it with your hands, but still such an indicator is not enough to start a confident start to create a furnace. It was for this reason that several of the lasts of the testing methods have long been preserved. Let's consider with you more thoroughly each of them.

- First you need to take half liters of clay and add quite some water to it. After adding, it is very active to knead this dough. As a result of the mixing, it is necessary to achieve a consistency when the mass stops sticking to the hands. And now, when you brought a mixture to the desired condition, it is worth riding about 5 cm with a ball with a diameter. Next, another similar piece of the dough is created, but to perform it in the form of a cake with a diameter of 10 cm. Now these details are left in full by one by one day for natural drying. When the specified period takes place, carefully check the workpieces made. At this stage, it is important not to detect cracks on the product. The fact is that cracks will indicate an overhead consistency of clay, and in this case this solution will require an increase in sand in its composition. In the event that there is no crack, it is worth a test. It is worth reset the ball about one meter on a solid surface. When maintaining the integrity of the clay will be considered skinny and for the execution of the bath, it is not too suitable. The composition needs to be made more fat, bringing clay into it with sand with small compositions. As a result of this situation, the mass will consist of half the fifth part of the total. (See also: )

- Now consider a different solution of the solution, thanks to which a clay furnace will be created with your own hands. For this, two liters of clay takes and poured with water in comfortable dishes, then start stirring with a stick. When stirring, you need to monitor clay on it. Such a test is carried out to determine the fatty clay. In the case of 100% adhesion, we are talking about fatty clay, and such a breed requires the addition of sand. So that there was a fitness of a suitable composition of fat in clay, it should be sticking individual clots. Well, accordingly, if the thin layer remains, then this clay requires the addition of fat.

- Well, another vintage method of checking clay composition On quality, this is the influx of a small amount of water in the floor liter clay and kneading the test. At the initial stage, this scheme is very similar to the first option, but after the rolling of the ball size, 5 cm the process changes. Now it is worth placing between two skulls and gradually produce smooth squeezing. Squeezing stops as soon as cracks begin to occur on the product. The essence of this method is that it is possible to determine the fatty clay.

Direct making solution

After several ways to check the clay composition are already known, it will be rationally to consider direct work on the manufacture of the solution for chimney masonry. All the masters speak one voice that it is the work on creating a clay composition is the most complex question. Note that in this work it is necessary to take into account the individual approach to the construction of each particular furnace. The fact is that any global furnaces are manufactured with their own hands in a certain ratio of solid components.

The main solution that is used in such a work is or dosage one to one or one or two. In decoding this ratio, the first digit will indicate the clay content, and the second digit for the presence of sand. As for bringing the mixture to the desired consistency, everything will solve water here. Water calculation goes to the volume of clay - one fourth part of the fluid. But for the beginning, determine the desired composition.

In construction practice there are several options for the preparation of the composition for work.

- There is a folk version of the preparation of clay, and he begins with the preparation of a wooden box. He is frowning with tin, and clay is soaked for three days. When the period takes place, sand is added to it. Only the moment is noted that with the number of that volume, which will go out, they will have to perform legs, leaning into rubber boots. And as soon as you are all high quality, you can check the correctness of the mixture. Having dippeding the shovel into the solution, the successful indicator will be when the clay solution will slowly, not sticking to the slide. (See also: )

- There is an option simpler in which the clay of medium fat is used. Such a composition does not require the addition of sand. In this situation, a special shield is applied, and the mound of clay is already produced by a thin layer and at the same time wetting water. So, gradually overlapping a row to a row, a height of up to 30 centimeters is displayed, and then the rebier of the shovel is sharply nailed. This technique allows you to separate the resulting composition into pieces. That is how in this situation you can conduct high-quality mixing of the clay composition. And in conclusion, it is worth indicating that stirring with this method is carried out about five times.

- And one more embodiment of a rather rapid focus of clay composition for the fireplace. In this method, the clay is placed by layers in a barrel and wetted with water. After some time passes, the material soften and will be ready for stirring. But in order to remove precisely from this solution solid particles, you need to apply a sieve having three three cells. To achieve the necessary density, water can be added during the mixing process. However, in the case when it is necessary to add sand to achieve the right solution, then it is necessary to sift all the ingredients before mixing. Regarding sand sifting, it is necessary to use a sieve of one and a half per millimeter.

To date, of course, you need to take into account the fact that there are many different additives that will make the mixture perfectly and efficiently. So, to perform any furnace or even a barbell with a firebox with your own hands will not be a lot of work. But still, first you need to determine for yourself the foundations of this direction.

The use of materials is allowed only if there is an indexed reference to the material page.