For the manufacture of chimneys apply various materialsSome of which have been used for several centuries, while others have become actively used only a few years ago. Any type of removal for smoke has its own characteristics, so it is important to have an idea of \u200b\u200beach of them.

Materials for chimney

The considered structural element of the heating system can be built from traditional building materials, but wealthy hosts can afford and materials created by the latest technologies. The choice of solutions for a particular house primarily depends on the economic feasibility, the requirements of fire safety and the aesthetic views of the owner of the housing. We advise you to explore more information about in addition to this article.

Metal chimneys

As mentioned above, metal pipes For the removal of smoke are divided into single-layer and two-layer. Single-layer are a cylinder, which, as a rule, is installed inside the brick or ceramic chimney. Two-layer consists of two cylinders of different radius, between which the layer of the heat insulating material is placed, the role of which most often serves basalt minvat.

Tip! If the external design of your home is decorated under ancient, then to maintain the stylistic uniformity, the metallic chimney can be covered with copper casing.

Black metal

High-quality chims from this material from above are covered with a layer of enamel, which reduces their exposure to priora and corrosion. As a result, such a product may last time at a temperature of up to 500 ° C, while admissible are short-term differences to 700 ° C.

The key advantage of pipes for drowning smoke from black metal is the most low pricebut operational characteristics do not allow them to be an effective solution for chimney heatingoperating in intensive mode.

Stainless steel

This material is ideal for chimensions of any types. Alloy stainless steel tolerates the temperature to 850 ° C well, and also withstands peaks up to 1200 ° C. Earlier, we have already written about and recommended adding an article to bookmarks.

The best brand for the designs of this type is considered to be AISI 321 (there are molybdenum impurities), but widespread also have AISI 316 and AISI 304. It is worth noting that many unscrupulous manufacturers produce products from less heat-resistant brands, as a result of which they can be lit through 10-15 years of non-intensive use.

Tip! Choosing a stainless steel chimney, be sure to ask the quality of the steel. You can independently evaluate this parameter using a magnet: good steel has a large number of alloying additives, as a result of which it does not make a magnetic.

Sandwich chimney for the furnace with their own hands

Best option For mounting a chimney, with their own hands there will be a stainless steel sandwich system. It looks good and answers all modern fire safety standards. An important advantage is the fact that it is most simply assembled alone, without having experience and special knowledge. Enough to adhere to the following recommendations:

- The installation process should begin with the lower elements.

- In the contact places of pipes with wooden and other fire-hazardous materials (in the attic or roof area), it is necessary to use isolation, for example, stone cotton wool.

- In order to protect the surface of the ceiling in the region of the passage, the steel platform must be mounted.

- In case of creation outdoor pipe It is necessary to include in the system of tees designed for condensate.

- The above-mentioned elements are inserted into the following.

- It is advisable to protect the upper yield of the chimney with the help of thermogrybla, weather, a deflector or a sparky.

The convenience, comfort and safety of operation and gas boiler depends on the correctness of the project and the correctness of the surveillance of the smoke wood stove Bath. In today's article, we will talk about how the chimney installation scheme looks like for different types of heating devices.

General rules Installations and installation of chimney:

- Fire safety. It is achieved by laying insulation between chimney and combustible flooring materials, as well as thickening of the chimney walls. It is also necessary to observe minimum distance between the wall and the chimney pipe. A favorable solution is to use a pipe sandwich.

- Availability of good traction. The first rule of thrust: the longer the channel for removing smoke, the better the thrust. The optimal length is 500-600 cm.

- Tightness of the exterior of the pipe. This will ensure the correct and long smoke performance.

- The smallest resistance for the passage of smoke in the exhaust canal. The walls of the channel must be as much as possible.

- Compliance of the material for the manufacture of chimgoda temperature regime and chemical composition Reference gases. When using a different type of fuel should be used different chimneys.

- High smoke temperature in the exhaust channel. If this rule fails, condensate will be formed on the walls of the chimney, which contributes to the destruction of the inner surface of the chimney. And less vertical partitions in the smoke removal system, the better. This is especially true for large stoves.

Competent float mounting for wood fireplace and stove

A feature of firewood, like fuel, is a big heat from them. It follows from this that the temperature of the smoke in the bathing furnace bath or fireplace will be high but uneven. Not every chimney will be able to withstand such a long impact.

Most often for mounting a chimney for heating devices such as a stove for a bath or a fireplace with a wood firebox, a heat-resistant brick is used (see chimney with your own hands).

Making brick chimney

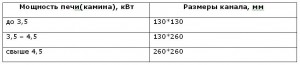

The correct scheme of the chimney of the brick in general may look like this:

- Most often, a housing tube is used for a wood-burning furnace. That is, it continues the exhaust hole of the oven itself or fireplace. It should be known that the masonry of the inside (indoors) is best done on the clay and sandy solution.

It should be known: all the work on the masonry from the outside of the building must be performed with the addition of cement and water to the solution!

You should know! In order for the protrusion of the otter to be forceding water, it is necessary to make angular slopes from cement plaster from all four sides.

- After external expansion, the main riser is made, as in the attic room. For beauty, a brick head is usually laid out.

- Completes the brick chimney of the cap protecting against exposure ambient: Wind, precipitation. By form, the protective umbrella can be different. The best option is the deflector.

A graphic scheme of the chimney of a brick furnace for home or bath is presented in the figure below.

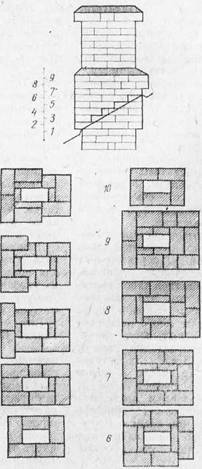

It is the two-column smoke removal system that is optimal for use in large furnaces and fireplaces with considerable foci on firewood. It provides more or less uniform heating in the room, and also has a minimum of the obstacles to the movement of smoke to the exhaust channel.

Features of double chimney for fireplace

Another of the variants of the chimney is a double tube. Outside, it is made of brick, and a metal cylindrical part passes inside it. If the pipe is made of stainless steel, then this variant of the chimney is suitable for installing a gas boiler.

Combined double decays for fireplaces have several advantages over bricks:

- The channel for the movement of the smoke has a smooth surface, without obstacles.

- The fire safety of the building is increasing.

- The laying of the outer part can be done without a roller.

- Increases the life of the chimney.

- It improves the tightness of the whole chimney.

The figure below shows the scheme of the chimney of a fireplace or a gas boiler having a combined structure.

A feature of such a design is that it is usually done in a radical performance, and not an atmosphere. That is, the chimney itself is located directly next to the heating unit.

- When installing the combined chimney, the foundation is first made, which has a minimum height 30 cm.

- The laying of a mine of the brick is made in accordance with the same conditions as when installing a conventional brick chimney.

- Due to the design features of the double channel, the outer mine is placed vertically without mandatory thickening of the walls in place ceiling overlap.

- Below, immediately after the foundation, a niche is made with a doors for cleaning.

- The metal pipe made of stainless steel is assembled from top to bottom in such a way that each subsequent knee is inserted inside the previous one.

- All joints of the inner part of the combined chimney are processed with a sealant with a contained heat resistance to the manufacturer at least 1000 ° C.

Right installation of chimneys for gas equipment

Features of waste generated during the operation of the gas boiler, imply certain design requirements for chimneys for this type of heating devices (see installation of chimneys of various types).

We collect chimney for a boiler with a natural burden

The overall chimney mounting scheme for a floor gas boiler with a hole for removing the combustion products from the back of the case is as follows.:

- Since in the smoke formed during the operation of the gas boiler, acid-containing substances appear, chimney should be made from an acid-resistant stainless steel. Such systems are sold in the store and the process of their assembly is not particularly difficult. The optimal option is a two-channel chimney type "Sandwich".

- The main part of the pipe is on the street. To give stiffness, it is fastened in one or two places on a wall bracket.

You should know: since the allocated combustion products in gas equipment have a low temperature, then the formation of condensate is possible. To protect the boiler from water from getting inside when using a single-channel chimney, a condensate collection should be mounted into the system, as well as warm the pipe that takes place on the street. A more rational solution is to use a sandwich chimney.

The sandwich tube of three layers is consisting:

- The inner layer of the tube sandwich is experiencing serious chemical and thermal loads, it is used for its manufacture, stainless heat-resistant steel;

- The middle layer of the tube sandwich is a heater (basalt fiber);

- Outer circuit Sandwich pipes - galvanized or stainless steel.

The cross section of the sandwich pipe is oval, since this form is optimal for the chimney mounting for the gas boiler.

You should know! All contacts with combustible substances in the walls and overlaps should be isolated with non-flammable materials.

- When the roof is released, the pipe has a discovering part (skirt), which performs the same function as the otter in the brick tube.

- For better protection against the penetration of precipitation under the roof, the pipe is inserted into the hole of a peculiar apron having a square shape.

You should know! Before buying the roofing knot, the chimney (apron) be sure to measure the angle of the roofing surface of the surface! This will allow you to make a smoking pipe as accurately as possible through the node hole and ensure the highest tightness of this design.

- Completes the chimney of the conical or fungal headpoint.

Mount the hood for the wall boiler

There is a type of gas boilers with forced exhaust combustion products. Inside the exhaust camera, such devices are "Duich" - fan.

Chimneys such boilers are characterized by minimal size in length and the smallest complexity in montage. They consist of two channels, isolated high quality stone wool. The inner channel serves as an exhaust, and the outer-fear of the air from the street.

The chimney scheme for the boiler with coaxial output is simple, installation is carried out as follows:

- On the boiler puts on a removal with an angle in 87 degrees.

- Next is the hole in the wall under the pipe. Then the boiler is removed from the anchors and hosted on the markup (pumped) through a hole, taking into account the gasket of non-combustible isolation in 30-100 mm along the entire length of the circumference of the pipe.

- Now I wake the pipe into the hole and insert it into the removal, which is already attached by special screws to the boiler body.

You should know! To seal all compounds in the coaxial chimney, a special sealant and a wide clamp are included.

Chimney is a very important part of the bath design. This in the past remained times when the furnace was treated in black, with special art, which allowed smoking only the walls. But with modern baths, it is absolutely not to do without a chimney: after all, it is he who removes the products of the combustion process of wooden fuel due to the rift of natural origin.

It's simple: clean air goes into the furnace, and the gases come out. But in the process, when you build a chimney with your own hands or install acquired, you will encounter considerable difficulties. And we will help to figure it out!

It is absolutely natural that such a number of bath owners are looking for how to make chimney and seek to understand everything yourself - after all, such installation in the country is hardly worth a thousand dollars. Therefore, if you decide for everyone to take yourself - you will try, just read this article carefully.

What is the standard chimney?

Classifications of chimneys There are many: internal and external, single-circuit and double-circuit, and ... but most importantly, regardless of what chimney you want to collect and install in your steam room, there are certain rules, and they need to know.

So, some distant from the construction of the bath owners are confident that the chimney device is quite simple and is only a few pipes, in a special interconnected. And all sorts of "extra" devices and elements really seem to be superfluous. In fact, there is nothing unnecessary in chimney - take away a couple of elements, and the problems will not make it wait. Therefore, studying the question, how to make a chimney correctly, we will begin with what will get acquainted with its main elements and their destination.

The perfect chimney is a strict horizontal design. But in practice it is often increasing much more difficult - the pipe goes straight, then horizontally through the wall, then again right ... and also through the ceiling and roof. For which there are a variety of knees, tees and nozzles.

So what is knee? The chimney can not always pass through the overlap of the second floor strictly vertically - it can interfere with the beam, for example. And it needs to be bypassed - and for this, the knees with the most different angles are used. If a horizontal portion of the pipe goes from the furnace, then it should be mounted onto a knee or tee. If you use the knee - think how to clean it then, and it will have to clean it.

More universal knee option - teeIn it, in contrast to the first option, also an element of cleaning is also provided. This is a special removable glass at the bottom or its analog. The only rule is a tee and pipes must be perfectly approaching each other and absolutely hermetically combined so that the smoke could not penetrate into the inner rooms of the bath through imperceptible slot.

Further, so that the chimney safely passed through wood coating The second floor of the bath, uses such an element as passing pipe . It all looks like this: cut a hole in the ceiling, put the nozzle, we are well insulated with it and remove the pipe. Also, in the case of the roof - for it, the nozzle is also used, only at an angle.

Used in the chimney mounting and brackets - These are special devices that hold pipes and they do not fall. Correctly mount the chimney pipe with wall brackets every two meters.

And finally roof cutting - an element that allows you to hermetically spend the pipe through the roof of the bath. So that neither the rain, nor the melting snow in the attic or the second floor fell. The roof cutting should not be replaced by dubious materials and even more sealant if the bath still sits - all this will collapse over time, disappear, and sometimes, unfortunately, and ignite.

Important! By purchasing chimney and its complete set, be sure to check the certificate, and this is not the same as a simple list of what products are consisting of. Be careful!

Install the chimney in the bath yourself

Why is it so important that the chimney worked correctly? First, combustion products can not only spoil furniture and steam room, but also seriously affect health.

So, any chimney installation is always made according to one of these principles:

- Over smoke - when a tee is installed in the system, withdrawing condensate

- By condensate - when such a tee is not used.

That is, the chimney goes from the furnace "according to condensate", and after the tee - "on the smoke". More details about connecting video options:

Stage I. Design of chimney

First of all, select the right project for your chimney, better together with a specialist. And the starting point should be the oven that you install in the bath - each of them has its own requirements, and each works on its own principle.

Now carefully inspect the ceiling, check where the beams are. So you will know if you will have a chimney, or with bends and transitions. But remember that horizontal parts always reduce the thrust slightly, and it is still well accumulated in yourself.

Stage II. We collect chimney

If you do not get a collected pipe right on top, collect it on Earth. Weight, of course, will turn out yet, and therefore in this case can not do without a hinge that can be cooked with a pin and iron. And lift the pipe to the height is convenient with the help of horns and stretch marks.

All the place of joints of pipes, tees and knees should be well bonded by clamps. The tees themselves are secure using the support bracket.

Stage III. Passage through the roof

As we have already spoken, the chimney through the roof of the bath is displayed using a special cutting that needs to be selected in accordance with the inclination of the roof - 15-35 ° or 35-55 °.

Next, accurately determine the place where it is the pipe that will take place, mark the size and cut out the opening from the inside. After that - in the roof, and remove the pipe. From the inside the location of the flue of the chimney with the help of a cushion sheet, and they put the roof cutting outside. Tilt the angle by adjusting the cutting part of the cutting, and we start the edge of it under the lip of the roof or under the edge of the roof - as you succeed.

On the walls of the nozzle, we set the insulation - it can be foil mats from the basalt, for example. Moreover, it is precisely the internal cavity of the nozzle.

Stage IV. The end of the installation of chimney

Now the adjustable apron is fixed on the pipe to seal the joint and increasing the chimney to the desired length, covering it with a metal umbrella to protect against atmospheric precipitation.

And so - the last. Those parts of the chimney, which may be subject to corrosion, should be covered with heat-resistant paint, and the joints of the clamps are sealing.

In the first place - fire safety!

Now let's look at the main rules that need to be remembered by building yourself the chimney:

- Rule number 1. No joints with other pipes!

- Rule number 2. The chimney should not have a horizontal portion of more than one meter.

- Rule number 3. It is impossible that the chimney comes into contact with any other communication, especially the gas pipeline or electrical wiring.

- Rule number 4. At least twice for the heating season bath chimney Need to be cleaned.

- Rule number 5. Out of the roof, the chimney should go no less than half the meter.

And the most important criterion of fire safety is the distance from the surface of the chimney pipe to flammable building structures.

And finally, as for the strength of the thrust and serviceability of the chimney, the diameter and height play the major role here, namely, their ratio. And it all depends on what kind of oven you are, what power it is, and how high the roof of the bath.

The chimney in the classic Russian bath has its own requirements - the maximum heat resistance of the material and the minimum of turns with bends. Follow the clear instructions, do not show ingenuity and trust the professionals in everything - and the roast heart of the bath will work properly more than a dozen years!

Related records:

2014-06-12 16:38:35

Probably, the perfect chimney must have the most vertical design and smaller horizontal parts, and so everything is described by intelligent. I would like to add that you need to avoid turns at an angle of 90 degrees, because soot will be collected in this place. If there is no way out - to make a connection with a tee with "revisions" so that it is easy to clean the place of connection from soot. The pipe should choose a thick-walled to serve longer. And another question - what material is better to use for thermal insulation at the point of exit pipe with steam room? After all, there is usually the maximum temperature.

2014-06-10 01:02:12

A very detailed and clear lesson, I have long wanted to read something similar, only here is not so many such good sites on the Internet as this. Many thanks to you for every article, I love to read this site, just like balm on the soul. I myself do not understand anything in the baths, but since that time I decided and put it on my own country cottage area I realized that the bath is now an integral part of my life, because every time I arriving at the cottage, I am first there, even if terrible heat on the street. It best helps to get rid of not only from pain in the joints, but also remove all the tension in general from the body. The chimney did me the builders, they did to the glory, so I think that it is worth trusting them.

2014-06-10 10:34:03

In general, everything is quite clearly painted, but I have a question about the problem of another plan. There was an unpleasant situation in one of the winters when very low temperature held for a long time. Condensate was formed on the inner surface of the chimney, the chimney is brick and very high. From the inside laid out with a red brick outside silicate. Now we have crumbling brick outside; What is happening inside you understand already and describe difficult. How can the chimney be altered in order to avoid such unpleasant consequences in the future? Restore the existing in my opinion is already simply not really and does not make sense.

No boiler, oven or fireplace is not able to work without chimney - or rather in a state, but in this case all products combustion fuel will remain indoors. It is said that our ancestors in the old days were treated in the older, but personally I believe in this weakly - with such a production, people would die from carbon monoxide. Yes, and that they were less consistency than we, too, believe weakly. But the essence is not in this - so that the removal of combustion products happened effectively, the chimney still needs to be able to do correctly. As in any other work, there are their subtleties and nuances that we will talk about in this article - along with the site We will deal with the question, how to make a chimney with your own hands? Moreover, we will consider the most popular materials used to manufacture smoke systems, as well as read their features.

Sandwich chimney do it yourself photo

Chimney do it yourself: how it works

By and large, any chimney, regardless of the material from which it is made, as well as the additions that make their Master-Peckers, chimney is just a pipe. It is also called in the people - namely the channel, according to which the products of burning are transported beyond the limits of the house. Yes, some requirements put forward to it. Yes, it has some nuances that guarantee stable operation without reverse thrust. But, nevertheless, it is an ordinary pipe, which is simple enough, and it can be of two types.

It concerns the varieties of chimneys, but in order to produce correct installation The chimney do it yourself, pipes and the condensate collection will not be enough. At a minimum you need to take care of the pair of moments.

In general, this is the whole design. As you can see, it's not so difficult, as it may seem first. The only thing that can still be supplemented is insulation that helps reduce the amount of condensate formed in the top of the chimney. It is used here as standard mineral wool, and any other non-combustible insulation. Modern manufacturers have already learned how to make insulated chimney pipes, which are called a sandwich chimney. In fact, this is a designer, about the assembly of which we will talk a little later, but for now, if I wonder if you can watch a video about its mounting.

How to make chimney do it yourself: materials

As mentioned above, the chimney can be made of several types of materials - each of them has its own characteristics, and they need to know, solving the question, from which to collect chimney in the country? With them and will figure it on.

Alternatively, it is possible to consider the manufacture of chimney from the asbestos pipe - it does not burn and is practically not destroyed under the influence of atmospheric factors. Moreover, asbestos, asbestos, weakly heats up, which makes the exploitation of the chimney almost safe in terms of fire.

Montage of chimney with your own hands: Important things

By and large, that realizing the principle and device of the system for the removal of combustion products from the furnace or, do the chimney with their own hands will not be difficult. But, as in any other case, there are subtleties and nuances, which seems to be a bit, but they are important and consider them in the installation process.

In principle, this is all that you need to know in order to properly make a chimney with your own hands. The only thing that remains to add to the end of the topic is to say a few words about the warming of the chimney with their own hands. As mentioned above, the mineral wool or basalt plate, which not burns and withstands very high temperatures is used for this purpose. It is simply wound around the chimney, after which they are fixed outside the waterproof material, which, in turn, is fixed with wire or aluminum scotch, which is much more attractive. The chimney from the sandwich tube does not need an additional insulation. Well, all other pipes are preferably isolate, ranging from overlapping and ending with their riding.

According to the overwhelming majority of lovers bath traditions Russian steam room, like the Finnish sauna, should be treated with firewood. For this purpose, the steam room is installed in the room, and the combustion products are dismissed out. The question is to properly mount such chimney in the bath, which will ensure good traction and last long, and most importantly, is safe. This article will allow you to familiarize yourself with the existing kinds of chimney pipes and their installation methods.

Types of chimney

At present, homeowners set chimneys for bathrooms 3 species:

- stainless steel pipe or conventional ferrous metal with thick walls;

- a double-walled pipe with a layer of non-aggravated insulation - sandwich chimney;

- traditional brick chimney.

The usual tube is the simplest option, but it is still applied less often. People prefer cheap security, and therefore increasingly inclined to sandwiches. Yes, and black condensate flows, spoiling all appearance A brilliant surface of the stainless steel, few people like. Although, if you make some effort and mounted the pipe as it should be, such trouble can be avoided. Below we will look at how to do it.

For reference. Ordinary metal pipes on steel bath furnaces Typically put the owners who love to do with their own hands and maximize on the materials.

The two-way sandwich design of the channel greatly simplifies the installation work and makes the operation of the bath is much safer in terms of possible fire and fire. As the furnace in any case is inside the building, then in its path the chimney meets various building construction - wall, overlap, roofing. And they are not always consisting of non-aggravated materials, which means that the usual hot pipe of the gas plant represents a high fire hazard.

The chimney from sandwich pipes is good, that the temperature on its surface is much lower than the outbreak of the majority of construction and finishing materials. Nevertheless, in accordance with the rules of fire safety from a double-walled and brick gas plant, indent to combustible structures is also made. By the way, the first 2 types of channels are mounted together with steel baths, and the third, respectively, with bricks.

Note. If the furnace itself is a brick, then the pipe for combustion products is being done as much as metal gas ducts are put in other cases.

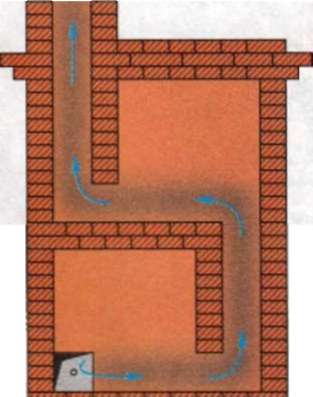

According to the method of laying the installation of the chimney in the bath with their own hands is made outside or inside the building. With an outdoor location, the horizontal or inclined area coming from the furnace permeates the outer wall, and only then joins the vertical area. The inner layout implies the passage of the vertical chimney pipe through the design of the overlap and roof. Here are these nodes and represent the greatest fire hazard, the consequences of the wrong installation are reflected in the photo:

In the photo, when passing the ceiling, the distance from the pipe to combustible materials is clearly unavoidable, which is why the latter began to smoke. The error in the lower photo is obvious - the short vertical plot is unacceptable, which should rise in this case over the rod of the roof.

Rules of installation of chimney

Places where the passage of pipes through the ceiling and other building structures should be considered taking into account the fact that they are covered with wood from the inside, that is, a combustable material. At the same time, it does not matter from which material the wall or overlap itself is built, it is enough that there is a combustible facing. In general, the postulates of smoking channels are heard in this way:

- before installing metal or masonry brick oven It is necessary to successfully choose the place to make the future chimney of the bathroom bearing structures Roof. It makes no sense to make extra turns of the pipe, and the brick canal and rotate it is impossible. Total number turns of the pipe should not exceed 3;

- the horizontal portion from the stove to the insertion into the vertical channel in length should not exceed 1 m. Exception - inclined at an angle of 45 ° gas - sometimes used instead of horizontal. But here you should not get involved, make this segment as short as possible;

- one-way metallic chimney should defend non-protected flammable overlap materials at a distance of 0.5 m. If combined surfaces close non-combustible screen, the interval can be reduced to 38 cm. All requirements of fire standards are shown in detail in the figure below;

- on the same figure it is shown how to properly set the chimney in height so that its cut does not get into the weathered zone. Then the power of natural traction will significantly decrease;

- the vertical gatal channel must be equipped with a condensate system and drain.

Modern correct chimney The brick is inside inserting stainless steel or ceramic elements. It is necessary to avoid the destruction of the walls from the effects of condensation, which due to the uneven operation of the heat source freezes in the pores of the brick, choking it with pieces.

Starting from the attic overlap, the single-liter pipe is strongly recommended to protect the heat-insulating layer of a non-controlled insulation, the optimal version is basalt fiber. Outside, insulation is wrapped with galvanized steel casing. Then condensate will not appear outside the pipe, and the attic space will be protected from fire. When the chimney is made through the wall, the same retreats are observed as for the passage through the overlap.

First O. brick structuresWhat is the continuation of the masonry of the furnace. A passage node, called cutting, is performed by expanding masonry to standard sizes, as shown above in the diagram. It turns out that when crossing the overlap you need to withstand the wall thickness in a half of the brick (380 mm), and roofing - 1 brick (250 mm).

![]()

Steel pipes for gases are usually collected from sections inserted one to another. Moreover, mount the chimney in such a way that the condensate inside the gas plant could smooth down. That is, the upper section is inserted into the bottom, it is called the "condensate" assembly. As for the modular sandwiches, the inner tube of the inserted upper section should enter the bottom, and the external one - clamp the housing of the bottom outside. In this way, there is a removal of precipitation, calm flowing to the ground.

Important. No assembly "on smoke", that is, inserting sections one to another on the contrary, is not allowed.

If you have decided to make a chimney for a bath through the ceiling, then you should prepare the opening of the required size in the overlap. Then make a box with a bottom and a hole for the pipe from the roofing, fasten it in the opening and then put the smoke canal. The space between it and the sides of the box is filled with clay, vermiculitis is either tightly stuffed with basalt cotton. Detailed detail of the node can be taken from the scheme:

Council. Instead of a complex passage node, you can apply a self-type water tank, built into the overlap and performing 2 functions at once. Similar successful solutions offer many furnace manufacturers, the details are shown in the drawing:

Vertical external chimney is attached to the wall on the brackets in such a way that each section accounted for at least 1 mount. If the sections are long, then the brackets are set with an interval of 2 m. Performing turns, you should avoid the setting of the knee angle of 90 °, try to use taps under 45 or 30 °. The upper slice of the chimney can be covered with precipitation by the usual umbrella or install some deflector. Better the one that turns after the wind, not letting him blow inside the pipe.

How to clear the chimney in the bath?

Brick or stainless chimneys serving bath ovens need to be cleaned as needed. Practice shows that with year-round use of the bath, such a need comes at least 2 times a year. For this purpose, there are special rams that are tied to the rope with the load so that they can be lowered from top to bottom.

You should drain condensate through the tap at the bottom of the pipes, climb onto the roof and omit inside the ERS. Before that, you will need to remove an umbrella or deflector. It is very convenient when a chimney with a hole (revision) is mounted in the bath, through which access is available below. Then the cleaning can be done on both sides, and then remove the refused soot through the hatcher.

In addition to the mechanical method, there is a chemical purification of chimney. There is a remedy for sale, called Pedenville, which is laid in the stovet fifth and burns there in accordance with the instructions. The tool is quite universal, suitable for any solid fuel heaters and not once verified in practice.

Conclusion

Install a bath oven is just half anteen. Installation of such an important part, like chimney, take time no less, or even more. It is important to trace the compliance with the 2 main requirements: the execution of fire standards and the presence of good stable thrust.