Today, almost anyone can afford a plastic window. They are not only relatively inexpensive, but also have good performance characteristics.

However, the experience of one and a half decades of using PVC windows has shown that they also have their weak points. They vary in quality and performance. It is important to be able to understand plastic windows so as not to get a "pig in a poke". We will help you!

Requirements for plastic windows: nuances

There are several important requirements for modern plastic windows that every buyer must take into account.

Structural strength

As a rule, plastic profiles do not fade in the sun, are resistant to sudden changes in temperature, are outwardly neat and have a considerable number of other positive properties, which can be capaciously called "high manufacturability".

However, these PVC profiles are inferior in flexural strength to aluminum, steel and wood models. Still: with large temperature drops, the dimensions of the plastic window are significantly deformed. Therefore, today the work on ensuring geometric stability and increasing the rigidity of plastic frames is not standing still.

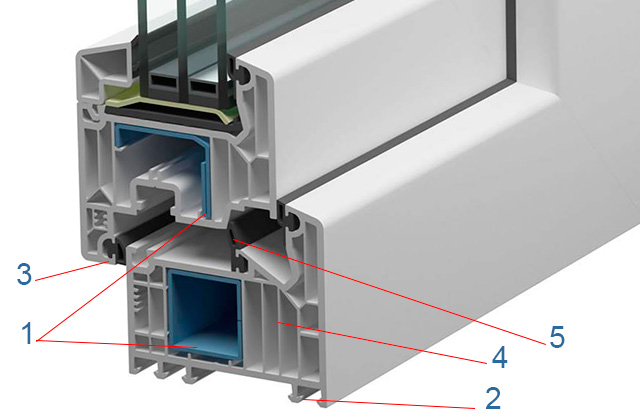

PVC Windows - Sectional View

It is not difficult to make a PVC window structure stronger if you increase the thickness of the profile walls. This will also have a positive effect on the thermal insulation and burglary resistance of the plastic window, which will be discussed a little later.

By the way, according to GOST 30673-99, the thickness of the front walls of the A-class profiles for both window and door frames must be at least 3 mm.

Parts of the frames will not warp and bend during sudden temperature changes if they are equipped with reinforcing inserts made of steel with a U-shaped section. Although these inserts are not always necessary, for example, in the frames of vents and in horizontal bars of narrow sashes with a length of no more than 450 mm.

If the plastic window is without steel reinforcement, then not only the profiles will begin to bend in the heat, but the tightness of the entire structure will also be broken: the window will stop opening and closing. Therefore, experts recommend checking the presence of reinforcement. Look at the outside of the window frame; the screw heads should be visible there (no more than 400 mm apart). Thanks to these screws, the steel reinforcement insert is installed inside the PVC profile chamber.

In addition, make sure that there are steel liners in the casements as well. However, it is much more difficult to do this: it is necessary to disassemble the double-glazed windows.

The second way to increase the rigidity of the window sashes is to glue glazing beads on the glue, having previously fixed the glass units with them.

The third and last way to reinforce window frames is to increase the height of the PVC profiles. Profiles with increased height are called intermediate, since they are in size between the window and door profiles. Such plastic profiles are found in most modern systems. And they are mainly used in large-sized and sliding window structures, since with them the light transmittance of the window decreases by 15-20%.

Thermal insulation

Thermal insulation of a plastic window

This is the ability to retain heat and not let the cold pass inside the room.

If you want to have comfortable living conditions in an apartment, then purchase plastic window structures from three- and four-chamber profiles with a width of 58 to 72 mm.

As for the insulating glass unit itself, there is no single answer to this. Some experts argue that it is better to purchase a single-chamber profile with a width of 20 to 24 mm, since it does not create additional load on the hinges due to its low weight. And also such a profile has the best light transmission (by 13%).

![]()

Energy Saving PVC Windows

Others believe that a single-chamber profile is ineffective if its double-glazed window is not filled with an inert gas, which, in about 7-10 years, manages to "pour out" from the chamber.

If you are interested in energy-saving windows, then know that they are more appropriate for a winter dacha or a cottage. Of course, such window structures are almost 2 times more expensive than conventional ones, but thanks to them, you can save on heating - about 5 to 8% and after 6-8 years energy-saving windows will pay off.

By the way, today the most common type of energy-saving glass unit is a two-chamber one with an inert gas (most often argon) and with a thickness of 32 to 34 mm. One of the panes of the two-chamber double-glazed unit has a low-emission coating, which completely covers the single-chamber one.

Providing air exchange

Plastic window ventilation

As a rule, most companies produce high-quality PVC windows. However, for example, a plastic window with a size of 1 x 1.2 m in winter will pass no more than 7.5 m3 of air per hour. Of course, this volume is not enough for good ventilation. So, according to SNiP 31-01-2003, about 30 m3 of air should enter the room. It turns out that in order to get rid of the draft, you have to pay a high price - the temperature and humidity increase, there is a lack of oxygen.

Some experts advise airing all rooms in the following way 2 times a day: open large doors in them in turn for about 5-10 minutes. However, this method can hardly be called convenient, because the supply of fresh air will not be enough for the whole night.

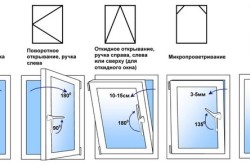

Tilt & turn window

Other experts recommend equipping plastic window structures with small vents or tilt-and-turn fittings that have a micro-ventilation function. A plastic window with such fittings will not cause strong drafts, but dust and street noise will freely enter the room.

The best option for window ventilation are special overhead valves that allow you to control the air flow over a wide range - from about 5 to 50 m3 per hour. They do not become sources of drafts, since they are located in the upper part of the translucent structure.

Flap on PVC window

In addition, these valves can be equipped with special noise protection labyrinths and acoustic canopies. But nothing is perfect. So, overhead valves have their drawbacks. They do not always fit into the design of the window opening, and besides, their price "bites". You will not find cheap anywhere - only for 3-5 thousand rubles.

Soundproofing

Soundproofing PVC window

If you live in a house that faces a large street, then you do not necessarily need to install special noise-insulating window structures. They are soundproofed up to 50 dB. And the main element in this design is the so-called. asymmetric glass unit. It is of two types:

1) With glasses of various thicknesses.

2) With different distance between glasses.

Some experts believe that such a glass unit is more effective. Others are more correct that the best option would be a system with main profiles filled with polyurethane, and a box with a width of at least 80 mm, soundproof.

Burglary resistance

![]()

Anti-burglary fittings

If you live in an apartment on the first or last floor, then in a good way Burglary protection is the installation of fittings with mushroom bushings (trunnions).

However, there are also cases when thieves drill or cut through the overlap of the box and push a wire hook into the hole, turning the handle of the window window. In this case, fit the key lock handle.

And if you live in a private house, then experts recommend installing plastic windows, which are equipped with reinforced reinforcement, and their double-glazed windows are made of protective triplex. By the way, these double-glazed windows are fixed in the doors using metal corners, not glazing beads. And the structure itself is reinforced with steel plates, which are screwed to the reinforcing inserts through plastic.

Plastic window is an important architectural part of the building

To make the window easy to assemble, build in, let in light and retain heat, a huge amount of work has been done by scientists. Now you can look inside this invention and find out how it works.

Replacing "Khrushchev's" windows with plastic ones is as inevitable as replacing a kerosene stove with Ilyich's lamp. Just count how many windows have changed in Russia over the past 14 years, if our population is about 140 million people.

1. The profile is reinforced with a steel insert to increase the strength of the structure, it can be used in large stained-glass windows and partitions.

2. The outer surface of the frame is designed for a tight stop.

3. The overhang of the sash of the frame profile ensures good resistance to any gusts of wind.

4. The multi-section profile of the sash and frame reduces heat loss and provides good sound insulation.

5. Specially developed system of gaskets protects from dust and cold air at the junction of the shutters.

Glass and double-glazed windows

Number of glasses in to a greater extent determines the quality of the window. Below are examples of the three main types of glazing. Note that all indicators of thermal conductivity (R) are correct for ordinary glass - 4 mm. For K - glass (with sputtering of silver, gold, etc.), these figures will turn out to be much higher.

The most effective is a double-glazed window. It has a strictly measured definite distance between the glasses, which excludes air circulation and, consequently, heat loss.

* One air gap.

* Two air spaces.

- Stages of installation of windows

- Plastic windows and their installation

- Recess stage

- Self-installation of the window in window opening

- Installation of ebbs and the stage of preliminary adjustment of window fittings

- Filling all gaps with polyurethane foam

- Additional Information

Before installing plastic windows with your own hands, you should take care of preparing everyone necessary materials and tools. This approach to work will significantly reduce the time spent. The instructions for installing plastic windows will help you get a high-quality result of your work.

The principle of installing a plastic window is relatively simple. The main thing is that in the process of work all existing nuances are taken into account.

Stages of installation of windows

In order to install plastic windows with your own hands, you will need:

- polyurethane foam (be prepared for the fact that each window will require about 3 cylinders of material);

- wooden wedges;

- anchor plates;

- silicone;

- hexagons;

- self-tapping screws;

- dowels;

- super glue;

- gun (for working with silicone and polyurethane foam);

- screwdriver;

- puncher;

- electric jigsaw;

- building level;

- roulette;

- stationery knife;

- simple pencil.

The entire installation of a plastic window with your own hands is divided into several main stages:

- Works related to the dismantling of the old window.

- The process of preparing a plastic window for installation.

- Marking on the surface of a plastic window for the future installation of fasteners.

- Installation of fasteners.

- The stage of making small recesses in the window opening (intended for installing a plastic window).

- Installation of a plastic window.

- Installation of ebb tides.

- Hardware adjustment process.

- Filling the gaps with polyurethane foam.

- Installation of the window sill.

- The final stage of work or the process of control adjustment of the fittings.

In order to properly install plastic windows, it is necessary to strictly follow the rules of each stage of work.

Back to the table of contents

Plastic windows and their installation

Before proceeding with the installation of a plastic window, it is required to apply markings around the entire perimeter of the window frame. In this case, it is necessary to note the places where the special fasteners will be located. Fasteners are required on each of the four sides of the plastic window frame, they must be installed in increments of 70-100 cm. The last fastening must have an indent from the corner part of the frame at least 5 cm (up to 15 cm). If there is a support profile, the lower part of the frame does not need to be fixed.

Do-it-yourself installation of fasteners is done as follows. Having coped with the markings of the frames, you should start installing the fasteners. To do this, you need special self-tapping screws, the diameter of which should be 4 mm.

There are drills at their ends, which greatly facilitates the work with plastic windows. If you do not have such self-tapping screws available, you can use the most common ones, but in this case, first of all, holes must be drilled around the frame perimeter. For this purpose, select a drill that has a diameter of 4 mm and a length of no more than 5 cm.

Then you can safely proceed with the installation of the mounts themselves. In this case, the diameter of the (ordinary) self-tapping screw should be no more than 5 cm. For windows with dimensions greater than 2x2 m, it is better to choose a drill diameter of at least 8 mm. In this case, use a self-tapping screw equal to 12 mm. As elements for fastening, the use of special anchor plates is required.

Many specialists in this business prefer to use U-shaped hangers designed for installing drywall. There is no big difference in their price, as a rule, they differ in the thickness of the metal. The thickness of the anchor plate is 1.1-1.5 mm. As for the suspension, its thickness can be from 0.5 to 1 mm. As you can imagine, plastic windows will be installed more securely if the thickness of the fasteners is greater.

Back to the table of contents

Recess stage

Then, in the window opening, recesses are made, intended for the installation of fasteners, on which plastic windows will be installed. For this purpose, first of all, the frame (together with the previously fixed fasteners) should be attached to the designated place in the window opening. The dimensions of the recesses must fully correspond to the fastening elements of the frame, while their optimal depth is no more than 4 cm.

How to level plastic windows with your own hands? In order for the plastic windows to be installed correctly, it is necessary to use wooden wedges. During installation, they are placed under the window frame. In order to avoid mistakes when setting the upper and lower edges to the horizon, it is recommended to start the stage with the installation of two lower wooden wedges.

For a while, an anchor plate is attached to the top of the frame. This nuance is necessary so that the window does not dangle (this can significantly interfere with your further actions). Then you have to install the two upper wedges, after which the side wedges. At this stage, it is advisable to have a partner "at hand" who, for example, will hold the window itself, and in the meantime you can easily put wooden wedges under the frame.

Back to the table of contents

Self-installation of a window in a window opening

After making sure that the window is set as correctly as possible, you should proceed to fixing it in the window opening. Plastic windows are fastened with anchors or dowels.

Here you yourself can decide which material is better to use, but keep in mind that a dowel driven into concrete can withstand up to 60 kg, while the anchor can withstand a much greater load. The diameter of the dowels used must be at least 6 mm with a length of 75 mm. Fastening to wood is carried out using self-tapping screws 8 mm.

Back to the table of contents

Installation of ebbs and the stage of preliminary adjustment of window fittings

In order to protect the frames from water penetration, one should not forget about the installation of a special ebb. As a rule, ebbs are attached under the plastic window itself, but there are cases when this option is difficult. Then it is allowed to be fixed to the frame. If you have to face a similar situation, use self-tapping screws for metal, the diameter of which is 4 mm and the length is 9 mm.

After the ebb is installed, it is necessary to proceed with the preliminary adjustment of the window fittings. At this stage, you will need to apply hexagons. Your goal is to ensure absolutely free and unhindered movement of the sash. Make sure it does not touch any part of the window.

Letters often come to our mail with a request to tell us about the device of a plastic window. In fact, this topic is quite acute, since almost everyone in the house has a double-glazed window. Knowledge about the construction of the window, the operation of the fittings, handles, etc. allow you to properly care for them and extend the life of the window.

A classic plastic window with additional elements consists of the following parts:

- Frame;

- Double-glazed window;

- Sash;

- Fittings;

- Window sill;

- Slope.

We will dwell on each element in more detail and tell you what it is responsible for, what materials it is made of and what types are.

Plastic window frame

The frame is a fixed element. It is made of various PVC profiles and is installed in the window opening along its entire perimeter. Simply put, it is a square or rectangular plastic profile into which the glass unit itself is inserted directly.

The frame can be reinforced, reinforced against burglary.

Glass unit

A double-glazed window is a transparent element of a plastic window, i.e. the very "glass" into which we look. Depending on the number of glasses, hermetically interconnected, they are distinguished, and.

Plastic window sash

Probably everyone knows what a sash is. This is a part of a plastic window that is attached to the frame with fittings. The sash, like the frame, is made of a PVC profile, into which a double-glazed window is inserted.

A glazing bead is attached along the perimeter of the glass unit. About him below. There is a seal between the frame and the sash. Its function is to prevent blowing. But over time, it shrinks and then you need to change it. We have about the replacement of the seal.

Staple plastic window

Above we have already mentioned the glazing bead. With its help, glass is installed and fixed in a glass unit or window frame. Glazing bead is an elongated strip made of plastic profile with rubber gasket. Thanks to the glazing beads, the windows in the apartment acquire an aesthetic and finished look, as well as increase the strength of the entire window and extend the service life.

The main purpose of the window glazing beads is to prevent drafts, dust and extraneous noise from the street. However, glazing beads have a service life, after which they lose their tightness and require replacement. The procedure is simple and you can change the glazing beads yourself. Read more.

Plastic window fittings

Fittings mean everything that helps open and close a window - handles, strips, and other structural elements.

The best quality fittings are made by four German manufacturing companies: Maco, Roto, Siegenia Aubi and Winkhaus.

Window sill

The windowsill needs no introduction. It is a rectangular piece of plastic that is attached from the inside of the window opening at the level of the bottom of the frame. PVC window sills have a multi-chamber design, therefore they are durable, rigid and have good thermal insulation properties.

Window ebb

The ebb is attached to the bottom of the frame from the street. Its main purpose is to drain rainwater from a plastic window. The ebb can be plastic or metal. Most often, you can find metal outflows: aluminum or painted galvanized.

Slopes on plastic windows

Slopes are an important component of a plastic window. They are of three types: insulated, decorative, plaster. Read more about slopes in.