08.05.2015 13:11

Wooden buildings of the most different type are known to humanity from very long time. Peasant huts and baths were built, churches, schools, public buildings were erected. To this day, wood has not lost its relevance as construction material. It is not only easy to handle and easily succumb to the skillful hands of masters, but also absolutely eco-friendly, beautiful and aesthetic. Let's look for what you need royki..

What is the rookie need and what it is

Unfortunately, when building houses and other objects from a bar or logs, it is very often possible to face a rather serious problem - the deformation of window and door openings. With what it can be connected? There are several reasons for that:

- too wet wood, which was used in construction;

- incorrectly selected wood grade for this construction project;

- adverse weather conditions during the construction of the facility;

- disorders of building processes;

- very fast shrinkage building.

Minimize curvature to minimize is quite real. For this, firstly, you need to use high-quality leaked wood and, secondly, the roots need to be installed in each opening. So what is it and why you need?

In principle, it is an ordinary tree bar, mainly square section, which is mounted in the end of the finished opening before the door or window design will be installed. If you do not install, for example, the roof in the window, then when shrinking, the opening can significantly resize and even lose the correct geometric configuration. Installation in the doorways is also important and required if in a couple of months as a result you do not want to see the peashed door. The opening, made for the future window frame or door in the wall of the bar or log, is not supported by anything. That is why, during the shrinkage, its undesirable deformation occurs. Over time, the opening will definitely weaken, so the door frame or window frame can simply "hang" on the fastener.

Production and installation: tricks and nuances

To make a "correct" roof, should be remembered and knowing some subtleties of the process. Note that this product should be made from the highest possible dried bar. Wet wood for the production of roasted is not suitable. In its thickness and the width of the rooki, it must be perfectly accurately approaching the size of the propyl, in which it will be further installed. Its length should be shorter than the height of the finished opening of approximately 5-8 cm. It is this difference that will ensure reliable emphasis and will save the opening from curvature. The height gap is left only from above!

When installing, the roack should be attentive. Be sure to consider: they must be placed exactly in the middle of the sawing in the end of the bar or logs used to build the construction. Thanks to Riotov, it is possible to effectively solve the problem of sending door and window openings.

How to mount

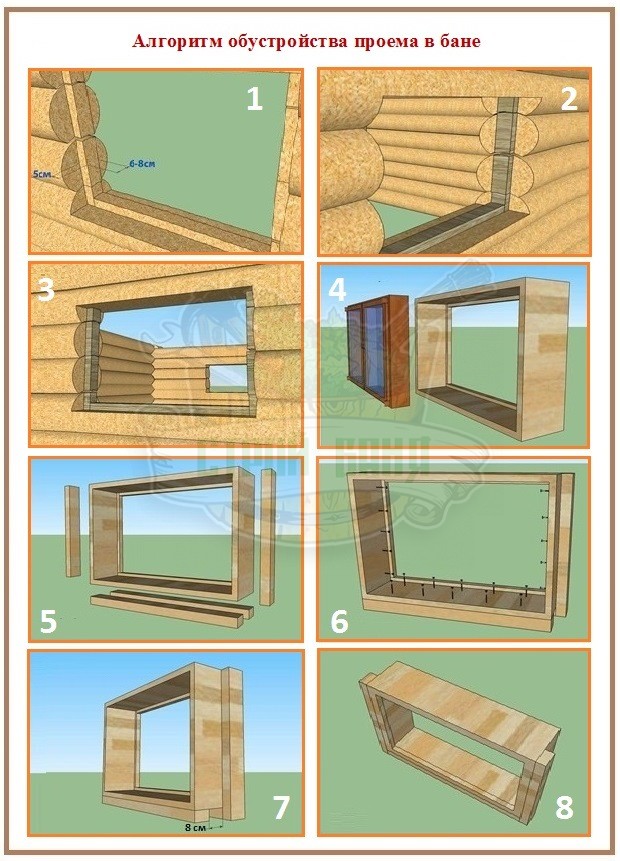

1. They cut the hole in the wall for the window or door, then the opening is treated.

2. In the inside of the opening, it makes a longitudinal cut in the form of an even, ideally strung groove.

Important!

The depth of sawing should accurately correspond to the thickness of the roof. The cutting length should be 5-13 cm more than the roof size.

3. Further, all the roasters are placed in the place prepared for them, and only then doors or windows are installed in the openings.

It is worth noting that after installing the door or window boxes, there is still a small gap between the roof and the upper part of the opening, approximately 4-6 cm. It is subsequently filled with insulation, which also plays an important role and helps prevent the construction of the construction.

Thus, it is easy to get rid of undesirable cases of deformation and wood curvature. They reduce defects associated with drying and seeding wooden buildings, so if you want to build a durable and cozy house, Take care of their installation. At first view of the rook - a primitive piece of timber, but its functionality is very high. It will not allow "Square" to the wooden structure so that irreversibly twisted the opening for the window or door, and you will have a few minutes to install the roof.

Changing in openings for the door or window a longitudinal spike on the end and inserting a bar-rooking, you may not worry that any mechanical or other impacts will affect the configuration or dimensions of the openings. No shrinkage will allow mounted designs to loosen on the fasteners, turn or lose its optimal functionality. The main thing is not to hurry with installation door box or window frame. Install the root, and with the wooden structure everything will definitely be flawless!

Dreaming Create your own cozy corner, you have decided to buildsrub . And so taking the Bar for the future dumpet, you involuntarily encountered a problemmanufacturing window and doorways in wooden house. Do it yourselfit may seem impracticable, but it is not. The main thing is to accurately understand the process and technological features of the task set before you.

Common reduction in the formation of the opening.

At the construction stage.

The opening is done at the stage of firing

The most difficult thing in any business start. Modern construction methods provide for the markup for future doors and windows at the construction stage. That is, the opening is cut off initially, and at the end of the construction you have ready-made holes.

How it's done?

It is very simple, determined with the location and size of the opening, and in the process of a set of the crowns of the building, drink the necessary size in the log with a frequency of 3-4 crown. This is done to prevent the possible extrusion of the crowns and after the end of the construction of these "crossbars" are fixed.

Tip: Make the opening already at 1/10 from the outgoing size, it will help with further alignment.

This technology is well suited for simple, and for a pinned log. The profiled timber allows it even easier to form the opening and does not require the presence of "crossbar".

After building.

The opening is cut in a log wall

As an option for making window and doorways in a wooden house, cut the opening in your own hands in the ready-made wall. This is done using conventional binzo / electric saw. The first and last log is cut into ½, and later it will facilitate the process of the souls. All irregularities are removed using the chisels and the ruble.

Applicable to all types of logs. If the building from the glued timber is needed caution due to possible chipping and detachment of glued boards.

It is worth remembering that the opening is needed in the place where there is no) bonding the timber.

Tip: For marking in case of drinking, you need to apply a laser level and a plumbing otherwise the result may be unexpected.

The formation of the souls and the method of its manufacture.

Making window and doorways in a wooden house with their own hands, first of all, you need to make a shock of the opening with one of the types of souls.

Why do you need it?

The opposite either is needed to protect the door and window openings from the natural drying and shrinkage of wooden logs during the operation of the building. It protects the integrity of doors and windows and does not allow their deformation. The clip is performed in the form of a frame of a frame from sidewalls, a heartbone and a windows (threshold).

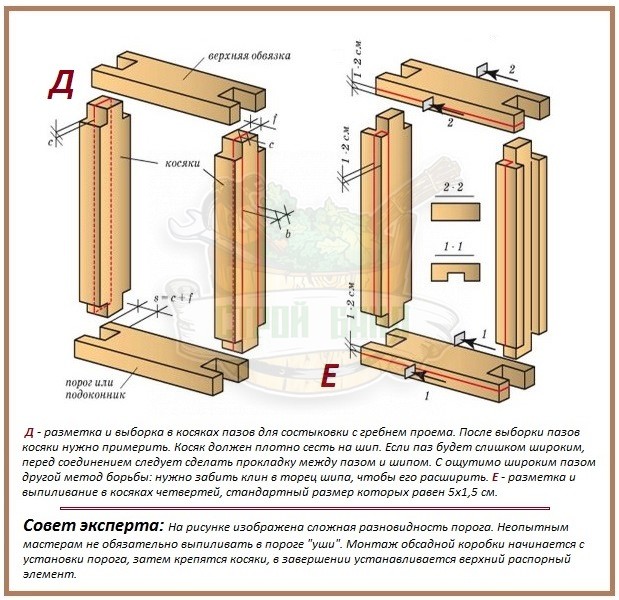

The process of manufacturing the scenes is the same for all types of brusons and divided into the following steps:

- Cutting "grooves" or "spikes" in the end of the log.

- The manufacture and facing the parts of the scenes (the technology varies depending on the type of chipboard).

- Sequential collection of all parts of the chip.

- Installation of the window or door.

Options for chipping window openings:

Monolithic connection

Basically distinguish three types of souls.

Consider the easiest performed.

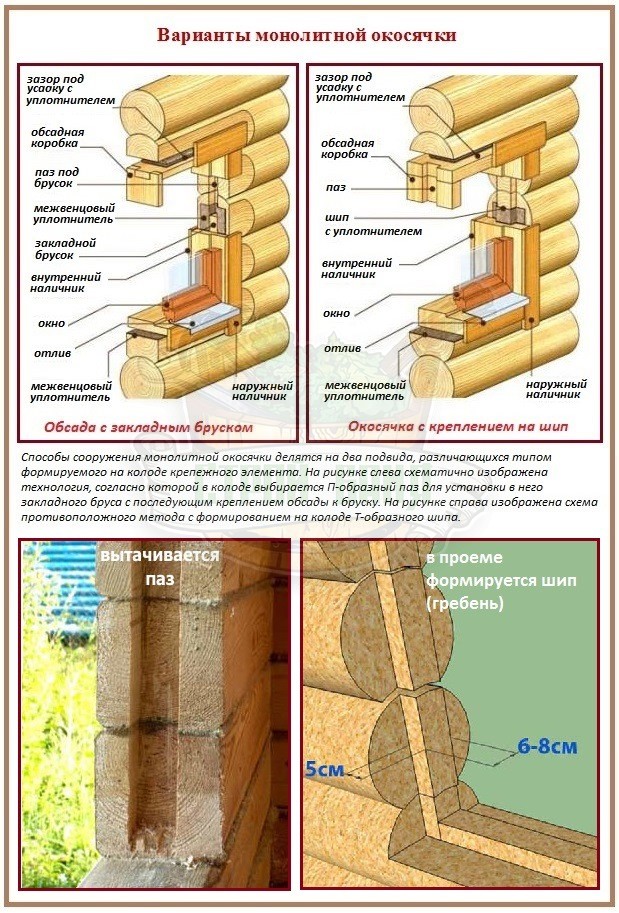

Monolithic connection. There are two subspecies.

In the first case, with the help of the chisels or chainsaws (if it provides an opportunity), the rubber is made ("groove") in the end of the bar of a depth of 10 - 12 cm. Next, using the same tools in the board under the placade (usually used the thickness board in 5 cm width in 15-20 cm) the corresponding spike is cut.

All sides of the chuck also at the end have additional grooves. At the sidewalls, the T-shaped protrusion of 5 cm, in the upper and lower part of the P-shaped sweep. They serve to clutch the chairs in a more stable design.

After the spike should, fit in the groove quite tightly (for this you can also use liquid nails or mounting foam), but, in no case, it is not "tightly" to score by self-strain (it is impossible to allow a tough landing). This is done in order for during the deformation and drying of the bar, the cloth could play a bit in one direction without damaging the window or the door.

This method is called T-shaped or otherwise in a deck.

The second option, the P-shaped (either in a deck), in principle, nothing is different and the main difference is that the spike will be on the log, and the groove is done in the chalkboard.

The first side parts of the souls are first mounted, then they are folded with a suboofer board, the latter is installed, also by the method of strut side parts.

The procedure for assembling the chipping and installation for doorways.

Although the process of training and installation is similar to the window chipping option, there are some differences here.

By selecting the type of monolithic connection (P or T) and cutting the corresponding postures in the first place, you will install the sidewall of the chipboard. Next, using additional grooves the lower part of the chipboard occurs. The latter is mounted. You need to make a platband to the casing (you can choose any suitable material). The platband serves as an insulating component and will not allow drafts.

Note: There should be space between the trick and the building bar of the building within 1/20 from the height of the window / doors. This is the so-called sediment clearance. The clearance itself is filled with the seal and hides under the platband.

Installation of the cerebral

All compounds are compacted and fixed with terrible nails (although hard mounting of the threshold in borders is allowed in the doorways).

What in no case cannot be allowed in the process of manufacturing window and doorways in a wooden house with their own hands.

First, it is not necessary to rely on your eye diamond, a hand and an old papin level. Only accurate marking with the help of modern devices will give the necessary result!

Secondly, forgetting or without considering necessary (and why I am a building in a bath, she will not give landing) leave, you risk, staying as they say "without windows, without doors."

The third that you need to remember is to death seven times once again. It is better to move everything several times than then try to close the gaps and get rid of the draft.

![]()

Strengthening design with liquid nails

No matter if you do not need to plant a clutch with a bar "hard" clutch, even if you just have a bathhouse. After heavy rains and the battery, the timber can lead to the side and the tip will simply turn out.

Do not save on antiseptics and other woodworking materials, not rare cases of rotting of timber in grooves and other contact places due to moisture penetration.

Do not try when the side of the side of the sides, the upper and lower boards, use the metal hammer or sledgehammer. This will lead to wood deformations. There are special rubberized or wooden options.

Video Installations

What you wanted to do, but forgot or several useful tips.

- Glued profiled bar It is worth cutting up with more "gentle" devices than chainsaw, for example, a grinding machine, in order to avoid its structural damage.

- Before you start mountingstacks it is worth it to carefully check its connections with other details (collect it several times outside the opening, insert separate parts in the opening and check their clutch)

- Oddly enough, but the package is not suitable for sealing the gaps and is quite elastic.

- One of the options for seals between the cerebral and the bar can serve as an ordinary glass gambler (it is worth tightly fill it into the gap and close with a platband), it perfectly holds heat and has excellent depreciation.

- Try to keep yourself from large window openings and mansard - it greatly affects the stability of the log.

Finally.

Thanks to modern construction technologies You can choose any desired window or door size and if you have a mistake in miscalculations, or simply during the installation process something went wrong, you can always order a door or a window of the larger area. And in order not to feel the fate in the future and do not try to master the manufacture of window and doorways in a wooden house with their own hands, it is better to invite the hands of a professional and master of your business.

Performing purely practical functions, windows and doors are at the same time an essential element of the architectural composition, to a large extent determining its nature. Window and doorways are organically included in the overall architectural solution, actively participating in the formation of proportions, scale, rhythmic system and architectural image of the structure.

Overlays are straight or curved depending on the floor of the overlap - beam or arch. On the outline of the curve, the arches are semi-curvous, lyric, threecenters *** (Fig, 82).

In stone or brick wall Window opening is usually expanding with slopes inside, forming the windows embrasure. A part of the wall between the bottom of the window; and the floor is called the windows wall. From the side of the room, it is covered with a subcast board, forming an internal windowsill; Usually it is performed from wood, less often from stone. Outside between the binding of the Aries and the edge of the wall, the windows wall is also covered by a sloping stone plate or hidden by a steel sheet. This is an outdoor windowsill, or a windows board, if the stove protrudes from the plane of the wall in the form of a shelf. Part of the wall between two windows is called a simplest ****.

The size of the windows are determined primarily by the functional requirements - to illuminate the indoor rooms. Secondly, they depend on the technical capabilities, the height of the room, which limits the height of the window, the design of the window opening overlapping, affecting its width, and finally, the dimensions and shape of window openings are taken in accordance with the compositional considerations, ideas about good proportions, dominant during the prevalence of a particular style.

* This name is proposed by prof. N. Sultanov.

** tympan is called the surface limited by archive arch, if the upper part of it is muffled, as well as curvilinear triangles on both sides of the archival, if the arch fit into a rectangular shape (Fig. 81, 85).

*** There are not mentioned in the arches such as faded, three-blade, cylinders, etc., characteristic of different architectural styles.

**** A part of the wall between the window and the angle of the building is called an angular common.

In the classical architecture, such views satisfied openings with a ratio of a width to height, equal to 1: 2, the limit was considered to be the ratio 1: 1.5, i.e. one and a half square. Naturally, the architectural requirements must always be combined with practical: with the classical form and proportions of windows and conditioning their size, the illumination of the premises was regulated by placing a larger or smaller number of windows.

The windows features are not limited to the lighting and insolation of the room, it also serves as viewing, and in part and ventilation opening. The window performs a visual interior connection with an external environment. In modern architecture, the latter function has gained great importance. The desire for modern architecture is the desire to destroy the sharp line between the inner and outer space, and to achieve more uniform lighting of the interior led to the transformation of entire planes of the walls into a solid window, often to complete the extermination of the outer wall and replacing it with a glazed surface, which contributes to the possibilities of modern designs.

Starting from the XVII century. In the large halls of large buildings in height of two floors, lighting in two lights was common, i.e., two rows of windows located above each other in accordance with the floor placement on the facade. Such double halls are available in many historic buildings of Moscow and Leningrad - halls in the Winter Palace in Leningrad, the Column Hall of the House of Unions in Moscow and many others.

Constructive techniques of modern construction give greater freedom regarding the location and choosing the size of window openings, allowing a wide variety of solutions. The use for overlapping window openings of reinforced concrete jumpers with severe reinforcement made it possible to significantly increase the width of the windows and give them a "lying" form at which the window width is much greater than its height. The appearance of such a window made possible more uniform lighting of the room, and also improved the visual connection of the interior with the external space, since one wide window can replace two or more vertical. The view from such a window is revealed panoramicly, not interrupted by simpleness.

Modern designs allow you to install lightweight walls on remote consoles. Through the use of such non-relaxed walls, it is possible to completely eliminate the simpleness and apply solid ribbon windows A large length or encircling the whole building is practiced in many buildings of modern architecture (see Fig. 73). These designs also allow the windows not by vertical axes - a window above the window, and arbitrarily, for example in a checker order.

Depending on the nature of the architecture and requirements of the composition, window openings have different plastic processing associated with a constructive solution or having a purely decorative value. In the simplest form, the window is a lumen in a smooth wall, devoid of any framing. The combination of such holes with each other and with the wall can create a feeling of harmony due to the perfection of proportions and successfully found rhythm. The form, devoid of decorative Uraz, who could hide its flaws, requires particularly accurately found proportional relations. Such decisions can be found in the works of strict classics, such as the structures of Palladio architects, kingdomy, Stasov.

Some wind processing techniques arose as a result of a constructive need. Following the overall pattern of development of many architectural forms, these techniques gradually lose the initial meaning, turning into a method of decorative processing that repeats the traditional form.

The most common technique for processing windows in the classic architecture is the framing of the window opening outside the profiled frame called by the platband *. The origin of this form is associated with constructive methods of formation of openings. The platband appeared as a result of plastic processing of jumper beams and supporting her stone jambs that were installed to prevent the immediate support of the jumper on the wall laying.

* It should be noted that the platband is like a form arising from the design of the opening exists not only in classical architecture. The design of openings by platbands was distributed in the architecture of various eras and styles.

This constructive reception was known from ancient times.

Framing from stone bars processed by profiles and forms a platband. In the case when the ends of the jumpers protrude beyond the limits of the jams, the internal profiles followed the outline of the span, and the outer-external contour of the jumpers and jambs. Thus, a form of a platband with ears was created.

In the classic architecture, the platband profile acquired a rather stable form close to the form of archived arches, with a small total removal. The inner part of the platband facing the impeller consisted of one or more smooth shelves, slightly protruding one above the other - fascia *, the outer edges were usually ended with the profile of kimatiyat or fillets with a shelf.

Often over the openings were a carnisik to protect against rainwater flowing along the wall. The simplest view of such a device is a remote shelf over the jumper. This carnisik is called Sandrick. It also was performed in the form of a small frontout. Normal - Sandrick's profile corresponds to the simplest classic eaves and retains its main elements - a remote slab that supports part in the form of one profile, and a crown cornice. Sandriks were placed on the openings and were applied with platbands without them. When opening with a platband, Sandriks were located directly on it or at some distance from it, forming freezers. Sandriks were often supported by brackets, which sometimes corresponded to the vertical shelves, walking along the edges of the platband, are the so-called countermenkers (Fig. 83).

Decorative nature is framed by the extension of the order in the form of a pilaster or three-fourth columns delivered along the edge of the opening and overlapped by an antablement with a fronton or without it. This technique was especially common in the Architecture of Italian Renaissance, but was already applied to the ancient era (see Fig. 19).

The openings with curvilinear overlaps in the classic architecture were processed as archives: archived with imposses or by identifying the clions structure of the arch with the seams, the selection of the castle stone. The arches seams are usually linked to the seams of the wall (see Fig. 82).

Arching span was also framed by a casing with Sandryak, Orders and Pilaesters with Antablem. A peculiar type of such fraction of the arched opening is the "Bramte window", named so named the famous Italian architect, who applied him in the building of Palazzo Kancheney in Rome. This technique originated from the way of facing the wall. A rectangular wpadin was left around the arched window opening, into which the stone frame was inserted after attenuation, framing it (Fig. 84).

A more decorative character is another type of frame of the opening - the "Sansovino window", which is an arched span, processed by archival and imposses based on small columns attached to the opening of the opening (Fig. 85).

The need to increase the light span, without changing its height and maintaining the norms of classical proportions, led to the creation of complex windows that are a combination of several

* In plaster, they are called platforms.

operactions. Such are double and triple windows, which are a wide opening, separated by racks supporting the jumper (Fig. 86). It is especially necessary to highlight the type of triple window, called the "Palladio window" - by the name of the Italian architect XVI century. Andrea Palladio. This is a wide opening, separated by columns into three parts: the average is blocked by a semi-curvous arch, based on the imposts that serve as jumpers of lateral openings and at the same time are antablems of columns separating the slope of the window (Fig. 32, 87).

In some cases, depending on the nature of the composite solution and the practical requirements, round, oval, elliptic, square layers, semicircular, multifaceted window openings were used. All these types of windows used usually as auxiliary - to illuminate the mezzanine, intermediate service, basement and attic floors, as the "second light" in the two sung.

The processing of doorways in the classic architecture was made by the same techniques as the design of the window. The difference was that the platband or another type of framing does not reach the bottom of the opening, and ends with a tumb, i.e. Stone insert, in which he rests. The large door prem allows the use of more complex plastic processing. Significant doors with developed plastic decorative processing are called portals. An example of majestic and richly processed portals can serve as the doors of St. Isaac and Kazan Cathedrals in Leningrad.

Overlapping

Overlap belong to the main structural parts of the building. Being one of the elements enclosing inner spaceOverlapping, depending on their nature, can have a significant impact on the architectural solution of the interior. In accordance with

the design of the overlap can be divided into two main groups - on flat (otherwise beam, or archit) and vaulted. Next, the main types of overlapping architectural forms and some processing techniques associated with their tectonic basis will be considered.

In the case, sometimes the lower surface of the ceiling forms a smooth horizontal * ceiling plane, its processing is not associated with the structural structure and can be performed by any decorative means with a laying, ornamental painting, picturesque plaffones **, trimmed with wood, etc., including imitation of the structural structure. In the simplest case, the ceiling is a smooth plane without any processing, which is characteristic of the overwhelming majority of buildings of mass construction. When the design of the overlap is naked, the architectural form of the ceiling is inevitably connected to its structural structure. The most common view of the overlap is flat, having in most cases at the base ballery design. Among the monuments of antique Greek architecture, a few samples of architectural solutions have been preserved

* In modern architecture there are not only horizontal flat overlaps. In some buildings, where these overlaps are not intergenerational, they do not serve as the floor of the overlying floor, they are sometimes inclined. In some cases, such inclined floors correspond to the inclined floor of the overlying room, as in the foyer of the concert hall in the city of Turku.

** Plafond (FR. RLAFOND - Ceiling). So called ceilings with decorative finish. Often, the painting of the ceiling was used or picturesque canvas were strengthened on it, specially performed according to the rules of floating painting, which are also called plafones.

boy overlapsin which the space between the colonnadium and the kite flooded with stone beams. For these beams, stone slabs were laid - strnotes. To facilitate the latter, the square recesses were chosen in them - caissons, or cassettes. The beam itself was often processed like the architects of fascia and a light profile upstairs. Thus, the design of the overlap at the same time was a harmonious architectural form (see cris.48).

However, a stone beam can be covered with a very small span, so the device of flat floors relative to a large span before the appearance of metal and reinforced concrete structures was carried out with the help of wooden beams or by pendant wooden ceilings to the rafters.

Open wooden beams In the form of rectangular in the section, BRUSIV was usually treated with decorative painting and carvings. The ends of the beams often relied on protruding console walls. The ceiling panels between the beams are also decoratively processed.

The use of a system of auxiliary beams crossing the main in perpendicular direction naturally created a system of rectangular caissons, which filled out the entire plane of the ceiling (Fig. 88). Due to the fact that the structural beams limited the compositional possibilities of the decorative solution of the ceiling, they began to replace with suspended ceilings, on the surface of which were placed decorative beams and caissons with a light box-made design, imitated the shape of the structural beams, and the position of them on the ceiling plane was obeyed exclusively decorative tasks and was not determined by the design . Such decorative caissons of the most diverse form were separated by light profiles, modeling or carvings, gilding and ornamental paintings. The Italian Renaissance Architecture contains many examples of this kind of solutions that are distinguished by exceptional decorative saturation and wealth.

In modern architecture, the tectonic form of flat floors revealed in ribbed structures reinforced concrete floorsin which the stove is strengthened by protruding beams. This design is in pure form having a somewhat utilitarian nature, in some cases a more expressive solution finds. An example of such a solution in modern buildings, whose architecture to a certain extent is based on classical traditions, are the interiors of the New Town Hall in Stockholm (Golden Hall, Gallery), the Gallery of the Messengers in the building of the Finnish Sejm in Helsinki, the exhibition hall in the architects house in Moscow, the railway station hall In Pushkin, etc. (Fig. 89). The system of main and auxiliary beams in ribbed reinforced concrete structures creates a clear caisson overlap structure, which can also be an architectural form simultaneously.

The embodiment of new design ideas in the device of reinforced concrete floors with ribs located on the lines of equal moments reveals new, interesting opportunities for the architectural solution of flat floors, as can be seen on the example of overlaps designed by the nervine engineer (see Fig. 89).

Due to the saturation of modern buildings with technical devices, suspended ceilings were widespread that are attached to overlaps in the following. If in the architecture of the XVI - XVIII centuries. During the construction of suspended ceilings, they were guided mainly to aesthetic considerations, in modern conditions the device of such ceilings pursues practical purposes.

The space between overlap and suspended ceiling is used to lay the electrical, radio, television and telephone wiring, as well as the placement of sprinkler systems, ventilation devices, lighting equipment, acoustic devices (the so-called acoustic ceilings in concert and theatrical halls).

Naturally, in the performance of suspended ceilings, aesthetic tasks are set - to find a harmonious architectural form. This is facilitated by the fact that dropped ceilingsnot directly related to the structural structure, give great opportunities for their plastic solution. For example, a system of built-in reflective heating in the Pension Cass building in Helsinki and the system of acoustic and lighting devices of the house of German radio Berlin create a peculiar, unusual structure and plastic surface of the ceiling (Fig. 90). In such solutions, there is its shaped synthesis of new equipment and architectural form.

The vaulted tectonic systems appeared in the architecture of the Great Ancient Civilizations (Egypt and Mesopotamia), but widespread development received only (in the architecture Ancient RomeWhere, along with the basic forms of clincolous, stone and brick arches, systems of cast concrete arches were developed. The main types of these arches exist in our time. On their basis, the classification was established and the terminology was developed, largely in force and now, when new system of vaulted structures appeared - thin-walled, prefabricated and monolithic, reinforced concrete and armo-cement vaults.

There are the following main types of brick, stone and concrete arch (Fig. 91).

The cylindrical arch is a semi-cylinder, two long sides of which are based on walls or other solid longitudinal supports, for example on beams supported by racks or arcades.

The varieties of the cylindrical arch are semi-curvous, elliptic, three - and multicenter vaults, so-called boxes, differing only by the form of the forming curve. The walls on which the arch is based, are called support, and the walls perpendicular to them in the echoes are cheek *.

Cross arch. If the segment of the cylindrical variety is mutually perpendicular diagonal with respect to the axis of the vertical planes, four parts are formed: two of them, located along the arch, are called platforms, two other, walking across the arch, trays (Fig. 92).

You can imagine two perpendicularly intersecting cylindrical crops with floors and shelgami, located at one level. The crossing lines of these surfaces fully correspond to the footsteps of the cross section by two diagonally arranged vertical planes, and four platforms and tray are obtained on the surfaces of two intersecting arches. If you drop the trays, the four platforms closed diagonally and form a crusade: the protruding corners of the diagonal joints of the crop-ribs are given in terms of the cross. The crusade is based on four points in which his heels are boid. Thus, the support and cheek walls may be absent, and the arch is resting on four rack supports - the so-called cavity. The platforms can be formed by the intersection of any vaulted surface by another archway having the same or smaller radius - semi-curvous, boxed, elliptic, etc.

A closer arch is the opposite of the crusade. It consists of four trays, which, washed down diagonally, form incoming angles as opposed to a crusade, whose ribs have protruding angles. Not only square and rectangular, but also polygonal and rectangular, but also polygonal in terms of space, was blocked up, and the architects were restored around the perimeter. Current arch is also known as the monastery arch.

The mirror arch can be imagined as a closed arch, the upper part of which is cut by a horizontal plane forming the so-called mirror. The curvilinear parts of the arch fraction of the mirror are called Paddugs **. The mirror was performed in the form of a flat or very color arch. In the first case, the arch had a trough-shaped form in the section, in the second case, he represented a node of a box profile with the middle part, outlined by

* Essentially, the cylindrical arch may not be closed in the ends, for example in indoor drives, tunnels. The end of the end can also be produced by a semi-bundle (horse) or a transverse segment, (tray). In this case, the arch is called closed.

** With flat floors, the transition from the ceiling to walls is sometimes a curvilinear surface, which is also called Paddug.

radius. The mirror of the arch, usually separated from the Paddug Relief Rama, was used often as a surface for a picturesque ceiling. The mirror arch, which appeared for the first time in the architecture of the Renaissance, significantly reduced the excessive height of the premises, caused by the use of cylindrical, crosses or closed arches, which was especially important with increasing the number of floors of buildings.

The dome arch, or the dome, is formed by the rotation of the curve (semi-rapid, semi-terminals, parabola, etc.) around the vertical axis. Thus, in terms of or in a horizontal section, the dome gives a circle, and in any other - a curve line *.

The dome can overlap not only round in terms of the room, where it relies on the walls throughout the perimeter, but also square and polygonal. In this case, the transition from the dome of a round outline to the room of a square or polygonal form is carried out by means of spherical triangles - sails, or pandaratives, or by means of the arches in the form of a part of the cone - thrombus, as well as using the arches system. Spherical sails carry a support ring in its upper hour, on which the dome or the wall of the cylindrical shape is erected - the drum overlapped by the dome. The drum was usually used to place window openings to illuminate bribing space. Semicircular placed placed, for example, appearances, overlap, as a rule, a semi-shot, or a horse.

Sailing arch can be considered as derived from the dome. The geometric construction of a sailing arch is obtained by cutting off from the dome surface of the side parts of the prism planes, the longitudinal axis of which is combined with the axis of the dome. The arch of this form is the case of the dome on the sail, when the dome and sails have a common radius and belong to the same spherical surface. Top part Such an arch is above sails, which is a ball segment, is called Skuchery. Most often, the square was blocked by the square in the plan. He received his name due to the similarity with the fitted wind sail attached to the four corners. The sailing arch can overlap polygonal, as well as triangular placed room, such as the overlap of the thin-walled sailing arch of a large span of triangular in terms of the room - the audience of the Massachusetts Institute of Technology. Like a crusade or dome on sails, a sailing arch can rely on separate supports, forming a canopy.

The term "unscrew" applies to any arches and even flat coatings having a small rise in a weak curve to the middle - plowing. A flat ceiling in large rooms is usually made somewhat plowed to eliminate the impression of sagging.

The listed basic forms of vaulted overlaps do not exhaust the entire diversity of these constructive systems used in the history of architecture. Exist different kinds and the combinations of the given archs, such as vaults on the platforms, a pagiary, etc. There are still a large variety of reinforced concrete and armo-cement vaults.

Methods of plastic development of heaps are very diverse. Here we can only touch on those of them that follow from the structure of the vaulted overlaps and reflect their tectonics. This is the reception of the cylindrical cylindrical arch of the rented arches **, according to which the slabs forming the surface of the arch are laid. This purely constructive reception, used in the ancient Roman and Romanesque architecture, introduces the rhythmic beginning to the architectural solution of a smooth cylindrical arch.

* There are the dome of elliptical or oval in terms of which the shape of which can be considered as the result of the rotation of the semi-terminal or seized around the horizontal axis. Depending on the nature of the forming curve, the dome is obtained - different shapes - spherical, in the form of a semi-sufficient, elliptical (in section), sphere-conical, with a fitted top, etc. All domes having a circle arc in cross section are called spherical.

** Loads are called arches supporting a set or intended for its strengthening; in dome systems - arches that serve as a support for sails and maintain the support ring of the dome or drum; In the Crusades and Sails Arches, located on the four sides of the arch and which are supporting it.

A common technique for processing arches, also associated with their tectonics, is caissonization. In a stone arch, cylindrical or boxes, caissons are obtained by creating a frame from the arches going on the curve across the vault, and crossing out of horizontal ribs located along the arch. The cells thus obtained overlap with plates *. However, in its pure form, such a design is extremely rare, an example, it can serve as the overlap of the portico of Capella Pazzi in Florence.

In Roman stone arches, the caissons were outstretched after the construction of the arches, as was performed in the Tita arch in Rome, where the caissons have already purely decorative importance, which is confirmed by the fact that the breakdown does not match the seams of masonry. The more organic character had caissons in concrete arches of ancient Roman facilities, which were obtained by laying on the formwork of wooden forms in the form of drawers with appropriate profiling. When concreting in places in the installation of forms, recesses were formed, caissons, on the surface of the arch. The most typical example is the caissonized dome of the Pantheon and the remains of the Basilica arches in Rome.

Cable treatment was used for the arches of all forms - crusades, dome, etc. The practical purpose of the caissons is to relieve very thick concrete arches. In the same way, caissons in vaults laid out of brick were created. Also, as in flat floors, the keysons of the arches were treated with thread profiles, smearing and other types of ornamental decor. Often in the center of the caissons were placed by sculptural sockets, which were sometimes performed in the metal, as in the caissons of the Cathedral of the Kazan Cathedral in Leningrad.

The appearance of reinforced concrete structures has opened ample opportunities for performing a wide variety of vaulted structures. This is especially true of thin-walled armo-cement crops, so-called envelopes, which, with thickness equal to just a few centimeters, can overlap huge spans. Wavy shell profiles that attach a kind of surface of the overlap are used to give vaults of greater rigidity. The rational form of these structures is simultaneously an expressive architectural form (Fig. 93).

Achievements of modern construction equipment cause new architectural forms to life, create prerequisites for the emergence of a new, modern style, which is characterized by the synthesis of constructive, technical and aesthetic elements.

* This design is similar to stone caissons in the overlaps of Peron of Greek temples. Wiole-le-Duke gives a scheme of such a structural stone arch, where horizontal ribs are ribs in the arches.

Vertical supports

A classic example of the architectural form of support is a column. In the ancient Greek architecture, the column racks carried horizontal overlap - antablement. In the late Roman architecture, a construction was arose in which the columns served as a support for the arches, and the arch directly rubbed the fifth to the cap of the column or between the fifth arch, and the intermediate part in the form of an antablemer was inserted. The introduction of arcade on the columns gave the opportunity to spread them significantly wider compared to stone architect structures, limited sizes of the stone beam. In the future, the reception of the design of the arches and arches on the columns was widely used in medieval structures and in the architecture of the Renaissance Age (see Fig. 10).

A common type of support is pillars, round, polygonal, square or rectangular in a horizontal section. Pillars can carry a beam or vaulted overlap or arcade. In the classic architecture, along with smooth pillars, you can find pillars with different degrees of plastic processing-pilasters, blades, panels, etc. They usually have a molding, base and completion in the form of a cornice or simplified capita. Poles that support Arches are usually completed by an impost profile. Powerful pillars supporting arcade or bounted arches are called pylons.

In the ancient architecture there are supports in the form of sculptural images of a male or female figure, such as marble female figures that support one of the Erech-Teion porticors in Athens, the so-called karyatids, or bark, or the Caryatids of the Belvedere Palace in Petrodvorez (Fig. 94). The same appointment sculptural images of men's figures wear the name of Atlanta, or telemons, a wonderful model of which serve the granite Atlanta Portica of the Hermitage in Leningrad. Naturally, such supports over time have lost a constructive role, turning into decorative elementwhich creates support (Fig. 95).

Antique Germes, i.e. stone square pillars, sometimes expanding up and ending with the sculptural bust, were also used in architectural compositions as a supporting element. An example can serve as the portico of the pink pavilion in Petrodvorez (Fig. 96). In the Hermitage building, the Germe is used as a vertical impression in double windows of the main facade (see Fig. 86).

AT modern construction Mostly reinforced concrete or metal racks are used as vertical supports, the shape of which is modified in a wide range of both in terms of proportions and with respect to the horizontal cross-section abuse. With appropriate reinforcement, reinforced concrete columns may have a very large height relative to the diameter and a small cross section at relatively large loads. Their cross-section can be a circular, square, rectangle, and the latter can be strongly elongated, so the stopper when the edge takes on the form of the rib. The stand can also be multifaceted, has a complex profile with Westerns in cross section, etc., which is achieved by using the appropriate formwork. These features contribute to the identification of the nature of reinforced concrete rack structures.

Some varieties of modern supports can be distinguished, characterized by the characteristics of their design. Such supports can open up the supports that support mushroom-like wilderfish overlaps, U-shaped supports that support overlap in two-points, spindle-like - reflecting the distribution of efforts in the rack, etc. (Fig. 97).

Balconies

Balconies are elements of a building that serve as certain practical purposes, improving the functional qualities of the structure. At the same time, they are important compositional elements involved in the formation of the building appearance and contributing to the achievement of its greater plastic expressiveness. Balconies contribute to interior facilities with outdoor space. summer periodEspecially in areas with a warm climate, they complement the useful area of \u200b\u200bpremises, which is very essential for residential some other types of buildings.

Section 7. Windows and doors

The windows are designed for lighting, insolation and air ventilation. For normal lighting of residential rooms, the windows area are taken within 1: 8 - 1: 5.5 floors of the floor.

The form and location of the windows depends on the architectural solution of the building. In addition to those specified, heat engineering, acoustic, and environmental requirements are presented to the windows and ease of use.

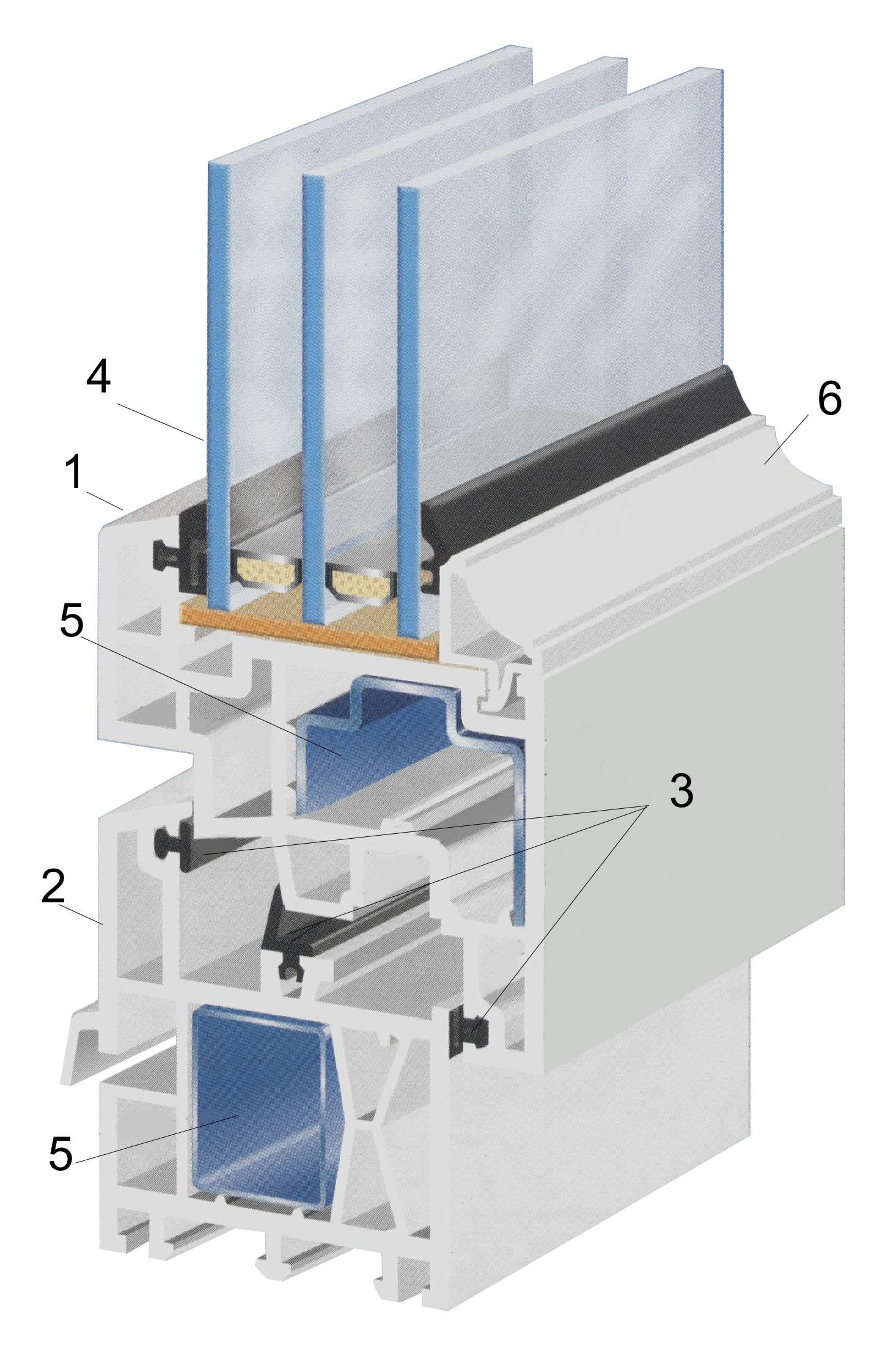

Elements that are filling left in the wall, and sometimes in the roof of the opening, are called the filling of the light opening. It consists of a window box, glazed window bakes, a submool board, exterior waters and glazing (Fig. 7.1). The combination of elements of filling the light opening in the assembled form is called the window block. The vertical side edge of the window opening is mounted inside for better illumination.

Fig. 7.1. Window filling elements:

1 - window box; 2 - binding sash; 3 - Framuga; 4 - windows; 5 - impost; 6 - the furnace; 7 - outdoor water; 8 - Glass

The elements of filling the window opening can be performed from various materials: wooden, metal (from steel and aluminum profiles), wooduminous, plastic (with reinforcing and without it, from various synthetic materials). Each material has its own features of use, has positive properties and disadvantages. For example: metal-durable, durable, comfortable in operation, but have a lot of weight, require a lot of metal consumption. Filling the openings from synthetic materials possess: low weight, unpal, beautiful appearanceBut the roads, to ensure the required durability, their material must comply with climatic conditions. The minimum warranty period on plastic windows According to GOST - 3 years. Wooden-easy, beautiful, resistant temperature drops and exposure to direct sunlight, environmentally friendly, but do not provide dense adjoining of the antimony, require periodic color to prevent posting, etc.

Wooden window blocks for civil buildings are produced in accordance with GOST, which provides for two block options: with separate outdoor and internal bindings (Series P), and with twisted bindings (C series), where both bolts are interconnected by bolts and disconnect them only To remove dust (Fig.). Paired reperseurs were widely used in modern mass construction. * / 1 windows with separate bindings are characteristic of buildings old buildings And for buildings built according to individual projects. * / 2.

Plastic windows are mostly manufactured with twisted binders. In addition to the traditional opening, plastic windows have swivel shutters, with the control of one handle.

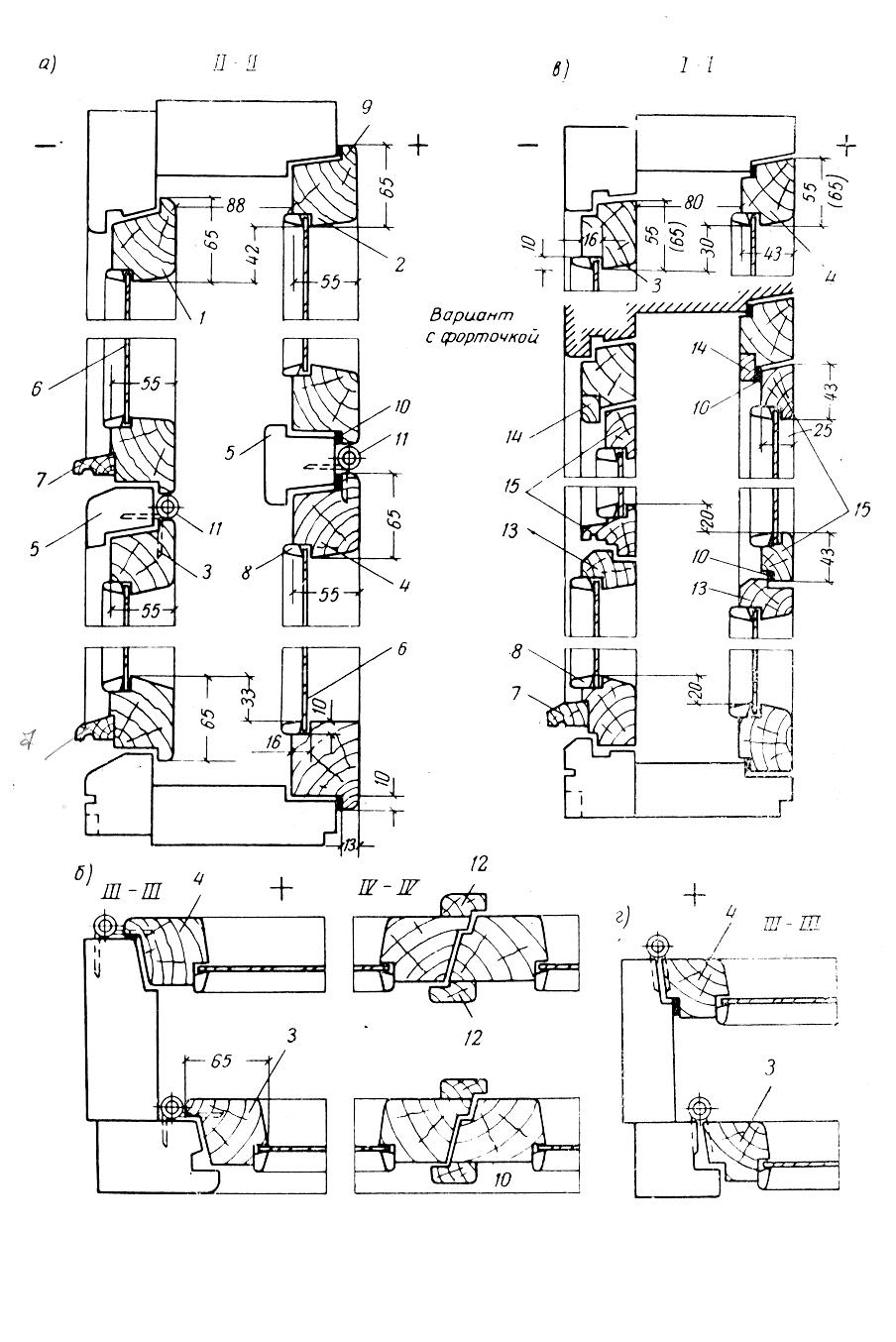

Fig. Separate-paired wooden binding with triple glazing.

a- vertical cut; B-horizontal incision on the impost.

______________

* / 1.The: Modern windows with paired wooden binders and double glazers have a heat transfer resistance of 0.38 m 2O C / W, which is insufficient, since the required heat transfer resistance (SNIP II-3-79 and SP №232 / 13 ) It should be about 0.60 m 2 o C / W for the central part of Russia.

* / 2. For new construction and overhauls with the replacement of window blocks, window blocks must be applied, providing the required heat transfer resistance (0.60 m 2 ° C / W). Such a design is: paired triple-glazed binders (Fig. 4). Heat engineering considerations as a material of the box is preferable to a tree (metal and plastic, condensate can fall on them), but the use of technological, extrusion profiles is allowed. (Plastics with a steel core or aluminum alloys). Strong and durable than PVC and aluminum profiles are polyurethane and polyolefins profiles.

Fig. Wooden window blocks with separate and binders

a - ordinary; b - with from the outlook;

1- Strapboard; 2-chipper; 3- tide; 4- moving;

Fig. Wooden window blocks with twisted binders.

a- Normal; B- wood aluminum; 1 - window box; 2-strokes for fastening glass; 3- slot for condensate; 4- insulation gasket; 5 - moving; 6 - internal binding; 7- outer binding; 8-tie screw; 9- screws; 10 - Aluminum facing profiles.

Windowoffs consist of opening, deaf or combined sash. The number of flaps determines the window type. In terms of the number of sash, the reels are: single, two-, three-rissed. In some cases, windows are combined with balcony door. Windowoffs consist of vertical elements - sash and horizontal - fraumug. Frames and framugs are opening inside the room; It creates the convenience and safety of their hits, as well as shifts and wipers of glasses; Open flaps do not spoil the rain and wind; Broken glass do not fall into the street. Opening the sash in different directions is permissible only in one-story buildings.

In the absence of opening fraumg for carrying out the premises in the cold time in the sash, the vents are arranged, at least one in each room. Footings with separate bindings represent an independent element and hang out directly on the window box. (Fig.)

By the number of windows windows can be with single, double and triple glazing. Triple glazing improves the heat engineering and sound insulation properties of windows (for example: they can be used in residential buildings overlooking the railway or a lively highway with an elevated noise level as well as to provide the required heat transfer resistance).

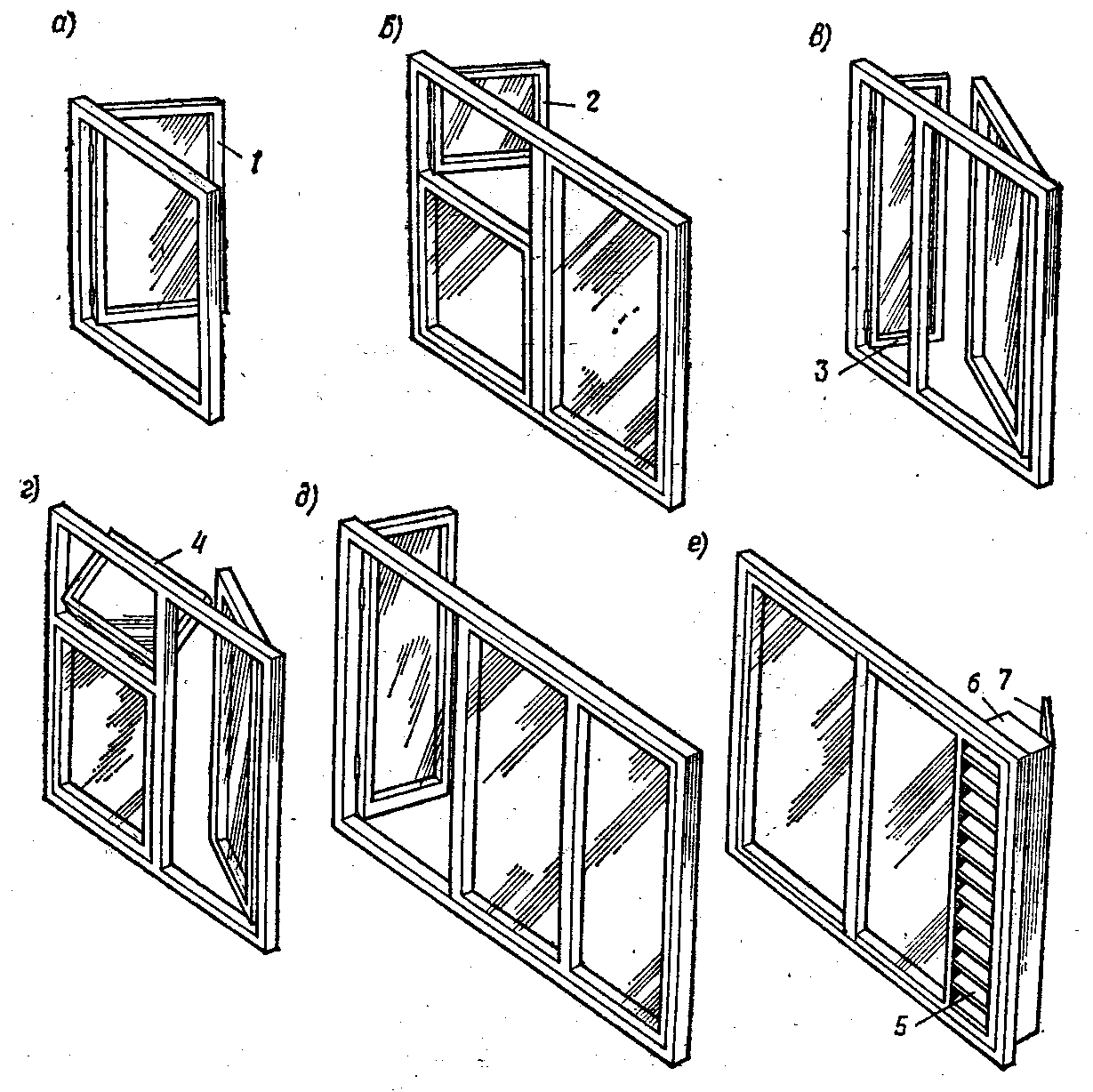

Fig. Window blocks for residential and public buildings.

a - single bed; b - bivalve (with window); in two-dimensional (with unequal flaps); g-bivalve (with fraumuga); d - three-rissed; e - deaf with non-opening flaps and ventilation valve; 1 - sash; 2-bit; 3- narrow sash; 4- framuga; 5-louvid lattice; 6-box; 7-door for ventilation.

For glazing windows, a conventional glass of 2-6 mm thick is used. Or glass with special properties, for example, patterned, tinted, passing ultraviolet rays, armored, etc. In accordance with the requirements of the premises in which they are installed.

* / Note: The windows with paired bindings give more light, save 30% of wood, 10% cheaper and 1.5 is easier by weight than the separate design of the binding, but have more heat loss up to 25%.

Designs of filling window openings.

Wooden window boxes installed in the window opening are naked to antiseptic mortgage details in the window openings of stone walls. The gap between the box and masonry of the opening is carefully combined with palauls moistened in the gypsum solution.

Plastic windows are attached to the way, and the clearance is sealed by construction foam. The design of Framug's sash consists, as a rule, out of four contour bars forming the strapping. The bars are connected in the corners through spikes on the glue and are attached to wooden brazers. Sometimes hills are introduced in the design - narrow intermediate lumps that reduce the dimensions of individual glasses. From the side of the premises of the strappings and hills, rounded squeaks are attached, and from the outside, a quarter is selected for inserting glass (folders). The glasses will be inserted on the smear, and on top of the second layer of crawls are strengthened with wooden strokes (straps of trapezoidal sections). In the lower bars of exterior sashs and fraumug there are fed to remove rainwater flowing from the glasses.

On the shape of the cross section of the strapping, the reversals are with a move (Fig.) And simple (Fig.). I turned around the protruding edge of the strapping, closing the gap between the binding and the box. For sealing purposes around the perimeter of internal flaps and fraamug, gaskets from porous rubber or a semi-cooler cord are strengthened. The same gaskets should be applied in the coarse of internal interlets without a pressure. Plaintiffs with from the outlook are more expensive than simple, but have a small imagination and easier to operate (they do not require putty for the winter).

In the paired bindings (Fig.) Internal flaps are hung on the window box, and the outdoor flaps are on the inner. Folds fasten with special screws.

Fig. . Window blocks For residential (A) and public (b) buildings.

1-window box; 2-vertical impost; 3- horizontal impost; 4ms of binding; 5thort; 6- hill; 7 - Framuga.

Fig. Dashing separate bindings

a, b- with from the outlook; in, m- simple; 1- outer framuga; 2 - internal fraumuga; 3 - outdoor binding; 5- Bruis horizontal imposses; 6- glass; 7- tide; 8-page; 9 - deposited; 10- sealing gasket; 11-loop of Framuga; 12- Outset; 13 - horses; 14-block; 15- Venting the window.

Fig. . Section of paired binding.

a, b-vertical cut; a horizontal cut; 1 - internal binding; 2 - outdoor binding; 3- slot for water drain; 4- sealing gasket; 5- loop; 6- windscreen board.

Standard window Girlian blocks for individual and brick buildings are not suitable for chopped walls. The design of the window boxes should fasten the wints of the cutters in the places of openings. Such boxes are called wells, they are much massive guest. On the backs of the side and lower bars of the box, the grooves are chosen, which wear on the crests in the ends of the logs forming the side faces of the opening, and in the lower log of the opening. The window unit should be greater than the thickness of the walls on the thickness of the inner and outer cladding (if the SM der. Walls are provided).

Reps are supplied with window instruments. These include loops (hits), window valves (upper and lower), brackets (handles), forwarders, devices for opening and closing Framug, etc.

Window boards in windows with wooden filling are made by wooden or reinforced concrete with an office facial surface. Svet windows from below should have a dropper groove for removal from condensing moisture walls. Window boards are installed in the opening on a layer of a gypsum solution with a slight bias toward the room.

The designs of steel bakes are similar to those used in industrial buildings.

Instead of wooden, it is possible to use window boxes from the precast concrete (Fig.), Which allows partially or completely abandon the jumpers and submone boards. For fastening such boxes of window bindings in them there are mortgage tubes.

Fig. Reinforced concrete window box.

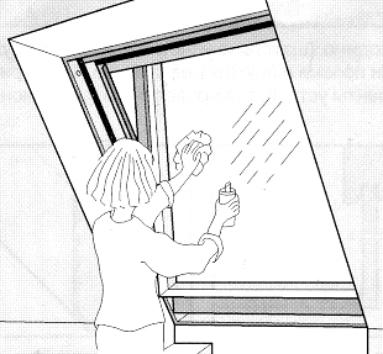

Mansard windows

A windows located in the roof plane can be used to illuminate indoors. They give 30-40% more light than hearing windows of the same size. An example of such a window can serve mansard windowsDeveloped by VELUX (Figure).

Fig. . Socan velux in the roof of the attic.

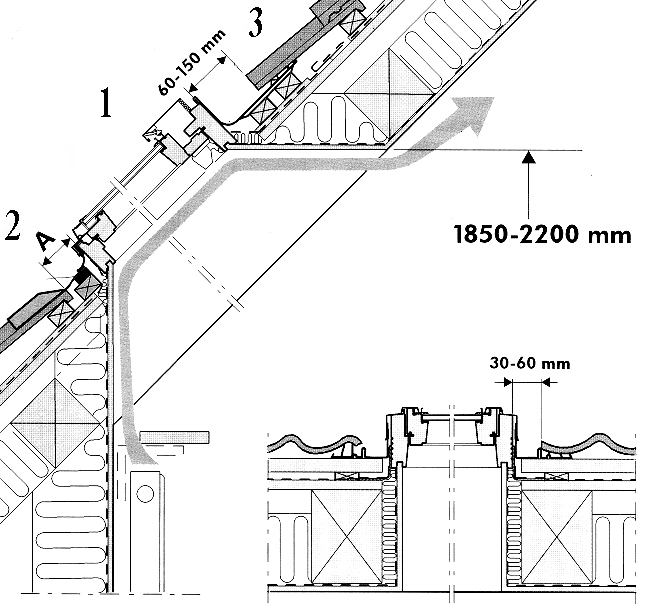

The design of the window block consists of a window box and a window frame made of high-quality wood with facing outside painted aluminum. The frame is a two-layer glass window with a turn of 180 o when opened (Fig.). Installing the window block in mansard roof shown in Fig.

Fig. . Overclocking the window is possible at 180 o.

* / Note: The double-glazed glass consists of two glasses with hermetically filled with a space with dry air.

Fig. Installation circuit Velux window in a naked roof.

1-window block; 2, 3-alard of waterproofing.

Window data are designed for use in roofs with a bias from 15 ° to 90 o. Fastening the windows of the box to the bearing roof structures (rafters) is carried out using mounting corners on screws.

Fig. . Window from PVC

1 - sash; 2- four chamber frames; 3-seals; 4- multi-chamber glass windows without an additional profile; 5 - reinforcement by corrosion-resistant steel profiles; 6-figured staple.

* / Note: To ensure sufficient illumination, the ratio of windows to the floor area is recommended.

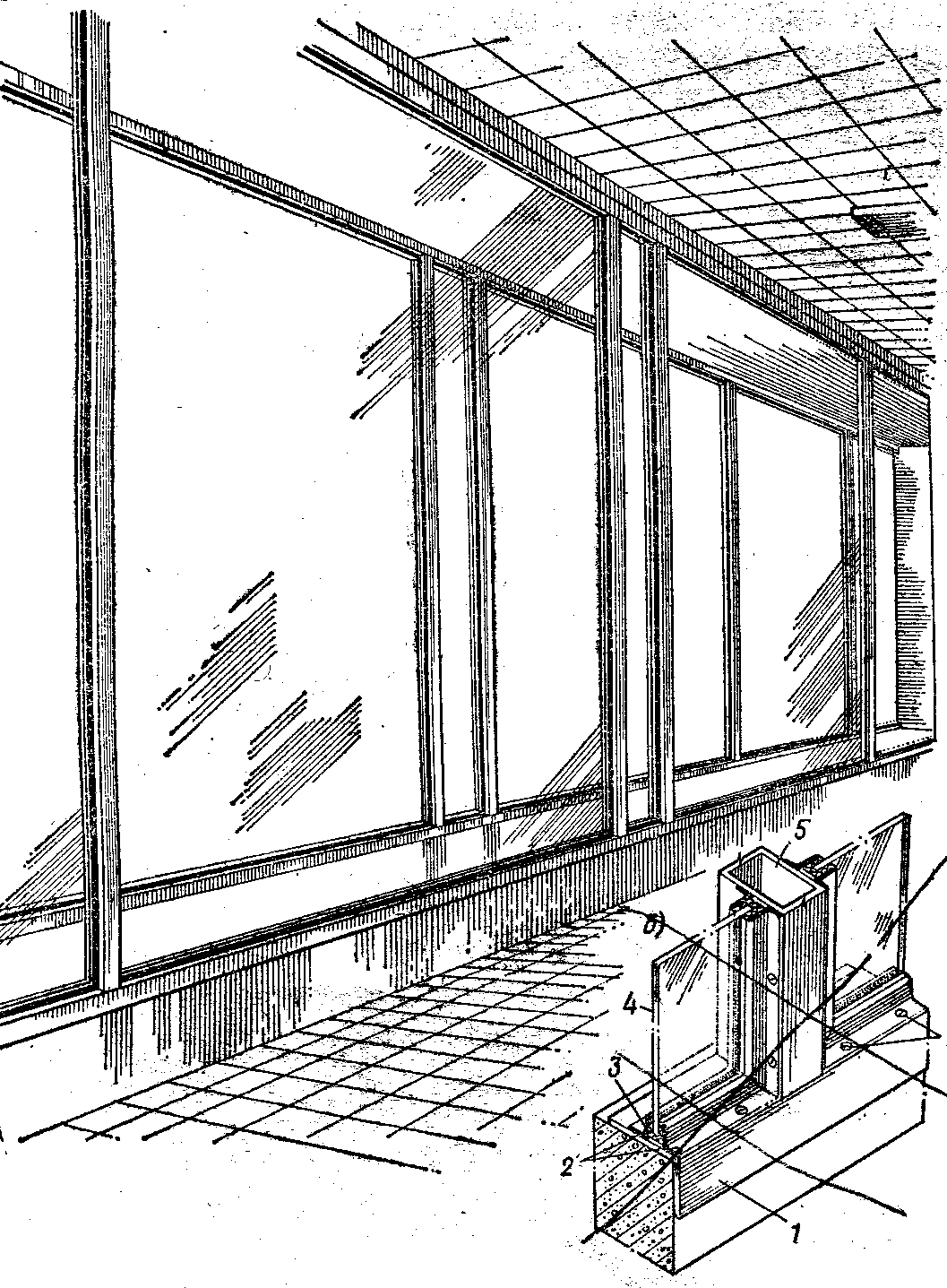

The glazing of large surfaces of public buildings (stores, sports facilities) is carried out using the device of glass windows. They can be on the entire height of the floor or form tape glazing. (Fig.)

Fig. . Showcase. General form.

Special display glass apply for showcases. They have a greater thickness than ordinary window (6-8m) and can have special properties, for example, to be mirrored, bulletproof, etc. They are installed in wooden, metal and plastic binders. The most common metal bounds for the window of the showcases are most common, as they are durable, durable, easy to operate. The design of the showcase should provide in winter Lack of condensate, fogging and freezing of glasses (Fig.).

Fig. . Showcase store.

a- vertical cut; B-details of fastening of glasses; 1,2-vertical

imposses; 3-fasteners; 4- display glass; 5 rubber gaskets; 6- welded rivets; 7- screws.

A special type of filling window openings is a laying of glass hollow blocks. These blocks have good traffic lights, but not transparent, since they have a corrugated surface. They are used in sports medical institutions and industrial construction. They are stacked on cement mortar and form a transmitted filling of the window opening of the thickness of the glass block. (Fig.)

Fig. . Filling windows with glass blocks.

At the location in the building there are external, internal. Outdoor doors are divided into entrance and balcony. Filling the doorway consists of a door frame and opening door canvases. Doors are single-bed, double and one-and-a-half - with two canvas of unequal width. By material, the door canvases are divided into wooden, glass and metal. Wooden are divided into shield and scrap and can be performed with deaf or glazed for illumination by the second light of auxiliary premises; With the same purpose, they are sometimes made with a fraumuga installed in a common door frame. Balcony doors are always done glazed (Fig.).

Shield canvases are solid or void shields with a thickness of 30-40mm. With plates around the perimeter or without them (Fig. A). Solid shields glue from wooden rails or make from chipboard. The hollow shields usually have a frame-and-wing design. Outside, the door shields are facing from all sides by veneer, plywood or solid wood fiber plates.

a) d)

a) d)

b) c)

b) c)

Fig. Door canvases.

a - general view of a one-board panel door; B- also a double panel door; V- also a biscuit shield door; G is also a panel door.

Pilented door canvases (Fig. B) consist of strapping, one or more furnished and panels, i.e. Shields filling the frame formed by strapping and furniture. Pilenks are glued from boards or plywood.

Door openings are filled with door blocks consisting of a box with hung cloths equipped with appliances. Doors sizes are chosen taking into account the necessary bandwidth and dimensions of furniture and equipment. The blocks of the internal doors are standard and manufactured in accordance with GOST. (Fig.)

Fig. . Installing door blocks.

a- in the openings of stone walls; B- in the opening of partitions; 1-balcony plate; 2- Door box; 3- tolender laying; 4- antiseptic wooden liner; 5- partition; 6-bar, framing the opening; 7- Calcarions.

The door frame consists of strapping with quarters for the doorway hide. If there is a fraumug, a horizontal impost is introduced into the box. In the boxes of interior doors, the lower bar of the strapping (threshold) is usually absent. Balloons of balcony doors, whose canvases are made from heat engineers double, manufactured by the type of window.

Installing the door frames in the openings of stone walls with quarters (in the outer walls) and without quarters are shown on (Fig.). When installing the door frame in the partition, the width of its strapping makes the thickness of the partition. Boxes are fixed with nails to the frameing opening of vertical bars or (with stone partitions) to the wooden plugs close-up. The seams between the box and partition for sound insulation are cocked and covered with platbands (profiled boards).

Fig. . Door box elements.

the sections of the bars and the cuts of the door frame; B - Detail of the installation box in openings with quarters; Wheel in openings without quarters; 1- Upper timber; 2- impossed (in fraumug); 3- bottom timber (threshold); 4- board (in the absence of a threshold); 5- Door box; 6- Wooden plug; 7 - caising.

* / Note: For internal doors, standard dimensions are installed: in height 2000 and 2300 mm., Width for single-board doors 600, 700, 800, 900 and 1100 mm., And for two-rank 1200, 1400 and 1800 mm ..

Glass doors are used in public buildings (shops, cinemas). They are performed from thick tempered glass 10 ~ 15mm. without strapping. Such doors are installed on metal boys, which, like door handles, are attached to the glass bolts. Metal doors are non-heat and are performed from 1 or 2 layers of sheet steel. Boxes and strapping of such doors are made from rolling profiles or tubular sections. The challenges include one, two, three-layer canvas with asbestos gaskets and facing from all sides with roofing steel. Boxes of such doors are also squeezed with roofing steel. Failure and hard-growing doors are installed in firemen, from staircases in the attic, and at present, the input doors made of metal have been distributed.

Door devices are: loops (hollows), mortise and overhead locks, Fale castles, combining in one device mortise locks and handles, brackets (handles) of various shapes and sizes, mortise valves for holding one half of the two-gas door in a closed position, etc.

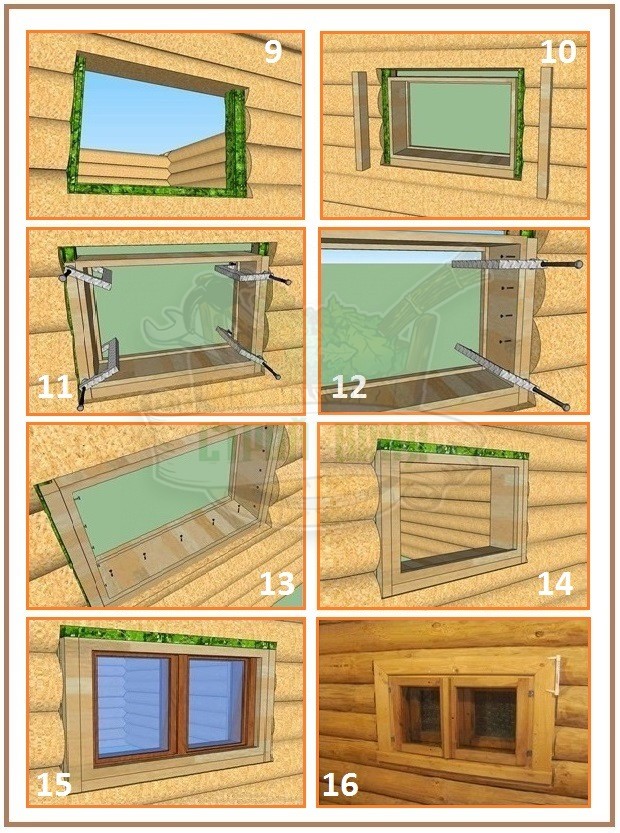

Regardless of the dimensions of the bath building and the aesthetic addictions of future owners, the issue of archiving of windows and doors requires a detailed analysis. To install the data of functional structures, openings are needed, the location and dimensions of which should be thought out in advance and calculate. Designing window and doorways for cans from a bar or logs is carried out taking into account specific rules depending on the operational features of the hygienic structure.

Why is it better to design everything in advance?

A number of important functions are assigned to the windows and doors of the country baths by analogy with their other associates. They are "on staff" to skip lovers of bath pleasures, natural light and fresh air flows. It is not necessary to contribute to the loss of the necessary temperature, the creation of drafts and violation of the technical condition of the construction.

Architectural background

Country baths are built to receive adorable procedures that attract not only standard hygienic effect. The indisputable priority of bath ceremonies is justified by the healing force and the toning effect. They are achieved by the effect of steam, heat or heat and a special atmosphere. Therefore, the main task of the construction recognize the preservation of a favorable regime, and not architectural "deposit".

Although no one claims that these two concepts should join irreconcilable contradictions with each other. In the name of the preservation of at all the cheap bath atmosphere, it is customary to do as little as possible, because of what the baths sometimes look "deaf" and "sunbathing". If you do not know how to competently design doors and windows for the bath, the aesthetic component can seriously suffer.

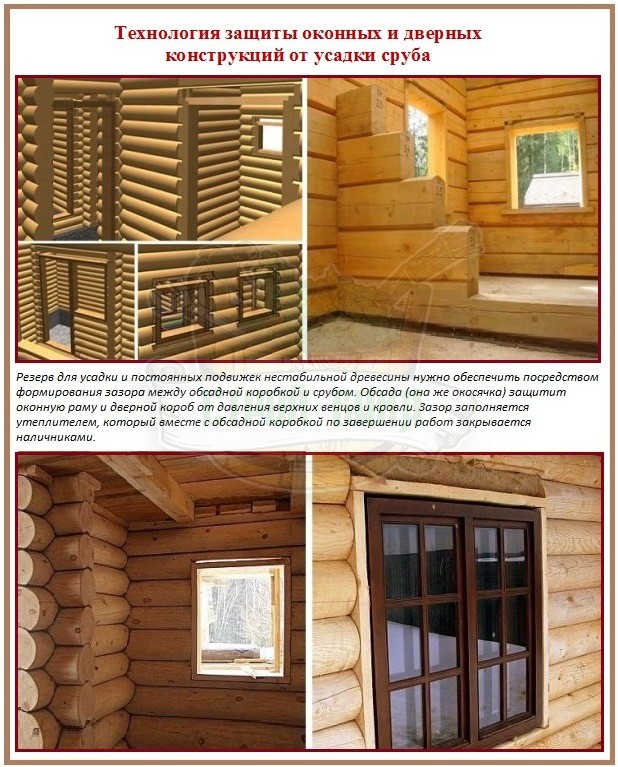

Accounting inevitable shrinkage

Couples and heat are far from the best wood allies, very sensitive to unstable humidity and fluctuations in the temperature background. The natural organic is increasing in volume, it is silent after the changes occurring around the bath walls. In addition, like all wooden buildings, the bath will definitely settle. In the first year, it is rather rapid by 3-5 cm, depending on the quality of drying sawn timber and varieties of wood. Then no longer as quarrels for 1 or less, however, the hosts peculiar to the wood will take place constantly, which is required to take into account when designing openings. Otherwise, the desired crowns simply give out window structures, and simultaneously breaks the roof and jamps the door.

Formation of openings B. bath WallsFolded from a bar or logs, it's not a simple matter. To ensure a reserve for tireless movement of wood, it is necessary to leave the gaps filled with insulation. Too extensive gap will provide the possibility of structures freely move without breakdowns and damage, but will be undoubtedly an attractive area for heat leaks. Not enough wide stock does not guarantee the safety of window frames and door frames, which again persistently pursues the idea of \u200b\u200bthe need for preliminary design.

Ensuring the strength of the structure

Among good reasons for advance planning plans to install window and door structures, there is a need for competent distribution of aggregates or multifaceted wooden coke connectors. They are used to hold the crown of the cut from transverse deformations and from displacements of long wooden elements relative to each other. In the simplicity between nearby openings, the mount should be made by setting the minimum of two connectors to the crown.

If the openings are formed directly during the construction and the simpleness fold out of a short one, it is impossible to forget about the installation of weak pins or cokes. However, the masters of a carpenter, brought up on the experience of previous generations, is strongly recommended to initially erect the deaf walls for a uniform shrinkage of the entire log. This method allows you to avoid sometimes tangible differences in the height of individual components after shrinkage. True, the consumption of lumber increases, which is not confused by those who want to build a beautiful durable bathhouse. According to the recommended scheme, all openings, in addition to the input fellow, are cut down or cut off by electric saw after a year's shrink shrink, but an inexperienced builder may not embed it in the required place.

In order to clearly designate the location of the openings and rustles in the "deaf" stacked firewood, the hole is left only in that crown, to which the windows board or the bridges of the interroom door frame will be rejected. Further, the logs or a bar are laid according to the principle of deaf walls, and the deforestation formed in the crown prompts builders, where you need to install connecting studs.

The impact of the option of the placade

Planning or climbing, it is an opponent - a mandatory element of the installation in a window frame or door design. It performs at the same time several important operating functions:

- serves as the basis for which windows and doors in the bath are attached, because Window frames and door boxes are strictly forbidden to fix the unstable wooden walls;

- its vertical elements play the role of peculiar guides, along which the gradual movement of door and window structures occurs during the shrinkage;

- strengthens the log house in the opening zone, providing a static position, simply speaking holds in the preceded position laid logs or timber.

In the arsenal of experienced carpenters there are many options for the production of souls, differing in the method of execution. All kinds decide end up common tasks. Structurally in any design, they are a wooden box, in fact, which is a buffer between the logberia and the fact that it is mounted in the opening. Any placade is fastened in the opening on the principle of "Ship-V-Paz".

Please note that the fixation of the casing to the cut of the screws with self-absorbers or nails is unacceptable. The density of bumps of spikes and grooves is achieved by laying insulation. It is forbidden to use the mounting foam on the stitching lines and log cabins.

Common ways of building casing boxes:

- Installation "in a deck". At vertical ends, the discharges are formed by either a neat cutting down the spikes are formed for subsequent attachment to them or thick boards with an outstanding or drank along the central axis of the groove. If an independent designer will prefer this method Society devices, then it needs to take into account the thickness of the board or the equivalent sizes of the faucet. They are partially narrowed by the opening;

- Installation "On the mortgage bar". In the vertical ends, the opening is selected for the installation of a mortgage bar. Because The "floating" bar is laid flush with the end plane of the opening, then only the thickness of the casing of the casing is affected by the size of this opening. But the windows frame or will be attached to it. So, the size of the placade should be taken into account;

- Budget analogue of the previous versionconsisting only in the installation of a mortgage bar in the grooves selected in the ends. According to this economical method, the frame is immediately attached to the movable guide on the mounting plates. Those. The stage of structures and fixation of the casing box to the mortgage bruss is completely absent along with the consumption of material.

The last budget method is not distinguished by reliability. It is possible to use it only to set the window frames small in size and weight. Loves bath doors Usually quite massive. Make them from wood, which under constant impact of moisture becomes even harder. The bar simply will not withstand the pairs of spiritual slaves produced by the broken baths.

We found that the windows and doors in the bath can be installed different ways, Following one or all the above methods. There are and actively apply numerous variations on the outlined topic of the souls. Often, the openings are not chosen during the construction period of the crowns for full size. Bring them to "to mind" before the direct finishes. However, the entrance door frame is recommended to form during a log cabin with the strengthening of the end of the deck to the mortgage bars. The front of the input opening is binding to a temporary jumper that excludes throughout.

In general, if you plan to build a bath with your own hands, at least approximate projects of openings are needed to mark the place of installation of the frames and attachment points with studs.

General rules of the device

The stack device in any of the listed methods is the strict condition for installing windows and doors in wooden log. Even if for his shrinkage was released for several years. The condition is equivalent at the obligation - the formation of gaps between the design mounted in the opening and directly the end of the collected crowns.

Between the mounted door or window design and the opposite, you need to leave:

- on the side faces of the log cabin 1.5 - 2 cm on the left and right;

- from above 6% of the height of the installed frame;

- the bottom is 0.5 cm for laying the insulation for the window of the window or bark as a natural waterproofing under the door frame.

Who is going to show personal carpentry and carpentry skills in own manufacture boxes and frames, easier. He only needs to accurately postpone the distances in each of the shut-off openings. To do this, armed with a feature - a carpenter tool look like a circuit. "Damocles sword" specifically specified sizes above their heads do not hang. A little more or a little less will be released - it is not very important. The main thing is to make the excess equal. After all, the home master will have to make frames under the openings, and not the opposite.

With the drinking of openings under the factory window and door structures will have to be scrupulously tinked so that the hole in the room is clearly fitted. In order not for too large gaps that reduce insulation qualities and aesthetic aspects. It is better to first cut the opening on the exact dimensions of the frame, and then rush along the contour of the surplus under the casing and the mounting gaps. Please note that the use of mounting foam on the pairing lines of the cluster and the window frame, as well as the clusades and the door frame is allowed.

Choose the right size

It is impossible to say that the recommended dimensions are regarded as a technological dictate, but adhere to the councils issued by the masters preferably. After all, they are based on the rules, for centuries that have formed in the medium of folk craftsmen. At the head of the corner of the design of openings, it is thermal insulation, according to which:

- bath doors are built with a threshold with a height of 10 cm to 30 cm. The threshold will be a barrier from drafts. It is necessary to arrange it according to personal sensations of comfort and security when overpanding. The presence of the threshold is required in the inlet door frame;

- there is no need between the steam and washer door threshold. On the contrary, it is necessary to leave a gap of 5 cm for the free circulation of the warm air flow;

- the optimal height of doors from 1.6 to 1.8 m. Too high doorway will become a zone of weighty heat loss. The width for the same reason is not to be carried away. The recommended size of 0.6 m can be 0.8 m. In extreme cases, the width is 1.0 m with insignificant deviations permissible for dense owners;

- the preferred configuration of the windows is a rectangle, the long side of which is parallel to the floor plane. In priority, the small sizes of window frames with the aspect ratio of two to three or three to four. Minimum height of 30 cm, a maximum of 90 cm length;

- the windows in the steamings are rarely established, but those who wish can not refuse themselves in the presence of a small rectangular or square window with a patterned glass. Locate it better at the level of the upper upper bath shelf;

- the maximum area of \u200b\u200bglazing in the steam room and the washer 5% of the total floor surface area;

- with the altitude of bath windows there is discrepancies. Who advises to retreat from the door threshold line 60 or 70 cm, who recommends 90 cm or as a reference point to choose the level of the eyes.

Instructing in drawings and video guide

And here and video:

There is a board of architects on the rational and most aesthetic location of the openings in the bath - a single level for the upper elements of casing boxes for windows and doors. In compliance with this rule, the construction with small openings will look quite decent. And thermal insulation priorities will be saved to the maximum. And the terrace and verandas will help to get rid of the terraces and veranda from the "sunposability" with small windows. Their vertical elements serving roofing or canopy supports will mimic window openings.