After the purchase country house People are increasingly wondering how to install a wood boiler. In this case, it is often not about heating, but about heat heating for household needs. Agree, buy for this expensive equipment is hardly advisable, it will be cheaper to buildwood boiler do it yourself.

A wood boiler is a modern, somewhat improved an analogue of an ancient and well-known to each stove on firewood. Consequently, the principle of operation of this boiler is extremely simple.

Fuel consists of genuine biomass. The plant was equipped with all the necessary measures to reduce emissions and, thus, meets all environmental requirements. The nominal thermal installation power is 980 kW. The fuel uses its own production residues.

Through local network Heating about 300 m long Administration, two large production workshops, a later project center and ventilation system are heat. The plant has a power of 550 kW. In particular, during the resolution, an exception was applied to burning the residues of grain crops.

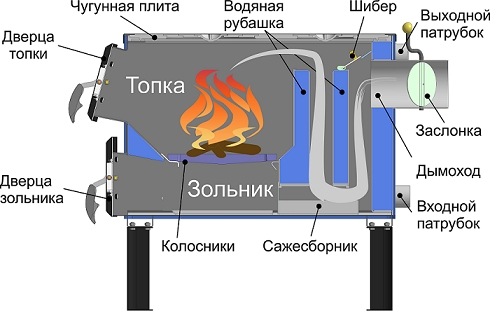

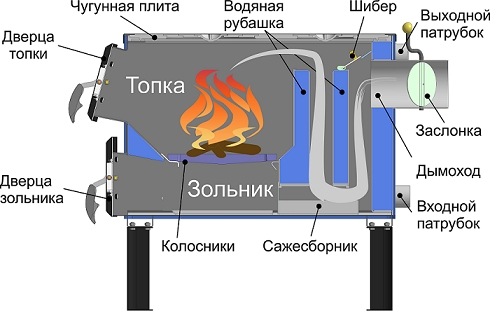

Firewood is placed in the fiber chamber, they burn there and transmit heat exchanger-free heat exchanger. Pipes transporting hot water into a common heating network are connected to the latter. With fuel burning, not only the coolant is heated. And the chimney pipe, and the boiler itself also participates in heat exchange, but only in the room where it is installed.

In the plant, experiments are carried out with various types of grains, as well as with alternative granules. Currently, the plant is controlled by industrial granules. With an existing flue gases system, current limits are currently no longer performed.

Therefore, the site was built new system Chimney cleaning to meet the current applicable emission limit values. The flue gas purification system consists of a mechanical pre-separator, the dosing system of additives, a tissue filter and a new suction exhaust fan. The additive is a mixture of hydrated lime and coke boiler.

![]()

![]()

To remove the smoke that appears when burning fuel, chimney is installed. In the chimney also settles the soot - another product of the burning of the tree. If it is too much, then the thrust will deteriorate significantly.

In addition, we have taken over the oversight of the construction and commissioning of the plant. Wood chips made of natural wood is used as fuel. Commissioning. The plant is specially designed to receive dry sawdust and wood chips. The supplied raw material ranges are adjusted to the quality of granulation through the processing unit and is fed to the existing installation of wood granulation.

The nominal thermal installation power is 220 kW. The firing type is firing wood chips with a water heating grate. Currently, the plants are burned with wood chips. It is designed in such a way that the grain can be used as fuel later. Manor house, one old separator, two apartment buildings and drying grains are equipped with heat using a centralized heat supply network of 240 meters long.

Important! For timely purification of the chimney, they leave special holes closed with dampers. Cleaning is made long brushes.

It is worth noting that today, together with fuel, special substances contribute to cleaning the chimney during burning are often loaded.

The expenses on the dispute, including the extrajudicial costs of the mediator, are carried by the applicant. The court decision is prior to execution, since the defendant is against providing in the amount of 110% of the amount to be executed. The plaintiff can prevent an intermediary execution by providing a guarantee of 110% of the amount to be executed if the intermediary has not previously ensured the security of the same amount.

The plaintiff appeals to the defendant with a request to cancel the purchase of boiler pellets and accessories. The plaintiff intended to repair his home at that time. In this house you need to install the boiler. The defendant conducted a part of the repair work in the plaintiff's house. This was followed by customer service intervention.

About modern wood boilers

Today's thermal generators of this type are almost perfect. After all, the technologies are developing and heating equipment, respectively, has undergone significant changes. Here are the main types of wood boilers:

- pellet:

- pyrolysis;

- open fireplaces.

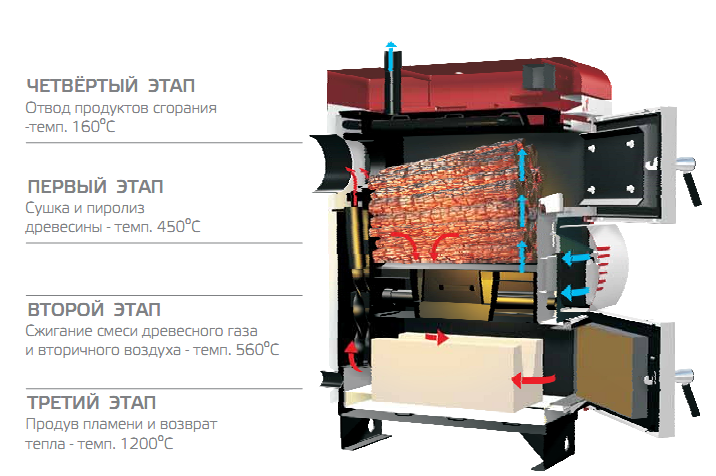

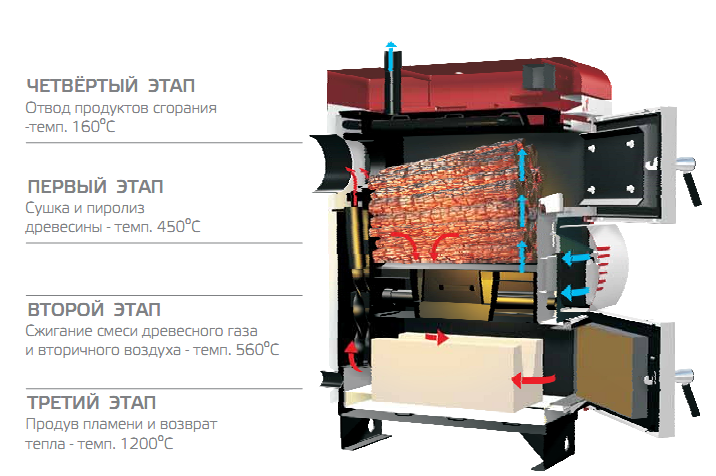

Separately, it is worth talking about pyrolysis devices, which, when working not only the tree, is burned, but also the gas formed during the combustion process.

The applicant claims that he has already made timely and permanent accusations regarding the heating boiler system. Another disadvantage was that the granules in the tank were not slipped, leaving at the same time the high residual content of the pellets in the tank, which was due to the fact that there was no adequate amount of intake manifolds. The microphone is constantly lit. There are problems with the contour of the mixer. Silicate is constantly formed in the pot of burners. The parties have already agreed to conclude an agreement that the commissioning of the boiler should occur only after the necessary repair work in the plaintiff's house.

Pellet boilers use woodworking waste, compressable in special granules. If we talk about fireplaces, they carry the aesthetic load rather.

During these repair work, the defendant completed heating and sanitary work, which would prevent preparatory measures to install the boiler. And other accused moved the heating tubes to the house. The plaintiff also complained about the deficiencies of the defendant, who was in place several times, even with his apprentice, but could never rectify the situation.

Therefore, the applicant had no choice but to refer directly to the manufacturer. The applicant probably always applied to the intermediary. Indeed, it was assumed that the defendant should take on the installation work on the boiler room, this is already at the time a year. However, it was true that he did not make a specific proposal. He did not discuss the details with the plaintiff and his wife, such as the price, in facts.

Where are used

Wood boilers are used primarily in populated areas located far from gas highways. It may seem that in such cases you can make a house with electricity, but in reality this energy is expensive and unstable.

More detailed information The actual and controversial situation can be found in response statements, applications and meeting protocols. Permissible action is unreasonable. The latter takes place here. The statute of limitations began with the delivery of things. The total land was transferred to the goods sold in this case the delivery time coincides with the transfer of service; Delivery was carried out by.

Only in these conditions, in accordance with contractual agreements or in good faith in relation to the risk of the seller, the early early and delivered thing can be verified by the buyer for their defectiveness. However, if at the time of sale or transfer things is still unclear whether or when - and if at all the seller - installation or commissioning of things, it is unilaterally at its discretion or at least the risk of the buyer when installation or input The service will be completed, and, accordingly, at this time, then check may occur for any defects.

Also, boilers on firewood are popular with dachensors who live on sites only on weekends. Home saunas and baths also do not cost without such boilers.

Important! In view of a minor power, such heat generators are inappropriate to apply for heating industrial facilities, but to create comfortable conditions in a small private house, it is quite enough.

In the latter case, it would be inappropriate to set the date other than the date of the transfer of the case at the beginning of the restriction period. It should be noted that the seller often bought a thing sold to the buyer in advance by a third party. In other words, the seller itself is subjected to a similar period of restriction for its own additional execution requirements. At least, in the case of the sale of a new product, as is the case here, it would be impractical that the seller is unilaterally incapacitated by the late input of the goods in the risk of only the buyer without adequately ensuring the right to appeal.

Pros and cons

Nevertheless, the parties were equally indisputable negotiations currently there is no information about it. In other words, the defendant did not make the claimant's specific proposal, and the details, such as the price, have not yet been discussed. Similarly, the date of this work between the parties was not established. Rather, this date depended on the expected repair work of the plaintiff. These uncertainties were as it were in danger of plaintiff. In particular, the defendant did not have a decisive influence on how quickly the reconstruction would be completed, and he did not have a specific idea of \u200b\u200bthis, even if he was engaged in repairs.

In wood boilers, like any other, have their strengths and weaknesses. Benefits include:

- autonomy from electricity - the owner may not be afraid of turning off electricity or voltage drops;

- ease of installation and operation;

- durability;

- ecology, because wood is a clean product that does not allocate any harmful and even more toxic substances during combustion; Although a carbon dioxide in non-compliance with the rules of fireproofing can be poisoned;

- low cost, which can still be reduced, if you independently make equipment;

- the availability of raw materials - for people living near forests, wood is free fuel.

It should also be noted that, along with firewood in boilers of this type, organic household waste can be burned (only solid, of course).

Not indicated, and it is also not obvious that the accused would make the repair only one. On the contrary, it is reasonable to assume that as the principal of updating the plaintiff had the right to decide on repairs and, therefore, was in a better position to evaluate when the work is completed, and then the boiler will be installed, although the specific date it was not clear. In other words, the future date of the planned installation of the boiler "stood in the stars", at least from the point of view of the defendant. Accordingly, there can be no question that already during the conclusion of the contract or delivery of the goods was established a contractual installation or commissioning between the parties, which could justify the adoption of a later delivery time and, consequently, the limitation period.

But there is similar equipment and disadvantages, among which:

Obviously, all the disadvantages described are very significant, but among them there is nothing about the workpiece of firewood. Firewood needs to be found, bring to the site, chop, find a place for storage and constantly bring to the boiler, because one portion usually grabs two or three hours. Of course, if you wish the firewood, you can buy, but it is again additional costs.

No specific additional actions of the plaintiff, who respondent did not before the expiration of this period of limitation, are also not represented. The plaintiff also did not refer to the relevant complaint against the defendant, so that any remedy by the mediator for any disadvantages should not be considered as a means of protecting the defendant in accordance with the current contract of sale, and acts in accordance with the existing warranty between the mediator and the plaintiff . This does not justify the new start of the current period of limiting any subsequent claims claims.

Instructions for the manufacture of wood boiler

The usual woodwood water heater is made quite easily even without the use of complex equipment. The main task is to transform the combustion of fuel to the drainage, which makes it possible to increase the frequency of refueling and, as a result, reduce fuel consumption.

It is true that the applicant originally argued, it is unreasonably that he constantly complained about the shortcomings of the defendant. He said that, although he meant that he first turned to the defendant in case of problems, but in concrete expressions he could not imagine him now. Accordingly, at least any reasonable lecture on specific complaints regarding the shortcomings declared in the present proceedings against the defendant to the corresponding time of the limitation period. The first, specifically presented contact with the defendant, in which concrete complaints were raised, was made in accordance with his own presentation, it does not matter to what extent the applicant has previously applied to the interlocutor for specific disadvantages.

For the workpiece, it is desirable to use a metal 200-liter barrel with thick walls or a small (1 m in length) cut pipe with a diameter of 70 cm. Elements from the "stainless steel" use is not recommended, since the thermal conductivity of this material is quite low: more wood will be required for heating.

The opponent is not from any legal point of view not to complaints about the applicant's complaint. Since the applicant addressed an intermediary, he also had to interpret it as notice of defects in accordance with the existing guarantee. The plaintiff and the defendant challenged that the plaintiff claimed that the defendant handed him an intermediary for his own incompetence regarding the problems with the boiler so that the claimant, by agreement with the defendant, requested additional work to contact an intermediary, this statement cannot justify any another assessment.

As a bottom, a metal circle of the corresponding diameter is used with a thickness of at least 5 cm. For support, 3-centimeter pieces of reinforcement are taken with a diameter of 12-14 cm. It will also require a blank for a grate - it can be a thick steel circle with longitudinal slots required for air supply to the fiber chamber And the fallout of ash. The third circle of 1 cm thick will also be required, which will serve as a boiler lid.

The defendant has already denied that he gave such consent. Rather, he simply indicated that some of his work could jeopardize the existing warranty. Living area was twice 80 m². At first he was inhabited by two tenants. The roof was isolated with mineral wool 100 mm.

Installing a new boiler with a capacity of only 27 kW and the installation of a solar thermal system with vacuum tubular collectors reduced the consumption of fuel oil to 000 liters per year. Previously uninhabited attic of the attic floor was completely removed and put on a prefabricated building. Living space increased to 320 m². The roof was isolated 230 mm, and the outer walls are insulated cellulose fiber 180 mm. The ceiling ceiling was isolated by a polystyrene fiber 70 mm, and the previous oil tank was replaced by heating the granules with a capacity of only 10 kW.

So, for the construction of a wood boiler, it is necessary to prepare the following materials:

Now you can proceed directly to the manufacturing process.

Procedure

The technology of manufacturing a wood boiler, as mentioned earlier, is extremely simple.

The first stage. Foundation

Under the wood boiler must lay out a solid foundation. For this purpose is used exclusively chammatory brick.

Stage second. Support

Then the reservoirs are welded inside the reservoir. Ponds need to be located in a horizontal position parallel to each other so that three levels formed.

- Level number 1 is the bottom of the heating device.

- Level number 2 is over the door pissed.

- Level 3 should be placed no longer than 20 cm from the construction cover.

Stage Third. Ku

One of the most important elements of any solid fuel boiler is the box. This box is divided into two parts (horizontally) - the first will serve as a susceptor, and firewood will be loaded into the second. For the installation of the box in the instrument housing (namely, the hole is made.

Important! The essence of the installation of this box is as follows: With it, you can pull the boiler from the adjacent room, which is especially convenient for the bath. In this case, the width of the box needs to be made at least the same as the thickness of the wall, through which it will pass.

Stage fourth. Pondered

Next you need to equip pissed. It is advisable to be made in the form of a nominating box - then you will not need to install the door. Moreover, with such a box it will be easier to brush the boiler from the accumulated ash and soot.

Stage fifth. Interior arrangement

The bottom of the construction is welded to the lower part of the body of the device. The grinding should be installed at the same level on which the top wall of the box is located. Then the chimney hole of the corresponding diameter is done in the furnace lid. The lid itself is also welded to the case.

Stage Sixth. Water heating tank

Water heaten capacitance is attached to the wall at a height of about 35 cm from the covers of the wood boiler. Water heating in the container will occur from the chimney pipe passing through it.

If the heating device is installed in the house, but it takes a hot water supply of other objects on a plot (both residential and economic), then the pipeline can be stretched.

Important! This pipeline should be covered with thermal insulation M material to avoid heat loss.

Stage seventh. Protective screen.

To prevent all sorts of tragic consequences, a homemade boiler must be protected by special protective screen. For the construction of such a screen, several carefully sharp wooden boards are taken, which are nailed to the bars in a horizontal position. There is another option - to build a fencing with a height of one meter from the brick, laid "on the edge".

Such a screen is necessary for the fencing of the hot body of the device from possible touches. Moreover, this is a good designer solution that can be used with a purely aesthetic purpose.

The number of accumulating soot depends on fuel and features of operation. So, coniferous trees give more soot. The use of raw wood, as well as poor-quality thermal insulation, leads to the formation of condensate. Ideally, it is necessary to trample solely with dry aspen lanes.

Video - Production of a wood boiler

Why wood boilers Heating remain popular aggregates for heating at home, because progress has long been holding up with time? The answer lies on the surface - the process does not always reach certain regions.

Gas highways are not extended everywhere, the installation of equipment is worth the fabulous money, with all sorts of permits from bureaucrats, electricity is expensive, liquid boilers carry more problems than benefits. Output one - use the traditional heating of housing. Everything in detail below.

The principle of action of the wood boiler and its types

It is simple - fuel combines with a large release of thermal energy. Air heating occurs if the boiler is not equipped with a water heat exchanger or pipe wiring system. Boilers are divided into the following types:What to choose? The solution depends on the goals - if you purchase a boiler for the heating of a residential building, then the savings should be preferred, since the process will occur continuously.

But at the same time it is worth choosing a boiler, an automated and extensive system of emergency situations. When the question about the heating of a residential building is not worth it, the usual classic will be suitable - to warm up and boil some amount of water quite enough.

How to choose a wood boiler

The parameters for which it is important to pay attention to when buying will set the tone to the entire process. Therefore, treat it with all liability. So:Power

This is what is indicated as kW. Before the purchase, the heat loss should be calculated at home, which are also measured in these units. If you do this correctly, then the resulting digit and will mean the required power. There are several ways to calculate:

When the number is received, it should be added to it 20-30% of the total losses for the use of DHW or poor insulation of the house. The final digit can impress.

Material of manufacture

Firewood or pellets do not give a large temperature in contrast to coal. Therefore, choose between steel and cast iron, it will be much easier - cast iron is more expensive. In addition, it has a fragility in mechanical blows or carrier temperature drops.

Steel options look carefully and have significant mobility unlike heavy alloy. You can purchase a combination - steel housing and a cast iron heat exchanger. Then, water in the pipes will not cool much for a long time.

The volume of the furnace

Owners should not forget that the large size of the loading chamber is good only for classic boilers. In other cases, small spaces are used, which are fully filled, otherwise there will be nowhere to go from the heat, and the smaller load leads to the overflow of firewood.

Safety

This parameter should be attributed to the protection against flame emissions, a smoke signaling device, anti-spare coating and other chips that make the process safe in all senses. All these devices are good only for constant boilers, that is, for heating residential buildings, not cottages, where owners appear only for the summer period.

Functionality

If the device's task is only home heating, then for the acquisition of a sufficiently single-mounted unit. For generation hot water We will need a wood heating boiler with two contours. Such an installation is more cumbersome, as it contains a water tank, by type of boiler, where the temperature of the water is constant. You can purchase and flow options, but such good only for small houses With 1-2 points of water, otherwise the water simply will not have time to warm up.

Conclusion - to select a boiler on firewood, you should consider many parameters and then use will become really comfortable.

Requirements for the installation site of the wood boiler

Safety rules, unfortunately, violated everywhere. In order not to happen misfortunes - and the boilers belong to devices, high fire hazard, even with all protective systems - it is important not to take a disregard for the following:As for the maintenance of the wood boiler, everything is simple - regular cleaning of the ashtar and chimney, maintain optimal loading, checking security automation. You should not neglect the warranty period received from the manufacturer - if during this period any trouble happens, you should contact the service center immediately.

Opinions on wood boilers

Of course, any acquisitions are made based on the opinions of people already using an aggregate for heating. Someone is pleased, someone disappointed. It is worth seeing this very much. So, the wood-burning boiler for the heating of a private house - reviews on the result:

Firewood in the boiler Logano burns very quickly. Maybe because the boiler is a classic. It was necessary to take long burning. Well, so everything suits - warm at home, not lower than + 22⁰. Firewood is forced to warm up by the way.

Mikhail, Zakamsk

The boiler acquired a combined - gas-firewood. But while I am heating the house only wood, gas in perspective. We can say that there are no minuses, only a common bookmark at our strong frostsBut they are not frequent.

Before the purchase, pyrolysis was considered - I like the very principle of action, squeezes everything that is possible, but the pellets in our lands lack, and if you leave from afar - delivery expensive. I had to take a classic, but I do not regret it.

Alexander, Kaluga region

Svetlana, Fokino

These are such different reviews. However, the most often negative opinions come from the owners who did not take care in advance to warm their own home or incorrectly fit the unit according to the parameters described. It is important to pay attention to the choice even before purchasing that the boilers are woodcuts for heating a private house showed themselves from the best side.

Installing a prototype of a Russian oven in his own house, the owner provides a residential object in advance with a proven heating method. Environmentally friendly raw materials, productivity in the form of a large efficiency make wood-burning boilers for long burning or classic leaders among many units to create comfort in the house. It is worth using the tips of this article to choose their design and then live in the house will be much more comfortable and warmer.