A decorative brick for finishing inside the room today is actively involved by people, regretting the premises in the house, office or urban apartment. The reason for this success of this building material is that it is absolutely natural, has natural beauty and is environmentally friendly. Using this material, it is possible to give life to even the most extraordinary and intricate ideas.

For internal cladding today is presented in a wide range. Each type of material has its own features and scope of application.

Gypsum

This material can be called the most affordable. The process of its production is very simple, and gypsum is used as a material. The final product is covered with paintwork, so that he does not differ from his fellow.

In the photo - Gypsum Brick for interior decoration:

Gypsum brick is distinguished by practicality, durability and resistance to temperature regimens. But the use of gypsum does not stand in those rooms where heightened humidity is kitchen, bathroom. It is possible to apply it when finishing a living room or a corridor. Its cost is 880 rubles per m2.

Ceramographic

In the photo - porcelain stoneware

In the photo - porcelain stoneware This stone is distinguished by its high strength characteristics. The process of its production occurs according to special technology. Grinding granite is placed in the clay mixture, then the presses are subjected to it.

The resulting from cerarmogranta is distinguished by its strength and durability. It can be used when placing the arch in the corridor, for the kitchen and the bathroom. Cost of stone B. Leroy Merlin It is 2200-2800 rubles per m2.

Ceramics

Ceramic decorative brick for decoration indoor space Particularly no different from the finishing brick. The only thing that distinguishes them is the thickness. Produce material by high-temperature firing using a small mixture.

The various binding components are placed in it. Apply for trim bath, kitchen and toilet. Its value is 18 rubles per piece.

Under a stone

This material allows the premises a noble aristocratic view. Apply it when lining a hallway or living room.

The decoration with decorative brick under the stone is no different from the facing by the real stone, but it is cheaper, and the installation process is easier. The cost is 1,800 rubles per m2.

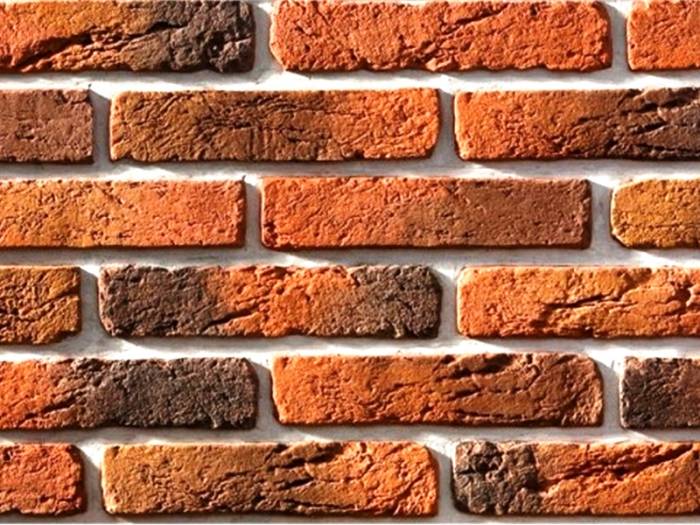

Clinker brick

This material refers to the category of the most expensive. With its manufacture, use such material as clay. High price speaks of high quality and its properties. During the production of the material, the brick was subjected to a firing, thanks to which he had high density and reliability. With the help of firing, it is possible to obtain an inhomogeneous color gamut.

For clinker bricks, a smooth surface is characterized. Use mainly for kitchen finishing in English style. In this case, the facing can be performed completely. For spacious kitchen room, it is advisable to apply a white clinker brick.

It is possible to apply the material not only for internal, but also outdoor facing. Inside the house use clinker bricks in those rooms where there is a temperature difference.

These are loggias, verandas, fireplaces and chimneys. To arrange an apron of the working surface in the kitchen, you need to use smooth clinker material. This part needs a wet cleaning, which is associated with high friction. Apply brick from plaster is unacceptable here. The cost is 3,500 rubles per 1 m2.

And for those who want to understand, will help you understand the information from the article.

What is a lime solution for brick masonry and how can it be done, is described in this

It will also be interesting to learn about and how to choose it.

You can glue a decorative brick if you stick to the following action plan:

- On the wall of the wall apply glue with a thin layer. Follow it to be enough for mounting 4-5 elements.

- On the opposite side of the brick also apply a solution.

- Press the material to the wall and correct its position. You can align the seams with a plastic strut.

- Laying each row should occur in the gender element.

- The glue that will come out of the seams must immediately remove the rubber spatula and rinse with a brush dipped in water.

Decorative brick today began to actively apply when cladding the indoor space of the house. And it is not surprising, because this material is distinguished by high reliability and long service life. Due to the wide range of products, it is possible to choose a certain option that is great for bleaching one or another room.

The desire to have a modern and beautiful house Forces the developer to use a variety of finishing materials. At the same time, the manufacturer does not sleep. As they say, demand gives rise to a sentence. And the speech today will go about brick. And rather about his imitation. So decorative decorative brick today has special popularity among others. finishing materials.

Increased interest and love for brick masonry Inside the premises have formed designers with world name. It is they who dictate modern interior design trends. And the stone in this case looks like it is not relevant. The laying of a brick outside is a kind of tradition for a Slavic person. But what to do if modern technologies and market building materials Allows you to save on the construction of a house box, using lighter cellular materials such as foam or gas blocks. In this case brick wall You can make at home with a facing stone in the form of tiles. Such a decorative brick will successfully replace the full appearance of traditional masonry.

Brick decorative: definition

Decorative brick is made on the production of a panel or tile, imitating natural stone. At the same time, under the brick, it is understood as imitation of brick blocks and imitation of rocks of rocks, sandstone stone, shelling, etc. That is, the decorative features of such products are not limited.

Depending on the purpose, the decorative brick is divided into facade tiles and on the tile for interior decoration. The first option is the products made of frost-resistant and impact-resistant material capable of pushing moisture. At the same time, the decorative stone is sufficient weight.

The second option of finishing material is a lighter tile made of plaster. In this case, the facing has a smaller weight and is afraid of cold and moisture.

Types of decorative bricks

All decorative tile Under the brick is divided not only for its intended purpose, but also by type of material from which it can be made. Thus, the building materials market offers the following types of decorative facing tiles under the brick.

Brick clinker

Such a finishing material is made on the production of refractory grade clay. At the same time, firing blocks of bricks occurs at high temperatures. As a result of such a "quenching", the tiles obtained perfectly opposes moisture, frost, mechanical effects, abrasion and burnout in the sun. Almost an accurate copy of the brick, only in a thinner performance. As a rule, such stones for cladding in width and height have the dimensions of the standard brick. Only thickness of tiles differs. It varies from 2 to 2.5 cm. Most often, such a decorative stone in the form of a brick is used to facade facades at home.

Important: If the decision to bore the house with clinker tiles-stone is taken at the design stage, the basement of the foundation must be calculated based on the weight gain. Since clinker facing bricks have a certain weight in their mass.

The advantages of clinker decorative stone are:

- Almost 100% naturalness of the appearance of the facade or basement;

- Strength increasing over time during operation;

- Simplicity laying;

- Durability of the material;

- Favorable value in comparison with natural brick masonry.

Ceramic decorative stone in the form of bricks

In this case, the production of decorative stone uses a low-melting clay. And to give a tile of structures and durability to use quartz sand, additives of carbonates, as well as dyes. With the rest of the latter, it is possible to get bricks of various shades from white lime to black burnt. Such a wide color gamut of facing material makes it possible to implement a wide variety of design ideas from Loft to an old classics. In production ceramic brick Equipped with decorative chips, which enhances the effect of making facing.

The advantages of ceramic decorative brick tiles are as follows:

- Strength and resistance to mechanical impacts;

- Inertness to moisture, sun, frost;

- Resistance to aggressive media;

- The durability of the material and at the same time comparative ease;

- Absolute environmental friendliness and aesthetics of cladding.

The ceramic stone decorative destination can be used both outside the house and indoors. Especially relevant to such a decor in the finishing of the fireplace portal, the kitchen worker apron, the panel in the living room, etc.

Gypsum Brick Tiles

Her destination is exclusively internal decoration of the premises. Make such a tile from a mixture of gypsum with water. Special dyes are used as a tinting agent. It is noteworthy that the gypsum tile can be made at home. It is only important to find forms for filling tiles. After final drying gypsum mixes In the form of brick, you can remove and mount on the wall using a special glue. And to give it a gloss, you can cover such tiles with a special protective varnish.

Important: Such a tile for interior decoration (gypsum material) is afraid of water. Therefore, it is possible to use it only in rooms with low humidity.

Dimensions of decorative bricks

For those who want to use decorative tiles-bricks in facing, it is worth understanding that the facing is available in various formats. So, if it is a facing for the interior decoration, then most often the tiles are standard bricks. That is, the height of the tiles can vary from 6 to 15 cm, the length of the tiles varies in the range of 16-24 cm, and the thickness of the facing stones is invariably equal to 2-2.5 cm.

If the use of facade finishes is assumed, then here to facilitate work, the master is offered a decorative finishing brick in the panel format. Such fragments are simulated easier and faster. The dimensions of such panels can vary within 320x340x25 mm; 380x200x25 mm, etc. (but strictly depending on the type of stone that mimics the panel).

IMPORTANT: If the decorative brick tile imitates rock rocks, then the sizes may look different - 210x102x48mm. That is, the thickness of the stones will be greater, and their height is less.

Areas of applying decorative stone

Decorative coating in the form of stone bricks Modern designers are used in a wide variety of interiors. So, the most popular points for cladding in the house are:

- Hallway and corridor;

- Kitchen work area;

- Decorative trim of balcony or loggia from the inside and outside;

- Fireplace portal and zone around it;

- Partial areas of rooms (corners, wall panels, panels);

- Facing the base, corners of the house or completely facade.

Features in the use of brick trim

If you decide to use the finishing brick, then in working with such a decorative stone you need to remember some nuances:

- Thus, the facade finish with ceramic or clinker brick requires an enhancement of the foundation, since pressure will be put on the walls.

- Panels in the form decorative bricks Actually use in systems ventilated facade. And when laying bricks on the wall it is better to provide small ventilation gaps.

- When laying a finish on the walls, it is necessary to ensure the perfect flatness surfaces. Otherwise, the decorative stone will disappear over time.

- Gypsum brick tile glue on plaster based glue, and ceramic and clinker bricks are mounted on a glue on a concrete basis.

- Before mounting the stone it is better to progress the walls. It will strengthen the adhesion between the facing and the wall.

- When internal finishing, the stone can additionally highlight the panel or the lined zone. This will give the texture to the finish.

IMPORTANT: Any type of decorative brick looks good in conjunction with a tree or simple plaster. Therefore, boldly create your own interior design or exterior at home.

Decorative brick for interior decoration is not some new invention of designers, it is often used for cladding fireplaces, kitchens, hallways. They also decorate the walls of bedrooms and living rooms. What is the reason for such popularity? They can be called several:

- aesthetic material quality, allowing you to create original design in the room of any style;

- operational characteristics that provide durability, wear resistance, fire safety;

- decorative elements are convenient in operation, they can be laid on any basis.

An ordinary brick is sufficiently heavy, so it creates an additional load on the overlap. In addition, the laying "steals" part of the area. Decorative products externally do not differ from ordinary, but much thinner. They are made of high-quality materials (most often plaster or clay), giving the surface desired texture.

Manufacturers offer bricks in a wide range of shapes, colors, textures. It can be traditional white or red, as well as elements of any shades. Of these, you can upload patterns, mosaic. Apply various methods Masonry and stripes, you can create an exclusive interior. Cement glue uses to fix cladding. If you have a certain experience, this process is quite simple and accessible to self-execution.

Material for manufacture

Types of brick acquired the greatest popularity: clinker, gypsum, cement. The main component of the clinker is clay. This species is characterized by a high cost due to a complex manufacturing process. The mixture is subjected to a firing that gives the material high density and strength. The edges are obtained smooth, and the color is inhomogeneous. It is often used for premises with temperature drops. It can be balconies, verandas, fireplaces.

Another species is a brick for decoration from plaster or a mixture of cement. It is made by manual molding method. For this, the solution is poured into the forms, leave for a durability. The finished element is then removed and subjected to final drying. If the mixture consists mainly of plaster, then the elements acquire white color. They are quite fragile, do not tolerate increased humidity. It is better to use them in places that are not subject to mechanical loads that do not require frequent washing.

The cement facing brick is solid, resistant to the action of moisture. They can be facing the walls inside the building and the facade. It is also suitable for wet rooms.

Pretty new kind is a brick of porcelain stoneware. It is distinguished by increased wear resistance, does not accumulate dust on the surface, is easily cleaned. His minus is a high cost. In addition, due to the content in the composition of the granite crumb, the material has a lot of weight, which complicates the installation. It is often used in rooms that differ in a complex microclimate (baths, saunas).

Another interesting option is an acrylic brick. It turns out easy, but durable. Long stay long. Thanks to the rich color scheme and the possibility of giving any form, the product from acrylic is an indispensable element of the facing.

Regardless of the source material, decorative brick for interior decoration has such advantages:

- durability - last a dozen years, without losing its color, while maintaining attractiveness;

- wear resistance - even an increased mechanical impact will not cause him damage;

- heat insulation properties - reduce heat loss from the premises, the walls are always pleasant to the touch;

- waterproof - to increase it will help the application of hydrophobic compositions;

- environmental safety - in the manufacture of natural components use.

Decorative brick is manufactured as separate elements and in the form of panels. The surface of the panel imitates masonry from several stones, work seams immediately performed on it. Installation of panels is much easier and faster.

What to give preference?

The dimensions of the bricks differ depending on the manufacturer, element style. Their quantity is calculated in the same way as the tile. Products from porcelain stoneware and ceramics are harder, so the most solution will be required. But they do not need additional protection. Acrylic bricks immediately have a coating that protects against external factors. They are light, so the installation will pass quickly and without much costs. The lack of them is one - high price. Gypsum bricks will need to be coated with moisture protecting, but the solution on the masonry will be needed less. For all indicators the most accessible option.

So that the finish is aesthetically attractive, the laying must be accrued neatly. Not many Master own it in perfection, therefore it is expensive. But the result long years It will delight a stylish and original view.

Order of masonry

Facing brick is a universal material that is suitable for masonry on concrete, plasterboard, wood. Preparation of the foundation is to clean it from the old cladding, alignment, priming. Improve the clutch with the base will help the reinforcing grid.

Before masonry, it is recommended to lay out bricks on the floor to assess their color, the coincidence of the shade, texture, size. If elements from different packages are slightly different, then you can alternate them. It will give cladding inhomogeneity, make it more natural. For angles, special angular elements are used.

First, on the wall make marking, determining the position of the lower row. The back of the decorative brick is also recommended to handle the primer. For gluing, a thick glue composition is used so that it does not slip from the wall.

First, the adhesive mixture with a spatula is applied to a small segment of the wall, rubbing it for better contact. Then the glue with a toothed spatula is distributed along the back of the brick. The prepared element is pressed to the surface, slightly scrolling it. The extruded surplus of the solution is immediately removed. To get beautiful seams, the struts from pieces of plasterboard or plywood are inserted between the rows. Complete the decoration of the seams, using a special composition or that solution to which the masonry was carried out.

Interior solutions

Bricks are used to design walls entirely or individual sections. It often becomes the framing of the head of the bed, niches, fireplaces, mirrors, helps zonate space. A white brick is recommended in the corridor or hallway. Due to lack of lighting, dark colors will make the room with gloomy, uncomfortable. If the dark background is still chosen, the light grout looks good on it.

Brickwork has become an integral attribute of Loft style. It is used to decorate the living room, rubbing in a completely wall. For greater realistic, the masonry should not be perfect, chips and scuffs will give her a cozy cherished view.

The style of "Country" is also perfectly combined with bricks. Use it in the decoration of walls, fireplace, ovens, openings - all this helps to create the right atmosphere. In this case, you can use both white brick and red shades.

Even in the style of "High-tech" brick looks modern and fashionable. Preference is given to smooth products with a glossy surface. Make sure the shades of white. The grout is selected as much as possible to the main cladding to create a monolithic coating. Extravagantly looks aged brick. His rude texture emphasizes the elegance of High Tech style elements.

Making the English-style kitchen, use light brick. If the kitchen is big, with good lighting, then decorate the entire wall. In a small room, only the workspace is more often faced. It is appropriate to the use of clinker brick, which is well clean, is not deformed.

Completing the construction or repair of the room, you approach the last stage of this grandiose action - interior design, where the key place is occupied, of course, the walls. Preparation options can be a lot: from ordinary whitewash or painting to the trim with natural wood. However, there is a very original, affordable and effective method To give your nest cozy and at the same time refined - use decorative brick for interior decoration.

The material looks like a brick used for masonry, only thinner and easy. The most common sizes: width 29.0-17.0 cm, height 5.0-6.5 cm, thickness 1.0-2.5 cm. It happens face and angular. It should be clarified that the decorative stone and brick for wall decoration are different types. Their essentials are that the stone has a embossed facial surface, a variety of forms and sizes.

The material looks like a brick used for masonry, only thinner and easy. The most common sizes: width 29.0-17.0 cm, height 5.0-6.5 cm, thickness 1.0-2.5 cm. It happens face and angular. It should be clarified that the decorative stone and brick for wall decoration are different types. Their essentials are that the stone has a embossed facial surface, a variety of forms and sizes.

Varieties and their characteristics

Depending on the raw material used in the manufacture, distinguishes decorative brick:

- Ceramic (clinker) is made of clay, which is molded, dried and burned. Thanks to this technology, the brick ceramic decorative has good strength, thermal conductivity, has a smooth surface.

- Of concrete mix - the binding element serves as cement, and fillers are sand or small ceramzit and perlite. Such products are durable, eco-friendly, have good water absorbing and thermal insulation qualities.

- Gypsum - in contrast to the two previous species, it is quite fragile, hygroscopic, has a low water resistance. For this reason, the laying of plaster decorative brick is done in places where humidity no more than 65% and the finish does not experience large mechanical loads.

The listed elements are made with additives of dyes, and their front side can be covered with a protective layer that protects products from the effects of moisture and temperature fluctuations.

Technical parameters of different types:

* AEF - the specific activity of radionuclides.

Using

Decorative brick is designed for interior decoration of houses and buildings, planning interior design, some nuances of its use should be taken into account:

If there is a fireplace in the living room, it is better to use ceramic brick with refractory qualities for facing its contour.

2. Decorative bricks for kitchen finishing are typically used to design a working wall. In such a room, a contrast design will look good: brick in dark colors and designs from drywall bright shades. If you want to get a kitchen in an English style, then the perfect option will be a plaster white brick suitable for interior decoration. Thanks to neutral color, such a stone can lay walls from the ceiling to the floor.

3. The decoration of walls in the corridor is executed, as a rule, fragmentary in those places where there are doorways.

4. Concrete brick, made "under ancient", with a rough facial surface and rounded corners, is suitable for designing basement rooms.

The main thing is that you need to remember: a decorative brick in the interior of your home must create comfort and comfort, and not a feeling of cold, dark walls.

How to make it yourself

From the mentioned types of finishing bricks are not subject to only ceramic production at home, because it requires the use of equipment for firing. Available for handicraft production There are products made of concrete mix and gypsum. Making decorative facing bricks With their own hands requires the following tools and materials:

- vibrationtola;

- plastic container for mixing ingredients;

- pallet;

- forms for fill;

- cement, gypsum, sand;

- citric acid;

- plasticizers;

- water based dye.

The manufacturing process consists of several stages:

1. The form for a low-end brick is made from plastic, rubber or silicone and can be made it yourself. To do this, you will need a suitable stone. Then, in the prepared formwork from wooden Bruschev Put the sample, pre-groaping it and the container with solidol, and poured with liquid silicone. The surface is smoothed by a trowel and leave to stick for 2-3 weeks. After complete hardening, the formwork disassembled, the sample is removed and the finished form is obtained.

2. Production of bricks from a concrete mix involves the fill of two layers of solution and its seal with vibrationtol (vibrating method):

- Cooking. For the 1st layer, cement M400 and river sand shallow fraction up to 2 mm in proportion 3: 1. In warm water, the dye is breed at the rate of 1-2% of the mass of cement. Diplot pigment is added to the sand-cement mixture. For the 2nd layer, the plasticizer is poured into the solution (about 2% of the total volume) and the binders: perlite or small clay with a dimension module up to 5 mm in a ratio of 1: 3 to a mixture of sand and cement.

- The first layer (1 cm thickness) is laid out in a form, pre-lubricated with soap solution, and 15-30 seconds on the vibrotole are compacted. In this capacity, you can use the old washing machine, turning it on in the "Fat" mode. Vibration is necessary to remove air from the mixture.

- After sealing the first layer, the second layer with a plasticizer is poured, and the form is again subjected to vibrations for 20 seconds. Then the surface of the product is smoothed by a spatula.

- Primary drying is carried out for 12 hours. At the end, the brick is neatly removed from the mold and laid out on the pallets for the final drying, which lasts from 48 to 72 hours, depending on the air temperature.

3. The manufacture of plaster occurs in the same sequence, except that the gypsum solution dries sufficiently quickly, so the mixture is prepared at the same product:

- G8-10 gypsums are stirred with water to a sour cream state, adding 0.5 mg of citric acid to it to increase the lifetime of the setting to it. If necessary, staining here also poured a painting pigment in warm water.

- The fill in the form takes place in one layer, before it needs to be labeled with a vaseline or soap solution, this will allow you to easily and without damage to withdraw a dried stone from it.

- Drying brick from plaster occurs within 20-30 minutes.

- Additionally paint the surface of the stone after it is drying. It is necessary to remove the dust with a rag and apply the paint (recommended on a water basis) the color you need.

Laying with your own hands

Before proceeding with the facing, you need to prepare a tool. You will need:

- building level;

- rope;

- roulette;

- construction line;

- pencil;

- brush;

- master OK;

- brush.

As well as consumables:

- glue for tile or liquid nails;

- strips of plasterboard for seams;

- hydrophobic mixture for brick surface primer;

- grout for seams.

Stages of finishing:

1. The walls are aligned with plasterboard plastering or placing, then ground.

2. Stop the brick is needed along the laid line, ranging from the bottom and the angle of the wall. With a spatula with a comb, the adhesive solution is applied to the wall. The stone lays down or with a 1,5-2 cm extender. For this, strips from drywall required width are cut and put between rows of masonry.

3. After 48-72 hours, you can carefully remove the auxiliary strips and proceed to the grout of the seams. The solution in a brick must be removed with a wet sponge.

4. Optionally, a hydrophobic composition can be applied to the surface of the stacked stone, which will facilitate further care for it and will protect from light mechanical damage.

Cost

Buy brick decorative is easy, because on the finishing materials market it is presented quite wide. Its cost depends on the type, color, size and additional surface treatment. On average, the price of decorative bricks in Moscow is as follows:

| Name | Size, mm. | Price, rub / m2 |

| Ceramic | 204x55x20 | 1 018–1 250 |

| From concrete mix | 210x60x15 | 635–854 |

| Gypsum | 235x70x15 | 805–1 000 |

| Articles |