For heating the garage, you can easily make it easy to make the furnace on firewood. It does not take much time and will cost completely inexpensive, because the use of infringement materials is allowed.

Why do you need to give a non-residential premises?

State standards found that in the garage the air temperature should not fall below + 5 ° C. If you do not adhere to these standards, the engine will not start, especially after the length of the car downtime.

For strong frost Even antifreeze can freeze. Significantly increases the number of vehicle breakdowns due to the negative effects of hardened water. Also, agree, carry out the repair of the vehicle is much more comfortable in heat.

Advantages and disadvantages of heating firewood

Semit solid fuel As a source of energy to heat the garage, you can get such advantages:

- low cost of firewood;

- no need to buy expensive installations and additionally spend money on electricity;

- small dimensions of the stove at high productivity;

- the heating device can be additionally used for cooking and warming up;

- simplicity of manufacturing and mounting installations on firewood. No further equip the massive foundation.

The disadvantages include that such heating devices are quickly heated, but it is also quickly given heat in environment. For supporting optimal temperature You need to constantly throw up fresh firewood. Fuel consumption increases significantly.

Varieties of heating devices

For the heating of the garage, you can make such types of stoves:

- bourgehog with a metal case;

- brick oven;

- heating device long burning.

To independently install the burzhuyk, you need to have skills to work with the grinder and the welding machine. Brick masonry In this case, produce much easier.

Bourgesic - Production Features and Constructive Elements

Bourzuyki scheme

This is enough simple designwhich consists of such elements:

- boot chamber or firebox;

- grate;

- confused;

- solnik;

- metal door;

- chimney.

For the manufacture of the installation, use a thick metal with a thickness of 4 mm. When fastening the chimney pipe to the upper wall of the cooler camera, it is necessary to strengthen it. This place is considered the weakest, the metal is most often here it is here.

As a grasp grille, use a solid metal grid. You can take ready or make your own hands from a corner or wire. In the grate grid, make a lot of fine holes to remove ash.

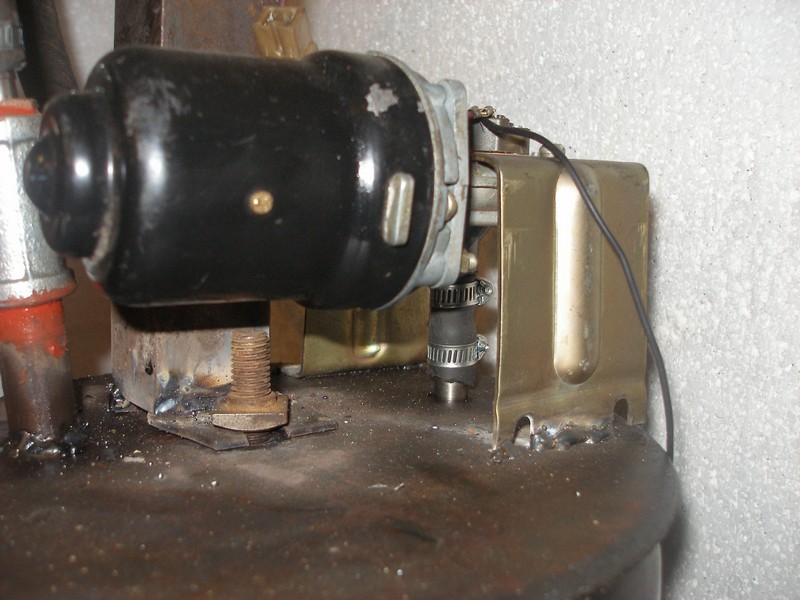

Step-by-step manufaction of steel pipes made of steel pipe

- Use a steel pipe with a diameter of 0.4-0.5 m with a length of 1 m, to which you need to fight legs.

- From the steel sheet, cut two circles of the same diameter as the pipe.

- In one circle, make the door for the firebox and the hole under piste.

- The length of the grate grate is equal to the length of the bourgeitors, and the maximum width is the diameter. It is best to use a metal mesh wide, which is slightly less than the diameter of the case. Insert it into the pipe and brew to the walls.

- We weld metal circles to the pipe. Follow the quality of the seam to achieve the tightness of the stove.

- Near the hole in the circle, attach a loop for which you suck the doors.

- On the cover of the case closer to the rear wall, make a hole with a diameter of 100 mm under the smoke pipe.

Next scheme of the furnace on firewood for the garage is suitable if you do not have metal pipe. Make it with your own hands is very simple, using metal trimming.

Manufacturing technology:

Brizuyka of bricks

For installation brick oven For the garage, you will need an additional fill of a small plate foundation 200 mm depth. Machine chamber completely stick from refractory brick.

On the front wall of the design, leave the window for the door and pondered. From the parts of the brick, at the bottom of the heating device, small protrusions for the installation of a grate grid.

To mount the cover, put the valves on the walls. Top to make a laying of 1-2 brick rows.

Also, a metal sheet can also be used to arrange the upper wall. Squeeze it on the burzhuyk, after which the gaps are gratifying chammed clay. In the upper part of the device, refer to the chimney hole.

Construction of long-burning furnaces

Due to the presence of a special damper, homemade furnaces of this type are very effective because the firewood is not lit, but for a long time. With the help of purges, the intensity of the flame and the power of the heating device can be controlled.

Long burning furnace with your own hands

To make the installation for heating the garage, you need to use a metal tank with a volume of 200 liters. In its top, make a hole for the chimney with a diameter of 150 mm. Also, refine a hole for the pipeline through which the fresh air will flow into the barrel.

For cargo, cut the circle of metal, which corresponds to the diameter of the barrel. We will breed the ranks. Also make a hole with a diameter of 100 mm, where to insert a small piece of the pipe. Such a cargo placed in a barrel under the cover. In the heating instrument housing, make two holes for supplying fuel and removing ash. Each of them additionally equip the doors.

Make the heating device with your own hands just enough using simple materials - metal sheet or barrel, corners, pipes, brick.

Video: Super Bourgeois for Garage

Secrets of treating pain in the joints from our regular reader.

Hello!

My name is Genady Alekseevich. I am a live shop with experience for more than 20 years. I am engaged in both the repair and construction of Russian ovens and fireplaces. Work always performs very high quality and carefully, which negatively affects the state of the joints. With the age of pain began growing stronger, right up to the state when I could no longer work. Reprobed by a lot of both drug and people's methods Treatment, I understood how seriously my disease is, since there was no positive effect. While I did not come across one tool, about which I want to tell you.

This is a unique mixture of the rarest and powerful natural healing substances. This tool has proven its effectiveness not only to patients, but also by science, which recognized it with an effective drug. Pain in joints and backs go for 10-15 days, as studies have shown. The main thing is to clearly follow the instructions in the methodology. Order a tool in the original packaging, with a guarantee of quality you can

If there is a need to heat the room, you can make a stove on firewood. You can make such an installation with your own hands, having certain welding skills, if it is assumed to use metal as a material. A fairly common variety of firewood ovens is burzhuyka. It is pretty simple, but its efficiency is enough to warm the oversized room. Not only firewood can be used to work, but also other varieties of fuel, namely: coal, trash, peat, wood waste.

Making a portable oven

A hiking stove on firewood can also be made independently. To do this, use the cylinder to be used to initially cut. It is advised to prepare it, releaseing propane. The upper part will become the basis. You can cut with a grinder. Bottom is cut off. Next, you can cut the firebox door. After the door must be installed on the pre-welded loops. Next, go to the cutting confused, which should be located at the bottom. Now you can start mounting the brazier. Make it is permissible from the metal sheet (6 mm). This element is welded to the furnace, the lattice is put in advance. In the roastery, a hole for the chimney is prepared, in which after it is possible to insert the pipe. In order for the furnace to use the handles to her sides. In conclusion, the design is covered with paint.

Varieties of wood stoves

Heating stoves on firewood can be made not only from metal, but also from brick. But such installations are not so common, because they are not very easy to build. In addition, very strict requirements are presented to the material and peculiarities of the chimney. If you make the design of the wrong, then it will not heat the house, but will only turn into problems. It will be not very cheap to cost such an installation, and the construction work will take quite a lot of time.

Pros burzhuyki

The stove for greenhouses on the bourgeois-type firewood does not imply the need to install a complex foundation, it will not be required for the relevant documents. It is very simple to serve it, and the installation will cost free. Bourges can be used not only as a heating device, but also in the role of a cooking furnace.

Cons Burzhuyki

However, the stoves described have their own drawbacks, one of which is expressed in the soon fuel extension, while the second is in a quick cooled, which is due to the absence of the ability to accumulate heat.

Production features

The described stove on firewood - it is quite realistic to do it - should have a chimney pipe, whereas in the room where it is supposed to make it, it is necessary to equip the ventilation of the supply and exhaust type. In view of the fact that the installation is a source of increased fire hazard, it is necessary to comply with the rules for its installation. So, it needs to be located as far as possible from flammable items, among other things, a fence will be to build, which will exclude the emergence of a fire.

Constructive features

In order to appear in the possibility of independent manufacture of the household stoves on firewood, it is necessary to familiarize yourself with its constructive features. So, the basis of the product should be metal, the thickness of which should be 4 mm and not less. As an indispensable component of the furnace. Do not do when making a furnace and without a grate, as well as chimney and ash bar. Load fuel will be through the door.

In order to facilitate the process of making the furnace, you can apply a steel barrel as the base, but it is necessary to take into account that the thickness of its wall should be equal to the above. Gas cylinders that used steel pipes are excellent for this purpose, as well as sheet metal. It is useful to the metal corner.

If the stove on firewood will be manufactured with your own hands, it is worth considering that it should contain two cameras. One of them will perform the role of a ash bar, whereas the second combustion will occur. The furnace must have a slightly more impressive size compared to another camera. However, in each compartment must be the doors and holes.

Features of the device of grate

Before starting the manufacture of a furnace for your home or a steam bath, it is necessary to understand that the grate is located directly between the ashtar and the heat chamber. But the door is attached to the fire hole, which must necessarily have reliable valve. The grate of the fuel is placed, it is capable of enhancing craving in many times inner space. In addition, this element has one more appointment, which consists in sifting ash. From here it is to be removed as accumulation.

The stove on firewood into the garage can have a grate with a rather different size of the longitudinal holes. This parameter must be reduced if during operation it is supposed to produce a firebox not only to firewood, but also, for example, coal. Specialists advise exactly how and make it possible to provide all options for operating the furnace. In the roller chamber, it is permissible to install a pre-manufactured box made of fine steel. It will allow much easier to eliminate the accumulated ash, for this you have to just get a box of hole.

Device chimney

In order to make the chimney, it is necessary to do the hole in the upper plane of the structure, it must be appropriate to be used for this. It can possess the curved form, and it can be arranged at some angle. Make it is permissible horizontally or vertically. Ultimately, this will allow you to heat the room in a much shorter time. The bathing stove on firewood should have a chimney, the diameter of which should not be less than 120 mm. Otherwise, you will get a bourgeitogo that will get to smoke when working, while you will have to redo the design in order to solve the problem.

By making a pipe, it is necessary to remember that horizontal areas should not be larger in length than 1 m, while the degrees of their location should not differ from the value of 30 0. And the flue of the chimney, which comes out of the installation, should have a wall thickness, as in the design of the furnace, is at least 3 mm. After 2 m, the chimney can be built from a thinner steel, for example, 0.7 mm, this is due to the fact that the flue gases at this gap is not so aggressive at the temperature.

The firewood stove can be made using only it is necessary to consider that their installation is permissible only outside, this is explained by the fact that such a material is not able to cope with the effects of high temperatures. If you install such a pipe directly at the outlet of the flue gases, then in a short time it will lose its strength characteristics and will be folded or cut into cracks. But in relation to the relationship it can be noted that they are much more durable. They can be used if necessary to get rid of the gaps in the designs, which remained from the wrong operation with the welding machine. The outer area of \u200b\u200bthe pipe must be as high as much as possible relative to the surface of the roof, this distance should be approximately 1.5 m, which will become perfectly affected by the traction intensity.

Installation of the furnace

Firewood stoves should be installed in advance for this, it is necessary to prepare the strapping made from the corner. In addition, the design should be stable, for this, the base should be as hard as possible, the steel sheet should be put on the floor. It will come in handy in case of the furnace to fly out sparks during burning or fuel loading.

Podpopling steel sheet should be positioned in such a way that he played outside the installation by 20 cm from three sides. But as for the front side, the sheet from under the furnace should be 60 cm.

The stove on firewood into the garage or in any other room should be manufactured with the way that the joints should turn out to be sealed. This will eliminate the likelihood that smoke will fall into the space room, which is very harmful, first of all, for health, and even then - for thrust. Outside the pipe area, the minimum length of which was mentioned above, is required to securely fix with wire stretch marks, while its top part It is necessarily covered by an umbrella-sparking.

Increase the efficiency of the furnace

Due to the fact that the stove for baths on firewood should produce many times more heat, it can be improved in some way. As a rule, the bubzhuyka oven has a pipe that is located behind, which is quite traditionally. In order to increase the efficiency, it is necessary to mount this element of the design in front, it is done above the heat chamber. This will get the following effect. So, initially began to warm the walls of the furnace, which will increase the thermal return. But if after the manufacture, the furnace will be covered with brick, like the pipe itself, it will be possible to increase the period until the moment of complete cooling, it will, in turn, will allow you to save fuel in many times.

Such a brick stove on firewood will work even more efficiently if its inner walls lay out this if there is a free space, because the design dimensions will be increased. It is necessary to carry out such manipulations directly in the stationary compartment. If you still have not chosen a way to increase the heat capacity of the furnace, then you can consider the option at which additional fins are installed. In order to realize this method, it is necessary to attach stripes of thick steel to the side walls of the construction, which will be located perpendicular to the walls. At the same time, the heated area is increased many times, which will soon warm the surrounding air. If we put the container filled with water on the furnace, it will contribute to the preservation of the accumulated heat after the process of the furnace turns out to be terminated. Such water stoves on firewood can also be used to warm water, as well as cook food.

If you decide to make a furnace with edges fixed on its walls, it is permissible to apply the casing to protect. Its manufacturer can be made of steel or special heat-resistant materials. This will significantly reduce the risk of burning the burn at that time until fire burns in the firebox.

Another excellent method for increasing the efficiency is the use of steel pipes. They must have a significant diameter. They are welded on top of the furnace and direct in opposite parties, which should resemble the bake of the buleryan.

Correction of problems in the work of the furnace

The stove for greenhouses on firewood after the manufacture may not arrange you. There may be several reasons for this, for example, the design is unnecessary smoke. This problem may be accompanied by the complexity of molding. At the same time, it is worth thinking, according to the rules of Lee, a chimney was made, in addition, this sometimes happens when using raw fuel. The reason may consist in the ash bar, that is, it confused may have too large dimensions. Quite often, the diameter of the chimney does not correspond to the dimensions of the heat chamber. Moreover, the chimney may not rise sufficiently over the surface of the roof.

In order to avoid such problems, it is necessary to prepare a drawing of the stove on firewood in advance and work in the manufacture of it. But if all the factors described above were not justified, and the reason in firewood, then they should be stored correctly, that is, under the canopy. The dimensions of the furnace chamber are also compared, which, for example, limited to the 70x70 cm limit, and the chimney pipe should not be less than 110 cm. As for the size of the asset, by means of which the incoming air flow is adjusted to the furnace, its dimensions should be in 3 times less compared to the heat chamber.

Before making a stove on firewood, it is necessary, first of all, to think about how compliance with the rules of fire safety. This acts as the most important circumstance in the manufacture of such a design. Already then you can go to work on the manufacture and preparation of the place to install the furnace. It will be a key to success.

The garage for most car owners is not only a gentleman or mini workshop, but also a place for free pastime. And often it happens that in winter it is necessary to spend more time to spend the engine than the trip itself, and repair is more pleasant and more convenient to carry out warmth. Therefore, sooner or later, all motorists think about the heating of the garage.

Purchase or self-making?

The optimal option for heating will begarage stove with your own hands. Preparation of all components for this will not be much difficulty, but at the beginning you need to decide on the type of stove. For this, the following points are taken into account:

- ease of operation;

- reliability;

- low fuel consumption.

To choose the appropriate option, you need to get acquainted with all types of furnaces of furnaces.

Main types of burning

Modern heating equipment can be classified for a number of characteristics, but the main one is the type of fuel used. Based on this, the following groups can be distinguished.

Note! Installation of the gas boiler is better to entrust professionals to ensure all the rules handling such devices.

Garage stove - what it should be

To select a suitable design, you need to decide in advance with several important moments, among which:

- garage area;

- planned heating time;

- maximum budget.

Note! If the garage is made in the form of an extension to the house, it is desirable to install the device that will connect to electrical or gas network. If this is a separate room, it is better to organize an autonomous system.

The furnace must have the following parameters:

- the cross section of the exhaust channel is 10 cm;

- weight - no more than 35 kg;

- dimensions - 70x50x35 cm;

- volume - no more than 12 liters.

This is a simple option that is ideal for heating the garage room. The most popular among motorists is a construction called "Burzhuk".

Main advantages

Among the numerous positive qualities that such a stove possesses, it is worth noting:

- lack of necessity in the construction of the foundation;

- ease of operation;

- the possibility of using both heating and cooking;

- economy;

- autonomy from communications;

- low cost;

- small dimensions;

- high efficiency.

Note! The only minus can be considered a high fuel consumption, let and relatively inexpensive. Wood quickly burns out, and heat-sampled is not accumulated. As soon as it stops, the furnace housing begins to cool.

There are no clear requirements for the design of the design, everyone can make a "burgundy" taking into account their own needs and preferences. But in any case, the stove should consist of four main elements.

- The furnace chamber is a container in which fuel will burn.

- Grid located next to the base. It provides cravings and used to lay firewood.

- The roller is installed below the grille. It is necessary to remove the sump clusters.

- Chimney.

If desired, the "bourgeito" can be somewhat enhanced to reduce the consumption of firewood. For this purpose, the exhaust nozzle is installed not near the rear wall, but on top of the door. In this case, the walls of the furnace will be heated first, and then the gases will fall into the pipe. Therefore, the heat transfer time will increase.

What will be required in work

For the manufacture of wood stove These materials are required:

- channel;

- iron Capacity per 200 l;

- pipes.

To determine the volume of consumables, read the drawings of the garage furnace, carefully examine all connecting nodes.

Step 1. At first, the upper part of the tank is cut. To do this, you can use the grinder.

Step 2. Take the formed edges. The edges of the barrel wrapped in a hammer inside. Similarly, the edges of the lid are cooled, but this time out.

Step 3. In the center of the lid, the hole Ø10-15 cm under the pipe is cut. To do this, you can use the hammer and chisel.

Step 4. The channel is welded to the lid. At the same time, the hole for the plug can be both brew and leave for visual control of the combustion process.

Step 5. In the upper part of the case, the Ø10 cm hole is done under the chimney, the pipe is welded.

Step 6. The pipe of the corresponding diameter is inserted into the hole on the lid so that the surface is slightly rising above the surface. With this pipe, air will be supplied to the design.

Burnzuyka oven is ready.

Features of operation

After assembling the furnace, it is necessary to test for the correctness of the functioning. To do this, you need to perform such a sequence of actions.

Step 1. First, the cooler camera is filled with firewood.

Step 2. Installed and closes with a lid pipe for air supply. During the burning of the fuel, the cover is gradually lowered.

Step 3. Firewood is inserted, slightly wetted by gasoline, throws a lit match.

Note! If everything is done correctly, then these firewood is enough for about seven hours of work. The heat transfer time filled with firewood can reach sixty hours.

Video - "Bourgehog" with their own hands

The scheme of the aggregate on the exhaust oil is largely reminded by the "bourgeito" described above, but still has its own characteristics.

Main advantages

To the strengths of the design should include:

What will be required in work

To construct a furnace on the workout you need to take care of:

- exhaust pipe;

- pair of metallic tanks with a thickness of the walls of at least 4 mm;

- pipe under the upper capacity;

- connecting pipe having many holes.

Action sequence should be next.

Step 1. One of the tanks of 10-15 liters will serve as the bottom of the construction - it will be here that will be served. In the upper part of this container is done a hole.

Step 2. The cover is welded. It is necessary to make it so that with its help it is possible to adjust the air supply when burning testing - for this, the lid should rise / opous.

Step 3. The upper container will serve simultaneously with the heat chamber and the heating device. The thickness of the walls of the capacity, as already mentioned, should be at least 4 mm, because the design will heat up to 900ᵒ.

Step 4. The tanks are connected to each other by the perforated tube Ø36 cm.

Note! If a solid product is used, then it is necessary to do 48 holes Ø1 cm - 6 rows of 8 pieces in each.

Step 5. To the upper capacitance, the nozzle is welded.

Step 6. A galvanized pipe for exhaust is joined to the nozzle. To ensure good thrust, the height of the chimney should be at least 4 m.

If everything is done correctly, the result is a stove with such characteristics:

For full heating of the entire room, you need to adhere to certain requirements.

- The furnace must be installed as far as possible from combustible materials.

- Once in two weeks you need to clean the design.

- If the diameter of the exhaust pipe is greater than the exhaust, then the amount of soot will decrease.

- If instead of working out a clean material, then cleaning can be carried out less often - approximately once a month.

Trial launch stove

After assembling homemade design, you must perform the following steps.

Step 1. A piece of paper is placed in the lower capacity, the testing is poured over it.

Step 2. The fuel is lit (about ten minutes).

Step 3. With further work, it is necessary to pour in proportion to 4 l at a time.

Note! Instead of working, you can use diesel fuel.

For a more detailed acquaintance with the design, look the thematic video.

Video - oven on spent oil

Most motorists have a garage, which often serves not only as a refuge for the beloved car, and is also used as a workshop or the place of men's conversations. It often happens that in cold weather heating the engine takes time more than the trip itself, and as a result of this, the relevance of the planned trip is to be reduced to zero. Yes, and discuss with friends the latest trends in the field of vehicles are much more comfortable in the warm room. Agree that it is much better to carry out car repair or other events warm. Therefore, be sure to take care of the heating of the garage room.

The correct solution of the "cold" situation will be the oven for the garage with their own hands. Prepare components and assemble them independently will not be difficult if there are even small skills of working with different materials and tools.

When choosing a suitable type of garage oven, the main thing is:

What are the types of furnaces?

Modern aggregates for heating garages presented on sale on the market have certain characteristics that allow classifying equipment. The main factor is the type of heating material.

Based on such a principle, the following types of heating equipment are distinguished:

Requirements for the design stove for the garage

To decide on the type of stove, answer yourself a few next questions:

- How much money are you ready to spend on the heater?

- What is the area of \u200b\u200bthe alleged garage room for heating?

- How long do you plan to fuck garage?

Important! If the garage is an extension to the residential premises, then in this case we recommend installing the unit connected to the total gas or electrical network. If this is an autonomous room that does not have any living buildings with communications nearby - make a separate system.

So that in the process of operation, the furnace did not bring the inconvenience, the following characteristics will be suitable parameters of the unit being created:

How to assemble the design of a wood furnace with your own hands?

The economical furnace on firewood, independently assembled, is considered the simplest in service and ideally suitable for heating autonomous garage buildings. Often in the household of the car enthusiast is a heating structure with the name of the bourgeois.

Advantages of a wood-burning furnace

Such a stove has a lot of advantages, among which is distinguished:

Features design stove-burzhuyki

A variety of bourgeois stove structures does not have clear regulations.

Each wizard can build this design, given your own preferences, but in any case, such a stove has the basic elements of the design:

Important! If you upgrade the design of the burzhuyki, then it will be possible to significantly save the consumption of firewood. Such an effect can be achieved if the nozzle is welded to the stove body over the door, and not, as taken, behind the wall. Thanks to this installation of the nozzle, first of all the wall structures will be heated, and only then the firewood will fall into the pipe. Due to this, the time of heat recovery will increase, since the brick, concrete-clay or insulated metal pipe is cooled much slower than the steel case.

Materials for the design of a wood-burning furnace

To assemble a wood furnace independently, you will need to purchase the following materials:

Montaja technology

How to exploit wood stove?

After you collect the design of the furnace, initially test it on the correct functioning. Follow these steps:

Video

Browse the video in which an example of creating and operating a wood stove is clearly shown.

Stove on the workplace

Against the background of other similar designs, the oven for the oil garage is highlighted in economy, easy operation and inexpensive combustible material. The design of the stove on the workout is similar to the design of the bourgeitry.

Advantages of application

Among the characteristic advantages are the following:

Materials for construction

Overlapping oven can be constructed personally, which will not require a lot of effort and does not take much time. To build a homemade garage furnace, you will need:

Mounting technology stove for garage on oil

To construct the stove with your own hands on "Working", follow these steps:

As a result, correctly performed works, you will receive an aggregate with such parameters:

Rules of operation of the stove on "Working"

In order for the result of the work of the furnace to be justified and she fully heated the garage premises, carefully read the following instructions on the operation:

How does the stove work?

To establish work homemade oven For a garage on working out, do the following:

Video

To more clearly imagine the principle of device of such a furnace and operation, look at the proposed video below.

The main criterion towards the construction of a brick furnace is compliance with compact size, and in all other remaining the system of such a stove is similar to previous options.

To properly build a brick stove, be sure to follow the following recommendations:

Conclusion

No matter what kind of chimney for the garage you did not choose, in any case, it will give an expected result. With the help of any proposed, uncomplicated aggregate, you can always maintain a warm climate inside the garage premises. And in comfortable conditions and repair work is more pleasant to perform, and talking in a circle of friends.