Monolithic walls From light concrete is a good alternative to brick in strength and durability, besides less heat pipelines. Yes, and the cost is significantly lower. The main materials of concrete walls are ceramzite concrete, slagobetone and opilk concrete.

Concrete monolithic wall technology

The construction of monolithic walls is simple. First, the thermal insulation of the walls of the foundation, basement or base is installed formwork (the inner width of the formwork should be equal to the width of the future wall). Formwork shields better fasten with washers, nuts, studs.

Well, if you have enough formwork for installation throughout the perimeter of the house (at least at the first level). If you were poured ribbon foundation, for the first level of the wall everything is suitable. Before filling formwork, check all the attachments and joints. To form a formwork can be safely removed, corrugated pipes that protect from the joint with concrete are put on the threaded studs.

If there is no reinforcement, then concrete is flooded in the formwork. If possible, it is recommended to ram the mixture with a vibrator, especially at the corners. After drying concrete mix You can rearrange formwork at the level above and pour concrete again. Outside, concrete monolithic walls are not necessarily, but it is desirable to close the brickwork with the heat insulation device. But this can be done only after complete drying of the walls, and this is at least 3 weeks.

Walls from slagobetone

The walls of the slag concrete is the stronger than the less slag fraction. The thermal conductivity depends on the same. So choose smaller slag. But a large slag must also be present. To make a slag concrete mix, you need to mix all components (slag, cement, sand, water (preferably add clay and lime)). When concrete is ready, you need to use it for a maximum of two hours. Slag concrete walls may have a thickness of 55-60 cm.

Walls made of ceramzitobetone

Ceramzitobeton is the same slag concrete, only with clay instead of slag. The only difference is that clamzite is stronger than slag, so the walls of the ceramzite concrete can be made thinner by 5-10 cm.

Walls made of opilk concrete

The opilk concrete consists of a conventional concrete mixed with sawdust. More precisely, layers (preferably needles), cement and sand are mixed (preferably), and then water is added. Opolk concrete is a very fire-resistant, thermal insulation and environmentally comfortable material.

With so many advantages, there is a disadvantage: opilk concrete need good waterproofing. Just like with a slap concrete, the walls made of opilk concrete are laid with bricks, pre-arranged waterproofing.

Concrete walls with sawdust

Concrete with sawdust can not be poured into a formwork, but to make blocks from it. True, it needs to be done in advance so that they manage to dry. For now, walls of ready-made blocks will be erected, you need to pour new ones. Wall thickness from such blocks, not counting brick masonry Outside, an average of 30 cm.

To do this, it is better to make such a formwork that will easily move along so that the block can be launched, and quickly move back. You can also make a long formwork into several blocks in length, and at the same distance to put shields that can be removed and pick up.

As for reinforcement before the fill of concrete, the technology of the construction of reinforced concrete walls is not different from the technology of the construction of a belt foundation.

You can enhance the strength and rigidity of the walls and at the same time refuse to formwork, if you build instead of it brick walls In Polkirpich, and to pour concrete between them. But concrete needs to be poured as the walls are erected (every few rows).

Clean air, green plantings, the absence of urban noise - the reasons for the construction of country housing in lately It is becoming increasingly popular. However, smooth areas under individual buildings are far from everyone. What to do those owners who received areas in areas with rather large height differences? In this case, the retaining wall made of concrete will help, the technology of the construction of which has been worked out for more than one decade. Such structures are widely used in urban development, since the cities grow, and there are not enough smooth sites for the construction of new buildings.

Purpose of retaining walls

By appointment, the retaining walls are divided into two main classes:

- Decorative. The main purpose of such buildings is the landscape of a plot with a small slope of a more attractive aesthetic species.

- Protecting. Such walls withstand a significant soil pressure and are intended to prevent its location along the slope and flushing the fertile layer from the surface of the site.

Varieties of concrete retaining walls

The strengthening retaining walls from the monolithic reinforcement are divided into three types:

- massive;

- combined;

- thin-walled.

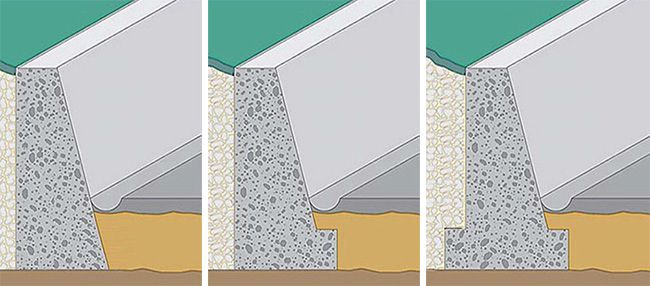

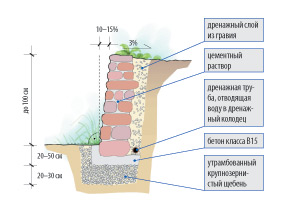

The first category of supporting walls holds the pressure of the soil only at the expense of its large mass (the strength also depends on the magnitude of the gluke). In view of the fact that the manufacture of such walls requires a large number building materialIn case of individual construction, they can be recommended to build low retaining structures (height above the level of soil 0.5 ÷ 0.7 m) on areas with a small angle of inclination. Then the recommended bulk value (⅓ from height) will be 0.17 ÷ 0.24 m, and the thickness (~ ÷ ½ of height) is 0.25 ÷ 0.35 m.

Combined products have less weight than massive. In order to increase their stability, the foundation is used by the foundation of broader sizes than the base of the wall itself (the soil pressure on the protruding elements of the foundation, partially reduces the load and thereby increases stability).

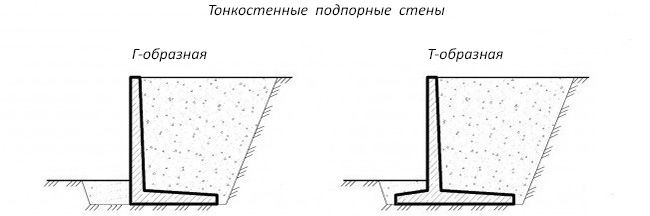

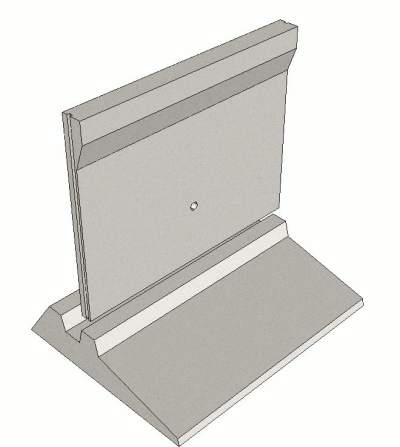

The thin-walled retaining walls made of concrete are made of g- or T-shaped. Since the width of the "soles" in such products is commensurate with their height, the vertical pressure of the soil on the support significantly reduces horizontal loads and increases the stability of the wall to tipping.

Such products can be purchased as ready-made sections made in the factory.

Homemade retaining concrete wall

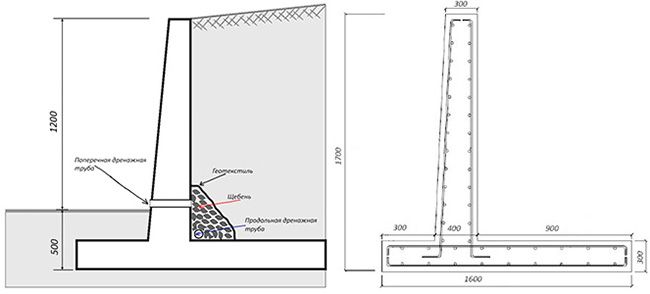

If the slope of the surface of your site is not too big, then make your own hands the retaining wall from the concrete will not be difficult. For example: you need to construct a retaining wall with a height of 1.2 m (above the soil level). In order to save a building material (reinforcing bar and concrete solution), we recommend choosing a thin-walled corner retaining wall with a T-shaped base. How to make a retaining wall of concrete (three main stages):

Preparatory stage

First we prepare sketch, drawing and reinforcement scheme.

Then proceed to land work. We make marking with pegs and construction cord. I dig up the trench of the required width (a little more width of the support with formwork) and depths (taking into account the thickness of the support and pillows from sand and rubble). The land from the trench we store on the free plot (later it will be needed for snowing on both sides of the wall). We fall asleep on the bottom of the trench of the sand (the thickness of the layer is about 0.2 m) and its trambra (periodically wasting with water). Then we fall asleep the same layer of rubble and also tamper it (vibrating or manual traam). On top of the equipped pillows are stamping.

Formwork and pouring solution

Now proceed to creating a reinforcing frame. The reinforcement bars "soles" and "body" walls should be interconnected.

Build formwork. First we make it only for the foundation of the wall. After that, we pour a concrete solution along the entire length of the foundation, sealing it using a vibrator. After setting the solution, we proceed to the mounting of the formwork of the most supporting wall. The technology of making formwork and materials used for its manufacture are similar to the arrangement of a belt basement.

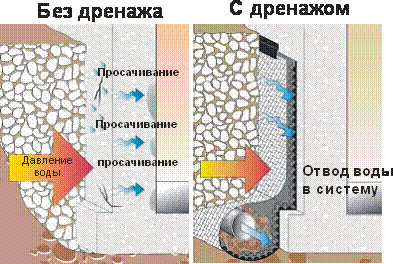

Important! In the process of arrangement of formwork, it is necessary to lay transverse plastic or asbestos-cement pipes for removal of groundwater and precipitation penetrating into the soil (the lower edge of the pipes should be slightly higher than the soil level from the outer side of the supporting wall). This will significantly reduce the load on the inner side of the vertical plate. Distance between transverse drainage pipes - 1.0÷ 1.5 m.

Then proceed to the pouring of the concrete retaining wall.

Attention! So that the formwork does not collapse or deformed during the fill, this process is better to produce in stages. First pour a solution on⅓ Heights along the entire length of the wall. Then we produce the vibration absorption of the flooded solution. Next, fill the formwork with a solution for another third and so on.

To ensure the greatest strength and uniformity, the whole design is desirable to fill in one day. After the solution is flooded to the upper edge of the wall and completely tumped, the surface is aligned and cover with a polyethylene film and leave it to the final drying. To prevent the rapid evaporation of water from the solution (which can be negatively affected by strength) in hot weather, the surface of the solution is periodically wetted.

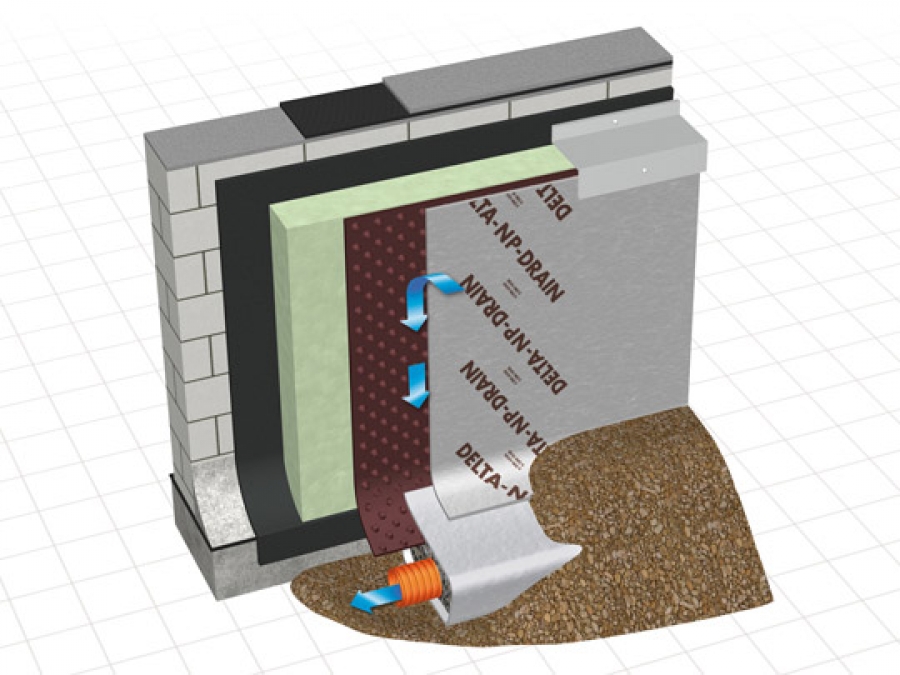

Waterproofing and arrangement of the drainage system

After 7 ÷ 9 days, we proceed to dismantling the formwork. To ensure the durability, the concrete wall surfaces are coated with a waterproofing material (for example, a special composition based on liquid rubber).

- Along the entire length of the wall from the inside (i.e., on the side of the slope), we put the perforated pipe (necessarily wrapped by the water permeable geotic).

- Then we fall asleep this pipe with rubble.

- A geotextile is stacked on top of the rubble (in order to preserve the free space, not filled with soil, between separate particles of rubbank).

- The free end of the pipe (with one or both sides of the wall) is deposited into a drainage ditch (or well) or the nearest watershed.

At the end stage, we fall asleep the free space around the wall.

Important! We proceed to the backfill of the soil only after the retaining wall from the concrete will type final strength and can withstand significant loads from the slope, that is, not earlier than in a month.

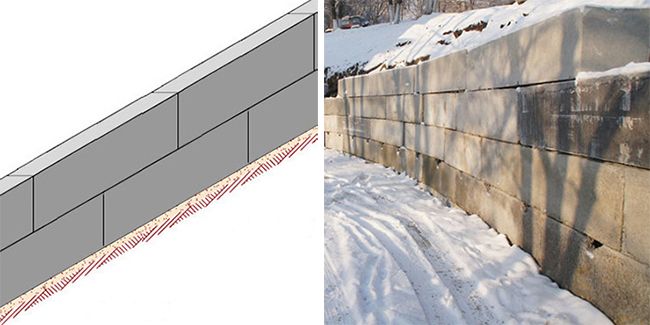

Retained wall made of concrete blocks

For the device of decorative retaining walls, blocks made of lung porous concretees are successfully used. The strengthening retaining walls from concrete blocks are made from the FBS (foundation blocks of solid), a width of at least 400 mm (by the way, this value will be the wall thickness). They are manufactured in the factory conditions. High strength and density (2000 ÷ 2300 kg / m³) material cause their widespread use in the construction of massive retaining walls.

Algorithm for the arrangement of the retaining wall of concrete blocks:

- We make markup, excavation and arrangement of the pillow of sand and rubble (all works are similar to the construction of a reinforced concrete wall).

- After that, we proceed to laying the blocks that fasten with a sand-cement mortar.

- Rows of blocks put the "rotary" (that is, each subsequent row we draw with a shift to the floor of the block in relation to the previous one).

- To increase the bearing capacity and strength of the wall in horizontal solutions, we put the reinforcing elements (metal grid or arm of reinforcement).

Attention! The weight of the standard block with dimensions 800x 400 x580 mm is 470 kg, therefore, for the arrangement of the retaining wall, it will take the use of lifting equipment.

In custody

The selection of the design of the retaining wall depends on its purpose (decorative or strengthening) and the characteristics of a particular section: the height difference, the characteristics of the soil, the level of groundwater, and so on. A properly designed and equipped retaining wall will serve without repair not one dozen years.

Not every owner of his own plot can boast of perfectly flat relief, from which it is necessary to conclude that from concrete, the construction technology of which will be described in the article, is sometimes an indispensable element that can act as a decoration of the garden and the structure that shares it into the zone. The construction of such a design can not be called a complex process, during its course it is possible to implement different fantasy landscape design.

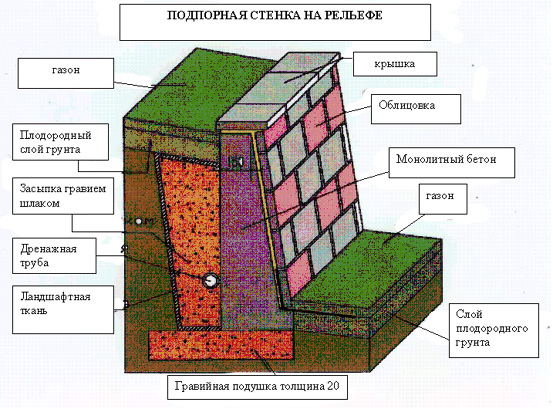

Wall device

The retaining wall of concrete, the construction technology of which should be complied with the work, can have a certain design that determines its function. Thus, some walls decorated, while others are strengthened. Each is designed for its degree of exposure and consists of the main elements, among them: the foundation, body, drainage and drainage. The foundation is an underground part and is designed to withstand the severity of the soil pressure. The ground part is the body, the inner side of which is in contact with the soil and encourages elevation in the site. Outdoor, the front side is open and can have a smooth or sound view. Protective communications are dragging and drainage. In the design process, it is necessary to provide methods for removing extra moisture, which will accumulate from the inside.

Parameters that determine the stability of the wall

The device of retaining walls from concrete should provide for each of the above elements. Only so the design will be as sustainable as much as possible and will show the ability to undergo high pressure. Therefore, it is necessary to calculate the factors that affect the strength. Some physical forces will be affected on the wall, namely: its own weight, friction and grip power, soil pressure, as well as the extra weight of the elements. The latter can be strengthened on the wall.

Impact on the wall

It is important to consider the phenomena that will influence the design, among them: swelling of the soil in the winter, vibration (if there is laid railway), flushing with rainwater, seismic phenomena and wind. Considering the latter factor, it should be noted that the retaining wall of concrete (height 2 m or more) will undergo strong wind loads.

Construction technology

The design described is a rather complex engineering structure, so in its arrangement it is necessary to take into account certain factors on which reliability, strength and durability will depend on. You can start building such structures on stable soils that contain clay, crushed stone, sandy, as well as gravel. For the successful completion of work, it is necessary to remember that the level of soil freezing should not be more than 1.5 m from the surface.

Underground waters should be 1 meter, an indicator of 1.5 meters from the surface of the Earth acts as an optimal version. If you yourself decided to carry out work on construction, then the ground part of the wall should not be higher than 1.4 meters. If you need a retaining wall of concrete (height 3 m), then it is best to turn to professionals, as there will be difficult calculations that take into account the pressure of the soil and its mobility.

From concrete, the photo of which you can see in the article must have a foundation that is distinguished by reliability if the design has a height of more than 30 centimeters. At the same time, it is necessary to follow the rule, which consists in the dependence of the depth of the foundation on the characteristics of the soil. Than unstable and lighter than the soil, the deeper it is necessary to lay the foundation. If the soil differs in density, then the ratio of the depth of the base and height of the ground part must correspond to the proportion of 1 to 4. If it is necessary to work with the soil of the average looser, the base depth should be 1/3 of the height of the support. If the soil is soft enough and loose, then the depth of the base of the design should be 1/2 height. The foundation must contain concrete, gravel and crushed stone, as well as a heavy length or compacted cement.

Waterproofing, drainage and drainage

The retaining wall of concrete, the technology and the device of which you can explore and implement yourself should provide for drainage and waterproofing, which will ensure reliability and durability. It is not enough to build a good foundation and install the wall, the design should be protected from moisture exposure, which is capable of providing a destructive effect. It is necessary to hydroize the inner side of the support.

The drainage is divided into longitudinal, transverse and combined. Transverse implies mounting holes in each second-third row, their diameter should be about ten centimeters. You can lay the tubes under the tilt, then the water will immediately go beyond the site. If you decide to equip a longitudinal drainage, then it is placed along the wall under the soil at the foundation level. For this, the corrugated, asbated or ceramic tube with a diameter of 10 centimeters is stacked. The elements are wrapped with geotextiles, which will absorb moisture, falling through small holes. In order to eliminate the penetration of water into the design of the masonry, which, with a decrease in temperature, the cause of the wall is caused, it is necessary to provide a cornese block or a visor with a minor bias.

Laying the drainage layer between the wall and soil

If you need a retaining wall of concrete, technology and device with your own hands you should be studied and manufactured according to a certain technology. The technique involves the arrangement of the drainage layer, which is located between the soil and the structure itself. After completing the assembly of the wall, you can start filling the space formed by the wall and the slope. To do this, you can use large-graft soils by type of pebbles, gravel and large sand. For this, it is quite often used by the brick battle and waste building materials.

It is important to consider that gravel will have some pressure on the support, but will perform as a drainage layer. The mixture for drainage should be filled with layers, each separate layer must be sealing. Preferred is the large-grass soils and sands taken from the sandy. The retaining wall of concrete, the technology of arrangement of which is described in the article should have top The laying layer, which can consist of after the latter of the last layer, should be left in this state for several days, without exposing the surface to the load. Strengthening materials due to this will gain their properties. After the completion of all of the above works, the terrace is started.

Features of the construction of the wall

The pouring of the monolith is carried out in the formwork, which will perform a broken configuration shields. Separate components are strengthened with the outside by the backups so that the formwork can withstand the pressure of concrete. Inside, reinforcing mesh rows are installed, which consist of metal rods and pipe cutting. Between themselves should be tied with wire. At an altitude of 5 centimeters from the surface of the Earth, it is necessary to put plastic tubes that will provide the removal of gathering water. The distance between them should be 1 meter.

To obtain a smooth outer surface, the formwork inside is trimmed by plywood or rubberoid. If you need a retaining wall made of concrete, the construction technology of which is described in the article, then you can build it from the booton, and there is no need to produce reinforcement. The device of such a design saves cement, as a significant amount will be stones.

The first row is stacked dry, educated emptiness should be filled with rubble and pour into a solution. After a row of stones, they need to be dried in solution, continuing operation until the formwork is completed. As in the case of monolithic walls, concrete structures should contain tubes for removing water.

Calculation of concrete for the construction of the wall

The retaining wall of concrete, the calculation of which you can do it yourself, should be flooded without large breaks in the work, otherwise it will not be possible to exclude the formation of seams. In order to calculate what volume of concrete is purchased, the internal volume of the future wall should be determined. To do this, it is originally determined by its area, and then the value is multiplied to the depth of the wall. This will make it possible to understand how much solution should be ordered at the factory. But if there is no such possibility, it is better to rent a concrete mixer.

The best solution to the arrangement of the household plot with a complex landscape becomes a retaining wall of concrete. With it, it is possible to stop slipping the soil, as well as securely strengthen the slopes and steep slopes. It is noteworthy that such a massive design in addition to the main protective functions carries excellent decorative solutions.

Types of designs

Wallpora walls often serve as the basis for embedding various elements of the decor, including terraces, flower beds and flower beds, which on a multi-level site looks particularly attractive and unusually, reinforcing the effect of the difference.

Sometimes artificial structures are mounted on an absolutely smooth surface only to ensure that the site gains individuality and uniqueness. In urban construction, with the help of monolithic walls, testers strengthen the trenches, butt, fences and anti-rolled engineering elements.

Applied materials

If speak about appearance Protective construction, then in the case of private construction, it is necessary to repel from personal preferences of the owners of the site and their financial capabilities. Usually, the retaining wall is erected from concrete, as well as other materials:

- ready-made concrete blocks;

- brick;

- natural stone;

- wooden logs.

All this beauty is quite realistic to make with your own hands, it is enough to study the thematic articles in detail and conduct an accurate technological calculation. Stages of construction, their duration and complexity of processes will be directly dependent on the selected material and landscape features.

Drawings of concrete retaining walls:

Rules for creating strengthening

There is a certain technology, without complying with the device of the high-quality design of any type. In most cases, a retaining wall of stone or concrete is erected at the inadlines, not higher than 2 meters.

If landscape ledges are not very large, (up to 4 m and high to 1.5 m wide), then the finished vertical element does not exceed one and a half meters in height and construction can be performed with their own hands, lowering complex technological calculation, which is only possible to use specialists. So that the protective structure served long years, It is necessary to properly spend all the stages from which the construction is.

Technical features

Strengthening from blocks or concrete is the most affordable option, so further the device of this type of engineering element will be considered. The calculation of the material is made on the basis of several factors:

- wall heights;

- water permeability;

- seismic stability.

The solution should well hold moisture and be plastic, so plasticizers are often added to its composition. Concrete walls, excluding ready-made blocks, usually imply a solid compound from the foundation and the main part of the structure. In this case, it is necessary to make a shot, the width of which necessarily turns on the reserve for formwork.

Dimensions

It is very important to choose the correct thickness of the wall that will endure the appropriate loads and will not be tipped off. For independent planning, there is a standard calculation of parameters depending on the type of soil and body height of the structure.

Foundation

If the decorative design on the household plot will not be higher than 30 cm, you can not fill the foundation, but make a small gluke in the ground. In this case, the support device is limited to planting a pillow of gravel and sand. In the case of a more massive wall, you will need to install the base, the calculation of the parameters of which will depend on the nature of the soil and the size of the elevated object.

Drainage

To avoid the accumulation of moisture behind the back wall of the backup and washing the soil, the drainage and drainage are organized. Drainage is three species:

- Longitudinal.

- Transverse.

- Combined.

In the first case, on one level with the foundation, a pipe wedged with geotextiles is stretched. Such a system can be done using a corrugated tube with perforation made of plastic or asbatem. Geotextile will absorb moisture and will not miss the sand particles, and the pipes will provide her altitude.

When arranging a transverse drainage during construction work In the retaining wall, tubes are laid or left holes (diameter 10cm). Such drainage should be mounted with a slope that will ensure water output beyond the terrace. The drainage step must be 1 m.

Mounting process

To correctly the retaining wall of the solution or blocks on its site, it is necessary not only to carry out the competent calculation of the parameters, but also to perform all the technological steps. If all processes will be carried out without a violation of technology, a protective-decorative landscape element will serve as many years for many years.

Trench

At the first stage, it is necessary to dig a trench, which will run along the contour of the future facilities. To speed up the process, usually resort to the help of the excavator, however, the final clearance of the walls and the leveling of the RVA is carried out by shovels manually. The depth of the peculiar pit depends on the size of the backup, and if its height is not more than 1 m, then it will be enough to deepen by 40 cm.

If it is decided to do without a trench, and this allows future design, before installing the formwork, it is necessary to carefully prepare the ground surface. Preparation consists in cleaning the platform from weeds and its alignment (cut off all bodies and irregular shovel).

Pillow and reinforcement

On the bottom of the trench or the prepared surface of the soil laid a layer of gravel and rubble. To give the foundation of a special strength on top of a choggy pillow, reinforcement rods or a special metal mesh are placed. Also along the entire contour, the reinforcement rods are vertically set up, which will firmly associate concrete mass.

Opal

The formwork for the retaining wall must be massive, as it needs to withstand pressure. For such a goal, shields from a 30 mm board are suitable, which are horizontally connected wooden timber 50 × 100 and are attached to stakes covered with a pitch of 0.5 m.

The construction of the formwork starts from the rear wall. To wooden frame Did not be bombed, metal bars are bought along the wall. At this stage, it is necessary to provide a drainage system according to the above example.

Solution

To retain decorative Wall The concrete was strong, and did not destroy under the influence of temperature difference, it is necessary to use high-quality cement frost-resistant brands.

The calculation of the components for the solution is carried out in the proportion: 1 water bucket, 1 bucket of cement, 1 bucket of rubble and 3 sand buckets. All components are mixed in a concrete mixer or trough, and the resulting composition is neatly poured inside the formwork.

Drying

It is very important to ensure the correct drying of the flooded design. So that the solution did not save, and the moisture left it from it gradually, the wall is covered with a film, which is periodically lifted and controlled as concrete grabbed.

In hot weather, the screed is watering with water, otherwise it can happen to crack the foundation and its further deformation. It will be possible to remove the wooden shields no earlier than in 5 to 7 days. After a complete drying (after 28 days), the surface is purified from spatters and tubercles with a spatula or silicate brick.

Finish

Currently, according to designers, brutal, untreated surfaces, to which, no doubt, protective device From the concrete wall. However, not to all owners of the nuclear area can come to the soul of such a landscape element, and then its decoration can be released from the situation. As finishing materials For the front surface of the protective structure, a tile is suitable for external work, a stone or paint along a concrete of increased stability.

As a plot for construction and the household plot is not always perfectly smooth. And if the angle of inclination is more than 80 degrees, then in order to safety, it will be advisable to implement the so-called "conservation" of rolling soil. For this, retaining walls are set, designed to prevent earthy collapse on the slope.

Device and functions of retaining walls

The retaining walls of concrete can be of a variety of designs defined by the functions performed by a specific building.

In the simplest understanding there are two types of retaining walls:

- Decorative.

- Protecting.

The differences between these two species consist in the fact that for each of them there should be a certain degree of impact and load.

But the structure itself is invariably consisting of such parts:

- Underground or foundationwhich accounts for all load pressure of the soil and the design itself.

- Body or ground. This wall protects the elevation on the site and from the outside can be both smooth and oblique.

- Protective communications (drainage and drainage). When designing a design, you should take care to carry out the removal of excess water and moisture constantly accumulating on the inner surfaces of such structures.

The retaining walls perform the following functions:

What can affect the stability of retaining walls

Very important qualities of retaining walls are stability and the ability to transfer high pressure. Otherwise, the construction will be subject to destruction, and the ground, respectively, simply slides. A number of factors can affect the strength of such structures, ranging from its own weight of the structure and ending with the pressure of the soil ().

Consider what it is necessary to take into account before making a retaining wall of concrete:

- The level of vibrations, for example, if the railway tracks are located not far away.

Tip! In the event that the height of the retaining wall exceeds 2 meters, with its construction, the wind force characteristic of a specific area should also be taken into account.

- Seismic phenomena of any nature peculiar to a specific region.

- The level of groundwater and the possibility of arms with rainwaters.

- Swelling soil in winter.

In many ways, the stability of such a design is determined by the thickness of the wall. This parameter is defined both height and soil type on which it is installed. In the event that the backup is high and installed on soft soils, then it is necessary to increase the width of the wall.

Highlights in the organization of the retaining wall

The device of retaining walls from concrete is very complex technological processrequiring a number of calculations. Here, the factors that affect reliability, strength, and therefore, should be taken into account.

If specialists are engaged in conducting such calculations, work will be guaranteed in accordance with all the rules and standards. But how to be if you decide to establish prefabricated reinforced concrete retaining walls yourself?

Here you will help the following instruction:

- The installation of retaining walls should be carried out only on stable soils, namely on clay, crushed, gravel, sandy, etc.

- For successful arrangement it is necessary that the freezing of the soil amounted to no more than one and a half meters from the soil surface.

- In the case of independent arrangement of the wall, you should remember that the ground part should not be more than 1.4 meters. For the arrangement of higher designs, it is necessary to resort to the help of professionals who are able to conduct special calculations and build a structure in accordance with all the norms and taking into account the characteristics of the territory.

- Groundwater should climb at least one meter from the surface. It is better if the depth of their location will be more than one and a half meters.

Arrangement of underground part

Note! If the height of the retaining walls exceeds 30 cm, then in this case the launching of a reliable foundation is a mandatory requirement. In the case of working on unstable and soft soils, the depth of the foundation should be increased.

Consider how the depth of the foundation is calculated depending on the burbility of the soil:

- If the soil is rather dense, then the ratio of the depth of the foundation with the height of support over the ground should be calculated as 1: 4.

- In the case of work on the soils of the average loyalty, it is necessary that the depth of the foundation amounted to a third from the height of the support.

- For loose and unstable soils, it is necessary that the foundation depth ranges half from the height of the wall.

Tip! Reliable foundation should consist of gravel or rubble, as well as sand compacted by severe clay or cement. Concrete solution Fills in a pre-prepared formwork following the example of a belt foundation.

The technology of the retaining wall of concrete provides not only the fill of the high-quality foundation and the construction of a durable wall on it. It should also take care of the waterproofing, because moisture will be extremely negatively affected by the inner side of the structure.

Therefore, here you need to take care of the organization of drainage, drainage, and also competently protect the design from moisture exposure.

How to organize drainage, drainage and waterproofing

The drainage can be three types:

The drainage layer is the space between the slope and the wall, which must be filled with large-grade soil. It is a soil mixed with large sand, gravel or pebbles. Also here will be small pieces of corpus bricks.

We draw a concrete retaining wall

Concrete walls are rightfully considered the most durable structures. If we are talking about precast concrete structures, it may take a cutting of reinforced concrete diamond circles.

But most often concrete walls are formed by the fill method:

- ROOM trench, the depth of which is determined in accordance with the height of the wall and the nature of the soils, as mentioned above.

- On the bottom of the trench we fall asleep the mixture of rubble with gravel.

- Stay armature carcass arbitrary shape.

- Install formwork.

- Pour concrete. Do not forget to provide pipes for drainage. You can also do holes in the wall, having carried out a diamond drilling of the holes in the concrete.

- When the concrete gets dry, the formwork can be removed.

- Align the walls with plaster.

- Now you can implement any facing work.

Conclusion

If you are the owner of a plot with a hilly relief, then you should not despair. Due to the installation of retaining walls, you can create a spectacular landscape near your home. But before proceeding, you will definitely need to make a plan and determine the burdens of the soil, for which the beam is used by the services of specialists ().

From the video in this article you can learn more about the device and installing a concrete retaining structure.