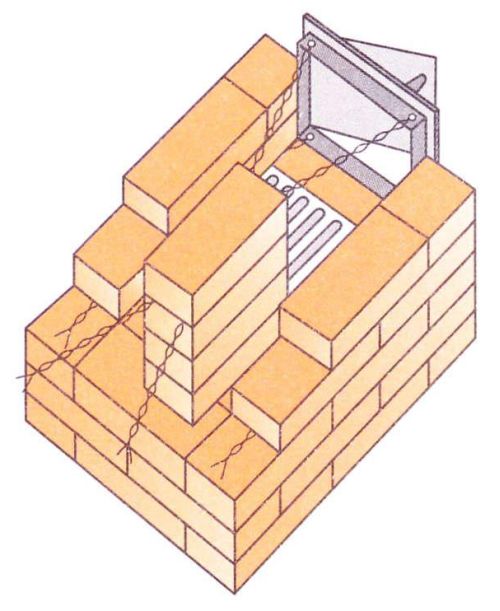

Materials used to fix the furnace doors: 1 - metal plates; 2 - Wire

Very often, the furnace is shifted only due to the fact that the coil door fell out of it. Typically, the doors fall out because they are fixed with weak aluminum wire or stranded wires. Sometimes metal plates are paved over the door opening and they are screwed off the wire. Plates and wire from fire are burned, then deformed, leave the masonry, and the door falls out.

Before installing furnace doors, you need to check if they easily open. There are tight doors that are developed over time. I did not meet in any rustic furnace of Russia near the laying door of asbestos. In modern conditions, the asbestos borrowed from industrial furnaces in which it, indeed, is needed that the furnaces withstand high temperatures.

In indoor furnaces, there is not such a high temperature, and the door frame is far from the fire and therefore its expansion is insignificant. Even under the stone-coal fuel, the door fastened the wire and did without asbestos. Despite the fact that part of the wire near the door is naked, the door stands quite firmly. For a larger warranty, you can drill holes in the door frame closer to its edge. Exist various methods Fixing the flue door.

Most the best way To avoid the loss of the door - when installing on top and bottom to stick to it metal plates with a thickness of 2-3 mm with advanced ends, then suck them into the brick.

Before installing the furnace door, you need to put three bricks in front of it onto the grille. Doctor with attached plates or wire put on the solution, are breeding plates or wires of wire on the walls, and other ends are put on three bricks and pressed on top? One or two bricks. The accuracy of the installation of the door is checked on a plumb. As a rule, we use a soft, annealed in the furnace or on the fire exactly elongated wire with a diameter of 2-3 mm, about 1 m long. Pull it easily, the ends, and more than you need, for a pillar or in a bracket, pulling and simultaneously pressing Her to them, then one, then the other end. Inserting into the hole of the door frame, the wire folds twice and tightly twist so that there is no rings. If they still turned out, especially near the door, they need to be filled with a hammer along the entire length of the wire. In a stretched position, pressing the door to the masonry, the wire is inserted into the hammer-made small chip (hole) 1 in the brick edge (5-10 mm depth) closer to the outer edge so that it does not weaken and crash. In the stretched position, the wire with the blades are tightly pressed against bricks in an angle 2 in all rows and on the solution are pressed with bricks, and then intertwined with masonry. You can direct it up. The solution near the door should be a little, the seam needs to do thinner, so it will be stronger to hold. The door is not scary to heat expansion, with such a bookmark it will have more than a hundred years. If the wire is prevented from above the door, then in this place the brick need to be out.

The doorway is good to overlap two whole bricks so that they connect to the center of the door. Often over the doors, the solution falls out and the vertical seam is shouted. To eliminate this enough in both bricks in places of laying a solution of the angle of the hammer to make notches-holes. Then, when compressing the solution in the seams, these foxes will keep the solution in the seam and it will not fall. Here shown doors with holes. They can be done by himself, simply drum down in a regular door.

Very often, the coarse doors are faced in the furnaces, because they have a bad constipation (latch), which sometimes falls off after a few days. Even when proper installation On the removal of the door without constipation begins to arbitrarily open. It happens because there is a heavy handle on the door, and it, as a counterweight, contributes to the opening of the door. To the door does not open up, all sorts of foreign objects are leaning to it - a kocherga or a closed, which begins to smoke and often lights up. Industry, apparently, is not able to invent reliable constipation for a coil door.

I propose an easy way to get rid of an arbitrary opening of the door at least in those furnaces in which the smoke is knocked out by wind from the furnace. This method will help forgetful owners. Close the door on constipation. With incorrect masonry pipe on top of the roof, the wind enters the pipe and knocks the smoke from the furnace. With strong wind, the door opens and the fire comes out with smoke, and sometimes burning coals fly to the floor. Therefore, it is impossible if the smoke from the furnace is knocked out, leave it unattended. In addition, it is necessary to put iron sheet on the floor. To the door did not open, you can make the gas.

During installation of the door in the laying, it needs to be kept closed, but not to constipation. Then you will see how it will open at a certain position. In order for the door not to open with open constipation, the top of the door must be rejected from the vertical position in the direction of the furnace by 2-3 mm. In this case, the heavy handle will press the door to its frame, but maybe in windy weather the door will open, so it is better to make a cap of the cap. Doors can be installed so that they open up the other side. For this, there are two-way constipation in the door. It is convenient if the owner of the left-hander or if they open towards the burning partition, but the latter can interfere with cleaning. To clean the soot you can install the doors with a height of one row, but for cleaning the gas ducts with a wire with a bow of a cloth, they are small in height and are not comfortable.

The hermetic doors fixed in the masonry with the help of glued plates, very heavy. It is difficult to mount such a wire, since they pull the wire from the masonry with their weight, but if you can fix it with the door with the doors so that it is installed with it, and the wire is intertwined with the following two masonry rows. The plates tightly hold the frame with the doors during the masonry. Such doors with wire fastening are dozens of years up to the demolition of the furnace. Sometimes doors, especially old, do not match the masonry and the door is formed on top of the door. In such cases, it is better to raise the door up in a closure with masonry, and under the door put on the solution thin brick fourth or to rush under the door of the brick on all its width, and for wires to push out shallow grooves, rising upwards. Easier and more reliable above the door fold the arch, as they did in the old days.

In order to vacation home It was warm and cozy, install the stove. Install the furnace, and the temperature mark will always be at the required level. The focus can be performed on their own, if, of course, you have special skills, and we will help you in this. So, we build a furnace.

1.

2.

3.

4.

5.

6.

7.

Masonry furnace

After a solid base is performed - the foundation of the hearth, proceed to the execution of the device body. First, the bricks of the first row are laying onto the bricks according to the coach, while it is important to control the sizes of the seams. After the position of angular bricks is determined, the row is placed on the solution, be sure to check the horizontality using the construction level. If the elements protrude out, they are precipitated by the blows of the image. After the first row is performed, it is checked with a roulette, both diagonally and perimeter. Make sure that all the diagonals are equal, otherwise to build a high-quality center will not work. Only after that the middle of the first row is filled with brick on the solution.After the first series of furnaces is performed, the construction of the second row is proceeded, as in the first case, controlling the vertical of the angles using the level. The execution of the second row is produced similarly to the first: first the brick is laying around the perimeter, after which they fill the middle. Setting the second row, nails are clogged into the corners of the seams, the length of which can vary from eighty to one hundred millimeters.

After that, all the angles of the posted row with pre-marked points of the points are lowered with a plumb.

Next, nails are clogged into the marked points, they are tied by a kapron cord and stretch it with force. With the help of a plumb, the cords are tested correctly. In case of error you can simply bend a little nails and correct the position. Further masonry will be much easier, thanks to the cord, and the time spent on the work decreases.

All subsequent angles are performed in the same way as the first and second row described by us. When you lay out each row, the outer surface of the device body is cleaned with the help of a construction workshop, which can be removed from the residue. After completing the four - five rows, they are wiped with a wet rag.

Special attention should be paid to the seams of construction. They should be as thin with as possible, since thick seams begin to quickly crumble and the masonry of the oven is destroyed. The solution should be dense and fill with the entire depth of the seam. At the same time, if you perform vertical seams, you should overlap it with a brick located above. Ideally, if you place the brick so that the vertical seam is in the middle of the upper element. Of course, this will be not easy to achieve, but, no matter how it was, the overlap must be at least a quarter of the brick.

During the construction of the smoke canal, the brick should not be laid out with the cracked side inside, it will later make it difficult to pass the flue gases.

The fuel chamber of the focus is considered the most vulnerable to high temperatures, therefore it is not out of the simple brick, but from a solid chamotte material. If there is an opportunity, then from the dressing of the seams should be abandoned at all, as it is noted the difference in thermal expansion and, as a rule, the quick destruction of the masonry. Thus, the lining is performed either on the edge, or the number is completely laid out. The lining and chamotal material are stacked with the organization between them of the gap of about five millimeters.

![]()

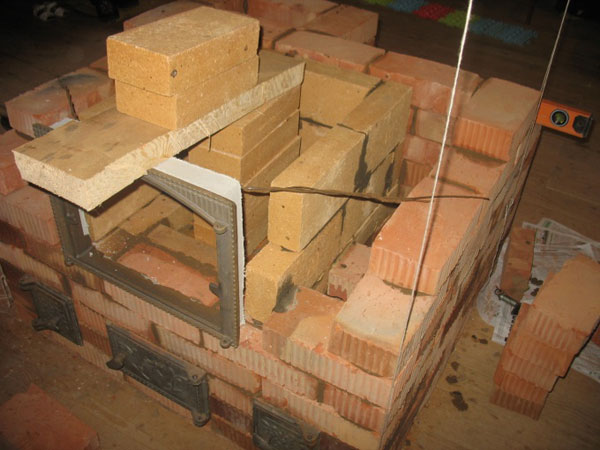

Installation of clear and configuration doors

Before installing the doors, check the tightness of the adjustment of the canvas to the frame. Also, attention should be paid to the check of the rotation of the canvas, eliminate the windows, etc. If there are some defects, eliminate them.Installing the door begins directly from the screw to the wire, which is inserted into the hole holes. The recommended wire length is fifty-sixty centimeters.

Where the door will be installed, cause a portion of the solution and insert the element, fastening it with bricks and checking the horizontal and vertical level. At the end, the wire is set in laying seams.

Installation of grate

It is important to remember the thermal expansion of materials. So, cast iron and brick have different indicators, it must be considered when installing the grate and other cast iron devices. If you do not leave the gap between the masonry and the body of the device, the headset will break the masonry, and the hearth will come into disrepair. Recommended gaps make up at least five millimeters. In addition, the semoliar changes several times during the operation of the heating device, so its free placement will not be an obstacle when replacing it.

Installation of the fuel door

The furnace door is installed in the same way, but it turns around asbestos cord. At the installation stage, the device is necessarily checked using a construction level and fixed with bricks.

If you are going to use a focus in intense mode, the wire that the door is attached can quickly fire, so it will be more advisable to replace the clemmer. For the execution of the beam, the strip steel is used, the cross section of which is twenty-five to two millimeters. Clammer's ears are removed by the frame for ten - twenty centimeters and attach to the frame with bolts with nuts.

Overlapping the door is performed in one second brick

or brick "in the castle"

If the opening is more than twenty-five centimeters, then the overlap must be performed in the form of a wedge jumper.

Installation plate

The first row, where the stove will be installed, first laid out on a dry (without solution). After that, the stove is mounted and its configuration is delineated. Next, in the brick choose the grooves with the condition that the slab subsequently will have an extension of about five millimeters. Brick is laid on the solution. Also, the groove itself is filled with the solution, and the asbestos cord is placed on the perimeter. Only after all these procedures omit the slab and deposit it with the CyanInstallation oven

The oven, installed in the furnace housing, turns around the perimeter asbestos. The wall adjacent to the oven is laid out on the edge, and the top is embedded with a solution with a thickness of two and a half - three centimeters. This will eliminate the ambulance of the walls of the oven.Masonry Arch and Arches

During the construction of furnaces and fireplaces, it is often overlapping a variety of openings, fuel cell, holes. To do this, use the method of laying the jumper, both simple and complex shape. The overlap in the wall is called arch, and between the two walls - the arch. The number of elements should be odd, and the central lock is called "Castle".The jumper usually begins to be laid out with petes, according to a pre-drawn pattern. During construction, you should adhere to the proposed package, since the height of the arch or the arch can be different.

It is very important when the furnace is erected properly install furnaces. This will protect you and take pleasure from observation of calmly crackling firewood or coal in the furnace furnace.

Stoves - confusion, furnace and clean doors, grate grating, gate (chunk) valves - are installed to regulate the combustion process and ease of operation of the furnaces.

Before installing the door, check for:

♦ Frame adjustment density to frame;

♦ free rotation of the cloth in hinges;

♦ no skew;

♦ the possibility of fixing their closure;

♦ The presence of holes for fastening in the masonry.

The chimnery gate should be freely walking in the grooves and tightly block the hole, the frame should not have cracks.

When installing furnace devices, it is necessary to remember that the metal and brick, heating, are expanding unequal. This affects the behavior of those devices that will be installed in high temperatures. If they are tightly closed in brickwork - with raising the temperature, they will break it. Therefore, the grille, flue-door, the oven and the cast-iron flooring is installed so that when heated is provided,

an expansion of them without impact on the masonry. For this, the grille is placed in the opening with a gap of at least 5 mm from all sides (Fig. 108).

The grate grid should be freely removed to replace in case of exercise or breakage. It is placed without a solution, and the grooves are filled with sand.

Special attention is paid to the installation of the heat door, since it is most exposed to the action of thermal expansion, and at the same time it should be installed so that the coarse space is tightly overlapped and reliable fastening it in the masonry. Fasten the flipping door with curvature steel (Fig. 109). The bottom can be fixed with a steel soft wire with a diameter of 1.8-2.0 mm, but it is necessary to close it with a solution. In the vertical part, the wire is difficult to protect from the effects of high temperature - it will quickly be abrupt.

Clammers are made from strip steel. Crazymer's ears should be beyond the door of 100-120 mm. Fasten the beam square to rivets frame. In the bottom hole of the furnace door, you can insert pieces of steel wire with a diameter

live so that they fall into the laying seams. Check the installation door setting - the top plank frame must be horizontal - and fix it with a wooden rail. One end of the rails put on the door of the door, the second - on 3 bricks, laid plastics, and put a brick on top on the rail.

According to the co-solution, put bricks, starting the masonry of each row from the door, gradually close it in the furnace array.

Installing the confusion and clean doors in the same way, fasten with a steel soft wire with a diameter of 1.5-2.0 mm, laying its ends in the laying seams. The infancy door is little exposed to the action of high temperature - the expansion of it is slightly, and since it should herdedly overlap the flooding space, it is tightly lit into the masonry, closeing all the seams clay mortar. It is necessary to strictly unstelling the horizontal framework of the framework frame.

Oven, as a rule, made from sheet steel. Therefore, when heated, they will strongly breed, if you do not leave the gaps for expansion. They set them in terms of the level, the frame is wrapped with a moistened sheet asbestos width in the Pollipich, an asbestos layer can be increased, just to the upper plane coincided with the plane of the masonry of a brick row, which is placed overlap.

The cast-iron plate on the kitchen and heating and cooking furnace lay strictly in terms of level. For stacking it in the bricks of the upper row, the grooves in the size of the plate with a gap of 5 mm per side are pushed. It is impossible to clamp even one of the sides of the plate - when heated the opposite direction will be combined. Better * Putting the plate on the clayas-scale solution. To prepare such a solution, they make a liquid clay pulp, an asbestos crumb is added to it, bringing the solution to the desired consistency. The top of the kitchen plate around the perimeter is watched by the same solution.

Sewer valves are placed so that the tightness of the channel overlapping is ensured or chimney. In bricks, grooves for the frame with a small gap

rum on the extension. Well put the valves on the clayabesto solution.

09.02.2007, 11:55

Tell me from practice how best to mount the furnace doors. On the wire, rivet and bending the plates or as some advise - drill a brick and put on anchor. Surely tried in different ways and stopped on the optimal version.

10.02.2007, 01:10

Yes, you are right, tried in different ways. Previously, years to 15 -20 tv, we always dripped with a wire or riveted with nails (for 250) to the steel strip from the wrap of wooden barrels, the benefit of them was lying almost in every yard. Now, of course, times are not those, but still knit, and we can take, and put on the bolts. Now it's kepy and on an anchor, and on the needles. It all depends on the design, customer and applied accessories (casting).

Based everything, for fastening the domestic casting, we use a black or stainless steel strip screwed or scanned to the door, and at the edges of the wire braid in the masonry, or the bending of the strip of the strip under 90 degrees. In the case of the application of the Finnish casting, it is sometimes on the anchor on the anchor. The door supplied to the clogged strip serves almost all of its life, does not fall and does not fall out. When mounting on an anchor, it is necessary to take holes in the door frame slightly larger than the diameter of the anchor, for thermal expansion. Installation on the wire, at first glance it may seem the simplest procedure, but it is not. Experience and some knowledge is needed, otherwise the door quickly looses and can even fall out. The wire must be soft, compossed, knitting, 2-3 mm, twisted tightly without gaps (!), Is well stretched and must go deep into the masonry, (and not at 15 - 20 cm, like some mountains of the Pechniks).

Choosing for you, all the ways are good and optimal to the specified place.

11.02.2007, 19:40

Thanks for the consultation. Probably I will mount the Finnish casting anchors. I would like to do so that it would be no longer coming back. Just doubt. Over time, the anchor due to different expansion coefficients can be breaking and falling. Maybe there are some tricks, such as a sealant into a hole or something else.

If that, tell me how best.

Yes, and more. What is the fitting needles. Briefly for concept.

12.02.2007, 00:02

I try to put the doors on the anchor only in the devices of periodic firebox with a small pace. Loads (type of barbecue, dacha furnace power, etc.) and tricks, but not previously indicated. It can not be cleared like that at any time you can pull the anchor. This is a plus anchor attachment, but for some reason, at high loads, I do not trust them, it may be in vain, it can be reinsured. There was no complaints.

Good luck.

22.05.2007, 23:06

Now it's kepy and on an anchor, and on the needles. It all depends on the design, customer and applied accessories (casting).

Hello.

Very surprised by reading the mount on the anchor of the coil door. After all, the anchor creates internal stress in the brick - with a serious temperature difference, it is not an additional factor in the destruction of the brick?

Zhirnov Vladimir

24.05.2007, 22:31

Good question!

In general, Kraft physics knows ... :)

Apparently he puts an anchor on the sealant

31.05.2007, 21:33

Hello, Vladimir!

Maybe you have a smile similar questions, but for such as I trying to make your only stove and do not claim the title of a "chimney professional", such subtleties are very interesting and your forum of professionals is very informative.

I, for example, in the same book on a chimney, in no description, I can not find, how does the exposure is laid out - is it mounted in the masonka or relies on the corner? Nowhere is not a word - as if it was at birth to the knowledge of knowledge.

Evgeny Kolchin

01.06.2007, 09:50

Vinni, naturally, this knowledge is not laid at birth ..

Here it is necessary to have skills in brickwork, i.e. the basics of Mason's skill - a ring, a tough, a bandage, as well as knowledge in the field of physics - the temperature expansion of various materials ..

So, if you put a corner into an exposure, then naturally it will warm faster and expanding pulling everything and everything that you have nearby, for such kidding to the corner, put a seal that allows you to compensate for this extension (example, installation of a gasket, gaps between Shamot and red brick), but not only in the subject ..

The second, if you "tie a brick exposure to an external laying, the same bad, since the outer wall is heated much later than all the inside the oven ..

From here, the exposure is laid on the inner wall and due to the dressing of the upper brick keeps

01.06.2007, 15:37

Evgeny! Thanks for the help.

Pal-Palch

29.07.2010, 16:33

29.08.2010, 18:19

Fastening the stem door SVT 405 with nichrome wire with a diameter of 1.8 mm. In each hole, 2 wires are skipped, which suits into dense pigtails and at the ends have hooks in the form of anchor.

On the pictures, the mount in the upper tier (wires are stacked into the cutting grooves cut into the brick), and in the lower tier, the same wires are between the rows of bricks in the solution of the seam.

Also attached photos of the fireplace door SVT 405 (external size 500x500 mm, planting size 410x410 mm).

29.08.2010, 18:21

Photo of the door mounting on the left:

29.08.2010, 18:22

Photo of mounting the door on the right:

The theme of the nichrome wire for fastening cast iron products in the furnaces (http://forum.stovemaster.ru/viewtopic.php?t\u003d1766)

Topic Fastening cast-iron door in the masonry (http://forum.stovemaster.ru/viewtopic.php?t\u003d3771)

Valentina

29.08.2010, 23:53

I dressed the director that on the fireplaces of the Meta I am in the store "Stoves-shop" (not reaching 800m to the "mill" at the external MKAD) received a 10% discount on the stainless pipes produced by them, and it is enough to name the last name of the Stribek (I can't eat anything there).

The director also promised to open an equally solid discount on Meta to my surname. Round there - regional sales manager said the discount is really installed. So far there was no order to check and make sure I invite you to try, who needs.

30.08.2010, 00:41

Substive not enough that sealed, so still managed blinds overlaps very tightly, not the fact that Finnish.

Yes, Finnish, as it were, the sealer doors svt blinds - the place is problematic. :-(

23.12.2010, 22:41

Here is a fucked problem. It is necessary in the future to install a flue door, but so that it can be easily removed. Those. Any fastening that is attached to the masonry array is not suitable. Anchor in the brick is also not suitable. It is necessary to maintain the ability to adjust the door along the depth of the firebox by the magnitude of the subsequent cladding in the future. Stainless steel is not applicable due to its absence.

I think to apply the metal strip bent the letter "g", which clings to the side of the brick addressed towards the furnace, but it is doubtful how long will live such a fastening if the strip is a thickness of about 2 mm. Maybe there is another solution?

23.12.2010, 22:57

Maybe 1mm is enough, and in the gland to walk the guarantine of the guarantine +. Is it that? It is used to protect the iron from fire during fires. And still top holes for cooling the door. :)

24.12.2010, 01:05

Can the bottom holes? Air will pull the air. Although I will not do holes unambiguously nor the top nor lower.

24.12.2010, 05:10

So what is the fixture on the needles? We did not find out?

24.12.2010, 05:29

Showing the "META" director "META" method of mounting the door with the help of the corners, width 12cm (so on the Kuznetsov website the doors are fixed using a stainless strip).

As a result, it seems to be expected to release the door of the MET with the extension of the inner frame 125mm with a bend by 20mm. That is, it will be enough to lay a niche of 260mm to the height of three rows and from above "enter" the door with basalt cardboard. That's all the mount.

The doors are very high quality, cute, exactly under our brick, sealed, with glass. Substive not enough that sealed, so still managed blinds overlaps very tightly, not the fact that Finnish.

By the way, I wrote on the mail "Meta" with the question: why they do not do the doors under the left hand and Horsho would still have a handle for cultural, for example instead of a plate, stainless. Tube F14-16mm. Such a handle and looks better and does not heat up.

24.12.2010, 05:31

Showing the "META" director "META" method of mounting the door with the help of the corners, width 12cm (so on the Kuznetsov website the doors are fixed using a stainless strip).

As a result, it seems to be expected to release the door of the MET with the extension of the inner frame 125mm with a bend by 20mm. That is, it will be enough to lay a niche of 260mm to the height of three rows and from above "enter" the door with basalt cardboard. That's all the mount.

The doors are very high quality, cute, exactly under our brick, sealed, with glass. Substive not enough that sealed, so still managed blinds overlaps very tightly, not the fact that Finnish.

I dressed the director that on the fireplaces of the Meta I am in the store "Stoves-shop" (not reaching 800m to the "mill" at the external MKAD) received a 10% discount on the stainless pipes produced by them, and it is enough to name the last name of the Stribek (I can't eat anything there).

The director also promised to open an equally solid discount on Meta to my surname. Round there - regional sales manager said the discount is really installed. So far there was no order to check and make sure I invite you to try, who needs.

Valentina, thanks for the offer.

By the way, I wrote to the mail "Meta" with the question: why don't they do the left hand doors? Horsho would still have a handle on cultural, for example instead of a plate, stainless. Tube F14-16mm. Such a handle and looks better and does not heat up.

I propose to form a joint offer-wish to leadership (to designers) of the company "META".

25.12.2010, 00:20

So what is the fixture on the needles? We did not find out? By the way, and on a stainless wire, someone attached? If yes, then share your experience as effective. I know that stainless steel does not burn, is it, or is it, or myth?

I wonder how this fastening looks. If anyone did, please show the photo or scheme?

Photos unfortunately not. And it looks like a wire, just a wire sticks inside the door and exposed to heat and fire. And the needles passes through the hole in the door frame and is attached to the holes with the threaded head. I first heated on gas stove Or the burner and bending at an angle of 90 *, so that the needle fits well on the frame from above and further on the brick. The end of the spokes bends in the seam brick masonry Or just fit into horizontal seam, but also with a curved end, so as not to slip out of the seam. This is if the holes are at the top and bottom of the frame. If the holes are worn, then you can also do in the side of the frame, then you do not need to bend head.

25.12.2010, 01:27

In Finnish doors, self-tapping screws and mopeds (cycling) spokes are invested. The most ordinary, as if only from the wheels were removed. Holes are drilled on the sides of the door, and that the aspective coincides with the rows of bricks! Those you put the door, put a row of bricks, insert the knitting needles into the hole. So bogulin clinging the brick over the axis lay on bricks, and the head of the knitting needle was in the door hole. We put the following rows from above, reach the upper holes, and insert the second pair of spokes. Threaded head is quite long, so you can then tighten the door, or unscrew the heads and remove it.

Mirkis Semen.

25.12.2010, 01:56

I wonder how this fastening looks. If anyone did, please show the photo or scheme?

What does the fitting fitting with the knitting factor at the SVT plant in Finland, see the photo 83 http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d22&p_ident\u003dLALBUM_2802140507.p_2503103456. The spokes at the factory do not, and are equipped with ready-made motorcycle (mopeds). In my practice, the side holes in Finnish doors did not coincide with the seams, it was necessary to cut the grooves in the brick, and the Finnish doors themselves are not painted by our rows themselves, under the door it had to put a gasket with a brick height of 20-30 mm.

But Finnish cookies back in 2007. They said what fastening yesterday. Yes, and we already have many fastening the doors on more modern technology (German-Finnish) - with a corner of stainless heat resistant steel with a thickness of 0.8-1 mm. In Germany, they are released, we have not seen their factory production manufacture. Who uses such technology, makes corners independently or orders them in the workshop.

My first in 2007. Acquaintance with this technology in Finland, see:

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d9&p_ident\u003dralbum_2802140507.p_2603174658,

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d10&p_ident\u003dralbum_2802140507.p_2603174658,

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d11&p_ident\u003dralbum_2802140507.p_2603174658,

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d12&p_ident\u003dralbum_2802140507.p_2603174658,

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d13&p_ident\u003dLALBUM_2802140507.p_2603174658,

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d14&p_ident\u003dralbum_2802140507.p_2603174658,

http://mirkis.sitecity.ru/Lalbum_2802140507.phtml?pix\u003d15&p_ident\u003dLALBUM_2802140507.p_2603174658

25.12.2010, 02:17

25.12.2010, 02:19

Thanks for the info.

German - Finnish technology taxis ...

25.12.2010, 02:37

Mirkis Semen.

25.12.2010, 02:41

How much does the door just like this "yesterday"? And how do you like fastening on their samabs? I also did not coincide the holes sometimes, but then Toli, I began to do the seams thinner, it was toli because of the brick, but usually do not feed. Although I have more often put. Maybe because of this. And they are better coincided by many more than many. How many times they spoiled that these inventors producing doors even probably and brick did not see!. This also applies to fuel, but especially to the cleaner.

1. On the knitting needles, I began to bet since 1998. There were no problems with "eating". And you can pull up. But it is inferior to such an attachment on the corners, the fact that the latter more maintainable - the door is easily removed, i.e. It is easy to replace, and it is very important that the protection of the red brick choke is being implemented.

2. Fastening the flue doors on self-drawing has not practiced. Because The same Finns said that this is the day before yesterday. In the Finnish book (in Russian) Yukhani Keppo " Brick stove and fireplaces. Masonry "This method is very criticized." Cold "doors - confusing, cleaned - you can.

25.12.2010, 02:52

Well, I protect the red brick, I protect the "on the Us" cutting, and the chamoten then comes to the door itself. But what there is no corner, and a fierce of stainless steel in stores is a fact: (I'm needed when I need a stainless steel, so I buy a pipe, cut and straighten. Although troublesome, it is available. In anyone, you can find the town in any terrain and whirlpool.

Mirkis Semen.

25.12.2010, 02:54

Taxis, it's when everything is available. I went to the shop, pinched my finger - "Give this door and the corners of the fastening to it," that's then taxis. In the meantime, as 100 years ago, the wire rolls, probably in 90%.

I agree. That the new technology for many people is not very accessible. It is necessary to order corners, have self-tapping screws for metal "Klopiki", dense basalt cardboard (better Finnish parks). For residents of remote places, the wire is still a wire, the beammers are cheap and angrily.

Zhirnov Vladimir

25.12.2010, 02:58

In the meantime, as 100 years ago, the wire rolls, probably in 90%.

RULIT, as long as!

25.12.2010, 03:04

25.12.2010, 03:07

RULIT, as long as!

Semen Mikhailovich also I somehow, told about the cutting of the thread in the frame of the door and fastening it with ordinary bolts

So it is possible and car whiskers to sign, spring for fastening torpedoes and all sorts of cladding. And then you do not need to cut a thread - screw the screw: grin:

Mirkis Semen.

25.12.2010, 03:09

RULIT, as long as!

Semen Mikhailovich also I somehow, told about the cutting of the thread in the frame of the door and fastening it with ordinary bolts

Yes I remember. I always tell me. Highly original wayHe came up with Kopaev V.Yu. (Moscow Guild). Received a patent for the invention. This forum has already been discussed somewhere. And even Kopaev himself responded to those posts.

Mirkis Semen.

25.12.2010, 03:14

And the main years is 20 years old. And then you can repair, all one firek is sought. Ordered and where, and how much? And how much time leaves to enter, come, pick up the order ... Yes, even search for challenge. So everything is not so unequivocal. Basalt then cardboard is not everywhere. And somehow for three days killed on the fact that there would be a grinding circle on the stone in St. Petersburg to find. That was not all here. And the chamdes needed to shoot.

I agree that troublesome and expensive. And not at each facility, the customer may pay all these innovations. But if the order is solid, then the preparation is serious.

25.12.2010, 03:21

25.12.2010, 03:25

Well, I do " folk stoves", I need that b along the road from home to the object everything will be caught. So I'm afraid that I still be a" not progressive "liver for a long time. But if the wire will end, I can always sit down, or have a neighbor from the fence-ripples to pull out . There is always a good soft wire on Ryabice :) Yes, and I don't go to the boxes. Although all more often, the people ask the Finnish door. So there are the knitting needles, so it's no longer necessary to run.

25.12.2010, 03:28

I noticed that polished stainless steel (corners on the door frame) do not even darken, then can the usual sheet steel can be used?

It all depends on the design of the furnace. In some furnaces and the door to raspberry, heats up. And if the door is worthwhile, for example, because of the futures, then there will be a simple corner to stand all my life. Yes, it melko and in the laying to embed it. Then he will not hang around.

Mirkis Semen.

25.12.2010, 03:34

Yes I remember. I always tell me. Very original way, I came up with Kopaev V.Yu. (Moscow Guild). Received a patent for the invention. This forum has already been discussed somewhere. And even Kopaev himself responded to those posts.

I found it, it was in March of this year http: //www..php? P \u003d 20952 & postcount \u003d 4, and the theme itself http: //www..php? T \u003d 2258

25.12.2010, 03:38

And a beamer, by chance, are it not shortened corners? Also to look.

25.12.2010, 03:42

Clearmen, these are strips of tin, screaming approximately cm 2-3, and a long cm 25-30. Screw (I usually trim nails) to the doors, through the holes. And the free end is refilled in the masonry. Holds better than wire, and do not pull out.

25.12.2010, 03:56

Mikhail Thank you, now I understood.

25.12.2010, 12:15

Taxis, it's when everything is available. I went to the shop, pinched my finger - "Give this door and the corners of the fastening to it," that's then taxis. In the meantime, as 100 years ago, the wire rolls, probably in 90%.

Ordered and where, and how much? And how much time leaves to enter, come, pick up the order ... Yes, even search for challenge. So everything is not so unequivocal. Basalt then cardboard is not everywhere.

Well, I make a "folk stove", I need that b along the road from home to the object everyone will catch. So I am afraid that I still still be a "not progressive" liver. But if the wire will end, I can always sit down or connect, or a neighbor from the fence-ripples to divert. There is always a good soft wire on Ryabice :) Yes, and I don't go to the klyamers.

That's what it is here, unless I didn't even see the doors of Finnish, but I put everything for the most part of the local filling or old Soviet, or Tsarist Poland.

And you say yesterday.

25.12.2010, 13:05

Vova, do not worry strongly. We love, opening the mouth, look at bright candy from abroad. Forbidding that we live in a country with huge experience chimney heating. So without seeing the spokes and other things, you have not lost much. If the door on the wire holds for 20-30 years, then it is necessary to replace it with the fastening if it is more technologically accessible. And if behind the corners, plates and other things, you need to run two days, or to drag on yourself ... then it suggests the question of whether you need it?

25.12.2010, 13:13

I found it, it was in March of this year http: //www..php? P \u003d 20952 & postcount \u003d 4, and the theme itself http: //www..php? T \u003d 2258