Many manufacturers offer a wide selection of materials for decorating build facades. Most in the original method Achieve the uniqueness of the building appearance is to create mounted ventilated facades. This technology is different not only by the variability of the color range of panels, but also by the form, texture and even name of the materials.

Widespread use of panels made of polymers (plastic).

Benefits

Plastic panels have a number of indisputable advantages compared to other materials designed to finish facades and even in front of metal panels:

- Small construction weight;

- Durability of the material;

- Low price of material and installation work;

- Simplicity of maintenance and repair;

- Large assortment of species and shapes.

In our country, a stone was considered the traditional finishing material, which is why the line of plastic panels imitating the stone surface is most extensive both by textures and in colors.

Types of plastic panels under the stone

Most popular in the market finishing materials Consider plastic panelsimitating the dasane, butt or natural stone . At the same time, manufacturers provide a complete line of the necessary taps, corners and planks of a given texture and color.

It is especially worth noting that different manufacturer of panels use various sheet sizes, so it is desirable to purchase plastic panels on the base and walls of one manufacturer. Installation and fastening systems are practically no different from different manufacturers. All panels are mounted sequentially from the starting plate, while the subsequent panel palas is inserted into the previous and fixed.

Manufacturers

In the finishing materials market, there are a huge set of offers for the sale of plastic panels, but many of the selling firms are dealers, and not by manufacturers. The main manufacturers of plastic facade panels are: Nailite, Novik, Docke (Dek), Fineber, Holzplast, Vox and Viola profile.

Different manufacturers vary not only the price of finishing material, but also such parameters like a color gamut, panel size, the quality of the source raw material.

Nailite is widely represented in our market. One of the main reasons for this distribution is a great experience in creating facade panels. The company was founded in 1978 in the United States and has been importing its products for many years different countries World.

The main series are: buttone (from simple to premium class), cedar, natural stone and a duck stone. In this case, each series panels can be performed in several embodiments (usually two, three types) of the color scheme.

Glacier White Brown

The dimensions of the sheets (useful length) range from 22.86x183.83 cm to 45.7x102.2 cm It is worth considering that the total length of the sheet is somewhat larger due to the mounting elements hidden during installation.

The prices of Nailite official representatives vary from 509 rubles per panel.

The main dealers in Russia are the company: the European, Top House, Westmet, Technonikol.

NOVIK is a Canadian manufacturer of plastic panels, but it is focused on a large line of plates performed under brick masonryAlthough there are also panels that imitate the trees, natural stone and cedar.

Panel size (useful length) varies from 101x45 cm to 80x60cm. Each model range has its own special sizes, while the minimum price for one panel will be from 464 rubles and higher.

The main dealers in Russia are companies: Mirkrovlya, Grotesque, Megroy, etc.

Docke is a German manufacturer of plastic panels. The main series are: brick and stone (natural and dasane). A feature of this company is an expanded panel colors palette. There is from five to ten varieties of colors of panels, despite the fact that many manufacturers are limited to two three colors.

Earthwood Brick Wheat Cherry  Dark nut

Dark nut ![]() Amber

Amber

The useful panel area varies from 0.42 to 0.45 m 2. It should not be forgotten that many famous manufacturers provide a free calculation service of the required amount of materials and components. Some are limited to special calculators presented on the company's website, and some companies exit the measurer specialist on the object. But the departure of the specialist is not always possible due to the remoteness from the representative office.

The minimum price for one plastic panel is 479 rubles. Many prices are valid for Moscow and Moscow region. Prices in other regions need to be clarified by local missions and dealers.

In order to clarify the location of the nearest Docke dealer, it is enough to visit the official website of the company, where more than a thousand different offices, intermediary firms are presented.

Details about the quality and types of Docke panels.

Fineber represents a large number of serials of facade plastic panels on the market: stone, wild stone, large stone, natural stone, brick, facing brick, rock, slate and facing stone Britt. Colors of design of each series can be from three to six. The smallest area of \u200b\u200bthe coating is the "Natural Stone" series.

Earthy large stone white slate beige big stone gray Facing brick Ceramic stone gray-green

Fineber has a wide network of representative offices throughout Russian Federation. Prices and delivery times of the company's products vary from the region. A complete list of representative offices is presented on the official website of the company Fineber.

Why the FaineBer front panels are among the best read.

Holzplast.

HolzPlast has recently recently entered the Russian market. The start of his activity is counting since 2005.

The company produces plastic panels in six different series by texture: brick, boot, dolomite, parphyr, chip and tuff. In the range of companies 14 colors of panels, but some series are available only in three colors, for example, dolomite in beige, gray and white.

The sizes of plates of this company are unified among themselves and make up 79.5 sm59.5 cm.

Holzplast has about 520 representative offices throughout Russia only in Moscow and the area of \u200b\u200b150 official sales points.

VOX offers two series of plastic panels: under brick or stone. Moreover, only in one size for each type: 109.5x44.6 for panels for stone and 111.3x46.7 for panels made under the brick.

Vox is relatively recently published on the market of facade systems and a dealer network is not as extensive as the famous Docke, Nailite or Novik giants. But at the same time, today its representative offices cover the major major cities of the Russian Federation.

For what praise Siding Vox learn.

Alta Profile

The Russian company of Alta-Profile since 2007 began to actively act on the market of facade systems. A relatively large number of series of colors of plastic panels makes it worth it to compete with more famous manufacturers.

The novelties of this company became the Canyon series panels, which almost immediately began to be produced in five color categories: Colorado, Montana, Nevada, Arizona and Kansas.

What you need to know before buying.

Moreover, one of the smallest prices for the panel is 415 rubles.

Technology of installation of plastic panels for stone

Installation of panels can be divided into 3 stages:

- Preliminary surface preparation;

- Frame device;

- Installation of panels.

Mount panels start with starting and finishing profile installation, as well as guide profiles. Installation of the panels themselves are as follows: the panel is raised into one guide profile, fuse arc and then roll in another guide profile. The side on which the small mounting shelf of the panel is inserted into the starting profile. In order to start the panel in the starting profile, you should use a rule and a conversion.

Video on the installation of plastic facade panels

Plastic facade panels are enough interesting decision For registration of the facade of the building.

With the overhaul of any house, the most important stage of work is the outer decoration. Now the industry manufactures ready-made panels for this from the most modern materials. Being an unsurpassed decoration for outdoor decorationFacade panels reliably protect the house from dampness and cold. In addition, the facing panels are good additional sound insulation for the facade of the house.

Now the building materials market for facades of the house has the opportunity to satisfy the most picky customer. It can be found on it to find facing panels for facades of various shapes and coloring, various compositions and different prices.

The most common types of facade panels include:

- Plastic;

- From natural wood;

- From layerwood;

- Insulating porous composition;

- Fibro cement;

- Ceramic.

Not always withstand competition even facade wooden panels. Natural, expensive compounds of the panels for the facade have long been successful, displacing new, artificial materials. New decorative inexpensive panels for the facade and more durable, and allow manufacturers on inexpensive equipment to carry out the most diverse art forming elements.

Wall panels for the outer facade, usually do not require surface processing - priming, shtcloth or painting. The desired properties of surfaces - coloring and form - are given by the manufacturer already in the production process. This determines their construction value. After all, the decorative facade panels are easy to install, are able to create an individual ornament without attracting design specialists.

Fibrocement panels

The main raw materials for the production of fibrotent panels are cement with sand. They add micro granules that are able to regulate the moisture content of the composition in the optimal range for any weather.

On both sides, these facade wall panels are covered with a protective composition, which is very durable. Many dozens of years protect the structure from any adverse external factors. Aesthetic and beautiful outside, they remarkably tolerate temperature fluctuations.

Dignities of panels for exterior decoration from fibrcement:

- High strength characteristics;

- Simplicity of mounting on the surface of the walls;

- Frost resistance (up to 100) cycles;

- Long service life;

- Heat resistance;

- Soundproofing;

- Low price range.

The special advantages of these panels for the outer decoration of the house should include one hundred percent fire resistance.

Panels for facades under masonry

Considering their ease, even the owner itself can be facing the house. No special techniques construction technologies It is not used.

Facade panels under the plaster

Many love, so prefer to decorate her or from a bar. It is clear that it is not convenient, the wall surface is not even. There will be a sentence. Manufacturers have prepared a new product with the simulation of the plaster system on the facade.

In fact, it is the same panels made of polystyrene with an external decorative layer, which are manufactured in the design under stone or under the brick. But now, the thermal insulation base is applied as a decorative layer imitation of the plaster facade. Why imitation- because actually the outer layer is not made of plaster, but from plastic. It is painted and completely repeat the texture of plaster- ,. It is convenient to use such panels: mounted on glue, immediately close the large area, are simultaneously insulation. Such plaster does not crack and do not appear chips after severe hail. However, the house will not "breathe" and behind the microclimate will constantly have to monitor, more often to ventilate, it is better to establish forced ventilation.

In fact, it is the same panels made of polystyrene with an external decorative layer, which are manufactured in the design under stone or under the brick. But now, the thermal insulation base is applied as a decorative layer imitation of the plaster facade. Why imitation- because actually the outer layer is not made of plaster, but from plastic. It is painted and completely repeat the texture of plaster- ,. It is convenient to use such panels: mounted on glue, immediately close the large area, are simultaneously insulation. Such plaster does not crack and do not appear chips after severe hail. However, the house will not "breathe" and behind the microclimate will constantly have to monitor, more often to ventilate, it is better to establish forced ventilation.

There are other types of facade panels under the plaster. For example, manufacturers of Japanese  fibro-cement panels have cement panels under the plaster. In its composition, they do not contain insulation, this issue will have to be solved separately. But the fir-cement panels are installed on the crate and have an indentation from the wall. And, if, at the bottom and at the top of the wall make some kind of products, the air will circulate and constantly carry out the humidity from the outside and condensate from the house. In such a house there will never be mold and wet walls indoors.

fibro-cement panels have cement panels under the plaster. In its composition, they do not contain insulation, this issue will have to be solved separately. But the fir-cement panels are installed on the crate and have an indentation from the wall. And, if, at the bottom and at the top of the wall make some kind of products, the air will circulate and constantly carry out the humidity from the outside and condensate from the house. In such a house there will never be mold and wet walls indoors.

What facade panels are better- which is the basis of which polystyrene foam or without this filler, solve you. However, the mounting speed of the facade is overlapped by the operation of the facade, in which the insulation is made separately, the facing separately.

Facade panels under brick

Brick buildings are traditionally reliable and aesthetic facilities. They also speak about the decent material level of tenants, and good taste. But here the construction of a brick building has never been cheap. The most expensive material is the brick itself, the work of Masonicians does not seek.

Facade panels under the brick give the building the same appearance as completely brick. But the price, such as the shield, is at times cheaper.

But the external difference between the brick building from the building, lined with wall panels under the brick, can only be seen near or even determine the power.

The panels for the outer decoration of walls under the brick are manufactured in a monolithic and combined structural design. Combined panels consist of two layers - external plastic and internal polystyrene.

Fasten the facade panels under the brick is needed on the glue composition. If hot adhesive connections are used, they are obtained almost inseparable, long-term.

Facade panels that imitate brickwork will be much lower than the price than ordinary facing walls From decorative brick. And laying of walls decorative brick - The lesson is not cheap.

The panels can be used both the wall covering completely and for the design of only the ground floors or levels of the building. To give the base of natural protrusions on the wall at the bottom, a special lap is performed from metal profiles or from wooden bars.

Ground Siding

The branded manufacturer of finishing materials delivers the cladding panels of the base siding, which have a view of a brick or natural masonry. Such panels give the ground elements of houses a familiar kind of natural brick or stone building. The panels are designed to finish the house outside, so they are not afraid of a wet climate, easy to install, have resistance to bright sunlight.

Product advantages:

- Lower price compared to the price of cement panels for facades;

- Ease of installation, minimum costs for further care;

- Perfect aesthetic species;

- Without loss of properties and the type of long service life;

- Full compliance with all existing quality standards;

- Are non-combustible facade panels.

For the manufacture of outdoor facing base panels, only high quality raw materials are used, which fully complies with these Ecology and Construction Rules.

Having a small thickness, the facade panels without insulation are very durable. If we consider that the manufacturer guarantees long lines of the service of such panels, they are simply indispensable when finishing modern buildings facades. Of course, such an intuitive installation of facade panels can be performed with your own hands, any savings are always plus.

Any of the listed panel coating of facades of buildings is only a cheap substitute, a simulator of classical building technologies. However, if you think about such parameters of materials such as thermal conductivity, moisture resistance and noise insulation, then it is quite possible to obtain the result of the opposite sense. Masterfully made panel coverage of walls and facades of houses for these indicators may even exceed traditional construction methods.

How to calculate the facade panels to the house

The calculation of the front panels to the house is carried out according to the following instructions:

- First, find out the area of \u200b\u200bthe cladding. To do this, multiply the perimeter of the house at its height. Then we subtract the area of \u200b\u200bthe openings.

- Then find out the area of \u200b\u200bone panel. To do this, multiply the height of the panel on its width.

- And last, you need to divide the first value to the second. Those. The area of \u200b\u200bthe house is divided into one panel area. We get the number of panels in pieces. We add a small supply of 5%. We can go buy.

If one of the varieties of your panel is the same angular panel, we consider it separately. For this corner of the house multiply to the height of the structure. We divide the resulting value to the height of the angular panel.

Now we will analyze on the example. Suppose we have a house 6 * 8m, 3m high, in it 2 windows 1.2 * 1.8m and one door 0.9 * 2m.

- We consider the area of \u200b\u200bcladding. The perimeter of the house is the sum of the lengths of his parties. We fold 6 + 6 + 8 + 8 \u003d 28m. We multiply to a height of 28 * 3 \u003d 84m. Now we consider the area of \u200b\u200bthe openings: windows 2pcs * (1.2 * 1.8) + 1 door (0.9 * 2) \u003d 4.32 (windows area) + 1.8 (door area) \u003d 6,12m - this is the area Operactions. Now we read the area of \u200b\u200bopenings 84m - 6,12m \u003d 77.88m from the area.

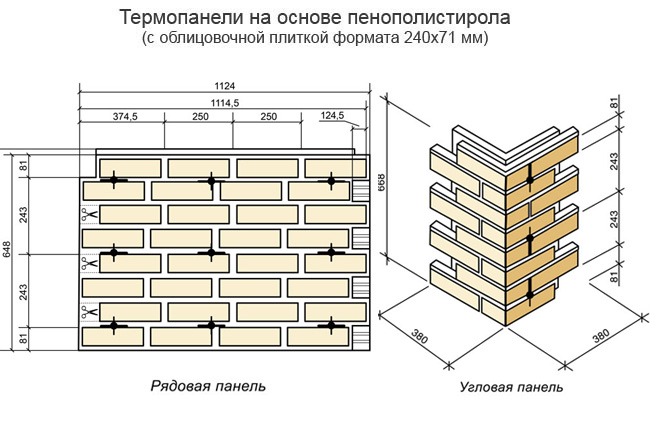

- Find out the area of \u200b\u200bone panel. Height 0,648m, length 1,124m. So 0.648 * 1,124 \u003d 0.73m.

- Calculate the number of panels in pieces. We divide the facing area to the area of \u200b\u200bthe panel 77.88m / 0.73m \u003d 107 pcs. Add stock 5%, we get 112 pcs.

Now we consider the angular panels on the same principle. And we subtract the angular from the ordinary panels.

For accuracy of 100% in the number of panel, it is necessary to make a layout layout in the drawing.

The simplest thing to turn to the manufacturer, as accompaniment to sell the sale for sale is free and for sure you will consider it all better.

The most relevant at the present time materials for the external finishing of the house are plastic panels for walls. This is due to their practicality, high quality and acceptable plastic cost. Its universal configuration is suitable for lining any room in the house. This article is devoted to varieties, benefits and production. plastic profiles.

Features of the production of plastic panels

The basis of all types of such profiles includes high-tech material polyvinyl chloride, which is used to produce not only panels for outdoor and external finishing of the house, but also laminate. The production of polyvinyl chloride (PVC) is currently fully automated, so the manufacture of profiles does not represent a special difficulty, it is enough to purchase high-quality equipment.

The production process consists of several stages. First of all, the specific amount of petroleum products and stone salts is converted into the consistency of the smallest powder. And then, because of this, the powder is formed by a polymer. The current method of production of PVC is an extrusion, which is the process of extruding the molten composition through a nozzle of suitable parameters. And to achieve the necessary properties, it will be necessary to add and mix the mixture of other materials simultaneously with the extrusion process.

Varieties of plastic panels for walls

Profiles for finishing walls from the outer and outside of the house are significantly different. For example, plastic facades are manufactured using additional materials to increase stability to weather conditions and an increase in service life.

PVC wall panels for the exterior finish of the house are three species:

- Plastic lining is rectangular profiles with hollow channels and characteristic parameters. The width of the lining varies in the range from 100 to 350 mm, the thickness is 6-10 mm and length to 6 meters. The fastening is made on the shap of the tree, thanks to the installation groove.

- PVC leafy profiles. They have an appearance of tile and can be decorated with various patterns and patterns. Basically enjoy the demand sheets with dimensions of 1220x2440x3.2 mm.

- Sandwich panels or tiled profiles. Made in the form of a rectangle or square small tiles. Their sizes range from 30 cm to 1 m.

Plastic lining is used for indoor and outdoor facing. This species is characterized by excellent properties of noise insulation, thermal conductivity and an excellent decorative type. It should also be noted elasticity that allows you to flex a panel using a bracket. Such profiles are often used to decorate walls in the bathroom and kitchen, as they have moisture resistance. Due to the fact that plastic lining is made by special technology using hard polyvinyl chloride, it is not amenable to deformation and rotting. Also, this species is absolutely resistant to ultraviolet radiation and does not mow under the influence of the Sun.

A special advantage of PVC lining is considered to be easily in the installation and the possibility of material to perfectly hide the irregularities and other wall defects. There is no need for careful care of the wall panels, sufficiently wet wet wipes. Lining is a fireproof material that does not stand out harmful substances. In the catalog of modern lining, you can choose a shade for every taste.

PVC leafy panels

There are such sheet plastic facade panels:

- PVC facade panels imitating metal. Profiles for outdoor cladding at home are produced by alloy using different modifiers. The panels performed "under metal" has an appearance similar to aluminum or galvanized steel. Sizes of plastic panels of this type: Thickness - 0.5 mm, weight - 0.8 kg per square meter. Can be with a smooth or perforated surface. The advantages of such panels for the outer decoration include: long service life (at least 30 years), moisture resistance, resistance to low temperaturesNoise absorption.

- Facade PVC panels, imitating stone. They are produced by combining several materials, which significantly improves the technical quality of profiles. Basically, the inner layer is made of sheet polystyrene, and an external - from the alloy of polymers and polyvinyl chloride. Such panels are characterized by thermal insulation qualities. Therefore, it is decided to establish this type of outdoor cladding at home, you can provide not only aesthetic decorative look, but also an excellent insulation. To all other things, the facades made "under the stone" significantly save the cost of repair, because there is no need for additional insulation robots.

PVC wall panels of this type are perfectly suitable for finishing facades, ceilings and walls indoors. The main plus of leaf profiles is quite low cost in comparison with other finishing materials. Plastic sheet panels today have become a really worthy substitute for an expensive ceramic and tile, which is also characterized by complexity in the installation.

Thanks to the panels of this type, you can convert any defect indoors in the perfect surface. Like all other types of polyvinyl chloride panels, leafy profiles are characterized by a high level of resistance to moisture and environmental qualities that allow them to establish them in buildings with special requirements.

Sheet profiles are an optimal version of wall finishing, which does not require special efforts to clean.

The method of manufacturing finishing materials from PVC allows the surfaces of various textures and shades of the color gamma represented in the manufacturer's catalog.

Dignity

In addition to the lightweight and rapid process of installing plastic profiles that imitate tiles, a number of such advantages should be noted:

On the plastic panels for the walls of the house every year, consumer demand is increasingly rising. After all, they have a lot of benefits, and production technology is constantly being improved.

715 0Updated:

2016-09-23

2016-09-23

Panels for the stone for the outer decoration began to be used now much more often. Why? They are affordable, easy to install and unpretentious in operation. In addition, they are represented by many species, textures and colors, which makes them the leader among other facing materials. What types of facing panels should be applied and how to install them will be described below. And in general, is it worth buying a facing panel under the stone?

Before paneling under the stone is an important task - to meet the needs of the client in external aspects and specifications. Professional finish at home panels often allows this to do. But do you suit this stove and how much the price is satisfactory for your budget?

Outdoor cladding of the house can be a real problem for those who do not know which material is better to use. What is it worth starting? To date, there are almost a dozen popular types of facing. Which of them are the most profitable?

It should be understood that not only beautiful outdoor materials are used for outer decoration, but at the same time practical design elements. The additional layer of the facade should not be a decision for the year. So that the new layer soon did not have to change, to the selection of cladding it is worth coming with all seriousness.

The most favorable options must comply with price-quality ratio. Next will be given the most common types of finishes.

Finishing options

There are only two types of materials that are used for external facing - natural and artificial.

There are only two types of materials that are used for external facing - natural and artificial.

The finishing of natural elements will cost at least 2 times more expensive. To such a type of facing includes a tree, stone, glass. Usually these materials are used for facing work on small areas, such as single-storey houses and other buildings. They have a long service life - up to 10-20 years - in case they will take care of them. Over time, the impregnation will deteriorate, and the protective layers will be folded, then this outer layer will have to be replaced. Although such types of house facing are still popular, but they have replaced new materials - artificial.

The most advantageous option for repair and decorative works became polymer elements for the skin of the house. Facing from these artificial materials has become popular after some time after their appearance. Cheap polyvinyl chloride and fibro-cement panels are perfectly tolerated even the worst weather for a long period. Heat, cold, wind or slush will not affect the decorative qualities of this type of facing.

From artificial materials it is worth highlighting the PVC panels under the stone. Visually, they are almost identical to natural stone, can even repeat the color and glitter of some minerals. Such decorative elements Quite simply mounted on the facade of the house outside with the crate. But only the texture of the stone this option is not limited. You can choose a panel under a tree, metal, brick almost any color. One of the best manufacturers of such products are German companies. Neither in the photo, nor with a personal assessment, it is almost impossible to distinguish a natural stone from the texture made from PVC.

In addition, there are also fibro-cement panels. They also realistically repeat the stone texture, like PVC, only suggest a slightly different type of installation. The only drawback of this material is the absorption of moisture. Its porous structure requires additional drainage systems, as well as a layer of waterproofing. But the rest of Fibrocement is an incredibly reliable option for outdoor decoration at home.

Natural materials for lining at home are used much less frequently. One of the few options can be considered wooden MDF panels under the stone. The use of stone for the scenery of the facade was practiced for a long time. And this type of finishing is still in fashion. MDF is a relatively cheap material that can replace visually even a stone. However, problems with humidity may arise. Increased humidity spoils such a cladding, so you have to use the waterproofing layer to protect it from the destructive action of moisture.

Nuances when installing

Now it is very popular to use decorative panels under the stone. They give a solid and strict type of building. But it is necessary to comply with some rules to eventually get a high-quality facade:

Now it is very popular to use decorative panels under the stone. They give a solid and strict type of building. But it is necessary to comply with some rules to eventually get a high-quality facade:

- Finishing the house from the outside should be carried out in dry warm weather.

- Panels under stone are laid out only the bulk of the facade. The base must be bred by a special type of panels.

- Finish PVC panels It can be done independently. For this, there are special installation instructions that are included in the set. To get the same appearance of panels, as in the photo in the instructions, all manufacturer's recommendations should be followed.

- When installing artificial elements between them, it is necessary to leave a small gap. During operation, they can expand and not to damage the adjacent elements, they will need a little space.

- Plastic panels for stone are mounted on a special metal or wood crate. It is worth paying attention to its protection against moisture.

The most popular type of finishing facade is artificial stone.

Such cladding can be obtained using PVC, MDF and fibro-cement panels. Almost all types can be installed in person, but to speed up the process, it is recommended to invite the team of specialists. Upon completion of the work, even a unbroken construction will be on the view more solid and interesting.

The exterior decoration of buildings is one of the key stages of private and multi-storey construction. In the current market of building materials, you can find various facing options, however, the facade panels are most popular.

This product is represented by a variety of model range, respectively, the buyer can give his home the original appearance and individuality. In addition to architectural features, the material reliably protects the wall structures from negative influence ambient, Provides additional thermal insulation of indoor rooms.

Separation of facade panels for destination

Panels for the outer finish of the facade can be divided into two categories, depending on the target application. It looks like this:

Wall

These are large panels designed for wall structures. With impressive dimensions, such elements have minimal weight: up to 5 kg, Accordingly, even one person can cope with their installation.

Cocal

Such panels are designed to protect the most vulnerable part of the building - base. Therefore, the material is impregnated with a special composition, which is resistant to a humid environment and resists the formation of pathogenic microflora.

Such models look much thicker, have a denser structure. When installing the base panels, it is sure to lay a layer of heat and waterproofing.

It is possible to install the base panels only at temperatures above zero degrees, for wall facades - compliance with this condition is optional.

Characteristics of the type of material

Facade panels are presented in the construction market a very diverse model side. In the manufacture of products use different kinds Raw materials, which affects not only the appearance, but also the technical properties of finished panels.

By type of material used, they are divided into the following groups:

Plastic facade materials (PVC)

In fact, this is a kind of siding, which has a denser structure. As a result, it turns out quite rigid and high-strength material, resistant to any external influences. It is worth noting that the plastic panels have a solid service life during which they do not lose their initial properties and a presentable appearance.

The key advantages of the facade plastic panels are the wide palette of shades and the lack of special care requirements for the material.

Vinyl panels for outdoor decoration

This category is considered the most popular building materials. Panels are made of artificial raw materials, where 80% Makes up polyvinyl chloride. For resistance to mechanical effects, modifiers are added to the composition, the desired color is achieved by pigment colors.

Durability - up to 30 years.

Operating temperatures -50 - +50 degrees.

Fireproof - G1..

Moistureproof.

The material is easy to cut.

Ease - weight 5 kg / sq.m

Not subject to rotting and corrosion.

Easy installation and repair.

Additional protection of the house from heat losses. Coefficient of thermal conductivity - 0.16 W / m * to.

Resistant to ultraviolet radiation, does not lose color.

The technology of producing vinyl panels allows the use of recycling raw materials ( no more than 5%), which reduces the cost of finished products.

Polypropylene finishing materials for walls

This is a popular kind of baseball panels created on a polyvinyl chloride basis. The material is made in the form of fine horizontal planks that are convenient for installation and implemented in the available price segment.

The use of polypropylene panels give the building an original appearance, however, the material has a significant disadvantage: high sensitivity to mechanical damage. In addition, under such panels necessarily laid a layer of insulation.

Ceramic (clay) products for finishing facades

Such panels are called clay and refer to the most demanded category of finishing materials for facing facade. The basis of products is the cement, in which silicate materials or synthetic fibers are added, which ensures high strength of finished panels and resistance to any external factors and mechanical damage.

In addition, the indisputable advantages include environmental safety and a wide selection of texture. An explicit minus is considered weight, which is noticeably higher compared to other models.

Fibro cement plates - natural composite material

Products of this group are a fibro-cement base, reinforced with metallic or polymer fiber. Such models have high sound insulation indicators, prevent heat loss. In appearance, the material usually simulates brickwork or cladding with natural stone.

Life time - 20 years.

Frost resistance - 100 cycles.

Not subject to corrosion and rotting.

Does not vary from ultraviolet radiation (as part of paints - resins and substances-absorbers ultraviolet rays).

Do not combustible - NG.

Hold the temperature differences.

The components of this slab do not contain substances harmful and environmental.

You can restore any geometry of the facade, eliminate irregularities without preliminary preparation of the wall surface.

Reduces heating costs. Coefficient of thermal conductivity - 0.12 kW / m * to

Bending Strength - 21.5 MPa.

Noise absorption coefficient - 29 dB.

Increase the unlimited service life of facades of buildings.

At the same time, manufacturers offer more 30 variations Color palette, which ensures freedom of choice. The disadvantages of fibro-cement panels include elevated weight, which makes the installation impossible without prior enhance wall structures.

Metal facade panels (aluminum coated polymers)

This category includes panels made of galvanized or stainless steel, however, the most common material is aluminum with a polymer coating. Such panels are often called composite due to a multilayer structure. It looks like this: the outer sides are made of aluminum covered with anti-corrosion coating. In the middle there is a mineral filler from non-combustible material.

Specifications

Durability - service life - 30 And more.

Frost resistance - 50 cycles.

Moisture resistant.

Do not corrosion.

Fire safety - NG.

Do not deform when the temperature drops. Operating range OT -50 to +50. Degree.

Easy mounted.

Have a different color and coatings.

Noise absorption coefficient - up to 20 dB.

High impact resistance - 50 kg / cm.

Acid resistance and alkalis.

Bending Strength * - 118 MPa.

Such a structure provides panels with high rigidity and dynamic load resistance. The polymer coating protects the foundation from any external influences.

Fiberglass materials for protective and decorative facing

In fact, wooden panels for finishing facades (plaquen) are reminded by lining, but the key difference is the fastening of the "flush" elements. As a result, it turns out natural materialwhich practically does not destroy under the influence of external factors.

Life time - 10-15 years.

Frost resistance - 100 cycles.

Due to high density, deformation does not occur, panel cracking.

Environmentally friendly material.

Carries out heat protection and energy saving. Coefficient of thermal conductivity: 0.15 W / m * k.

Provides sound insulation - sound insulation coefficient - 30 dB..

Bending strength - 45 MPa.

Ease of installation.

Such a casing can serve several decades, not destroying, while being completely natural material.

Natural stone panels

By structure, such products are a conventional composite panel, where the outer side is finished with a layer of natural stone. The panels have absolute nonopication, resistant to any external influence, frost resistance and bending strength.

The disadvantages include high weight and low sound insulation.

Facade porcelain stoneware - a reliable solution for ventilated designs

In this case, the outer side of the panel is separated by porcelain with artificial material creating a complete imitation of the natural stone. Products have high frost resistance, wear resistance and neutrality to any aggressive medium. The use of such panels is significantly expanding the horizons of architectural fantasy.

Durability - 50 years.

Frost resistance - 100 cycles.

Low water absorption - 0,02% .

Resistant to ultraviolet radiation.

Resistant to acids and alkalis (except for plastic acid and its derivatives).

Fire safety - NG.

Bending Strength - 30 MPa.

Resistant to temperature drops. Operating temperatures: -50 - +60 Degree.

Easy replacement of damaged plates.

The disadvantages of the facade plates from porcelain is a high cost.

Glinders for facing facades of buildings

In the manufacture of products, fiberglass is used with the addition of various resins. The panels have a lot of indisputable advantages, on the texture can imitate any natural surface.

Products attract attention to the presentable appearance and a wide palette of color, however, can push the buyers with high cost.

Wall Sandwich Panels (for mounted facades)

Such products are used for mounting mounted facades, represents a multilayer structure, where there is a layer of insulation between metal sheets. Material is often used in the private sector, due to low cost, rapid installation and relatively good technical specifications.

Durability - before 30 And more.

Operating temperatures - 180 - +100 Degree.

Fire safety - G1..

Environmentally safe.

Not susceptible to rotting and corrosion.

Protect heat loss - thermal conductivity 0.02 W / (MK).

Bending strength - 24.3 MPa.

Swelling from moisture - 1,86 % .

In addition to the feedstock, the front panels are divided into other criteria.

Popular structures

![]()

Panels for the external finishing of wall structures may vary by texture. Models are very popular, which are a complete imitation of natural building materials. For example:

Under the brick (clinker)

Initially, clinker tiles were developed for sidewalks, but due to the high technical characteristics Found the use of wall structures in the finish. The material accurately copies the brickwork, imitating the aged surface or firing traces. Thanks to this, you can give home any architectural style: from an old castle to a modern cottage.

Under a stone

These models imitate the walls of the walls with natural stone. The panels look beautiful and presentable, can be installed on an aluminum profile or glued with special compositions immediately to the wall structures.

Under the tree

Such panels are accurate imitation of the wood of valuable rocks. This texture is considered quite popular, therefore it is found on all the varieties of wall panels.

Choosing a suitable texture, you can give the building any appearance, while saving on the use of natural building materials.

Advantages and disadvantages of panels for facades

The panels can be made from various raw materials, sometimes creating an accurate imitation of natural materials: wood, stone. In addition, the market there are panels of different sizes and structures. However, for any variety, their strengths and weaknesses are characteristic.

To indisputable benefits Facade panels include factors:

Absolute protection of the facade of the building from any natural phenomena, including sharp temperature differences.

All panels without exception are made of artificial material, which is immune to corrosion and the appearance of fungus, does not fade away from the long exposure to direct sunlight, supports a pleasant microclimate in the premises.

Installation does not require preparation, finishing works can be performed under all weather conditions.

For fixing, you can use any fastener: brackets, nails, screws.

When installing is allowed horizontal and vertical location panels.

Some models create a complete imitation of wall cladding with natural materials.

Facade panels can be used to reconstruct dilapidated buildings and structures that breathe new life in them.

From express disadvantages You can select the following:

Installation of some models requires the involvement of professionals, which significantly increases the cost of work.

Certain types of products are not suitable for regions with harsh climatic conditions.

In addition, facade panels for decorative finish Have a fairly high cost.

Features of mounting facade panels

One of the key benefits of the front panels is the possibility of mounting with your own hands, without the involvement of specialists. Three main options for finishing works can be distinguished:

Straight

In this case, the cladding is placed immediately to the surface of the walls. It is important to understand that this technology is suitable only for perfectly smooth surfaces. For direct laying, clinker panels are excellent, which perform the function of additional insulation and decorative trim.

On Cherchetku

This method is suitable for all types of facade panels. In this case, it will also be necessary to align the walls, albeit not so careful as in the previous version.

On special fasteners

This option is suitable for walls where the installation of an additional layer of thermal insulation is envisaged. In this case, the panels are joined among themselves the system of built-in mounts. The system is ideal for the arrangement of ventilated facades.

In most cases, the installation of wall panels is reminded by an assembly of a children's puzzle, where the plates are joined together and fixed with fasteners.

Reliable manufacturers proven time

When choosing building material, the main thing is to find a good manufacturer. Wall panels are in high demand, so there is a mass of fakes on the market. Verified manufacturers with good reputation include products of such brands:

Alta-Profil.

This is a domestic manufacturer, one of the first to start producing wall facade panels in Russia. The company has its own production facilities, carefully monitors the quality of products. As a result, consumers get high-quality facade panels at affordable prices.

Dek.

Motherland Brand - Germany. For the European manufacturer, facade deck panels are sold in amazing low pricesAt the same time traditionally affect high quality and long service life.

This is a Japanese brand, which is among the absolute leaders of the Russian construction market. Panels of this manufacturer 90% Consist of quartz and cement, the surface has a porous structure. As a result, the products have high strength and frost-resistance. The facial part is covered with a ceramic layer, which makes panels resistant to any external environment.

Another Japanese manufacturer who won the confidence of Russian buyers. In the manufacture of products, wood fibers, quartz, cement, mica are used. The highlight of this company is the lack of chemical components and additives of inorganic origin.

This is a trademark of the Russian company Tern Polymer. Panels are available on an automated production line using high-tech equipment. The company produces wall and base panels of various colors and textures.

Russian manufacturer working on german technologies. The basis of the products is based on polyvinyl chloride, allowing you to give the finished products any texture.

Wandestein

This is a trademark of a Russian-German enterprise. The product range includes wall and base facade panels, has several collections.

Products of all manufacturers have quality certificates of the international sample.

In the photo samples of private houses with decoration from materials considered in this article