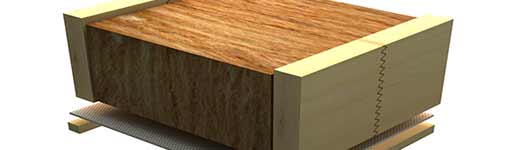

Foundation

Monolithic reinforced concrete pile-screened with a bave of 1.8 meters and the fill of the insulated slab

Outdoor wall in plaster 1. Plastering system Caparol (Germany)

1. Plastering system Caparol (Germany)

2. Plate insulation density 130 kg / m2 50 mm thick

3. Caparol adhesive system, 2 mm

4. Cleaning GHSV, 12.5 mm

7. Saving GSP, 12.5 mm

8. Covering GLK, 12.5 mm

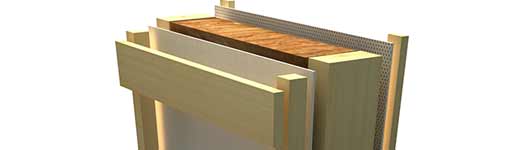

Outdoor wall with trim under the ventilated facade 1. Planed vertical wooden chamber drying case with a moisture content from 8 to 12%

1. Planed vertical wooden chamber drying case with a moisture content from 8 to 12%

2. Windproof membrane, ONDUTIS R70

3. Planed horizontal wooden chamber drying drying with 8 to 12% humidity from 8 to 12%, filled with a soaplier technobox standard 50 mm thick

4. Cleaning GHSV, 12.5 mm

5. Planed wicked wooden frame frame 144x70 (44) mm chamber drying with humidity from 8 to 12%, filled with insulation KNAUF "Framework structures TR 037 Aqua Static" thickness 150 mm

6. Parosolation membrane, ONDUTIS SA115

7. Saving GSP, 12.5 mm

8. Covering GLK, 12.5 mm

Facade

Caparol Maintenance System (Germany) / Fibrotic panels KMEW / Brusade imitation / siding

Internal partitions 1. Saving GSP, 12.5 mm

1. Saving GSP, 12.5 mm

2. Planed scrambled wooden frame frame 144 (94) x70 (44) mm chamber drying with humidity from 8 to 12%, filled with insulation KNAUF "frame structures tr 040 aqua static" thickness 150 (100) mm

3. Trying GSP, 12.5 mm

Technology building panel-frame houses. Part 2

Inter-storey overlap 1. Plywood, 18 mm

1. Plywood, 18 mm

2. Planed scrambled wooden frame frame 194x70 (44) mm chamber drying with a moisture content from 8 to 12%, filled with insulation KNAUF "Framework structures tr 040 aqua static" 100 mm thick

3. Parosolation, ONDUTIS SA115

4. Planed Wooden Disease 20x44 mm Chamber Drying Humidity from 8 to 12%

Attic overlap 1. Planed designed wooden frame frame 194 (144) x70 (44) mm chamber drying with a moisture content from 8 to 12%, filled with insulation KNAUF "Frame structures tr 040 aqua static" thickness 200 mm

1. Planed designed wooden frame frame 194 (144) x70 (44) mm chamber drying with a moisture content from 8 to 12%, filled with insulation KNAUF "Frame structures tr 040 aqua static" thickness 200 mm

2. Parosolation, ONDUTIS SA115

3. GSP, 9 mm

Roof panels 1. Wooden doom 25 (32) x100 mm chamber drying with humidity from 8 to 12%

1. Wooden doom 25 (32) x100 mm chamber drying with humidity from 8 to 12%

2. Planed Wooden Distribution 20 (44) x44 mm Chamber Drying Humidity from 8 to 12%

3. Windproof membrane, ONDUTIS R70

4. Planed designed wooden frame frame 194x70 (44) mm chamber drying with humidity from 8 to 12%

5. Planed Wooden Board 20x44mm Chamber Drying Humidity from 8 to 12%

Roof coating Metal Tie GRAND LINE (Germany)

Metal Tie GRAND LINE (Germany)

Additionally At factory B. wall panels A two-chamber double-glazed glass with a profile with a thickness of 70 mm with lowers + accessories, a gofrotrub is laid under the wiring. Installed painted porches, terraces, balconies according to the project. All outdoor entrance doors are installed.

At factory B. wall panels A two-chamber double-glazed glass with a profile with a thickness of 70 mm with lowers + accessories, a gofrotrub is laid under the wiring. Installed painted porches, terraces, balconies according to the project. All outdoor entrance doors are installed.

Often our customers, examining in the portfolio ready projects houses and cottages are asked by one question - "Why do we prefer to build brick buildings?". And as an example lead various options frame houseswho become popular in Russia.

Our specialists are always ready to tell all the advantages of classical construction in front of new directions, which make it objectively to give preference to houses from Innovasy. One of the negative points is that the quality of frame construction is now much lower than in Europe, since there are many unscrupulous manufacturers of components.

However, each developer can independently appreciate all the advantages and disadvantages that German houses for building houses have in the context of various climatic zones of Russia. Below we give a complete and reliable description of this method of the construction of cottages, which is so popular abroad.

Original German Technology Building Country Houses

German methods of facilities of cottages are very different from all from all, which can be found in the domestic market. It is in their originality and snorkeling stones that are able to overshadow the pleasure of erected structures. First of all, german housework construction technologies Based on the need to build private houses in a sufficient density building. Therefore, all sets are created as ready as possible so that the process of the structure does not require a lot of time.

Distinctive features of the described technology concluded in the accuracy of designing the future structures and compliance with all technological processes. It should be remembered that the German love for pedantry is fully reflected in the method of frame construction of cottages. Any slightest deviations from technological process lead to the sad finals. When choosing such a method of facilities, you must contact a reliable company that will provide high-quality.

Construction of houses in German technology: Benefits and Disadvantages

To fully light all the nuances of the construction of cottages in German technology, we will not share them on positive and negative. In each section, you can learn about all distinctive features of a frame structure.

Accuracy calculations

For the German construction technology, cottages are characterized by the use of high-precision computer programs. It is with such instruments that architects and constructors Innovasy are developing their projects, which improves the quality of project documentation and the subsequent erection of your country residence. As frame construction It implies the preliminary manufacture of components and subsequent installation in place, the entire construction process depends on the scrupulousness and accuracy. Any inaccurate digit will lead to a violation of all construction and installation work.

Manufacturing and design

Construction of houses in German technology It occurs in several stages that are interrelated. In terms of design, this method of building cottages has some limitations. Standard developments are sufficiently similar, and all production processes and the number of involved personnel have already been calculated. Making cardinal changes will entail a complete restructuring of the process of manufacturing kits at home, which leads to an increase in the cost of building a building. However, in the framework of the finished frame parts, small adjustments can be made so that the project will comply with your wishes for planning, floors, the number of rooms and communications.

In the field of production of components, German houses construction technologies are very original and not at all similar to popular Finnish or Canadian cottages. It should be noted that almost all processes for the creation of the house occur in production, and ready-made parts of the structure are supplied to the object:

- Floors and overlaps are already with black coatings and built-in systems ready for connection;

- Walls can be with inserted windows or without them. In any case, the kit comes fully prepared for the finish, that is, from the inside and outside the walls are sewn, insulated inside the insulation and communications were carried out, until set sockets and hoods;

- The roof is also supplied finished or consists of several parts that are fastening at the place;

- All places for attaching individual parts are clearly recovered and calculated that the German technologies that do not allow approximate values.

Materials

According to the rules, all components are made only from natural and natural components. The main beams are created from wooden bar, and jumpers from the edged board. The step of installation of the inner parts in the ceilings cannot be less than 35-40 centimeters to provide the necessary rigidity.

In the walls, vertical racks can be mounted differently, depending on the project documentation, but the most acceptable space almost never exceeds 1 meter. As a heater can be used as a mineral wool that possesses less degree shrinkage and polystyrene foam blocks. The thickness of the bearing walls is not less than 150 millimeters, and partitions are up to 100 millimeters. Communication systems and wiring is mounted in protective covers or boxes.

Internal and external black sheathing is made from plywood using windproof materials from the outdoor side. Thanks to its environmental friendliness, such houses do not affect the health of residents and do not distinguish harmful volatile substances into the atmosphere.

Separately, it is worth mentioning the processing of wooden components with special protective solutions. They impregnate wood and do not allow to develop mold fungi, various bacteria, insects and rodents. It is also important to apply only dry wood, which was dehydrated using special equipment. Then she will not change its strength characteristics and will last about 100 years. The maximum permissible parameter of the design shrinkage according to any of the directions - width, height, diagonally - 1% of the overall size or mass.

Foundation and installation

Since the creation of cottage sets uses natural and lightweight materials, then for such a house does not need a particularly solid foundation. On reliable soils, a fairly small-breed base of the tape or slab shape. Also often used pile Fundam with concrete strapping. It can be arranged on the surface of the Earth, to be slightly overwhelmed, is at a distance from the surface.

Before installing the main components, the foundation surface is covered with a thick layer of waterproofing material, which prevents the penetration of moisture to the structure. The installation process is quite simple to see, but requires the use of severe lifting equipment, cranes and manipulators. That, as the entire cottage comes to a plot in the form of a constructor, then its assembly takes about 4-6 days. This fact can be considered one of the key advantages of German technology. So, the assembly process itself is as follows:

- The foundation with a waterproofing layer is stacked by the first floor of installed size. Separate parts are twisted with each other with pre-made holes and metal bolts;

- Walls are installed on the overlap. Depending on the size of the cottage, they can be solid, that is, on the entire width of the facade, or separate through the rooms. An important feature is that the wall panel must be convenient for transportation and installation. It is also calculated at the design stage. The walls are bonded between themselves and in the corners using bolted compounds. Additional seam protection is not required, since the panels already have all the necessary gaps and tolerances;

- On top of the walls and partitions of the first floor, the upper overlap is stacked, which exactly corresponds to the floor at the lowest level;

- Next set the wall panels of the second floor or residential attic. The method of fastening is exactly the same as for the lower components. Note that the wall panels already have mounting places for overlaps and roofs, calculated with an accuracy of a millimeter;

- Roofing pie Assembly also stacked over the second level walls and is fastened with metal connections. All mounting places and recesses have a small gap, no more than 3 millimeters to ensure sufficient mobility with wooden components in seasonal extensions and narrowings;

- The final stage is the covering of mounting places from the inside to hide all the ugly technical openings. Also at the final stage, windows, doors, staircase and all communications systems are connected.

Exterior finish

German technologies Construction houses Also distinguished by their multifunctionality in terms of external design. At the request of the customer, the perfectly smooth external surface can be trimmed by any material like: natural or artificial stone; brick; Blockchaise with imitation logs; Wooden or plastic clapboard; siding; Stucco. You can also make any actions on the original decoration, for example, in the style of the half-timbered chalet.

Important refinement - In the process of external sheat, it is necessary to leave the ventilation gap to ensure the removal of steam and condensate from under the surface finishing material. Additionally, insulate the houses created in German technology, since they themselves have very high indicators, heat and sound protection.

What to pay attention to when ordering such a cottage?

The main disadvantage of technology lies in the particular production of its production. If you compare with Germany, then there the manufacture of ready-made sets of houses is strictly standardized and subject to mandatory certification. There are services that track compliance with production technology and control quality. In Russia, when ordering a house for German technology, it is impossible to check the compliance of materials hidden under the trim wall and roofing panels. The search for a literate and responsible manufacturer can delay for a very long time. Even if you manage to find it, then there is no guarantee that the built house will serve you declared 50-100 years.

Facing architecture can be immediately recognized. It is associated with the houses of Germany and Europe. Often the roof in such facilities are covered with a tiled roof. To date, such a canonical type of residential buildings are used as a designer sister. And on the other hand, this is a symbol of German quality. But in fact, the construction of the XV-XVI centuries has been preserved in Germany, which are currently being operated. Therefore, many argue that houses in German technology have an increased service life.

History of German houses

In fact, the famous German houses, whose photos fascinate, have appeared for no accident. The design of structures in which the main material is wood is characteristic of both wooded areas and the distinguished. In the countries of the Baltic and Northern Seas (Germany, Denmark, United Kingdom, Holland, etc.) there were many skillful carpenters who built high-quality vessels. These masters knew how to properly construct a reliable design of wood, so they began to build and structures.

For the construction of the first houses, the pillars were laughed directly into the ground, and the connecting beams were put on top of them, rafters, after which they started the construction of the roof. Of course, after 15 years, the pillars are comparatively rotted quickly. Over time, they began to establish on the sample of a stone foundation - the huge boulders in the ground in the ground. The service life of the column, and therefore structures, rose ten times. But it was necessary to compensate for the binding to the ground with a multitude of transverse slopes, thrust, teres and ties.

For skillful carpenters, such a connection was not a problem. They were performed on the naval methods and techniques. Today, all connections are replaced by simpler, using steel fasteners (anchors, screws, brackets, threaded thrust).

Design features

Actually, german House - This is a special frame made from elements of large and medium sections, with filling the sinuses of an external temperature circuit. The remaining elements of the structure (roof, foundation, partitions, walls) can be made in the same way as in other houses.

Reliable frame is not a problem for skillful carpenters. But filling the sinuses is a difficult task. After all, the quality of the walls depended on this, and consequently the fate of the whole structure. At that time, the sinuses were filled with saman or globbit material. This material was used on all continents. Today it also becomes popular, it is used in the eco-building.

In the beams cut the grooves in which a paired or woven grid of the rods were inserted. Saman was applied to her. Sheet material for exterior decoration The buildings at that time were not invented, and the board was too expensive to use for these purposes. Therefore, the buildings were plastered, but first apply a solution on wooden beams Not succeeded.

Therefore, the walls remained with visible beams, which in the future and became a business card of German homes.

Distinctive feature of the half-timbered house

Many vintage German houses have one distinguishing feature. Looking around, you can see that each new floor at home hangs over the previous one. At first glance, it looks unusual. An explanation of such a design is sufficient. In coastal areas, rains often go and sediments, staining along the walls, the water fell to the lower floors. Their walls are very nailed. The upper floors quickly dried at the expense of the wind and the sun. The lower due to moisture could rot, and this is unacceptable. Therefore, the upper floors endured ahead.

This feature of construction has become ineffective with the invention in the construction sphere of high-quality waterproofing materials. Modern facades, foundations, walls and wood are reliably protected from frost and moisture. Therefore, modern German houses have perfectly even wall planes.

Changes touched I. roofing material, due to the weight of which it was impossible to take a visor even half a meter. Today use light sheets that can divert water from the wall per meter, or even more.

Canadian technology or is German yet?

Old German houses can be safely called the basis of all the technologies of the framework. After all, B. modern construction by frame technology Almost everything is repeated. There are no transverse slopes in systems. Today, experts only use another thickness of the material ( modern beams Steel a little thin). Many believe that Canadian, but finished structures are often referred to as Finnish and German. And this is true, because this technology has built the buildings before the opening of America.

Today in frame houses it is hard to see ancient European houses, because they have a characteristic advantage - the covering of high-quality sheet material and the decoration of the building outside. The construction of the structure was improved, and nature won, because the consumption of wood has decreased significantly.

Vintage method of housekeeping and modern materials

Thanks to the covering with a solid sheet OSB, the design has become even stronger, tougher and more reliable. Now you do not need to use powerful beams and racks at the initial stage. Outdoor decoration and sheet material reliably protect the wooden frame from negative impacts ambient: solar burnout, weathered, freezing. Thanks to such protection, the life of the construction has increased significantly.

Good German home has a business card - visible beams of the structure. Today they are used only in decorative purposes. Of course, the walls of the Saman and clay remained in the past, and the space is filled with high-quality and environmental insulation. Today is also used as filler and straw.

Previously, the sinus finish was a problem, and today this process takes the same forces as interior decoration walls. Thanks to the use of modern facade putty, this process is easily performed and simple.

The framework of the structure remained a sample of the reliability of the entire structure. Metal elements were helped to speed up and simplify the process of installing the German house.

Output

German House is a qualitative reliable structure. His structure practically does not have differences from other houses. Remember, deciding to build such a house, you can fulfill your dream and live in a European-style house.

The frame house is a structure that the framework of the framework. The value of the term "frame" is the base, the backbone, the skeleton of the future object. The frame is installed on the foundation, it is trimmed with special panels, it is insulated, the roof is erected - the house is ready.

Frame houses first appeared in Germany, then in America and Canada. That is why there are several erection technologies - German, Scandinavian, Canadian. In Russia, the first houses of this type were built in the 50s, now interest in them considerably increased.

This article will introduce you to the main types of frame houses from the tree.

- frame-panel (panel);

- frame-frame ("Canadian");

- celestial-beam design (half-timbered);

- frame-racking;

- frame with continuous racks.

Other options for frame houses are either combinations of listed species, or small modifications of the above-mentioned frames. Consider each of them in more detail.

Frame-shield (panel) houses

![]()

Such houses are produced at the factory. In accordance with the project, the framework is made, panels (shields), inter-storey overlaps and even roofing. Each element is marked, has the necessary holes. A complete set of home is delivered to the construction site where it is carried out. Construction technology frame-shield house It is quite simple, but in order for the house to be durable, warm and reliable, the norms and rules should be clearly followed.

The main advantages of frame-shield houses are:

- high construction rate - all parts are made and marked, materials are processed by the compositions that prevent rotting and reproduction of harmful microorganisms, flame retardant impregnation;

- the affordable cost of construction - materials from which the whole design consists is much cheaper than a stone or brick. Savings also occurs at the expense of the total weight of the house - it does not require a complex, expensive foundation for him;

- the incompetence of the shrinkage - immediately after the construction of the walls and the roof can be processed to the inner and exterior decoration.

The advantages of frame-shield houses can also be attributed to a greater heating rate of the room under the condition of high-quality insulation. The insulation materials presented today in the building market can make the house as warm as the laying of 5 bricks.

The minuses of frame-shield houses are the lack of ability to redecessing, as well as the need for special technique (crane) for loading and unloading. The panels have a weight that does not allow them to raise them.

Technology "Platform"

It is one of the varieties of frame-shield technology, its other name is pallet or platform. This method of construction implies an assembly of frame elements on a platform representing a draft floor from itself on the first floor, or on the inter-storey overlap.

The walls of the future house consist of shields that are insulated and squeezed by plates. For this purpose, plates of two types are used: OSB and GVL. OSB plate (Russian translation - oriented PCP stove) - glued and compressed wood chips laid in different areas. GVL is a gypsum fiber leaf, which includes high quality gypsum and fiber from recycled waste paper. Both types of plates have increased strength and are not exposed to strain.

Prepared walls are set to a permanent place, and the new platform is installed on top, where the walls of the second floor are prepared.

The skeleton house from OSB is characterized by good moisture resistance and ability to maintain a comfortable microclimate even under adverse conditions of the external environment.

Building on this technology can be mounted from structures made both in production and on construction site.

How to collect quickly transfers frame houses In Canada, watch in the video:

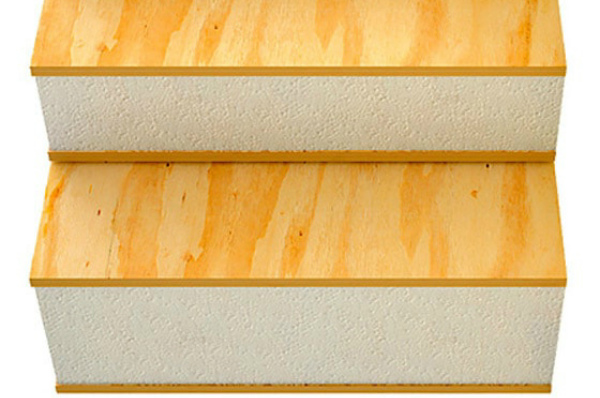

Canadian technology SIP.

SIP - panels

SIP - panels

SIP is a structural insulating panel, which represents the structure from the insulation, framed by sheets of OSP. This is a reinforced version of panels for frame-shield houses. The structure of this type is erected by the "platform" technology.

Three layers of the panel (OSP - insulation - OSP) are interconnected by a bar of a spike-groove with the use of polyurethane glue. Polystyrene foam (foamed plastic) is a highly efficient insulation used in the production of sip-panels. To increase the strength of the fitting of the layers to each other, the prepared "Pie" is pressed.

High-quality sip-shields can be manufactured only in factory conditions. They have small dimensions, which allows the walls of the builders forces from 2-3 people.

The heat-insulating and strength properties of the Sip-panels are such that only 14 cm of their thickness may well be replaced by a semi-a-one-meter wall of brick or meter - from aerated concrete.

German technologies

Frame houses in German technology - another option to use the platform method.

This technology provides styling in the shields of communications and thermal insulation. In addition, windows are installed, the primary wall decoration and the floor assembly are carried out. All these operations are made exclusively under production conditions. The need to use lifting mechanisms significantly increases the cost of construction.

Summing up, it should be noted several negative moments.

A truly durable and warm frame-panel house can only be obtained by high-quality assembly and insulation of the shields, but the ability to control the course of work is completely absent. In such a situation, only one option is possible - the choice of the manufacturer with a good reputation. Compared to houses built on other technologies (we will tell about below), the frame-panel houses are less reliable.

Frame-frame houses

The framework construction method has a significant difference from the panel: the framework of the house is assembled at the construction site in the form of a unwanted framework. Only when the entire design is installed, proceed to its insulation and trim.

Houses on frame-framework technology - the most suitable option for female on their own. Their advantage is also in the fact that the owner of the future at home sees, from which it is built, how to be held necessary work And the assembly is carried out.

The frame of the house (frame) can be made not only of wood, but also from metal, in particular, the frames of the LSTK (light steel thin-walled structures) are popular. Frame houses from LSTK are energged if the climate is wet or there is a high-quality construction forest.

LSTK is a new promising construction technology from a solid, sustainable, convenient in the work of a stainless steel profile. The estimated service life of the house with such a frame reaches two hundred years, but frame houses are built from the LSTK not so long ago, and it is impossible to confirm this in practice.

Framework technology allows you to maintain construction at any time of the year. The absence of shrinkage is also significant plus.

When using this technology, it is possible to carry out the most original architectural projects at the initial stage, as well as later, if you suddenly need redevelopment.

The frame-frame house is very attractive and in terms of cost, especially if it is erected frame house from LSTK.

The minuses are the elongated deadline for the construction and the need for wood processing at the construction site.

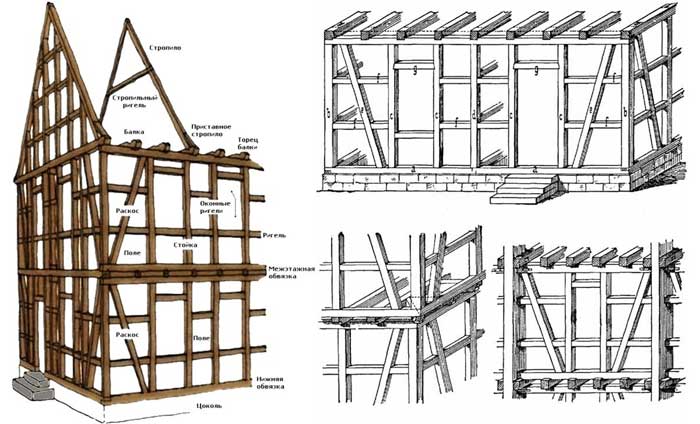

Ceiling-beam (half-timbered) frame

German (cement-beam) frame type - amazing, one of the most ancient types of frame houses. It originated in Germany, so called "German", but later received distribution in Europe, and today and Russia carefully looks at him. We will try to understand what denotes the name.

"Famverk" translated from German means "Section, Reta". The sections are formed from horizontal beams, vertical racks and windows, the latter can be located at any angle.

The feature of the Stammerk style is that the beams and racks (frame) are not hiding behind the trim, but, on the contrary, allocate them from the outside of the wall in all possible ways, which gives the house that characteristic appearance.

The frame is performed from thick bars having a cross section from 100 × 100 to 200 × 200 mm. The space between racks and beams is filled various materials. Previously, these were clairger blocks, but now brick, global material, OSP slabs, and even glass is used. Houses with glass walls look just amazing!

For a warm house device in our difficult climatic conditions, the half-timbling type of houses is not suitable, as it requires significant insulation. But the frame house in the style of Fakhverk has such an original form that architects often offer such a way as imitation. That is, the frame is used by another, and outdoor finish Fully corresponds to the style of the step.

Frame houses with continuous racks are differently called Finnish. One-piece vertical racks passing through two floors is the main element of the frame. To ensure the high strength of the design requires perfect vertical installation Racks. Inter-storey overlap Install the supporting boards embedded in the beams. The continuous racks are tightened by lags of overlaps, due to which the design acquires the desired rigidity.

This type of construction is characterized by the fact that the vertical racks perform the role of piles to which the main load is laid. Stiffness enhance horizontal beams. This design is good on swampy or subloping territories.

Other types of frame houses

Double frame (Technology dock)

The technology of double bulk frame (doc) is one of the most promising construction of frame houses. The essence of the double frame is that the bearing racks are located in a checker order, which contributes to the elimination of cold bridges. The line of racks in this case is not single, but double. The gap between the racks is filled with insulation, the double support of which provides improved thermal insulation.

Frame Bruce Houses

The frame of the house from the bar is almost the half-timber with a frame base filled with a wooden bar. Lupates can also be used as a placeholder (logs, dying only from two sides). The house is obtained by alive, breathable, environmentally friendly, that is, truly wooden.

Frame-log houses (frame-crushed houses)

The walls of the frame-log house are logs laid horizontally between vertical wooden racks forming a frame. The external charm of this house is that the frame - outside, it can be seen. It gives the construction at the same time lightness and elegance. Frame houses from wood are perhaps the most beautiful and eco-friendly houses.

Norwegian frame house

The main difference between Norwegian frame houses - carved reference pillars. Columns from powerful logs to make the work of art can only professional rubbing. It is the columns that are becoming decoration that attracts the attention of others.

The frame from the pillars with the strapping from the bar is going on the foundation earlier. Walls and partitions on wooden frame Mounted between columns. Modern thermal insulation materials that they are filled with natural and eco-friendly. Norwegian skewed houses are shed with wide boards - or glued, or planed unedged.

Scandinavian technology

Scandinavian frame houses are collected from the finished household complex produced at the factory.

Frame base - dry planed board. The peculiarity of these houses is the presence of a brigade. Bolshoe is cut in a rack on top of a board that performs the role of strapping. As a bolt in Scandinavian houses use a bar. With such a frame device, there is no need for horizontal wooden jumpers near door and window openings, as well as dual racks, which, with a different design, support these jumpers.

The heat exchange between the two sides of the rack is reduced by applying frame racks with thermal insulation mounted inside with a special way.

OSP plates when building houses on the Scandinavian technology are used, as a rule, only to enhance the corners of the construction. The problem of stiffness here is solved with soft wood-fibrous plates or special facade drywall.

Another feature of the Scandinavian technology is that all sorts of pipes and cables are located in the walls.

Swedish technology

Swedish frame houses - houses built with a harsh climate. The main thing in Swedish technology is a high degree of energy saving. The effect is achieved by applying a special galvanized steel profile. The design of the profile is such that its thermal conductivity is lower than the wooden bar of the same size.

Advantage metal profile It is also its good moisture resistance. On metal elements of the design, mushrooms and bacteria, damage to the tree, this material is unavailable for rodents.

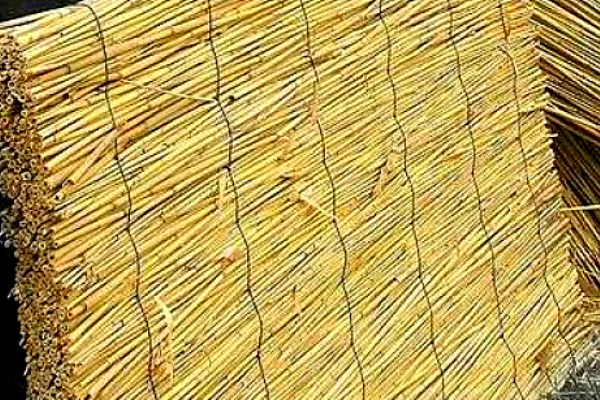

Frame coat houses

As a variant of the insulation material for frame houses, the reeds sometimes use. Cheap, low-conditioned, light reed insulation in optimal humidity conditions can serve no less than wood. From a well-dried root, dense mats are manufactured, which are placed inside the frame. Flashing the frame of the reeds is recommended after the roof of the house is erected.

Frameless house

This is an ordinary panel house in which bulk materials are used as insulation, such as sawdust. In the feasibility of using sawdust, it can be doubted, however, there are methods for their processing, allowing you to allow such a solution.

A feature of the American houses is a large area of \u200b\u200bglazing, which gives the structure lightness and transparency. It is characterized by an extensive zone, which combines the kitchen, dining room and living room.

Conclusion

So, we introduced you to which there are varieties of frame houses, their features, advantages and disadvantages. Summing up, once again, we note that the distinguishing features of the frame houses are their faster-based, relative low cost, the real opportunity to build a frame house with their own hands.

What a frame house is better to choose if it is decided to build, maybe it is not always easy to determine. But the frame house building deserves attention!

Fakhverk - The technology originated in Germany in the XV century, was distributed not only in the homeland, but also throughout Europe. Today, half-timbered houses are building not only Germans, but also in Russia. They are quite popular and received a lot of positive feedback. How to build this magnificent home yourself?

What is a half-timber? Let's deal with

This is a frame house and this type of building construction is a lot of durable beams interconnected at right angles and fortified oblique cross-axes (backups and disclosures). These backups (discharge) give the designs greater stability, and the entire building is reliability and durability.

The space between the beams and crossbars, which, as a rule, is left visible outside, filled with various materials, this is the frame houses, it doesn't matter whether it is or a board, in the header use.

In ancient times in Germany, the Germans were used to use clay mixed with. There is even a house built in the 13th century, which the German builder built in 1347.

In ancient times in Germany, the Germans were used to use clay mixed with. There is even a house built in the 13th century, which the German builder built in 1347.

Beams from the bar for such time, did not rot, and the wood became durable as a stone. This house, just just one century. Europeans have long been aware of the reliability of these houses, gradually they begin to appear in Russia. And all this was done by hand, without the use of power tools.

It is surprising that the half-timbered house can stand more than 500 years, it proves the reliability of this type of construction.

Today, technological solutions can be the most diverse, in half-timbered construction, instead of walls panoramic windows, brick, wood, natural stone, etc. apply instead of walls.

Feature of German frame houses in Germany

A characteristic feature of the house in the style of Fakhverk is the speech of each top floor over the previous one. This historically existing feature is not related to the desire to increase the area of \u200b\u200bthe upper floor. This was done to protect the facade of the house, which is also carrier carcass Total buildings, precipitation and extra moisture. Thanks to such an indent, water flowing along the walls of the upper floors is flowing directly to the ground, and the facade of the lower floor remains dry.

Homes in the style of Fakhverk

Despite the fact that the widespread freight household houses was associated with a certain extent with the desire to save wood, this technology perfectly showed itself and has a number of advantages.

It is pretty inexpensive and environmentally friendly construction, which you can afford to build with your own hands. Homes in the style of Fakhverk are unusual and beautiful.

With modern construction, the glued bar of conifers is used more often, which provides buildings and durability buildings, but you can also use a regular bar, the main thing is to choose a dry-quality dryer.

Modern houses for half-timbered technology

Thanks to the use of modern, the modern Fakhverk style house will not only be aesthetically attractive, but also warm and cozy.

Choosing a material to fill the space between the beams, you can show fantasy and use, along with traditional building materials, glass, carved wood, clay mixtures, etc. It will be favorably played and protects the staining of beams or filler with modern paint and varnishes.

Having all these advantages, half-timbered at home are built today, many are ready to build similar designs with their own hands. In addition, fairly lungs in their essence, half-timbered homes do not require the construction. It is perfect for them, which will allow you to put such a house at least on the slope and on the purchase of land.

Video about modern glass frames Facing houses