IN last years For heating of bath buildings operated on country areasGas furnaces are increasingly used. Gas furnace for the bath with their own hands is most often made of metal. Such a furnace has several advantages. With some of them you can read below:

- The cost-effectiveness of gas units, which is advantageous of them from wood and electrical heating systems.

- Practically waste-free combustion of fuel, not requiring systematic chimney cleaning.

- Small weight on gas heating devices that do not need special foundation.

- Ease of maintenance of such structures.

- Long service life (at least 25 years).

The main difference between gas furnaces from other heating devices is the form of fuel used in them, as well as the mechanism of its combustion in the heat chamber. In this regard, when operating such furnaces, special attention should be paid to compliance with the rules of safe treatment with mixtures entering the furnace furnace on the channels of centralized gas supply or from the gas cylinder.

Device and principle of operation

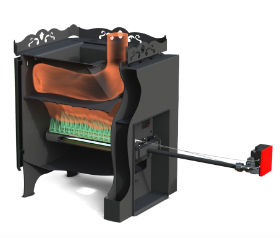

The basis of the design of gas furnaces is a rigid frame, which is manufactured, as a rule, or from a brick, or from metal. When choosing a material, we advise you to draw attention to the fact that brick gas furnaces require more time for their extracts, but it remains longer to retain heat accumulated in them. And metal structures are rather small, but after such a heating, they cool very quickly.

Inside the frame there is a combustion chamber with a burner directly over which the stone is located with stones laid in it, which are heated from the place of combustion of the gas mixture with hot air. It should be noted that the heater is performed as a metal deep pallet with sides, excluding the ingress of the splashing water to the place of combustion of the fuel.

The principle of operation of the central heating node of gas furnaces is very simple. The gas entering the furnace is mixed with air in a special chamber, located immediately in front of the burner, after which the resulting mixture on the thin tube is supplied to the place of combustion and is ignited from the external igniter (from the match or burning with its help paper twist, for example). The air flow to the place of combustion of the mixture is provided with the help of a small and partially overlapped hole, called confused and mounted in the bottom of the case.

The metal design of the gas furnace has the following advantages:

- Despite the small thickness of the housing walls and a limited number of stones in Kamenka, such a furnace warms up very quickly and can be ready for use in very short time.

- Metal furnaces are compact and can be installed in small bath buildings without the use of the foundation.

- Such structures do not require high time and in the presence of required material And the tools are manufactured as soon as possible.

Note! In homemade gas furnaces, it is advisable to use the burner of the simplest (atmospheric) type that does not require an electric power supply and use of special automation for its work. You will need to purchase such a burner in advance in order to correctly choose the size of the camera combustion chamber below it.

Water tank in such structures can be located both above the heater, so inside the chimney pipe. At the same time, it is used to heat water thermal energy Preheated air discharged through chimney, as well as heat released by heated stones. Most often B. metal structures The chimney is paired directly through the tank with water heated due to contact with the walls of the hot discharge pipe. This design allows you to make an aggregate sufficiently light and compact, which does not require a significant place for its placement.

In some embodiments, water heating is carried out due to the contact of the tank with the gas chamber case; In this case, it is hung on the back or side wall frame design.

Production procedure

Before assembling a metal gas furnace, you will need to prepare the following purchased parts and infringement materials (blanks):

- gas burner atmospheric type;

- exhaust balloon used earlier for gas welding;

- the workpiece of the metal door placed on the technical hole, providing access to the combustion chamber;

- old brake disc from a heavy truck, which can be used as a lining for parish stones.

In addition, you will need gas pipes with a diameter of 50 mm, designed to supply gas and air into the combustion chamber, as well as a segment of 100 millimeter pipes needed to arrange chimney.

And finally, you will need to prepare a small sketch with instructions on the size of the main prefabricated assemblies of the design (hull, pallet under stones, chimney pipe, etc.).

Manufacture of housing

The manufacture of the furnace body is organized in accordance with the sketch prepared earlier and is carried out in the following sequence:

- first of all, with the help of the Bulgarian, the formation of an old gas cylinder is cut, cut according to the sketch of the sketch;

- then, two small holes used to supply air and gas cut into the obtained billet;

- after that, three cutting round blanks are prepared in the size of a cylinder circle used as partitions that form separate work areas of the furnace (firebox, water tank and heater);

Build construction is carried out using any of the types of manual welding available to you. At the end of welding the body of the future furnace with sections under the furnace, it is necessary to carefully clean the seams using the same grinder.

When assembling should not be forgotten that in the section taken under the tank with water, the seam pipe guide must be optionally used simultaneously and as an additional heating source.

Registration of channels of fuel and output of combustion products

To organize air supply to the furnace furnace, you will need a previous pipe Ø50 mm, on the furnace part of which is pre-done about 10 of the holes of a small diameter (about 5 mm). Next, at the bottom of the cylinder body, a hole of a little more diameter is prepared, into which the pipe with holes is then boil. When installing, it is necessary to worry about the outer end of it (without holes) by about 20 cm spawned from the cylinder housing.

The joint of the pipe with the case is thoroughly edged over the entire contour of the welding, after which it will be possible to proceed to the design of a small sash (improvised door) installed at the inlet of the pipe and serving to regulate air flow into it.

Similarly, the pipe is installed, used for supplying gas to the burner of the flue system. At the same time, you will need a special adapter to connect to the gas line or to the cylinder, which ensures the coordination of two mating channels, whose joint is necessarily compacted by a sealant.

At the next stage of the assembly of the furnace, it will be necessary to securely secure the chimney pipe at the top of the channel formed directly in the tank with water (it can be simply welded to the base of the partition used as the tank cover). (Do not forget to prepare a small sectoral hole in the tank cover, which is necessary for filling fluid into it).

At the final stage of the work, you will need to prepare the window of the appropriate size and the subsequent hitch on it a special door through which access to the gas burner will be provided.

When mounting the furnace, special attention should be paid to the part of the structure directly adjacent to the wall or partition of the bath structure in order to protect them from excessive heating and ignition. To do this, between the adjacent planes you will need to lay a special gasket from refractory material (From asbestos tissue, for example) or a layer of clay. If necessary, you can use a special reflective screen made from stainless steel for these purposes.

Since its invention, the bath has undergone a lot of different changes. They were made of wood, clay, stone and metal, and the heating systems in them were constantly finalized and upgraded to achieve maximum efficiency.

Choice and mounting

To begin with, it should be said that such devices greatly facilitate the whole process. preparatory work and heating. The user does not need to do the workpiece and independently stir the oven. However, the exit period for the premises at the required temperature is at least eight hours and at the same time no one should be in the room so as not to get from the products of gas decay.

How to choose

- Choosing bath furnaces, first of all, you need to pay attention to performance. It is expressed in the area of \u200b\u200bthe room in which the product will be installed and is indicated in the technical characteristics.

- You also need to immediately determine the type of controlling device, which is almost always sold separately. It is better to take advantage of specialists who can suggest the desired model.

- There is a bath gas furnace in the design, which provides for the location of the water tank. The choice of similar models is to determine the convenience of using and the location of tanks. Professional masters at the same time advise to acquire on the pipe, as they are more practical and effective.

- Separate attention should be paid to the fact that some products can work on both natural and liquefied gas. Therefore, you need to choose them in accordance with the fuel used, and in combined systems you need to check the presence of circuit nozzles.

Tip!

Buying such a product must be immediately clarified about the presence of adapters and connecting couplings that may be needed when mounting.

If they are missing, it is worth buying these details at once in the store.

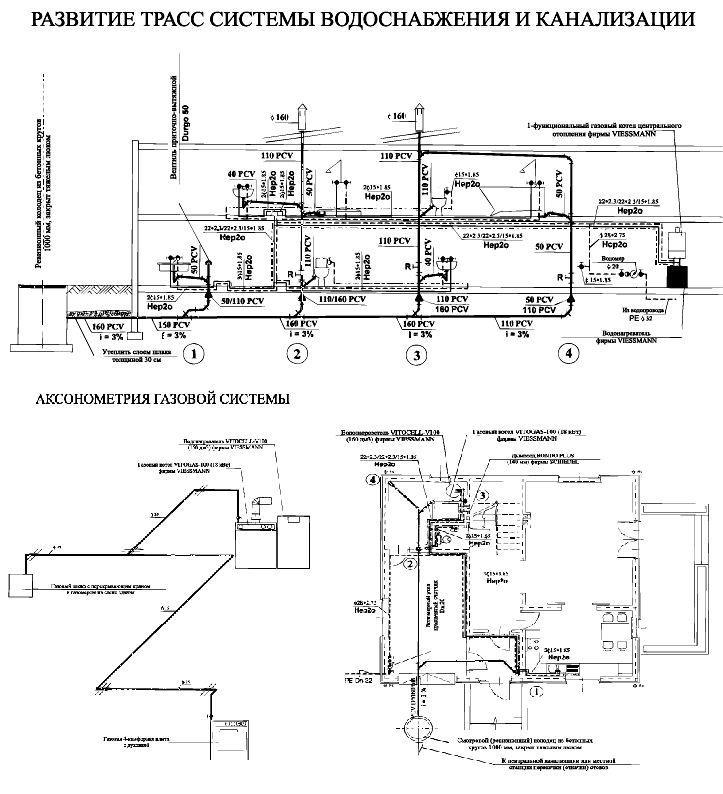

Project

To begin with, it is worth understanding that it is impossible to create a project for the entry of the pipeline to the room. If this use is not provided in the building, it is necessary to contact a special service that will not only prepare everything required documentsBut I will enable input.

Such measures can not be taken if the balloon gas is used for functioning. It is simply connected through the gearbox to the device.

Special attention should be paid to the fact that the ventilation system will need to work, which is manufactured according to the principle. It is also displayed on the project, which is developed in the gas service.

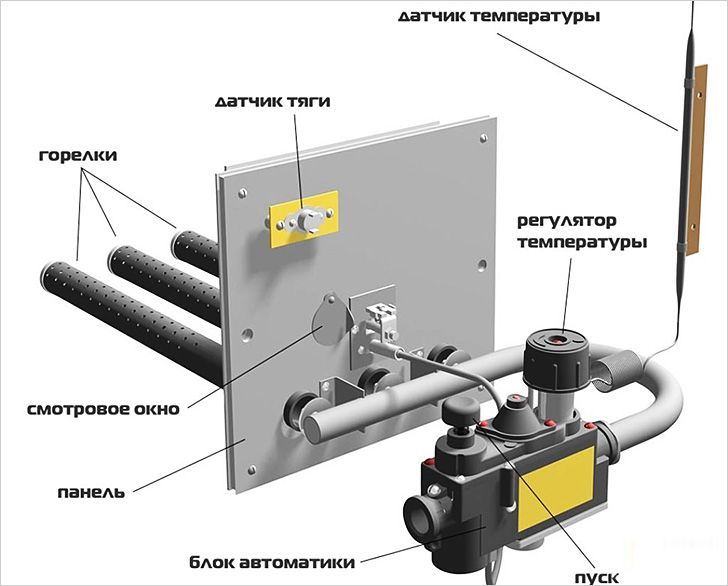

It is worth noting that gas burners usually indicate in such drawings bath furnacesused on the device. They have a certain labeling and work with a specific type of fuel.

Installation

- First you need to mention that the product requires a solid and reliable base separated from the foundation. It will ensure the stability of the design and eliminate the heat removal.

- Then take care of the protection of the walls. The fact is that gas furnaces for baths allocate a large amount of heat that adversely affects the surfaces are too close.

- To exclude such interaction, the device from the walls should be separated using a heat-resistant material. For these purposes, you can use asbestos or graphite fiber sheets. However, professional masters recommend using special screens in the form of a small fence.

- Further installation depends only on which gas burner for the bath furnace is used. If fuel is used from the total highway, it is necessary to carry out a connecting hose from the entry point in the steam room. At the same time, all passing places in the wall must be sealing and insulated.

- It must be said that the hose necessary for connecting the furnace and the gas supply point must be made of a special material. It should well tolerate high temperatures and exposure to moisture.

- If it gets fuel oven for a bath from a gas cylinder, it must be placed in a separate room, which will be protected from high temperature insulation with a reflective surface. Some masters prefer to display a balloon outside, where it will be located in a place protected from direct sunlight.

Scheme gas burner For furnaces in the bath

- If the gas stove in the bath has a water tank, which is installed on the pipe, then it is mounted at such a height so that it is convenient to use it. However, the higher it will be located from the furnace, the less heat will be.

- After the furnace was installed, proceed to the installation of the control system, if it is not built. Do this in accordance with its individual installation guidance.

Tip!

Quite often, such products are equipped with electronic ignition systems.

Therefore, it is also worth holding a cable to the steam room, which is placed in a protective corrugation.

Using

The main feature that gas stoves for the bath is equipped with autonomy. It is enough to set the necessary temperature and click the ignition button.

After the product comes out to the specified mode, it should turn off. This means that you can go steam away, let's stand out, a few minutes to remove gases through the ventilation system.

Many designs of this type are heated with their work. This will create steam and additionally lift the temperature.

Tip!

When the furnace works in the steam room should not be.

This rule is advised to install print and hang at the entrance to the room.

Output

In the video presented in this article you will find additional information on this topic. Also, on the basis of the text, which is presented above, it can be concluded that gas furnaces greatly facilitate the process of creating and maintaining the required temperature in the bath. They are very practical, easy to handle and do not need constant care.

However, it should be noted that the price of such products is quite high and the quality of the finished device is sometimes dependent on it. At the same time, such a furnace needs in the introduction of gas to the room, which is sometimes not always safe.

Constructive features of gas stoves

In its device, the furnace on gas differ little from classic wood or modern electric furnaces for the bath.

Gas production - universal oven for a bath, with the possibility of using different species Fuel: low pressure natural gas or firewood, to obtain steam, water heating and heating of the paril compartment, adjacent rooms with a volume of 6 o 24 cubic meters. Original design solutions in combination with carefully selected materials provide high reliability. In the "Uralochka" models, steel 4mm thick is used, and the elements of experiencing the maximum thermal load are made of steel 6mm thick. With us you can buy a stove in a bath at the most attractive prices.

Features of the design of gas models furnaces for a bath: a powerful burner with non-volatile automatic control and safety; Work in automatic mode at a given temperature in the steam room (+70 .. +120 ° C); The unique heat exchange system of the furnace structure is uniformly distributing thermal loads. The combustible features of gas furnaces also includes the chimney system with an increased length of the passage of flames and combustion products - gases.

Materials used in the manufacture of gas-breed furnaces provide reliability, environmental friendliness and safety. In the manufacture of gas stoves for the baths are used modern technologies Cutting, bending, welding and formation of metal. The furnace is made in strict and modern style - these are ergonomic shapes and classic colors: black matte casing covered with silician paint, decorated inserts and frames made of mirror stainless steel. Products organically fit into any interior of the bath and sauna, complementing it. The model range is designed for the volume of steam room from 6 to 24 cubic meters.

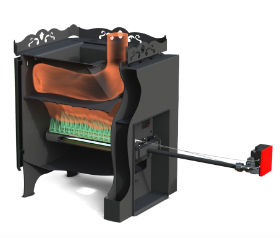

Gas Furnace Design for Bath

The design of the gas furnace for a bath consists of the following elements:

1. Gas Melting device with automation and security system

The main tasks of the GSU installed on the furnace is reduced to heating, automatically maintaining the desired coolant temperature (air in the pair) and turning off the gas supply in abnormal situations. Safety of the operation of bath furnaces with GSU guarantees equipment for automatics of control and security SabK-T, which allows you to automatically turn off the gas supply to emergency situations With overheating of the coolant (air in the steam room), the flame is resetting on the ignition burner and violation of the thrust.

2. Fire with the original heat exchange system and the built-in stepped chimney system.

3. The chimney system is designed so that the fuel combed with the maximum heat transfer and ensured the qualitative removal of smoke gases into the atmosphere.

4. The heat exchanger (T) is a replaceable option that provides its placement in the stationary space, on the left and \\ or the right side of the furnace, allows tuck For water heating, which can be placed in the adjacent room, for example in washing.

5. The tunnel is the opportunity to place the fuel door in the adjacent room for a comfortable use of the furnace. The tight design of the tunnel provides the convenience of mounting and disassembly.

6. Fire door for wood stovewhich can be outweigh to change the direction of its opening. The cooker is removable - it is easy to replace it with a gas-melting device with the system of automation and security SabK-T. Safety of operation is provided by a self-established handle.

7. Capacity for a heater having a ventilated operation mode and having a traditional design of an open type. The large volume of stones quickly warms up.

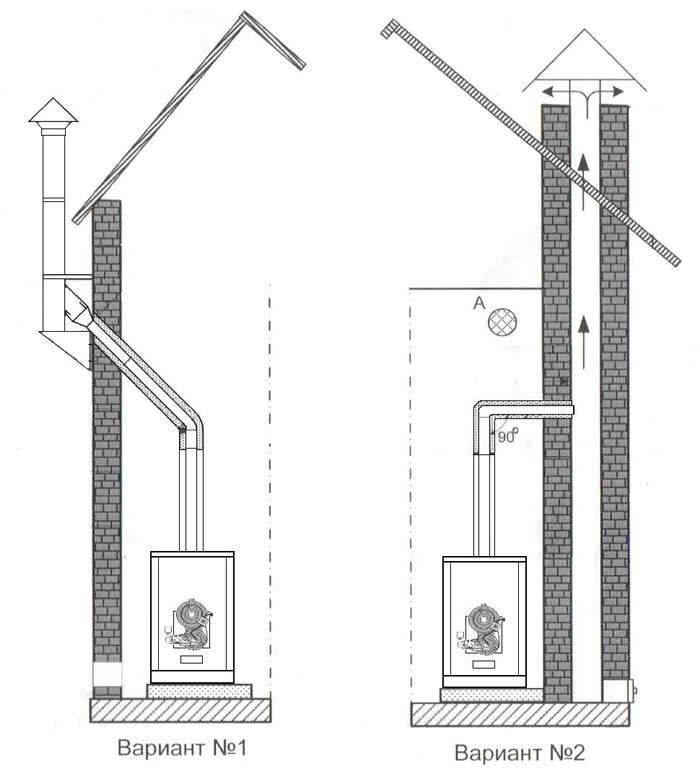

Safety and instruction manual require a number of conditions when installing a gas furnace:

- the distance between the heating device and the wall of combustible materials should be at least 50 cm;

- the base is fireproof bricks or Flame refractory slab should perform from the edges of the product by 10 cm;

- the fuel receiver or the opening for the burner without a lining must have dimensions within: in width - 35-45 cm, in height - 47-55 cm. With a lining: in width - 51.5-66.5 cm, in height - 61.5 -68 cm;

- the burner and front side when installing the furnace should be directed through the opening, having a width of 42-46 cm and height from the base 55-65 cm;

- near the aggregate is better to mount fencing from materials that impede convective exchange;

- the pre-tribbon high at least 220 cm should be equipped with exhaust ventilation, the doors in it open only out;

- the length of the chimney (from the burner level) should be at least 5 m, and the place of attachment chimney The furnace should be hermetic.

Benefits of bathing gas stoves

High efficiency. These competitive characteristics of gas furnaces for baths are manifested during the period of their installation, and during subsequent operation. Equipment of this type is economical for the heating of a bathroom with an area of \u200b\u200b12-15 m² and more. For efficient work The ovens installed in the bath of such an area is needed about 200 kg of stones. After a complete warming of the steam, the gas can be turned off. The heat of these stones is enough to comfortably steam in the bath for 4 hours.

Wide functionality. The gas furnace in the bath can be used not only for heating steam room, but also for water heating. To this end, the equipment provides a tank for hot waterHeated through the products of combustion of fuels allocated through the chimney. Gas furnaces They differ in the method of the device of this tank, which can be placed both above and under the stone. However, the chimney in both cases passes directly through the tank.

High efficiency. Gas furnaces differing in power and use are characterized by highly efficient use of fuel. And when completely melted, the energy consumption is significantly reduced, since the heated stones retain heat for a long time. During one heating season, 5-cm with a propane-butane mixture (or propane) is capable of maintaining heat in the house with an area of \u200b\u200babout 200 m². Thus, gas consumption for a bathroom during the year is small.

Fast heating. The bath furnace on gas is able to quickly increase the air temperature in the steam room to the desired level. The speed of heating walls of the room depends on the season: in the summer, this procedure takes 3-4 hours, in winter - more. However, the resulting heat can truly gently envelop a person soaring in the bath. With the help of a gas furnace, you can get absolutely any ratio of air humidity and its temperature. After the rapid heating of the heat transfer plane of the unit, it is almost instantly transmitted by stones, internal and adjacent space. The stones themselves themselves will maintain the stable temperature in the bath, being a powerful heat generator.

Disadvantages of bass furnaces

The main disadvantages of bathing furnaces on gas include the possibility of their installation only if there is a gas station or centralized gas supply. However, after having coordinated the project, it is possible to install a gas stitch even in an urban apartment, the premises of which is trimmed, for example, with linden clapboard. Installation gas equipment It is carried out with strict compliance with all established requirements. In the device of autonomous gas supply, the bath should be taken into account that gas is fuel that has high safety requirements.

Which allows you to quickly heat the room and is able to maintain the required temperature in it sufficiently long. All models are safe and durable.

To a number of standard advantages of these models: high heating rate and the ability to maintain the heat required, the gas furnaces for the bath are manufactured taking into account local operating conditions.

What you need to know about gases for a bath for a bath:

Today, the Russian bath only remotely reminds her ancestral. It is characterized by design, equipped with modern equipment and fuel used. Now the bath can be heated not only by firewood, but also electrical, infrared and gas units. Gas furnaces for the bath won the sympathies of buyers thanks to the efficiency and convenience of operation. In a short period, they warm the parley room and do not require the presence of the user. Such heating devices are produced several varieties, differ in the design features and installation rules, and they are not completely problematic to buy them.

Benefits of gas bath stoves

- Compact sizes. Small dimensions of the aggregates are due to the lack of large furnaces and the ash bar, so even in small parilots they do not occupy a lot of space.

- The ability to select the optimal temperature mode. The owner of the gas furnace is enough just to establish the desired temperature, and, without distinguishing to throw firewood into the furnace, is completely enjoying the adoption of bath procedures.

- Easy operation. Cleaning the aggregates working on gas.

- Higher environmental friendliness compared to wood counterparts.

Features of the use of gas stoves

The heating rate of the room depends on the season. For example, in the summer, steam walls are heated for three hours. Characteristics of gas aggregates depend on the type of fuel used. In addition to the thermostat, they are also equipped with a fuse that stops supplying the gas after the flame is resetting in the burner. The equipment is also characterized by the location of the fuel combustion chamber, which is located directly under the heating, which contributes to the rapid heating of the stones. Gas furnaces, like woodworking analogs, require chimney devices. Democratic equipment price, functionality and convenience of operation ensure large purchasing demand for it.

Gradually go to the past times of Russian baths, which treated "in black". More and less common in country houses National stoves, despite its advantages that became a lot of romantics. A modern man prefers innovations that allow you to think about the process of work of this or that aggregate.

But a special bath atmosphere remained unchanged. To wear a hat, take a basin, a birch broom and go to the wake of "bones" - here are some of the few things that make an ordinary person to truly Russian. It seems that it is anew to be born, and all the alarms dissolve in water and pair.

But a special bath atmosphere remained unchanged. To wear a hat, take a basin, a birch broom and go to the wake of "bones" - here are some of the few things that make an ordinary person to truly Russian. It seems that it is anew to be born, and all the alarms dissolve in water and pair.

However, over time, both the oven and fuel for it changed. Comfort in the steam room became directly dependent on the functionality of this product. Therefore, select the heating equipment still at the design stage of the bath. Someone prefers to build an aggregate independently (which can cause a number of problems, especially in the field of fire safety), someone - buy ready.

Products meet a wide variety. There are furnaces for a bath on a gas or electricity that use firewood as fuel or several species uniting at once. Heating was recognized as a certain popularity. But such aggregates are usually used in saunas.

This article will consider only gas furnaces for the bath.

A similar product is cheaper in operation than woodworking analogs, as well as easier, cleaner, environmentally friendly and functional.

A similar product is cheaper in operation than woodworking analogs, as well as easier, cleaner, environmentally friendly and functional.

To begin with, attention should be paid to the possibilities of using gas fuel. In the time of communism, this topic was considered in a certain sense of the forbidden. In the consciousness of the Soviet man from that period, a number of stereotypes were firmly. For example, that when treating the dentist will hurt. Or that in the sauna is always stuffy. Among these "problems" thoughtfully existed: gas - danger, gas is impossible. With the first pair dilemm managed to figure it out, the third is already on the way.

Modern Russian requirements for this type of fuel may seem ridiculous (for example, a ban on the laying of pipes in the wall). However, they are one of the most demanding in the world.

But, despite stereotypes and "strange" laws, modern people still put such a product as a gas stove, in a bath.

This unit quickly raises the air temperature in the room to the desired level. Although a certain period of time is needed to warm the walls - specifics depends on the season. In the summer it takes three to four hours, in winter - much more. But it is precisely thanks to such a high-quality warming of the walls, warmly will be able to truly gently envelop a hubby man.

The device of gas stoves is not much different from classic wood or modern. Nevertheless, these units have some features that are related to physical and chemical properties Fuel.

The device of gas stoves is not much different from classic wood or modern. Nevertheless, these units have some features that are related to physical and chemical properties Fuel.

The product has a thermostat, a housing, a fuse (it automatically stops the supply of gas in case the float is fire). Under the stones is a hermetic gas chamber, where he burns, actually gas.

This unit, like its woodworking analogs, needs chimney. However, the fuel is not provided with wood or coal, but through a special gas highway. For natural gas - general, for propane and propane-butane mixture - individual.

Liquefied fuel cylinders should be placed in the safety rules of safety, which is buried at a certain distance from the house and the bath specified in the same rules.

In practice, it is found that the reservoir with propane, having a volume of five cubic meters, will be able to maintain heat in the room, which reaches 200 sq.m. For one season.

In the amount of weather flow specifically for medium-sized baths is not very large. In addition, compared with natural gas, thermal conductivity in propane is significantly higher. And its properties make it possible to store and carry fuel in a liquid form.

In the amount of weather flow specifically for medium-sized baths is not very large. In addition, compared with natural gas, thermal conductivity in propane is significantly higher. And its properties make it possible to store and carry fuel in a liquid form.

Natural gas changes state of aggregation Only with very high pressure, therefore it is transported only by shared highways, especially for this purpose.