What is the main thing in the bath? - Of course, warm! I want the bath warming up quickly, well kept warmly: to warm up the bones could be warm, to relax and relax and the soul. Back in ancient times, people knew medical properties hot steam. The goal is clear, requires implementation. The heart of any bath is a steam room, its functionality depends on the choice of a heating furnace. Depending on the type of fuel consumed there are electrical, classic wood, combined and gas stoves for the bath. Each view has its drawbacks and advantages. Consider today that it represents a gas furnace for a bath.

Variants of gas furnaces of gas stoves. Disassembled not a prepared person in the variety of species and installation features not easy to clarify the situation to consider the types of gas stoves for the bath, their design features and specifications. All gas furnaces for bath can be divided into several groups.

Principles of classification of gas aggregates

- by manufacturing material (stone, brick, metal);

- according to the type of fuel used (gas or combined);

- by the type of burner;

- by the method of the device of the tank for water heating.

Stone and Brick Gas Furnaces

Stone and brick gas furnaces for baths do not have significant external differences from traditional wood-burning furnaces, actually, this is wood stoves, refurbished under gas. The arrangement of the bath stone or brick gas stove is absolutely not to the detriment of the beauty of the interior - the classic view of the ancient Russian bath is preserved. Why then retreat from tradition, you ask? - For the sake of the undoubted advantages of gas stoves - they are well kept warm, evenly warming steam room, moreover, gas as fuel is often more accessible to firewood.

The lack of these furnaces is very long warming up. The stone, in contrast to the brick, has the best thermal conductivity, because the stone furnace is heated faster than brick. Device stone I. brick stoves requires certain knowledge and skills, so it is better to use the services of an experienced cook.

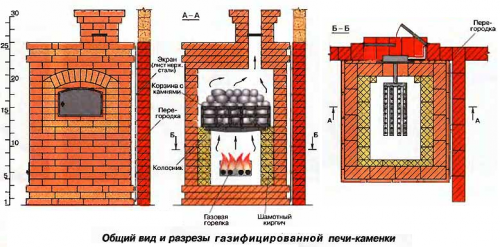

Scheme of the device of a brick gas furnace

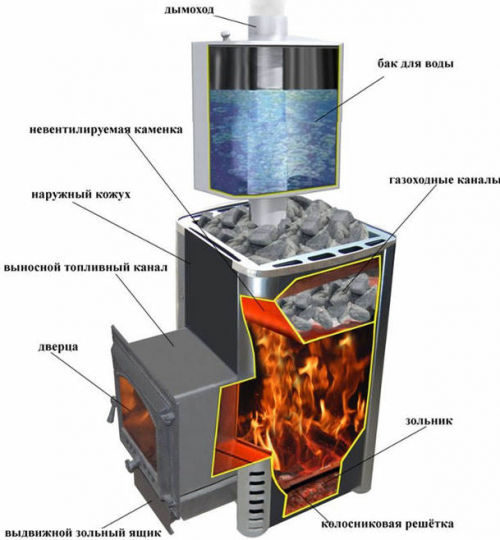

The figure shows a general view of a gas brick furnace, for fire door (In the classic wood model of the furnace, it is used to load wood) is a heating, the heating occurs due to energy emissions from the combustable fuel. Kamenka is located above the gas burner.

Metal gas furnaces

Today you can see a lot of metal gas furnaces today, they are much cheaper than brick or stone and install metal gas furnaces easier. One of the undeniable advantages is a compactness that allows you to install such furnaces in the baths of various sizes, in addition, thanks to the thin metal, the furnace is very quickly heated by steam room. And, importantly, it is possible to choose the furnace of the required power for more effective use Fuel, and therefore, it is possible to save on energy resources.

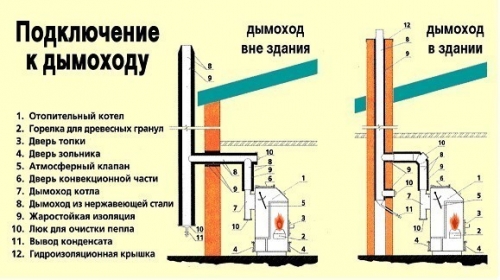

When installing metal gas furnaces, thermal insulation is required. Firstly, the heat insulation of the floor furnace with the help of a brick layer and a screen of galvanized steel sheet, secondly - thermal insulation from wooden wallsThirdly - the thermal insulation of the chimney when it passes through the ceiling and the roof.

Metal furnace can be installed in a few hours a brigade of three, and for outdoor decorative decoration One working day will be required.

The answer to the question "What gas oven for the bath is better - a stone, brick or, nevertheless, metallic?" It depends on how often the bath is expected. Brick, or the more stone stove is a heat grid, massive. Such a furnace is advisable to choose if the frequent use of the bath is assumed. If the bath will be used on occasional case, periodically - it is better to choose a metal furnace. However, do not forget about the dimensions, for comparison, the weight of the brick oven is from 750 kg, the minimum metal weight is 45 kg.

Power calculation rules

How to find out the required power? - by non-hard arithmetic calculations. It all depends on the area, and if it is accurate - from the size of the room. According to the standards for 0.4 cubic meters, Bani accounts for 252 cywlor. We multiply, substituting your values, and we get the necessary power. It is possible to calculate the economy of the unit, if you take into account how many times a month it is supposed to drown a bath.

Gas or gas-wood?

By type of fuel used, a gas furnace for a bath can only be gas (uses natural or liquefied gas) or combined (except gas can operate on solid fuel). Combined furnaces are universal, make it possible to use firewood for their work, which positively affects the bath atmosphere. Multifunctionality is an indisputable plus, but there is also a minus - large sizes, which significantly complicates the installation of combined furnaces. As for the issue of exploitation, pure gas furnaces are much easier and safer combo.

Choosing an important detail - burners

The most complex assembly of a gas furnace is a burner, the safety of the furnace operation depends on the serviceability of its functionality. Burners in gas furnaces are two types: atmospheric and inflatable.

Atmospheric device gas burners Very simple, the air in the combustion chamber of the furnace comes under the action of thrust. Such burners do not create noise in work and do not require electricity, can operate at low gas pressure, but when it is swigs, the flame force is required.

Inflatable gas burners are very effective, have a forced air supply with an electric fan. The indisputable plus of such burners compared to atmospheric is the cost-effectiveness and stability of the gas pressure drops in the highway. There is also a disadvantage - dependence on the power supply, in addition, the fan is noisily. The inflatable burner is not suitable for brick stoves, because for the fan operation will need complete tightness of the furnace and chimney channels. Such a condition is complisible, because the brickwork "breathes", with an overpressure created by the fan, carbon black gas can penetrate into the pair of steaming in the brickwork. The atmospheric gas burner can be installed on any furnaces.

Ways to accommodate a tank for water heating

The gas furnace in the bath introduces additional functionality: it serves not only for heating steam room, but also for water heating. For this, there is a tank in the furnaces for hot water, Water in which heats up the combustion products of fuel, drawn through the chimney. According to the method of a device of a tank for heating the water, the furnace is located with the placement of it above or under the heater, in both cases the chimney passes directly through the tank.

According to the cost of fuel, gas furnaces are economical, if you compare the gas furnace with a classic wood carving - less wroks (you do not need to harvest the firewood of the future, clean the chimney from the soot and straw ash).

Those who choose the factory oven to improve the bath, useful information will bring the video clip:

Installation gas equipment The site requires strict compliance with all rules and safety standards. Gasification of the gas furnace naturally need gasification of the bath. Gas - fuel is explosive, safety requirements are very high, so the bath must comply with the current construction standards.

With the question of which it is better to buy and put a stove into a bath, a consumer has several options: the range is represented by wood, combined, electrical and gas models. The advantages of the first group include efficiency, autonomy, lack of inertia, compactness, control over the volume and quality of the pair of allocated, the available cost. They are installed in the presence of a main gas supply or connect to cylinders with liquefied fuel with mandatory observance of safety standards. Purchase a gas stove for a bath with the necessary indicators is not difficult, this segment is represented mainly by Russian manufacturers: thermoform, heat carrier, Kutkin, Ermak. Preference is given to aggregates with the possibility of dunklement by water tank.

Features of models

The device is adapted to the furnace with natural gas, steam is highlighted with direct water supply to a closed heater with middle temperatures 600 ° C. Presented by two modifications: with walls from structural or chrome steel, design hides the gas burner. It is recommended for use in the Russian baths of paired volume in 6-18 m3, the highlightable steam is light. An important advantage is the simplified installation of the fuel channel and the possibility of picking the burner with the desired power. Products are certified, reviews about the manufacturer positive, warranty (3 years) applies to any malfunction (provided proper connection Gas furnace).

2. Urengoy INOX, thermoform.

Model with deep and capacious heating, heating is carried out in 4 sides, the quality of the steam is high. The recommended Bani mode is Finnish, thanks to the built-in shielding convector, the furnace produces soft heat. The furnace elements of the gas furnace are thought out, taking into account the exposure of frequent thermal loads: they are made of high-alloy steel, the thickness of the walls is 3 mm. Two modifications are available: anthracite and terracotta, the door is made of tinted glass, all communications and tubes are hidden.

3. Standard M-2.0, Kukkin.

Refers to multifunctional gas furnaces: Operation in Turkish, Finnish and Russian bath. Thermal power generated with small dimensions of the device itself allows you to quickly and quickly warm the pair to 25 m3, there are also more economical modifications - up to 18 m3. These gas furnaces are made under the order, as the manufacturer produces mostly combined. But the demand for standard M-2.0 is steady, reviews indicate the reliability of the model at affordable price. An additional advantage is the ability to choose a facing: from talco chlorite, coil or jadeite. The appearance of these gas stoves for the bath is very noble, they are suitable for any type of interior.

4. Kusatherm, Kusatek.

Compact device with unique structural design: due to the presence of a fan, combustion products are removed through the walls, and not a vertical chimney, the heating occurs inside the spiral pipeline from the refractory steel. This allows you to install a gas furnace in the middle of the steam, put it on all sides by stones, place around a bench or apply any design option. The model range is represented by aggregates with a thermal power from 10 to 90 kW, which is suitable for rooms with a large volume of heated air, while the fuel consumption is twice as smaller in comparison with domestic analogues. The equipment includes thermal insulation of the floor, equipped with a reliable automatic control system with a digital panel. The fan and the burner are located outside the heated room, the device is absolutely safe, when the pressure drops, its operation stops in the highway. There is no constructive deficiencies in Kusatek, the only restriction of application is the price, a ten times superior domestic analogs in power.

5. Complete 50, warmth.

This option is well suited for commercial baths, the device heating the steam rooms with a volume of up to 70 m3. It refers to gas bathrooms with high efficiency, the temperature of the outgoing gases is not higher than 200 ° C, the heat is evenly distributed not only in the firebox zone, but also in the complex smoking pipe system. This allows you to heat up to the required state up to 300 kg of stones, which means the rapid formation of light steam in the desired volume and long-term support for a comfortable microclimate. Recommended for use Gas burners: Ferolli Sun M6, WeishaUpT WG5, Lamborghini EM 6-E.D1 with single and two-speed operation modes, power reaches 100 kW. The design is exceptionally reliable: the thickness of the heating walls is from 4 to 6 mm, the material is the heat-resistant steel with the addition of chromium, the safety of operation is confirmed by positive reviews of the owners.

How to choose the stove?

The main operating characteristic is the produced thermal power: on 1 m3 of the volume of the parley, no less than 1 kW is required, it is desirable to provide a reserve. According to reviews, it is better to choose a stove for a bath with a little more productivity than necessary, especially if you need quick warm-up. The next factor is the reliability of the structure, the specialists unambiguously recommend fireboxes with thickened walls. The units with an open stone faster than others heated the room, but small inertia has the opposite direction - the same in the speed of cooling. To produce a pair, stones are watered from above, adjusting its parameters is difficult. Options with a closed heater not only accumulate heat, but also control the water supply, random emission is excluded.

The description of the product, the availability of the certificate is necessarily studied, the recommended scope of application and operating conditions are compared. Any malfunction is best excluded at the time of purchase. Gas furnaces Inspected for damage, connected elements are checked. Evaliable characteristics include dimensions and weight, they are selected taking into account the mandatory gap between the wall and the device - from 50 cm. By weight, metal gas stoves benefit from stone and do not require the foundation, but the base should still be thermal insulating. Another factor is the power and type of burner, to eliminate breakdowns, it is better to choose a model with the recommended manufacturer with parameters. It should be no less in performance at least.

Distinguish options with built-in and remote tank To heat the water, the first species occurs more often among solid-fuel or combined devices. At the gas assemblies, this container is usually placed in the course of the movement of combustion products and is bought separately (or mounted on its own, the process is simple). The optimal volume is 8-10 liters per person. When operating a stove for a bath with water tank, filling is monitored, it is desirable to provide a system of automatic control over the level.

Reviews

"I installed 2 × 3 m in the steregoy furnace from the thermoform, the model was pleased. Oxygen inside does not burn out, the heating occurs quickly, the heat is soft. The pair is formed after watering the stones in the top of the gas stove, it is a bit, just for my taste. Gas consumption also suits me - not more than 1.7 m3 under the condition of continuous operation. Disadvantages or faults during operation did not find. "

Daniel, Moscow.

"I decided to buy a gas furnace for a personal sauna, the main criteria for the choice were economical and simplicity of service. The cost of installation amounted to 14,000 rubles, at that time it was about a third of the value of the model itself, but, in my opinion, all investments paid off. A huge plus I consider a completely warm tiled floor, far from always observed at my friends with a wood stove. "

Vyacheslav, Kazan.

"During the construction of the Russian bath, he won the device for having warm the steam, considered mainly electric and furnaces on gas, as there is no time to prepare firewood. He stopped at the Inox Taimyr from the thermophore with a closed heater and never regretted. We use the bath at least once a week, but I did not notice a significant increase in gas consumption, it seems to me, firewood would be more expensive. "

Ilya Semin, Ekaterinburg.

"I use the model of the gauge kutkin for heating the steaming for more than three years, a year later added a water tank, there are no complaints to work. The room in 12 square meters is well heated in 30-40 minutes, the closed Kamenka gives high-quality pairs (wet and dry), if necessary, it quickly overlaps. "

Vladimir Markov, Samara.

| Name | Manufacturer | Main characteristics of models | Price, ruble | |||

| Parilla volume, m3 | Gabarites, mm. | Stones weight, kg | Furnace weight, kg | |||

| Taimyr Carbon. | Thermophore, Russia | 6-18 | 745 × 450 × 800 | 70 | 60 | 17000 |

| Urengoy Inox | 6-12 | 645 × 450 × 705 | 30 | 35 | 14000 | |

| Comm 50. | Teplodar, Russia | 30-70 | 830 × 650 × 920 | 300 | 150 | 119000 |

| Standard M-2.0 | Kutkin, Russia | 18-25 | 620 × 450 × 900 | 80-90 | 60 | 83000 |

| Kusatherm 25/30 | Kusatek, Germany | 25-30 | 500 × 500 × 800 | 1500000 | ||

To the universal joy of owners of their own washers, gas furnaces appeared for the bath. Today they are actively bought by the reasons for the low cost of gas, the compactness of the furnaces themselves and rather high efficiency. In addition, with a constant connection to the gas, there is no need for systematic and extremely bullive workpiece of firewood. If there is no centralized gas liner on the site, a gas producer can be installed. As an option, a gas stove for a bath can work from a cylinder with propane.

Combined models of heating units

As soon as the gas stoves for the bath began to receive the first reviews, the manufacturers became clear to add a spare energy source into the design of the stoves. An example of such a decision can serve as a gas furnace for Bathi Uralochka, - a joint project of two Russian factories, Khirovsky "Ermak" and Ulyanovsky "Gas-Building". The multifunctional unit gives a high efficiency, does not pollute the atmosphere and can even make adjusting space. At the request of the owner of the bath, you can melt it either with gas or a classic way - firewood. The stove is designed in such a way that it can be used as a database for steam equipment in Russian or sauna. The impressive dimensions of the unit are fully justified by a roomy heat exchanger capable of carrying out, water heating in an amount of up to 60 liters. With regard to this gas furnace, a large number of positive feedback was obtained for the bath.

If the gas-wood-wood furnace for a bath has large dimensions due to the design features, then in the aggregates from the producer of the thermophore all attention is focused on the efficiency, obtained from the burner burning "blue fuel". There is no special compartment for burning firewood there, so the sizes are suitable for the premises of any sizes:

- Thermoform 10 - for a small parch volume up to 10m3;

- Thermophore 16 - for the middle steam room to 16m3;

- Thermophore 24 is a modification for the premises of the impressive size and heating of adjacent rooms by volume up to 24m3.

Many mistakenly believe that the most best Material For the manufacture of steaming stoves is a stone or brick. The fact is that modern furnaces having metal parts (body, casing, etc.) are tested for work in critical temperature conditions in laboratories under the supervision of scientists. It turns out that the minimum service life of thermophore gas furnaces under the bath compartment is 10 years, while the stone masonry must be occurred periodically. Naturally, according to this criterion, the classic heater does not have any comparison with modern units.

Why thermoform?

The main tasks that stood in front of the designers of these stoves were the ability to quickly warm the air in the steam room and work in much (with strong frosts and high heat). With this task in the design bureau, more than successfully coped. The hull from aviation steel is able to withstand any temperature loads, including sharp drops when water gets. Afterbing the well-developed combustion products in an additional system allows you to quickly warm up air indoors (hour and a half). This value is maximum for winter time, in summer, such furnaces will cope with the preparation of the premises to the harvest in just half an hour.

It is worth noting that the homemade gas stove for the bath loses its industrial analogues not only by execution of high-quality materials. Indeed, all the elements of the thermofor, practical tests have passed. Thus, the presence of a special cover convector protects a person from infrared radiation, and the outer part of the furnace of the furnace is made in such a way that they will never be denied it. And, of course, the efficiency, the whole design of furnaces, which are manufactured at the factories, is maximally designed to obtain a high effect of fuel combustion. Therefore, we should not expect serious results from our own creations.

![]()

Some features of the practical use of heating aggregates operating in gas

The standard device of the stove, operating on a gaseous fuel, is mounted inside the housing of the burner to which the gas is supplied. During the operation of the main heating element, the air indoors is very quickly heated, the pallet with stones and a water tank (if available). If the gas furnace is installed in the bath, then it is necessary to take into account that the stones should be preferably round. Such cobblestones are able to withstand the rapid heat up to 200 degrees, rapid cooling during the guar and not collapse.

Acquisition of stresses of dubious origin, and even more so operating on gas, is at least adventurism. Sad statistics of explosions, fires and a large number of burns says that there is nothing to save. So, a gas stove for a bath for a bath, perhaps perhaps the replacement of the burner to a more powerful or new due to the planned replacement. One of these design features is a gas stove for Bani Urengoy, when buying which you can independently choose a burner with a capacity of up to 26 kW, which is most suitable for operation in specific conditions.

The global transition of the light industry from the aggregates of wood-based on gas is designed for savings, but it will require some investments on re-equipment. You will have to spend money on the dismantling of the old stove and installing a new one. But do not forget that the gas stove in the bath was originally designed and felt on the basis of electrical and wood analogues. Therefore, some modern representatives of heaters, for example, heat furnaces, originally installed for heat heating, can be supplemented with gas burner and function on gas. This information may be useful for those who do not want to start large-scale pairing work. In practice, the rotation of the source of fuel is really worth it, because now the bath will be heated in just a few minutes.

How much will it cost in the content of gas stoves for baths

Savings from the use of gas heaters will directly depend on the value of the burner consumption. This means that from the choice of the latter and all indicators of the cost of heating the room and hot water will be calculated. Starting from small premises, a gas-shaped fuel counter will show a standard in the region of 3-4.5 cubic meters per hour. With a price for gas in 5-6 rubles, it will be no more than 25 rubles per session of the bathroom to rest (heating by some furnaces is a maximum of 50 minutes).

The second calculation method is to bring to the standard for heating a unit of a pair of steam room. So, for the meter of the square, approximately 500 kcal is necessary. These values \u200b\u200bare available in the characteristics of all products, so calculate the planned flow rate per season will not be difficult. Some models of gas burning are initially have a compact form factor for resource saving. The popular gas stove Rus is an ideal solution for installation in any bath, is the best price ratio - quality, performance and energy costs.

Natural gas can be called the most inexpensive view of the fuel. And thanks to such economy, gas furnaces are becoming increasingly popular, including when used in the baths. Devices that work on gas are very compact and easy to maintain. Today we will look at how to make a gas furnace for a bath with your own hands and what is needed for this.

Features of gas stoves

Today, the gas stove can make a serious competition of wood. In use, it is much cleaner, easier and cheaper. It can quickly warm the steam air: in the summer in three or four hours, and in the winter a little longer. To work well well, it takes about eight hours. But high-quality heating provides comfort, warmth and comfort.

One of the main advantages of a gas bath, as we said, is economy. This fuel is the cheapest and economical, so you can save a good amount. On wood and electric furnaces will be required three times more costs! Gas furnace does not require much attention to you. The combustible waste is very small, so the heating box and chimney channels are practically not polluted.

There are rules for the installation of a gas boiler in the bath, which are very strict, but ensure high safety of use. The service life is about twenty-five years, and if you regularly perform prophylactic repairs, the furnace will work for a long time and do not break. If you do not take into account excessively strict safety rules, the disadvantages include only the mandatory availability of a centralized gas pipeline.

Gas furnace design

The device of gas furnaces is similar to wood, but has some differences in fuel properties. The gas furnace has a housing, a fuse (for stopping the fuel supply in case of attenuation), thermostat, hermetic gas chamber, chimney. The difference lies in the fact that the supply of fuel is carried out through the gas highway.

Gas cylinders are placed in a special tank for all safety regulations. As practice shows, the gas spray can of five cubic meters will be able to warm the room to a two hundred square meters for one heating season. It is worth noting that propane has a higher heat supply ability to compare it with natural gas. Such furnaces may have different power, the calculation of which depends on the volume of the bath.

You should know that 0.4 cubic meter accounts for 252 cywlolari heat. Therefore, you can easily calculate how much gas is needed. Gas baths do not require periodic heating, so they should be disconnected during use. Such furnaces work on a very simple principle - the air is mixed with the gas before entering the furnace. A separate part of the air passes into the furnace.

You can adjust the amount of incoming air into the gas furnace for a bath with the bottom door, which also allows you to clean the burner. Taking advantage of a special flexible hose, gas is supplied to the burner (or a cylinder is used).

Gas stoves classification

There are many different modifications of the gas furnace. You must define what bath you want and, based on this, make a decision. The most good option is a brick oven with an inflatable burner. An easier option is a metal furnace lined with bricks. Gas boilers We are divided into destination - they can be heating, heating and household. As a rule, heating furnaces are used in the baths, which differ in material, water heating technology and the type of burner.

Materials for the gas bath furnace

Homemade gas furnaces for baths can be built of stone, metal or bricks. Stone and brick will be melted longer than metal, but also keep warm long. But the metal gas furnaces are heated very quickly, but also cool up. It is worth noting that metal furnaces are the most compact. They are very simple in installing and use. If the metal oven is baked brick, externally, it will not differ from the brick.

Gas-burners

There are two types of gas burners: atmospheric and inflatable. Atmospheric burners are the most simple and cheap. For their work, automation system and complex equipment are not required. The combustion of gas supports the air that enters the combustion chamber through pondered or the coil door. The efficiency of work depends on the amount of air inside the bath, therefore a small amount of oxygen can lead to problems. There are inflatable burners, but such equipment is more complex.

The design of such burners depends on the fan that injected the air from the outside and depends on electric current. The price of gas stoves for baths with inflatable burners will eventually get the highest, since this option is more expensive in terms of electricity consumption, but also more efficient. It is often used in the so-called combined furnaces, which can be treated not only on gas, but also on another fuel, for example, on firewood.

Water heating methods

There are gas furnaces with an already built-in water tank and a remote option. The first option is more convenient, since water is heated through fuel combustion products. Chimney must be installed so that it can pass through the heated volume of water. The heating of the tank produces and heat that comes from the heater. This option allows not to clutch the bath with extra devices.

As for the gas furnace with remote tank, it is usually placed on the nearest wall or in another room. The two elements are connected by the pipe system for which hot water passes, which is heated inside the furnace.

Gas furnace for baths do it yourself

Note that it is necessary to obtain permission to install a gas furnace to the bath. The best combination of humidity and temperature can create a brick oven. It may seem that this option is very difficult to establish, but with the diligence and observance of all construction technologies With this task, any good owner can cope.

Preparatory work

First you need to design everything and choose the most appropriate place. As a rule, the furnace is set near the partition or wall, since it should dump the steam room and maintain optimum temperature In the rest room. The main elements of the self-made gas furnace: the base, chimney (is isolated by mineral wool), a heater, a burner, a leaf of fire-resistant material, a pad, control unit.

When creating a furnace, you can use the remnants of the materials that have not needed during the construction of the bath, but it is better to buy new ones. We recommend that you do not save on quality, because a good oven will provide you with your reliability and durability. In the process of work, you will need materials and products: red burned brick, clay, galvanized tin, reinforcing bar, metal pipe, grate grille, sand, doors pondered, asbestos-cement pipe, firebox doors, water pipe and steel sheet.

Before making a gas furnace for a bath, you need to build a foundation. Its construction begins with a pit, the bottom of which should be located below the primer of the soil, which takes about seventy centimeters. At the very bottom, its width should be slightly greater than the main recess. This technique will help to avoid unnecessary trouble in the case of soil movement. The bottom of the pit must be covered with sand with a thickness of fifteen centimeters. The sand is filled with water, impregnated and falling asleep with a stone with a broken brick of about twenty centimeters.

After that, crushed stone is superimposed, formwork is made and a reinforced frame is established. Next, it is necessary to pour concrete, after setting which the formwork is disassembled, and the surface is covered by tar in several layers. The place that was freed from the boards can be filled with small gravel with large sand. Do not forget to establish moisture insulation at the top of the foundation.

Arrangement of walls of the furnace

After the establishment of the foundation you can do the installation of walls. For starters done protective Wallwhich can secure the bath from possible ignition. It is made of rifled bricks, which fastens cement mortar. For a brick bath, it is better to use a sand-clay solution. As a rule, clay is taken at a depth of no less than the element of the Earth.

It is poured with water in a special capacity for a day and thoroughly mixed. Sand must be cleaned from garbage and sift. After that, sand and claile is mixed in a 1: 1 ratio, then mixed with the addition of water. When the solution takes an absolutely smooth consistency without lumps, you can begin the construction. It is better to harvest the solution with small batches as expenditure.

The very first laying of bricks plays a very important role. The foundation is pre-placed a waterproofing gasket from bitumen to which the first layer is placed. All bricks are wetted with water, ideally you need to put a brick into the water and wait about ten minutes. When the brick is laid on the solution, it follows to the construction of Kirk a little.

Carefully check that bricks are tightly fit to each other, and the seams were not thicker than five millimeters. The second and the next rows are put in such a way that each brick is in the consequence overlap 2 bricks of the lower row. Before laying out bricks per solution, builders recommend putting them in a dry form so that you can see a complete picture.

Each stage of construction must be coordinated with the drawings of the gas furnace for a bath. During the masonry of the third row, it is necessary to integrate the door pondered, which is fixed with galvanized wire or sliced \u200b\u200bstrips from the steel sheet. In the fourth row there is a well for ash and grate. To reliably accommodate, it is necessary to make a deepening and leave a place for its expansion (enough single centimeter).

Installation of fittings

The sixth row should end the installation of the door for pushed, and the seventh complete the placement of the grate and the door of the furnace. Cast iron doors are most durable. In the eighth row, the partition is mounted - the beginning of the chimney. Bricks are stacked up to the fourteenth row, on which the chawliers are placed.

Make the opening in the front wall for the container in which the water will be warm and which is installed on the chawliers. Capacity vertically hold side walls. The fifteenth row is placed from halves of bricks and have them at an angle. Halves will be the basis for the masonry of the separation wall. Similarly, the three next row, as well as the first.

At the level of the nineteenth row, you can install the door producing steam. The thin stripes made of soft steel are set between the twentieth and twenty-first next, after which the container is placed for hot water, which is surrounded by bricks debris. From twenty-third rows install chimneywhich is chosen on the basis of the furnace modification. The pipe above the roof should rise at a distance of at least half a meter.

A massive gas boiler for a bath must have a big and heavy tube, and a small one. Remember that the pipe thickness should be at least half of the brick. The cross section for the passage of smoke must have the same dimensions. It is better to use a solution from lime or cement. The clay composition can blur rain, which will lead to destruction.

Final work

After completing all the work, the oven must be placed. This procedure will improve appearance and serve as an additional protection against fire. The plaster can be made from any solution by adding alabaster to it. You can use both plaster, but keep in mind that it has a property very quickly. An excellent option for plaster - clay, gypsum and sand, mixed together (can be eliminated by plaster).

Before carrying out the plaster, it is necessary to prepare the wall of the stove. It is purified from a frozen solution to one centimeter. After that it is better to scream. If you are going to warm the bath with liquefied gas, the balloon should be placed on the street. Many bath owners bury gas cylinders a few meters from their location. Recall that liquefied gas has a higher calorific value.

If you collect a gas boiler for the bath with your own hands, it is better to give preference to the SabK-8-50C automation system. This system perfectly supports the set temperature and familiar to all masters. It is also the most secure - due to the four degrees of automatic protection.

This automation has a property to disconnect the heating equipment when emergency situations: When attenuation of the flame, if the gas pressure drops below the settling mark, or if the pulse automation system is depicted. Such a furnace is erected from eight to ten days and dried within two weeks. After that, it is possible to start it to gradually pull out, but you should not immediately bring to a strong heating.

Security questions

To properly make the stove for the bath, you should explore the instruction of the gas furnace for the bath and strictly follow them. As you know, the gas boiler is an explosive structure. To reduce the risk of ignition, it is recommended to follow the following rules:

- The furnace should be at a distance of at least half a meter from the designs that can catch fire. This distance can be reduced if you put a protective barrier from refractory material (for example, iron). If the wall next to the furnace is made of fire hazardous material, in front of the door, install a special screen, which has a size in two erection opening.

- When mounting the furnace and chimney, you need to use a stainless steel pipe. Pipes can not stretch through residential premises. Chimney must be up to five meters from the burner level. Do not forget to make hermetically attach smoky pipe To the oven.

- The opening for the burner must have the following dimensions: height from 470 to 550 millimeters, width from 350 to 450 millimeters.

- It is necessary to carefully insulate chimney from heat loss. This is done in the place where it passes through the roof and the ceiling. The smoke trumpet is also insulated.

- The refractory base that is under the oven must perform a hundred millimeters from the edges of the device.

- The height of the room should be at least two hundred twenty centimeters. It should be arranged exhaust ventilation and installed a window with a window. All doors should open only.

- The gas pipeline, according to the gas furnace scheme for the bath, is performed from copper or steel.

- Flexible compounds must be solid, resistant to pressure and temperature, referred to by the gas tag and have a diameter of ten millimeters.

- If the centralized gas supply is not provided, it is necessary to install the removal of combustible products into the atmosphere.

- In front of the furnace on the floor, a metal sheet with a thermal insulation layer is fitted downstairs.

The gas furnace is perfect for the bath and for the sauna. Today this option is the most convenient and economical. If you decide to make a gas boiler with your own hands, you should seriously consider the safety rules and get permission from the relevant instances. In compliance with all the technologies of construction and relevant rules of operation, your oven will serve for a very long time and uninterrupted.

Gas furnace - a wonderful alternative to traditional wood furnaces and expensive electric windboxes for a bath. What is the difference in such a furnace, and what technical parameters you need to watch to choose it?

Features and specifications

Gas furnaces today not only equal to the level of their qualitative characteristics with wood-level, but in many respects even exceed them. In operation, gas stoves for the bath show themselves an order of magnitude easier, they work cleaned, and the process of heating the bath is cheaper than when using firewood.

The air in the doubles such a furnace warms up in warm summer weather, on average, for 4 hours, it will need a little longer in winter. For a good warming, the stove should work around 8 hours: it is a lot, however, the result will not wait to wait - a well-warmed bath can give the maximum comfort, comfort and warmth to its visitors.

Gas is the cheapest and economically consumed fuel, for the use of which will not have to pay huge amounts (in contrast to the electrical or traditional wood analogues, to use which the consumer will spend several times more). Increased attention and care for the operation of such a furnace is not necessary: \u200b\u200bthe combustible waste (ashes, etc.) from gas practically does not appear, and therefore the furnace and just once a few years.

Install and use the gas furnace for the bath must be in accordance with very strict rules, the violation of which threatens high risk Explosion, gas leakage, damage to people and property. However, if the rules are steadily observed, gas stoves for heating baths can serve without a small quarter of a century.

Preventive inspections and timely renovation and are able to make such a furnace with a reliable heat source that guarantees high-quality furnace and heat in the bath! Only one requirement can be to install a gas furnace - the presence of a gas pipeline, because the cylinders will have to change too often.

Read the same way about how to make heat creation for a bath furnace -

Technical characteristics of the furnace

Power - This is perhaps the most important characteristic of the furnace. It is important to pick up and optimal, suitable for ourselves the power indicators. An option with an installation of a furnace with a significant power reserve, "not rolling": the furnace will really heat the pair quickly, and then switches to the minimum mode or turns off at all. The air will be hot, and the stones do not have time to warm up, respectively, the water on them will not give them. Many bath owners choose the weakest furnace, which only slightly exceeds the required indicators to reduce costs. Such a furnace will heat the bath, working at maximum power, but it is known, a direct path to the exit of the equipment. Select the power of the furnace is needed in an average power range.

Calculation of power

In the instructions that are applied to each oven, manufacturers indicate both the recommended volume of the heated room of the bathroom and power in kW. You can choose an oven with optimal technical characteristics for yourself, based on two parameters: thermal power and steam room cubic.

To calculate the volume of steam room, you need to measure its height, width and length, translating all measurements into meters. If you multiply these three indicators, it turns out the volume of one room in cubic meters. In extremely, this parameter can be viewed in the Bani project. One of this calculated cube will not be enough:

- The ceiling or walls in the bath trimmed with a brick tiled or a stone - their area will also have to calculate, multiply by 1.2, and then add to the cabinature of the room designed earlier. Roughly speaking, 1 m2 of this facing volume increases by 1.2 m3.

- Glass doors standing in the bath will add 1.5 m3 more calculated volume.

- Log walls Without trim - the volume should be increased one and a half times.

Choosing the furnace itself, you need to calculate so that "to meet" somewhere in the middle between the two maximum values. For example, if the battery volume is 20 cubic meters, it means that gas stoves for the bath must be chosen so that the power indicators in them are 15-25 m3.

Another option to deal with the technical characteristics of the furnace is to calculate the power based on the size of the room. Construction rates say that 0.4 meters of cubic spaces Bani need to "issue" 252 kilocaloria. Puting its data into this law, you can also get so necessary power. The economy of such a stove for the bath is calculated on the basis of how many times the bath will be treated monthly.

However, one power indicator will be not enough to choose really good and appropriate to all the requirements of the owner of the bathhouse. Its attention will have to draw on the material from which the furnace is made. From the properties of bricks, cast iron or steel, the thickness of the walls of the furnace and depends on how much such a furnace is faithfully will serve for the benefit of its owner. Best option - Select oven made of alloy steel, as part of which there is a large number of chromium impurities: such a furnace is considered the most reliable of all those present on the market, and in addition, it preserves oxygen in the room much better than other "bath" heating analogs.

The fact is that there is no oxidation of chemically inert materials in the steel furnace. Such steel can be found in the collections of Russian firms "Feringer" and "Thermophore", the German company Kusatek, Finnish Heloi Kastor. Returning to all metallic furnacesIt should be noted that they occupy a little space do not need the foundation, easily installed and serviced.

Unfortunately, cast iron is no less suitable material, but for a number of reasons to find it today is extremely difficult. On the domestic market, it is possible to find it in the model row of Sudarushka M furnaces, which manufactures the factory center plant. However, this furnace will have to be converted to gas fuel. Alas, a brick oven on gas is the fruit of translated fantasies. But you can make the imitation of a stone furnace in a matter of days - to buy a suitable firebox and install a screen imitating brick masonry, or lay a real brick.

Choosing a firebox, you can not forget about where it is planned to be installed. The current gas furnaces for the baths are produced in two variations of the furnace: oblong - for the convenience of installing in the wall - furnace and ordinary. The oblong furnace is considered the best: with its help, you can trample from the adjacent room, without disturbing your own microclimate of the steam safety steam safety. Couple-produced pairs are also taken into account: the Russian bath requires dry dense steam. If the gas furnace is not able to produce it, you can purchase a steam generator that works even on electricity.

The burner of any heaters on gas has fuel consumption indicators, which will become indirectly determining the power and economic characteristics of this equipment. A small compact steamer will easily warm with a stone, the burner which consumes from one and a half to 4.5 m3 hourly. In the extreme case, the burner can be replaced by taking into account its threads, and the thread of the gas flow source.

Benefits of gas stoves for a bath before other types

The traditional firewood firebox is, of course, a great opportunity to create an atmosphere and warm the steam room in the traditional way, but only if the firewood is enough for this. There is an alternative, and even more profitable - gas furnaces for heating baths, which differ from other "bath" fellow by the following advantages:

- Small parameters. There are no large furnaces and ash splash on gas, and its sizes of its body are extremely small and do not occupy a lot of space even in the smallest pairs.

- Easy selection of temperature. Create the right climate in the steam room is very simple - for this, the heating mode switches are installed.

- Easy to operate - serious care and abundance of attention Such a Kamenka does not require due to the absence of the absence of sediment of ash or the appearance of coal.

Average market prices, model range

The compact furnace for the bath "Urengoy" from the Russian manufacturer "Thermophore" is made of heat-resistant alloyed steel and is designed for heating a bathroom with a size of 6 m3 to 123 m. The furnace weighs 35 kg and costs its consumer in 14 thousand rubles.

"Cascade" from the manufacturer "Teplodar" will warm the pair of up to 18 cubic meters, can additionally heat the water. Made of stainless steel furnace, and for its consumer it will cost 19 thousand rubles.

Casting furnace "Sudarushka M" warms the room with a volume of up to 18 m3, and excluding re-equipment will cost buyers at 34 thousand rubles.

But one of the most powerful gas stoves in the Kusaterm market for 90 kW can warm up a really big steam room for a long time. Consumer will spend 110 thousand rubles for such a furnace.

So, choose a suitable furnace working on gas, it is not difficult: the abundance of the options presented in the market and knowledge of the characteristics of the furnaces will not allow mistake!