No brick building can be compared with a real wooden house. Such a dwelling is different optimal temperatures and humidity, it is easy to breathe and lives in pleasure. Sweat only often the question arises how to drop wooden house? Easier simple - organize in it stove heating. Of course, the installation of the furnace cannot be called a simple matter, the procedure requires preliminary preparation and attentive planning.

Selection and types of devices

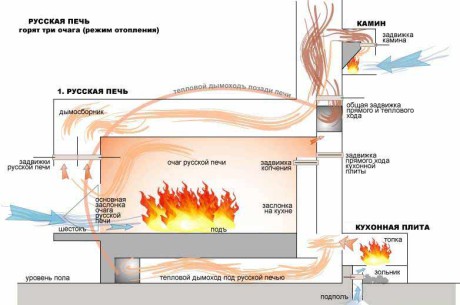

In a wooden house, the furnace is usually used not only for heating, on it, besides, you can cook food, boil the water. The foci used only to increase the temperature in the house is called heating, and cooking cooking. Based on what you want to choose for yourself, you need to take into account not only the stoves, but also stay on the fireplaces.The fireplace in the house is more used to decorate, while the furnace performs a purely heating function. The fireplace cannot become an alternative to the furnace, as it will ventilate the room anymore than it heats it.

However, there are also its advantages here - the possibility of observing living fire. If you are not afraid of difficulties, you can try the installation of symbiosis of these two foci in your home - Caminox. Of course, it is quite difficult to build this device on our own, but there is a mass of all sorts of models from domestic and foreign manufacturers who offer their customer high-quality devices equipped with a whole set of additional options. However, back to the installation of the furnace. This procedure is not easy, requires care and accuracy. Special zones represent places of locks of cast-iron plates, windscalides, etc. If you are not confident in your abilities, it is better to seek help to professional masters of a chimney.

The furnace in a wooden house can be not only brick, but also metal, especially, now the peak of popularity is experiencing all familiar bourgeities, which are manufactured using the latest technologies.

Metal furnace has many advantages. These include durability, reliability, fast heat transfer, fuel variation, the ability to control the temperature, as well as acceptable prices for heating equipment.

Of course, there are also cons, they are practically not adjusted. And this is, first of all, the rapid cooling of metal foci. Secondly, they are required to carry out special care. Thirdly, for large premises, this type of furnace is not suitable, as they simply do not heat the space.

Thus, in a wooden house it is more expedient to install a brick oven. Brick devices can heat any area. If you choose the right place for this. In comparison with metal aggregates, they are more secure, longer stored heat and do not require additional protection for the walls and the ceiling.

Furnace Installation Requirements

Planning the installation of the furnace is needed at the construction stage of the house, even if the installation will be completed later. The foundation of the furnace and at home should not be connected, as they have a different shrinkage and can entail the deformation of the focus. If you live in two-story houseOn the second floor it is better to install a bubzhuyk furnace or to organize steam heating. We will make a reservation that the latter requires quite large cash investments.Previously need to take care of fire safety. Under the floor, in the place where the furnace will be installed, two layers of toli or rubberoid are placed. Parameters of gas ducts reach thirty-five - forty five centimeters.

The most optimal accommodation brick oven The outer wall of the building is considered, so the focus will look more effectively and prepare on it will be much easier. If you need to heat the dwelling, the oven is better to install the room in the room.

There are installation requirements of the fireplace furnace:

- - Before the focal on the floor, a metal sheet is placed, which will exclude fire from falling out of the coal firebox,

- - From the furnace to the wall of the room should be at least one hundred and twenty-five centimeters, and before the ceiling - no more than one hundred and twenty centimeters,

- - Internet sides of the furnace should be removed from the wall at fifty centimeters.

Installing a fireplace

The installation of a fireplace furnace includes several stages, list them:- Paul preparation (laid out the base of bricks);

- Installation fireproof walls;

- laying tiles for base;

- Construction of a gas plant or chimney.

Heat-reflecting tile is also used for heat insulation of the walls. The procedure is also performed, as in the case of the floor. Sheets must first be primed and lining with tiles. The primer is performed in two layers, and ceramics are fixed on special glue. In places of transition advise to use decorative elements.

The alignment of flue products of combustion is best done using modern sandwiches, which belong to the finished factory equipment and do not require preliminary assembly and mounted. Alternatively, asbestos and brick chimneys. The most durable is brick chimneys, which relate to traditional devices used traditionally. The procedure for removing the chimney through the roof is more difficult to make it easier to do it through the housing wall.

Consider how to properly produce chimney:

- the first detail of the chimney without insulation is fixed to the connecting nozzle;

- hole for the chimney must be performed precisely in the place where it is provided. If there is a need, the circle should be treated with thermal insulation material

- the recommended height of the chimney is four - five meters, during its holding fixed by brackets;

- in the upper part of the chimney, a sparkium with a grid is mounted, which eliminates the penetration of precipitation into the chimney.

Brick oven

For masonry oven usually use hollow ceramic brick. During the purchase of bricks, you need to pay close attention to what the color of the material, there is no chipping and cracks, whether all elements coincide in size and configuration.FEATURES OF COMPLEX FURNACES OF CRIKE

The masonry of the brick furnace is characterized by a strict scheme that cannot be broken upon erection. Sometimes the non-compliance with the scheme entails the asymmetricness of the forms and, as a result, the destruction of the focus. When laying out the first row, it is necessary to be very attentive, since it is this series that will become a key to the subsequent correctness of the corners and the entire life of the unit. Before you start the masonry, the brick must be soaked in a special container for a few minutes.Before construction, the oven needs to be stocking not only brick, but also furnace accessories (furnace instruments). It is best to use cast iron elements. Entry accessories are called ovens, stoves, doors (fuel, infancy, cleaner), buckets, grilles and valves. If you decide to build a furnace yourself, then go to a special kit of the cook, they are sold in specialized stores.

The masonry of the furnace is performed on a clay solution. There are ready solutions, and you can also knead your own. For this prepare sand and clay.

Small trick - in order for the seams to be the same, use two thin wires.

A few more tips on brick masonry:

- if you observe the dressing of the seams, the laying will be durable,

- before performing masonry on the solution, bricks lay out dry directly on the floor,

- gas pipes should be smooth so that no decrease in flue gases

After the second and third row are laid, vertical guides in the form of wooden plates or ropes should be installed from the corners. Ropes will need to be tied to nails and secure on the ceiling exactly at a right angle to the plane of the focus.

The grille or grille made of cast iron is placed with a boss, so that solid burning products in the form of coal and ash rolled down into the ash chamber. The grateless is stacked without the use of the solution, the gaps fall asleep with sand, it will later be more convenient to get and clean the design. Only then the firebox door is installed on the mounting wire.

Wire is laid in the seams so as not to melt when heating the focus.

The last row will be installed a cast-iron stove of the furnace. First, it is placed without a solution, so get the outline of the plate, after that choose the grooves, put asbestos cord into it and only after that they make laying on the solution. Some variants of cooking furnaces, among other things, can be supplemented with brass cabinets and a tank for heating water.

During the chimney masonry, it is necessary to organize a valve on the summer move channel, which inner corner Departments for cooking.

The cap is adjusted to the ceiling opening, overlap with several bricks, and the resulting clearance is filled with mineral wool. Thus, ensure the heat insulation of the heating device.

After that, the decorative brick belt is performed and start to spread smoky pipe. It is believed that the brick tube is more durable than the famous pipes from metal and asbestos.

Brick furnaces are distinguished by their reliability and remain the main objects of heating in homes located outside the city.

How to organize heating in a private house? Is it possible to install a furnace in a wooden house, or should it be exclusively brick? Will there be an effective ordinary fireplace or have to put a full-fledged oven? Let's deal with the order.

What to choose for heating in the house?

If the task is to warm up the room, and not just bring comfort and a little heat into it, the usual fireplace is categorically not suitable. Almost all his heat literally flies into the pipe, which, in essence, is the vertical chimney.

Choosing a stove in a wooden house, you need to take into account its size and weight. So, heavy designs weighing more than 200 kg require a separate foundation that is not associated with the foundation of the whole house. But a large brick oven can heat three rooms at once, placing it at the intersection of two inland walls. For example, the front side with a cooking surface will be in the living room, and Boca is in adjacent rooms.

![]()

In addition, it will be possible between the body of the furnace and the wooden walls to lay a non-flammable insulation, and the floor in front of the furnace is to close the non-combustible materials. It looks very beautifully laid out around the stove tile.

If the furnace is only in one room, lay the tile and the wall behind it. In this case, it is advisable to provide an air gap in 5-10 cm - the effectiveness of heating increases significantly.

Furnace-burzhuyka - cheap, reliably and economical

For a cottage or a small country house with one room, a fairly ordinary stove "Bourgehogs". Due to the small size and thoughtful design, it not only effectively warms the room, but also economically spending fuel.

Benefits and disadvantages of bourgeoke

The advantages of using these small furnaces is obvious:

- economy - thanks to pyrolysis fuel combines completely and spent slower;

- practicality - the furnace not only warms the room, on its surface you can cook and disperse food;

- easy installation - no separate foundation is not required for burzhuyki, it is enough to put a metal sheet with a layer of asbestos or basalt cardboard between it and floor;

- universality - thanks to the compact sizes and big selection The appearance, the burzhuyka can be put in any room - from the Lester's house to modern cottage.

But the disadvantages also have:

- low efficiency - only 60%;

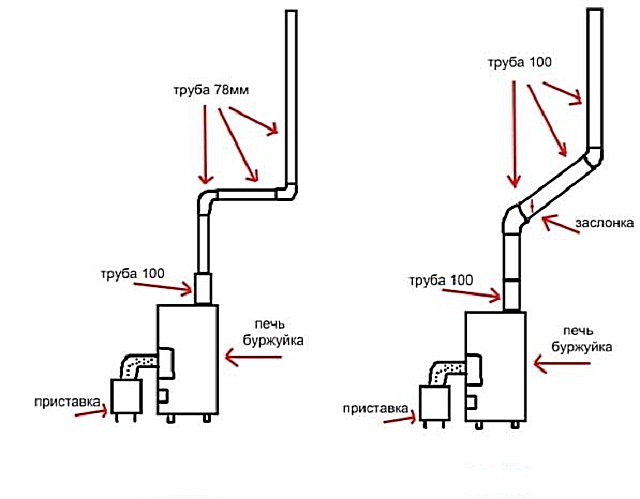

- the need for a high chimney device with a long borovoy - vertical part must be long from 1 m, and the borov can not be shorter than 2.5 m;

- small heating area - up to 60 sq.m.

Installation Bourgehog

Despite the fact that the design of the furnace provides for the presence of a special screen on the back and side walls, it is impossible to put it closely wooden walls or combustible plaster. It is put on a non-combustible base or even a metal sheet, which should perform along the contour of the oven itself by 35 cm (and better, by 60 cm). Under the litter you need to lay asbestoset or basalt (can be kaolin) cardboard - to comply with fireproof norms.

The horizontal part (borov) also performs the function of heating - it cools down the smoke before entering the street. The vertical part is wrapped with thermal insulation, and horizontal - no. Because of this, the boring itself is strongly heated, so it should be located at a distance of 1 meter from simple plaster and 1.5 meters from wooden walls.

According to the rules of security, it is desirable to have a height from 2.2 m or to close it with a protective box of metal mesh.

Furnace buleryan - smart and practical

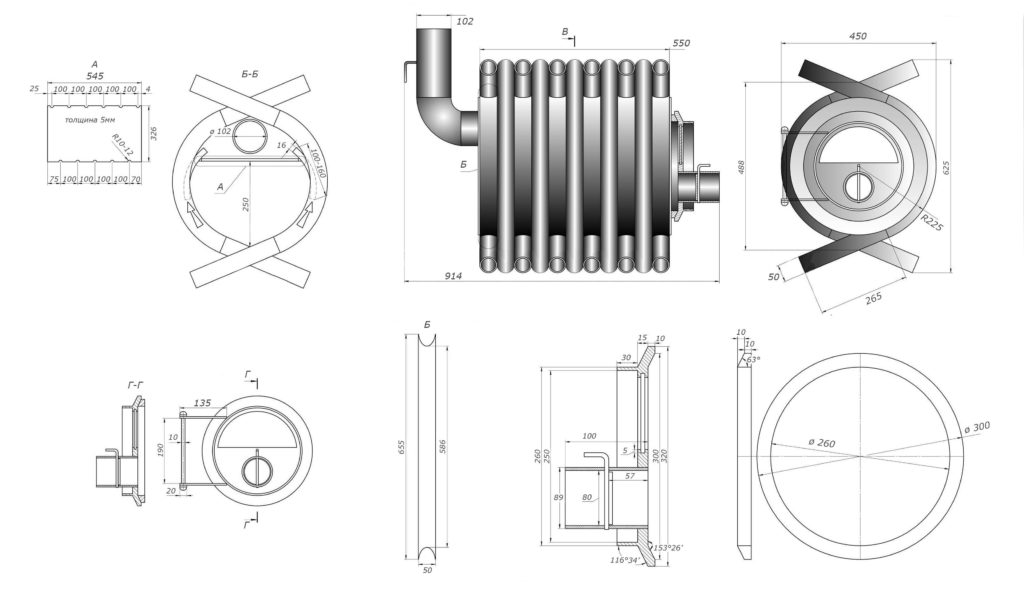

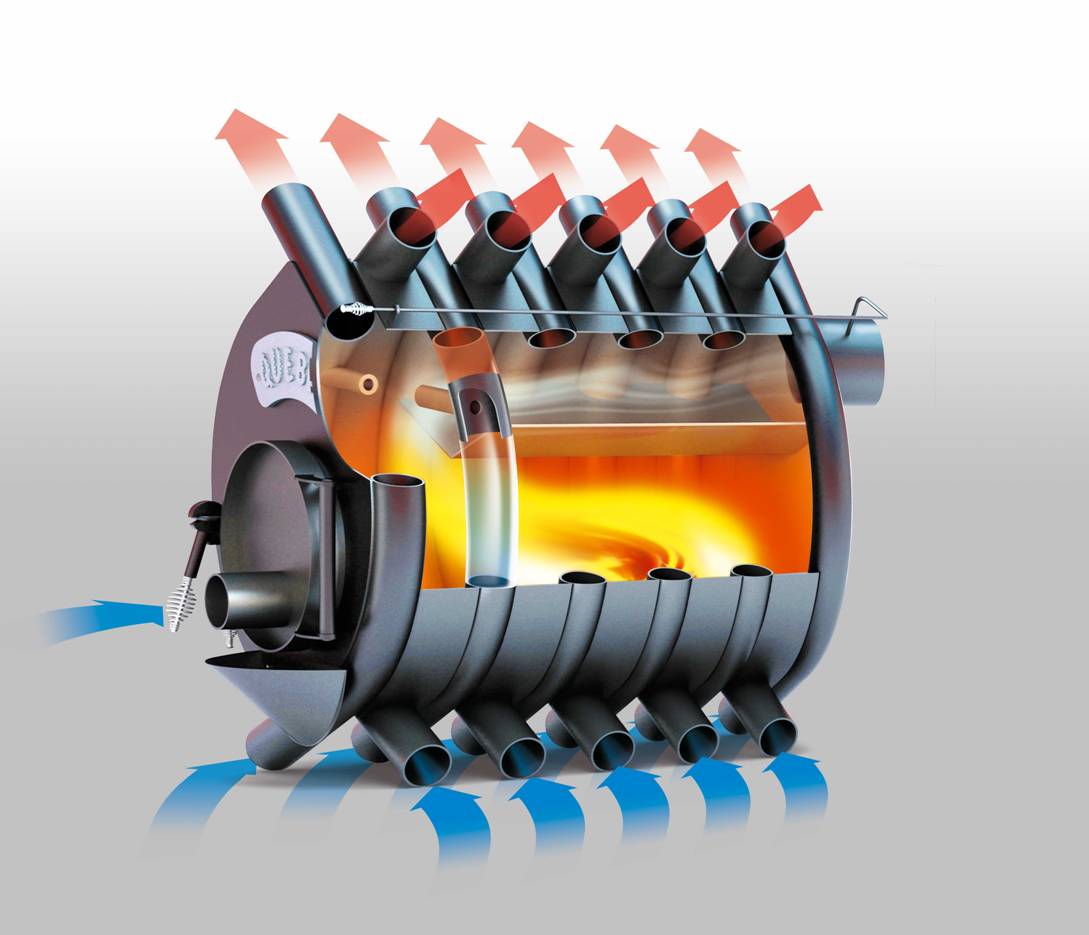

Canadians came up with their version of Soviet bourgeitors - Buleryan. This furnace also takes at a minimum of space and works on pyrolysis, issuing a high efficiency - up to 75%. But its distinctive feature is a convection method of heating the room.

Principle of operation and installation of a buleryan

It is due to them that convection is carried out. The cold air is absorbed below, heats up and revealed already heated.

The outlet temperature is 60-80 degrees. It does not need any pumps and electricity connections! The air indoors warms evenly and very quickly.

Buleryan is a wood stove, so, unlike bourgeities, it will not work in a row to tram it. But the original appearance And the simplicity of installation levels this flaw.

How to install a Canadian oven:

In addition, the buleryan can be chosen by brick, and choosing a model with a cooking surface, you can simulate a real Russian oven with a minimum effort!

Brick oven- "Baby" - easy and convenient

If you want to try your hand in installing a real brick furnace with your own hands, you can start from a small stove. Its installation takes only one day, and it is possible to fully use it in a week.

Her advantages:

- high heat recovery rate due to styling bricks Plafhmy and rib;

- excellent heat capacity, due to which the furnace remains warm for a long time;

- compactness - the furnace takes 0.4 sq. M.;

- low weight does not require a separate foundation;

- efficiency - for the oven you need only 62 red and 37 chammed bricks.

How to install a compact brick oven

A very simple order will allow to cope even a novice liver. The first row on the waterproofing sheet with a size of 78x53 cm with a saturated sand layer is 1 cm. What is characteristic - the first row is stacked "on dry", and each brick is slightly pressed into the sand.

IMPORTANT EVERYONE RADY Aligned in terms of level, otherwise the final result may be far from the ideal or even to be non-working. The second row is already placed on the clay. It should be borne in mind that a special red clay is placed on red brick, and chammatory refractory. Better to purchase already finished compoundsThey are much better than self-made solutions in quality.

First, a confusion door is installed, wrapped by asbestos cord several times, and a second row is formed around. All rows are stacked in accordance with the friend.

We must not forget that the doors and cooking stove are wrapped with asbestos cord, moistened in water.

One rear brick in 4 row stacked without clay - it is a "misunderstanding" brick, which in the end will need to get to wipe moisture and excess clay from the chimney. After that, it is placed in place, and the seams are embossing the corresponding solution.

The finished furnace can be blusted, pre-crushing the hob of polyethylene. Before fire door It is necessary to nail a metallic prestituct sheet of a M-shaped form. It must close the floor joint and the first row of the furnace. The perimeter also features a plinth of heat-resistant material that will not give sand.

The test fake can be made immediately, but only straw or paper, and that is not long. But it is possible to fully use the furnace only in a week when the clay is dry.

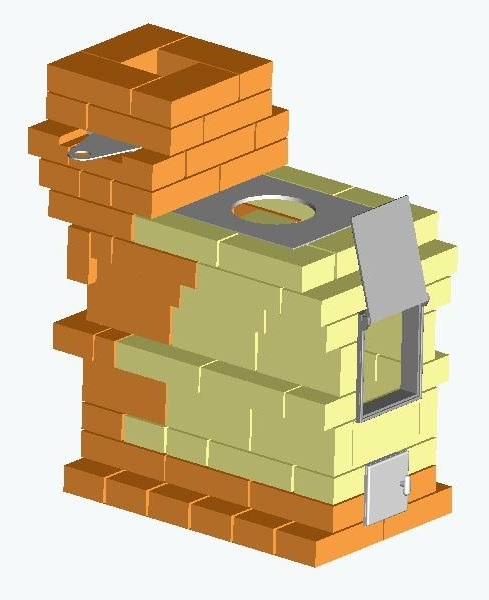

Brick oven with heating boiler - Maximum effectively

But the assembly must produce an experienced cook, as the order has 35 rows and the slightest error will result in fairly unpleasant consequences.

Main aspects of stove

The heating boiler built into the oven allows you to warm the house with a total area of \u200b\u200bup to 200 sq.m. But due to its design, the cooking surface of the furnace performs only auxiliary function, since, being over the boiler, it is badly heated. But it is convenient to dry mushrooms and fruits or warm the water.

Furnace equipment in a house of logs or wooden bar He has a number of features caused by an increased risk of fire. Tree is prone to fire. Therefore, the installation of the furnace in a wooden house should be carried out in compliance with safety requirements.

Video about the construction of a small stove with a supertop

Types of stoves

Wooden house can be equipped with brick or metal oven. The decision to choose one of the options is made on the basis of the study of the characteristics of each species.

Brick ("Russian") oven

It has an ancient Slavic tradition: our grandfarades not only prepared food on it and heated the dwelling, but also used it for sleep. The pros of this furnace equipment can be attributed to:

- Maintain heat due to long cooling.

- The possibility of heating the room of any size.

- Lack of need for additional protection of walls and ceiling in view of what brick walls Not subject to fusing.

- Resistance to ignition.

However, such furnaces are not deprived of the minuses:

- For erection brick design We need special skills and knowledge of technology. Therefore, this process should trust a professional.

- This equipment needs a solid in-depth foundation.

- The furnace is quite cumbersome and takes a lot of space that it is necessary to take into account at the stage when the location of the furnace is determined in a wooden house.

Vintage Russian oven with a sunbed

The furnace for the wooden house is also made of steel or profiled cast iron with a sheet thickness from 3 to 5 mm. The walls are two layers of metal, between which there is a layer of air. Such a design protects the room from a thermal impact.

The advantages of metal furnaces belongs:

- The availability of the acquisition of a fully equipped oven with chimney of the finished assembly equipped with a temperature control system.

- Exquisite design.

- Fast warming up, at the expense of which you can warm the air indoors in a short time.

- Heat transfer.

- Long period of operation.

- Consumption of any type of fuel.

Among the minuses of metal furnaces:

- Not suitable for use in the house of a large area in view of non-economic fuel consumption.

- Small heating time assumes and rapid cooling.

- Fire hazards requiring special control.

Metal stove in the interior of a wooden house

Criteria for choosing a material for a fiber chamber

The furnace in a wooden house, from which material it is not made, should be equipped with a floating chamber. Its linear dimensions are directly dependent on the heat transfer coefficient.

To determine what material to make a chamber for firebox, you must first of all know what fuel will refill the furnace. Using:

- Peat: The furnace chamber must be equipped with two lattices of metal.

- Coal: It is necessary to make a chamber of red bricks, and bold chamoten.

- Woods: We make a chamber for firebox from refractory brick.

Choosing chimney

In addition to the ovens itself, an integral element of the system is the chimney, outlining products of burning, soot and soot. The stove and chimney must necessarily be equipped with revision hatches. They serve to periodically clean the system from the soot and soot. Chimneys are manufactured from:

- Galvanized pipe, which is mandatory to thermal insulation with materials that are not burning. This type of chimney is heated to such an extent that it needs additional protection at the joints with wooden surfaces and roofs.

- Brick. Gilled brick chimneys are required to use in the furnace for a wooden house. Reducing the degree of heating, they are thereby lowering the risks of ignition.

- Ceramics. The design is quite massive, however, has better qualities among the above species. This is the duration of operation and a wonderful thrust. Among other things, condensate is not formed in such chimney.

- "Sandwich". Due to the multi-layered walls, such chimney is not exposed to overheating and therefore does not need additional isolation. However, after a decade of operation, it can exhaust, because of which the quality of the pipe is worsening.

Scheme of ceramic chimney

Independent installation of "Russian" oven

Before putting a brick oven for a village house, we will define it with its location. This issue turns out at the stage of designing the house during the fill of the foundation. A special foundation is made under the future stove. Here it is necessary to take into account the large sizes of the "Russian" oven. The best place For her there will be a kitchen, a traditional place for cooking. In a large high-rise house, the stove equip every floor.

Step-by-step guide to self-installing brick furnace

- Mowed in the subfield from 2 to 3 layers of rubberoid waterproofing or roofing. There must be an interval of at least 45 cm between them.

- Calculate the configuration of the beams on the ceiling so that the chimney pipe is in a distance from the matrices between the rafters. In order to avoid draft, it is recommended to put the stove next to the outer wall.

- Start stacking bricks spawned from two oppositely spaced racks. Thus, the clay will be distributed evenly and will not, sliding, weaken the seam.

- Masonry shape must resemble the correct rectangle. With an interval of 2-3 rows, it is necessary to check its evenness with a plumb.

- Perform the masonry of the furnace chamber from the grate.

- Lower the stove with a tiled tile or perform the stucco of its surface with a thin layer of asbestos.

Scheme of Russian stove

Possible malfunctions and ways to eliminate them

During the operation of the furnace equipment, certain malfunctions may be detected. We list the main ones and consider ways to repair.

- Chimney walls are badly warmed. Cause: One of the elements furnace system Craised soot or fell partition. You need to restore the partition and clean South.

- Cracks appeared on the surface. To eliminate the defect, they need to expand the brick blades, clean from dust, wet and close cement or clay mortar.

- Basic bread bakes poorly. So, the base of the furnace firebox is badly heated. It is necessary to shift the podium, falling asleep under it coarse sand and river pebbles.

- He burns the top edge of bread when baking. Cause: too low located arch. It should be raised to a couple of rows above.

- Replacing furnace equipment. For this, the solution is removed, which are knocked down, if necessary, part of the brick and gently push the oven, producing the replacement of the old one.

Classic stove with decorative stone and wood

The role of the furnace in the decoration of the house of the tree

The Russian oven in the interior of a wooden house is an integral attribute of a rustic style. To complement it by making the design completed, techniques are used:

- Fastening on the walls of the kitchen of wooden shelves with kitchen utensils, as well as hooks, for which you can hang scales or pans.

- The location of the Big Table in the center of the room, near which instead of the chairs are shop bezes.

- Arrangement of a special angle under the icon with a lamp decorated by a woven.

- Location next to the mirror output.

Features of the installation of furnace equipment in a wooden bath

Let us dwell on this process as the installation of the furnace in wooden bath. It has certain distinctive features:

- Select location. It should be noted that from the door of the furnace to the wall should be a distance of at least 25 cm. It is possible to embed the furnace into the wall only if it is made of the material that is not susceptible to intensely and is covered with tiles or its analogue at least 2 m in height. The drooping plot should be covered with non-combustible insulation.

- Under the stove in the bath is still at the stage of construction of the foundation pour reinforced concrete base. Then there is a metal sheet and a layer of thermal insulation. Otherwise, the installation of a furnace on the wooden floor without reason can lead to its destruction.

- All surfaces in the bath are recommended to be soaked with antipiren, and the furnace itself is separated by a brick wall (best of all refractory).

Brick stove in a tree bath

Furnace Installation B. rustic bath, as in any other room, there should be a person familiar with the nuances of easily flammable equipment. However, accurately following the above instructions, establish furnace equipment in your house will not be difficult and newcomer.

How relevant is the Russian oven in a wooden house of modern sample? The question is irresistible, since this device carries a lot of useful. But the construction and maintenance of it is associated with many difficulties. It is worth the issue of all sides, in order to the owners who have become invalid by the Russian appearance, took into account all the nuances in solving it is not a fireplace, but a stove.

The advantages of the Russian oven

We are indisputable by the fact of the efficiency of the unit - a special design allows you to use up to 80% of the fuel energy, which is unattainable with conventional batteries or fireplaces. Also related to advantages:

- Russian oven is used not only for heating the room, but also for cooking. In addition, heat has a beneficial effect on the state of wood, not giving moisture to penetrate inside. The furnace decorate under the fireplace, for consideration, grasp, clay and cast-iron pots are acquired. Committed to Kocherga.

- In antiquity, the ancestors used the healing heat for the treatment of osteochondrosis and other articular diseases. If the owners want to gain the effect of warming up, then before the construction it is necessary to discuss this option with the master. Lenhing or as it was called before, flavors, should not be split or in contact with chimney.

- The decorativeness that the Russian stove creates in a wooden house is created, incomparated with plastic or metal interiors - the object immediately gives the house true Russian style. Previously, the furnaces were painted in traditional motives - Gzhel, Khokhloma. Nothing prevents reproducing it today.

- The furnaces can be small and serve only for coloring or heating of small rooms. In general, distributed dimensions 1500 mm × 2300 mm. The furnaces are designed for large from 30 m² and small rooms.

There are disadvantages:

- The furnace is a brick building. The stone has an accumulation of moisture, so in order not to distribute the dampness, the Russian oven for a wooden house should be in operation. That is, in winter it needs to be made, as it should, and in the summer, pay attention to cleaning, plaster and general prophylaxis.

- The volumes of the real Russian oven are quite large, therefore the project should be scheduled for it. You can use a modest furnace, but the style then will lose the desired flavor.

- The design of the furnace can only be engaged only by a professional, as well as its regular prevention, for in the absence of experience, you can create multiple health risks and even the lives of others.

If the difficulties associated with installing such a design are not frightening future owners, it is worth trying to arrange your own cozy corner. Winter evenings in such housing will come to the mind of the word from the song of the old good Soviet cartoon - small house, Russian stove, wooden floor, shop and candle.

Safety measures when arranging a Russian oven

It is important to prevent overheating of the surfaces of a log cottage or houses located in the immediately close to the furnace. For such a goal use asbestos sheet. A receiver for fuel under coal, firewood should also not be contacted with hot surfaces. It is attached to the wall of the house, near the oven.

It is worth paying attention to chimney and ventilation. The first requires reliable masonry without the slightest fistula. Also, it is covered asbestos with a sheet and wrapped with non-combustible thermal insulation.

Ventilation, or rather, the system of moves should be both a supply and exhaust, in addition to natural.

Decorative Finish of the Russian Furnace

Deciding on such a functional subject in a wooden house, it is worth thinking about its decoration options. Simple white type is widespread - neat smooth snow-white walls. The only negative, with a frequent exploitation, a simple sour cream can not do, you will have to constantly update the view of the walls to maintain cleanliness.

The second most popular option - wooden houses with a Russian stove lined ceramic tiles. Many manufacturers offer for such a goal of imitation of tiles, former during our ancestors.

Facing a Russian oven brick. The design itself is laid out of a chamotte species, and the decorative layer can be clinker or ceramic. The first option is not afraid of any temperature drops, it is not very hot and will serve as additional safety in terms of ignition.

The comfort of the traditional national flavor, indeed, you can create two components: a wooden house - a Russian stove. Private real estate owners have long understood the charm of Country motifs - as one of the currents designed to emphasize the other tradition of the country whose representatives they are. Also, this interior is popular and abroad, not just as a wonder, but as time-tested functional heat protection, especially in the Nordic countries.

You need to enable JavaScript or update the player!