The Topas aeration treatment plant, the components of which are used in our EKODIN stations, were invented by an engineer from the Czech Republic Jan Topol.

The name of the invention, made in 1994, was formed from two components: TOP - the beginning of the name of the engineer and AS - the activation system. Wastewater treatment technology is protected by Eurasian and Russian patents.

The use of sewage treatment plants

EKODIN treatment plants are used to treat household wastewater that is discharged from individual buildings (cottages, summer cottages, country residences and houses) in the absence of a central sewerage system. This wastewater treatment technology uses a biological treatment method that surpasses the characteristics of foreign and Russian counterparts.

Treatment facilities for a private house EKODIN are fully automated. The user only needs to periodically (about once every three months) pump out sludge from the system using simple manipulations.

There is no need to call specialists to clean the septic tank. Autonomous sewerage complies with all sanitary and technical norms and standards established in Russian Federation... This testifies to the high manufacturability and efficiency of TopolVater treatment plants.

Discharge of treated wastewater from a septic tank can be done directly onto the ground. If purified water is discharged into nearby streams, reservoirs, etc., it is necessary to install additional equipment for ultraviolet disinfection and a sand filter.

Local wastewater treatment plants are supplied complete and ready to install. It remains only to install a septic tank.

The device of treatment facilities for a private house TopolVater

The "stuffing" of the treatment plant consists of four main compartments. The first compartment is a storage tank in which the primary purification of the discharged wastewater is carried out. In the second compartment, the aerotank, more deep cleansing at the biological level. The third tank is a secondary clarifier and the fourth acts as an activated sludge stabilizer.

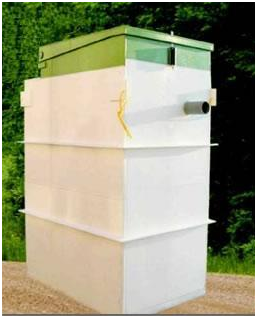

The device is made of three-layer polypropylene, a material that has a long service life. The septic tank is equipped with a steam-water-tight cover made of the same material, which prevents the spread of unpleasant odors. This allows the station to be installed close to residential buildings.

Purification of effluents in a septic tank occurs with the active action of anaerobic bacteria. The process takes place at the microbiological level and its rate is many times faster than natural decomposition. It is completely safe from an environmental point of view.

After passing through all stages of purification, the wastewater is suitable for use for economic purposes.

The TopolVater treatment plant does not depend on the climatic conditions of use. A pipe located at a slope will always be dry and therefore not subject to freezing.

Advantages of TopolVater sewage treatment plants:

- silent operation of the sewage treatment plant

- light weight, dimensions and space requirement

- easy installation and maintenance

- lack of extraneous odors during maintenance

- high degree of purification (up to 98%)

- automatic filter cleaning

- alarm

- service life - up to 50 years

- stable operation at all temperatures

- resistance to corrosion

- high-quality components: PEDROLLO pumps and SECOH and HIBLOW compressors

- absolute environmental safety

In addition to this, EKODIN, in comparison with similar biological wastewater treatment systems, is distinguished by its low cost and minimal maintenance costs.

The unique patented design of the wastewater treatment plant eliminates emergency situations when working. In terms of reliability, sewage treatment plant EKODIN is superior to other, more computerized stations.

To get acquainted with the prices for treatment facilities and buy a septic tank - go to the section prices for septic tanks.

Article tags: sewerage in a private house, local treatment facilities

Click on the topic name to learn more:

You may also be interested in:

| Who supervises the installation of sewage systems in a private house? Find out the list regulatory documents private sewers and authorities who can check the private sewers. You can also avoid popular violations of the installation of sewage |

|

| Private house wastewater treatment: problems, processes and methods What to choose: a cesspool in open ground, storage tank, mechanical septic tank or biological wastewater treatment? |

|

| Sewerage system in a private house and its operation Autonomous system sewerage in a private house, operation and causes of possible malfunctions. Tips for troubleshooting the ECODIN treatment plant |

|

| Sewerage installation in a private house, rules and features Installing a sewage system in a private house is a direct necessity for a modern person. Why is the installation of ECODIN sewage treatment plants one of the best solutions? |

Private houses of modern people cannot do without a stable, productive sewage system. Unfortunately, the owners do not always have country houses have the necessary cash and the possibility of installing a sewer system in country house... What if there is no opportunity, but the need has already arisen?

The optimal and profitable solution to the problem that has arisen is the installation of a treatment plant for the house, which will take on the role of a central sewerage system, and also provide country house with all the necessary benefits of civilization. What are the treatment facilities (septic tanks), and which of them are worthy of your attention? We will understand this issue immediately!

Two types of septic tanks

Autonomous local treatment facilities, or simply, septic tanks for a private house are divided into two main types, let's look at the differences:

Accumulative septic tank

A view that is simple in terms of the principle of operation and design, which is a sealed chamber. A sewer pipe is connected to this tank, through which household goods flow into the chamber. Waste entering the storage septic tank accumulates inside, after which it is pumped out using the pump of the sewage machine.

Septic tank with biological treatment

A complicated design consisting of several chambers connected in series, each of which performs a specific function.

As a rule, such treatment plants for country house contain 3 cameras. The first chamber of a deep purification septic tank performs the function of dividing domestic water into several fractions, and the second and subsequent chambers serve for mechanical and deep biological wastewater treatment.

Obviously, deep purification septic tanks are more preferable if the constant use, performance, reliability and durability of the local treatment plant is pursued, as well as in cases where it is important to minimize the negative impact on the environment.

Septic tanks Evrolos BIO are unpretentious representatives of pumping treatment plants. In turn, Eurolos PRO is efficient compressor aeration units. The price of both systems will pay off with high power and long life.

In addition, when using these stations, there is no need for additional wastewater treatment - this saves space and money.

Owner reviews

Why choose Eurolos?

You have not yet decided what to buy a treatment plant for a country house? We invite you to turn your attention to septic tanks from Eurolos - the following positive qualities will undoubtedly satisfy you and push you to make the right decision:

- High strength and reliability of the structure, which, thanks to the use of polypropylene sheet, is completely environmentally friendly and is able to withstand high soil pressure. The guaranteed service life of the body material is 50 years!

- High degree of wastewater treatment, as well as the simultaneous use of mechanical and biological treatment. For example, septic tanks BIO and AU PRO are high-performance treatment plants that provide an unsurpassed level of wastewater treatment, up to 95-98% and do not require the construction of a zone for additional wastewater treatment.

1.

2.

3.

4.

5.

Owners of country houses and summer cottages sooner or later are faced with the need to install treatment facilities for the disposal of waste effluents. There are several options for solutions on how to organize the processing of household waste without harming the environment in the adjacent area.

Treatment facilities for a private house help to avoid contamination of groundwater and drinking water sources, which are wells and boreholes.

In the case of installing a shower cabin, a kitchen sink and the need to connect a washing machine to the sewage system, the device of purification structures becomes relevant.

Types of treatment facilities

There are such main types of wastewater treatment plants:- cesspool;

- septic tank;

- additional wastewater treatment systems;

- biological treatment plants.

It will also require the arrangement of a convenient entrance for special equipment and compliance with the sanitary zone. It becomes impossible to use water wells and artesian wells in the surrounding area.

In addition, the disadvantages of cesspools are:

- the presence of an unpleasant odor;

- the risk of flooding during floods;

- small capacity.

Then pipes are brought to the tank through which the drains flow and the ventilation is brought up. From above, the container is covered with a lid, laying it on a high neck. It will be necessary to install a control system over the level of effluents. When filling the tank, a fecal pump is used to pump out the contents.

Such a treatment plant arrangement is better than a typical cesspool, since there is no soil pollution. In addition, the design of the tank in some cases allows for further expansion of the system with the arrangement of a septic tank.

Option two - septic tank device... Such treatment facilities for a private house as the simplest two-level septic tank are characterized by simplicity of solution and efficiency of waste treatment. It is characterized by the presence of two containers connected to each other different ways... Among the many options, this could be multiple tubes or a single tube. There are many models of septic tanks on sale, and each has a different design. True, two-level autonomous treatment facilities should be located away from a well with water.

In the first container, the waste liquid settles and becomes a relatively clean muddy substance, provided that detergents and aggressive substances are not used.

The second container is a filter with many holes, which is filled with a spongy mass (expanded clay or foam) capable of absorbing solid waste. As a result, purified water is discharged outside, which is used for technical needs, for example, for irrigating a garden and a vegetable garden.

The operation of a sewage treatment plant, which is a multi-level septic tank, such as in the photo, is an expensive pleasure. These structures are bulky and difficult to install. They consist of 3 or more containers connected to each other. After cleaning in such a septic tank, the waste is separated into process water and silt deposits. The clarified liquid can be drained into a nearby body of water or used for watering.

Caring for such a multi-level treatment plant consists in leveling the structure from distortions due to soil movement.

Option three - installation of an additional wastewater treatment system... In this case, the scheme of wastewater treatment facilities involves the arrangement of filtration fields and wells. On large plots, the area of \u200b\u200bwhich is several hectares, owners can afford to equip green lawns - it is under them that wastewater will turn into life-giving moisture.

On the territory of no more than 10 acres, it is impractical to arrange filtration fields, it would be more reasonable to use the services of sewers several times a year or manually pump out the collected sediments from the storage device of the structure.

Option four - installation of a biological treatment system. Sell \u200b\u200bbiological wastewater treatment plants as a single complex. Their cost is high, plus when buying, you will need to pay about 10% of the price for installation. As a rule, wastewater biosystems function perfectly under the condition of regular maintenance, during which the integrity of the complex is checked and consumables are replaced.

Biological modular wastewater treatment plants are monitored at least once a year, while the cost of maintenance is quite affordable. The system is similar in its parameters to the operation of a compact and highly efficient septic tank.

Optimal systems for a private house

As practice has proven, a split system is the optimal treatment design. For example, fecal waste is cleaned in a peat dry closet. To process the used water entering the sewer from the washing machine, from the kitchen sink, shower, install storage tank or a septic tank.

In the case when hygiene procedures and washing are performed using environmentally friendly means, it is possible to simplify the cleaning process and use solid and semi-liquid waste for the production of compost fertilizers. They are removed from the drive independently. There are other options that property owners choose based on their specific needs.

Wastewater treatment system maintenance

Each system and any equipment for treatment facilities needs periodic maintenance, pumping of collected waste, and replacement of reagents. It is advisable to entrust the maintenance of local treatment plants to professionals who are engaged in the installation of such facilities. You should also monitor the integrity of the tanks. As a result of damage to the treatment tank, an unpleasant odor appears at the site and a sharp deterioration in the quality of water coming from the wells occurs.The fact is that large reservoirs are pressed by soil and groundwater. To control the level of groundwater occurrence, it is necessary to build a storm sewer.

Stormwater treatment systems

When a suburban private house, it is necessary to design wastewater treatment facilities in the local area.Conditionally, the household sewage system is divided into three types:

- sewage treatment system that removes and processes fecal matter (high degree of biological activity and pollution);

- household waste water, food waste residues. In the case of using chemically active agents, the waste liquid is environmentally hazardous. If aggressive household chemicals are not used, then the drains, although they require cleaning, are absolutely safe for others;

- rain and melt water. To drain storm water and drain the site, you need to equip a special treatment system (more details: "").

When groundwater enters the well, it should be pumped out. Even if the sewer tank is secured with concrete slabs, a high level of occurrence of a water layer is able to push it out of the ground. In this case, the container is likely to be damaged, and its contents will spill onto the ground. As a result, soil disinfection will be required.

Storm drainage device

Mechanical wastewater treatment facilities are as follows. Plastic drainage pipes or halves of products are laid at the bottom of the shallow grooves, while leaving their top open. The grooves with pipes are arranged so that they have a slight slope in the direction of the drain location (for more details: "").A storm sewer is built around the building to protect the foundation, directly under the paths and the drainage system is led into a ditch. In areas where groundwater is shallow, deep ditches are usually kept open to dry the soil. It is there that the storm sewer is directed.

You can also arrange the drainage of rainwater into the sewer system. But this option is provided in the event that it is not possible to take them out into a ditch or a stocked pond, filled with purified water coming from a septic tank.

Being engaged in the arrangement of a sewage treatment system in their own households, the owners, through their own experience, begin to understand the meaning of the struggle for the environment in foreign countries. Abroad, people prefer to wash dishes with mustard powder and soda for floors and windows. They use soap root shampoos.

The use of environmentally friendly means in everyday life can significantly save on the design and operation of treatment facilities.

A large number of wastewater treatment plants from both Russian manufacturers and foreign analogues are represented on the Russian Market. And everyone, from Manufacturers to Distributors, are touting their products with each other! Everyone assures that their systems are the most reliable, that they will work for a long time, and most importantly with high quality in any operating conditions.

They say the truth, - Fear the Danaans who bring gifts!

An inexperienced consumer may be dizzy with such a variety of choices! And yet you have to make a choice! Right choice! After all, Local Treatment Facilities are one of the most serious issues in organizing a comfortable Home, although many treat it lightly! VOCs will not change every three years, like a car. As a rule, what you have chosen is what you will live with and put up with. This usually happens! After all, it is hard to admit that the choice was once made the wrong one, and you followed the lead of the Seller. Even if you have realized this, it is not easy to go to the idea of \u200b\u200bdigging everything over, digging up the old and putting on the new.

To do right choice, you need to put a lot of work and patience, study this issue, as they say from the inside, browse the entire Internet and chat on forums, read a lot of special literature.

We decided to make it easier for the future buyer.

To do this, we propose to consider the products of leading companies presented on the Russian Market and make a choice ourselves in favor of the best.

We will take the most prominent representatives of VOCs that are heard today, and try to objectively conduct a comparative analysis between them.

So, the comparative analysis will include:

- TANK (Russia);

- GreenRock (Finland);

- UPONOR (Finland);

- Carat-S (Germany, official representative in Russia, LLC "EUROVODA")

- TOPAS, TOPOL (Russia);

- YUBAS, EUROBION (Russia);

- GRAF KLARO (Germany, official representative in Russia, LLC "EUROVODA");

- FAST (USA);

- NV (Lithuania)

- GRAF PICOBELL (Germany, official representative in Russia, LLC EUROVODA);

The rest of the models, from other manufacturers, practically repeat some of the presented competitors.

Here, in our opinion, basic requirements for VOCs that modern treatment plants must meet:

- Purification principle (Septic tank, BIoreactor, SBR reactor);

- The total volume of the station;

- Station type (Flow type / SBR reactor);

- Treatment methods (anoerobic, aerobic, anoxic zones);

- Purification degree according to the manufacturer's statement;

- Maintenance (frequency per year);

- The use of household chemicals of non-BIO origin, chlorine;

- Large rubbish, toilet paper;

- Volatility (Yes / No);

- Station performance in case of power outage;

Let's consider these systems in more detail.

1. Septic tanks: TANK, FAST, GreenRock, UPONOR BIO, Carat-S.

These are classic septic tanks, however, with small innovations, which, in our opinion, are only advertising stunts to raise interest in the product.

The septic tank in Russia is well known to everyone. These are two, three containers in the ground from concrete rings (three, four rings each) Tanks, according to technology, must be completely sealed. These tanks are connected in series sewer pipe with a diameter of 110 mm, so that the drain cascade (by gravity) smoothly overflows from one container to another. In septic tanks, wastewater treatment is used by settling, i.e. anaerobic (oxygen-free) method. This method has been known since ancient times. It was noticed that if the drain is left alone for 3 days, then an interlayer of clarified (transparent) water will form on the surface. Accordingly, if overflow from one container to another is organized in a cascade, then all sediment and large debris will remain at the bottom in the containers, and clean water will come out of the third container at the outlet of the third container.

It is desirable that the total volume of the septic tank be equal to the 3-day water consumption, because in this case, the cleaning is of the highest quality! Many people neglect this coefficient, but in vain! The fact is that we clean the drain only so that later we can dispose of the drain water, purified of most impurities and fats, on the spot, into the ground, and not spend money on exporting it as a sewage drain. Indeed, there are 95-98 percent of water in the sewage, and only 2–5 percent of impurities, human waste products, household chemicals, fats. And when in modern house all amenities are brought into the house, the daily water consumption, respectively, and the drainage is on average 1m³ - 1.5m³ per day. A week and you need to call a flusher! Pumping services in different regions cost differently, but on average 1.500 rubles. - 2.000,00 rubles. If you press the buttons on the calculator a little, it becomes clear that the conveniences in the house are not cheap per year, approximately 100,000 rubles. in year

Advantages of these systems:

- perfectly defend drains and separate water;

- no need to worry about pouring into the sewer;

- not energy intensive, i.e. no electricity required, everything flows by gravity;

- MOT (dirt pumping) once a year.

Minuses:

- Smell because there is no aerobic treatment of the effluent, but with sealed hatches and well-organized ventilation, this disadvantage can be omitted.

- bOD and BB indicators are much higher than permissible values. Therefore, the drain is considered dangerous for humans and it must be cleaned (prohibition of discharge to the surface).

- The durability of drainage fields is less than when using treatment plants such as BIoreactor, because more frequent soil siltation occurs.

The use of various BIO loads in septic tanks, of course, gives a small effect in the quality of cleaning, but more, only to increase the cost of systems, and they are also tied to the company that sold the system, because BIO downloads must be changed at intervals of 1-3 years (check with the manufacturer), and these are additional costs.

SEPTIC Green Rock IISI 6

This system is a 3-chamber septic tank with a post-treatment filter filled with BIO loading. The manufacturer presents this system as a biochemical sewage treatment plant.

Before the start of wastewater treatment, it is treated chemically by adding a coagulant (aluminum sulfate) to the wastewater, after which the wastewater is directed to a 3-chamber septic tank. The principle of passing the drain from the first chamber to the second is better to learn from the sellers. From the information that is available on the websites of Sellers, it is difficult to understand the nature of the flow through the T-shaped overflow. The water clarified by 40%, from the 2nd chamber, enters the BIO filter using a circulation pump. Water is sprayed with a nozzle over the top of the BIO load, on which, according to the Manufacturer, large colonies of BIO bacteria have become entrenched. Further, the water enters the 3rd chamber for removal from the treatment facilities.

The price of Green Rock IISI 6 is 225,000.00 rubles.

For comparison, the Graf Picobell BIO reactor of the same capacity costs 150,000.00 rubles in Moscow.

And this is the cost only for the cleaning station, and you still need to spend money, and not small ones, on the complete organization of the VOC, where the cleaning station is only one link in the overall system! It is also necessary to take into account the fixed costs of purchasing chemicals.

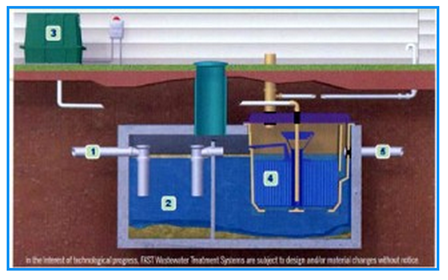

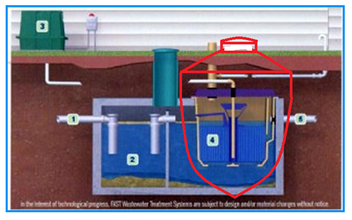

SEPTIC FAST

Yes, fans of the FAST system will forgive me, but this is the only system that I want to criticize, without apologizing, and question the assurances of FAST representatives.

Representatives of the American septic tank FAST advertise it as a deep biological treatment system, i.e. like a BIO reactor. However, if you carefully consider it, this is the same septic tank with applications for a BIO reactor. In other words, FAST is the modernization of septic tanks and drain pits. According to the principle of operation, it vaguely resembles the Baltic BIO NV reactor. But he is too far from NV, tk. it is, in our opinion, morally outdated.

Let's take a look at what FAST has to offer!

The classic approach to the design of a treatment plant for all manufacturers begins with the fact that they decide in which container they will create their treatment facilities. After all, from a high-quality container, at least 50% of success. Then they think about how to organize inner space this container so that the flows passing through the organized zones at the outlet are as clean as possible. They calculate the volume of containers depending on the performance of the systems, think over an algorithm for aeration of wastewater, settling, pumping from one zone to another, because the quality and reliability of cleaning depends on this.

The Americans, on the other hand, took the path of universalism, without much thought about an integrated approach to the cleaning station. FAST is an aerobic wastewater treatment unit that fits into any suitable container and works like a BIO reactor.

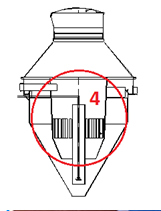

In the figure, zone 4 is the FAST BIO reactor. There is no point in describing this block, since this is one-to-one principle of the BIO reactor NV, and we have described this system more than thoroughly! If you remove all conventions, then this is visible with the naked eye! Here's a look:

FAST NV

Are they not similar? Like TWINS! Only NV is a comprehensive proposal for a treatment system - a BIO reactor in a high-quality case, with the correct logic of operation, and FAST is only a unit that works only for BIO treatment of effluent, for separating PLA from water, but how high-quality it is - you can only find out from users of this brand on forums on the Internet. The principle of operation is clear, it only smells of handicraft. Many who understood the NV principle also wondered, is it possible to repeat this principle at home? FAST Proves You Can ...

We will not prove that FAST is worse or better than others in the field of wastewater treatment, if it exists and it is more than 30 years old, then it still cleans.

We will just figure out how FAST offers to organize, on the basis of its block, a cleaning station. We will find out if it is worth the money that Sellers ask for it and figure out the frequency of maintenance. I think this is enough to get a complete picture of FAST.

So, Fast proposes, when organizing a cleaning station, to cast concrete bowls directly on the territory of the Customer or to use existing concrete structures (drain pits).

They offer two options.

1) a one-section concrete container (drain pit), a FAST block is inserted into it;

2) two-section concrete tank (two-chamber septic tank), the FAST block is inserted into the second chamber.

Concrete tanks are not included in the price, these are additional costs of the Customer.

The cost of the smallest Retro FAST system 0.25 (600 l / day - 3 people) \u003d $ 3800, which is approximately 125.000 rubles. Next, we add the cost of the container itself, where the drains will be merged, this is, according to various calculations, from 30,000.00 to 60,000.00 rubles, it all depends on the performers and the quality of the container manufacturing ( concrete works, waterproofing) and the cost of installation work on the organization, in fact, of the BIO reactor itself. The cost imperceptibly crept up to 200,000.00 rubles.

This is only the cost of creating a cleaning station. But since the wastewater after cleaning must be disposed of in the ground, the creation of a post-treatment system in the ground leads to additional, necessary costs. It turns out that this system, or rather a block from which you can make a system, is not at all cheap! The question suggests itself - Why buy a semi-finished product, when for this money you can buy ready-made solutions on the Market and cheaper than FAST /

Scheduled maintenance FAST sellers recommend to do it once every 3 - 5 years. Miracles do not happen! Garbage, ILA and fats during waste treatment, in different systems, accumulate approximately the same amount and FAST is no exception! So why, then, all Manufacturers recommend doing maintenance at least once a year, and FAST once every 3 years (the language does not turn out to be 5 years old). FAST's capacity is not much different from other systems. Therefore, in 3 years, if not cleaned, there will be such jelly in the container that the quality of the drain is unlikely to be satisfactory.

The declared data at the exit from the FAST system cannot be high, at least for a long time. This is due not only to the design of the system, but to the recommendations given by the FAST Representatives (to carry out pumping out no more than 3 - 5 years).

Why did we classify FAST as a septic tank? The fact is that having organized the aerobic zone, the system cannot be considered a BIO reactor until a high-quality anoxide zone (secondary settler) is organized, where the PLA settles with its subsequent discharge into the primary settler or a special PLA seal.

Someone might think, reading this article, that we are biased in our judgments. And we do not hide this. We are quite biased about systems in which Sellers, by advertising the merits of the systems, deliberately hide their deficiencies and the true cost of VOCs.

SEPTIC Carat-S

The German firm OTTO GRAF did not follow the path of advertising gimmicks. I just offered a classic septic tank based on a high-quality Carat-S tank and gave a 15-year warranty. We believe this is an honest approach. After all, it is still necessary to clean the drain in the ground and there is no point in complicating everything, because the level of purification, as in BIO reactors, cannot be achieved by a septic tank, and additional costs for the Customers are obvious!

The Carat-S septic tank is reliable and simple. All overflows are made from a pipe with a diameter of 110 mm. The overflow design is such that fats are retained in the 1st and 2nd chambers of the septic tank. The structure is rigid, does not require additional reinforcement. The volume of the septic tank is equal to a 3-day discharge. Not energy intensive. It is recommended to pump out wet sludge once a year.

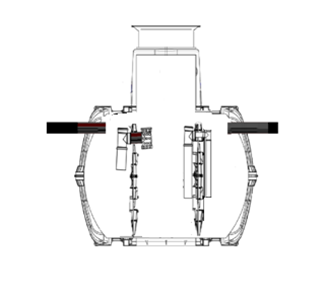

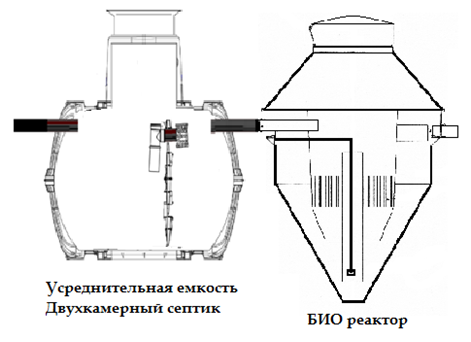

2. BIOREACTORS: TOPAS, TOPOL, YUBAS, EUROBION, ASTRA, BIOXY

In fact, this is one and the same SBR (Sequence Batch Reactor) reactor that was once developed by Czech engineer Jan Topol and from the outside these systems look like twin brothers:

And inside, the working part of these systems is very similar, with minor changes and upgrades, all the same manufacturers are different and the systems should be at least slightly different from each other.

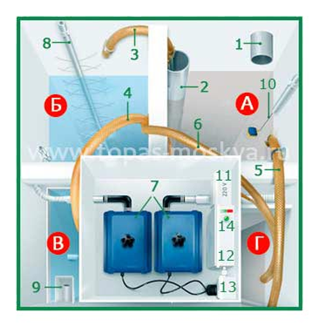

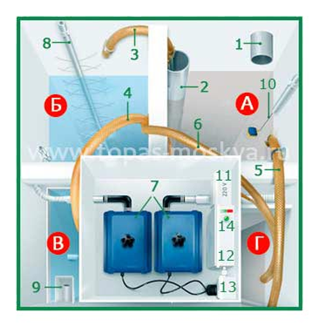

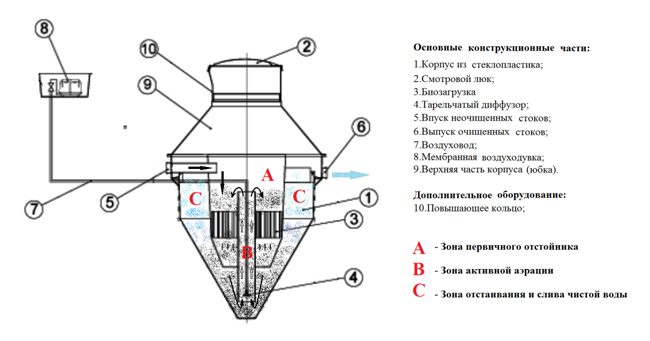

Name of compartments

AND. Receiving chamber

B. Aeration tank

IN. Secondary settling tank

G. Active sludge stabilizer

Topas device

1.

Drains input

2.

Coarse filter

3.

Airlift, main pump

4.

Airlift recirculation

5.

Sludge pumping airlift

6.

Stabilized sludge airlift

7.

Compressors

8.

Non-recyclable particle collection device

9.

Purified water outlet

10.

Level sensor

11.

Junction box for connection

supply cable

12.

Control block<

13.

Compressor sockets

14.

Station on / off button

Advertising of these systems on the territory of Russia is the largest and most aggressive. Relatively for little money Sellers of these systems offer a solution to all the Customer's problems associated with the treatment of household wastewater, both a small house and objects the size of a small village (up to 32 m³).

But as they say - Fear the Danai bringing gifts!

Systems operating on the principle of SBR reactors really give good results and work flawlessly if conditions are created for them and strictly monitor the timely scheduled maintenance, which leads to additional costs and not small ones. The Sellers of these systems deliberately keep silent about this fact or do not emphasize it, because it will compromise their systems.

Let's find out - are these systems really as flawless as the Sellers claim? What is true and what is a publicity stunt? Is it really a cheap product or is it still the initial price, and the main costs are ahead?

I propose to investigate these systems using the example of the TOPAS system, because the rest work on the same principle and there is no point in listing them every time.

The TOPAS station is a plastic tank in the shape of a parallelepiped, divided into four zones inside. These zones do not naturally communicate with each other. The total volume is underestimated to 2.4 daily intake of wastewater ( for small objects a 3-day volume is desirable), but the manufacturer believes that this is sufficient, since the methods that are used in TOPAS stations do the job well.

I would like to question such confidence, tk. laboratory indicators are very different from the realities of life. When the wastewater flows uniformly, without large admixtures of chemistry, without large salvo discharges, when the system has not yet accumulated large ballast in the form of old sludge, and fats do not interfere with the cleaning processes, then we can agree with the statement of the TOPAS manufacturers that their SBR reactor is a good solution in cleaning drains. But if the Customer only has to forget about the precautions and dump into the system, for example, chemistry of non-BIO origin, or drain more than 250 - 350 liters of water in one gulp, then the system will fail.

The fact is that SBR reactors do not provide for the main principle of treatment facilities - natural (cascade) flow of flow from one treatment zone to another, according to the principle, as much flow has arrived, so much has left. In systems of this type, the stock is processed in batches and at regular intervals. It cannot flow from one chamber to another on its own, after being processed in the first chamber it is transferred in portions to the second, there it goes through the next stage of processing and again it is transferred by the airlift to the third chamber, etc.

The success of the SBR reactor depends on the amount and intensity of effluents entering the plant, they must be strictly regulated. And the point is not only that the volumes are too small for freelance salvo discharges, but the productivity of airlifts pumping wastewater from one zone to another. After all, they must, at the time strictly allotted to them, pump a certain amount of wastewater into a neighboring tank. If you make the volumes large, and leave the power of the airlifts the same, then this will not give the desired effect.

Now let's talk about the microflora of this system! Why won't the system tolerate household chlorinated detergents?

In systems of this type, everything is squeezed to the chapel and the places for fixing microorganisms are practically not provided. Microorganisms in these systems are in suspension, i.e. in free float. And if chemistry gets there, then the first to suffer are microorganisms. They simply die, and new ones do not start so quickly.

The issue of Fats, which are rich in household wastewater in cottages, is also not properly resolved in TOPAS, and if a fat separator is not installed in front of the system in the circuit, then the fat enters the system and gradually clogs all the working zones of the system so that after two, For three years, the systems stop working normally even after maintenance.

Manufacturers, when advertising their product, reward themselves with the fact that thanks to the method of alternating aeration of wastewater in all zones of the system, they were able to abandon the anaerobic processes that take place in the primary sedimentation tanks!

This is a very controversial question! For high-quality wastewater treatment, a primary sump is necessary! In it, those processes take place due to which the wastewater entering the aeration tank is processed more efficiently! In the primary sedimentation tank, the effluent is prepared, the effect of chemicals is softened, the main dirt and fats are retained. Therefore, if TOPAS had a primary sump in the form of a high-quality 3-chamber septic tank (or at least a 2-chamber septic tank), then the TOPAS system could be considered a wonderful system that gives good results! But then the idea itself, - SEPTIC WITHOUT PUMPING OUT, becomes unfeasible! And the loss of the banner leads to defeat in the advertising campaign.

The smell in TOPAS, in spite of their Developers, IS! Despite the lack of a primary sump!

Where the family consists of all workers or students, that is, where there is no constant load on the system and it can, while no one is at home, process part of the incoming drain and free up the container for receiving a new portion, the system works stably! Just do not forget to do quarterly maintenance, otherwise TOPAS will fail.

But where there is always someone in the house, whether it is a cleaning housekeeper or small children who make the washing machine work in high-intensity mode, frequent guests and generous feasts, tasty and fatty food, that's where TOPAS malfunctions, for objective reasons, it it simply does not have time to process everything that goes into it. Therefore, in such houses, the sellers of SBR reactors advise buying systems with a higher capacity, for example, not TOPAS 5, but TOPAS 8 or even TOPAS 10, where salvo discharges are slightly more - not 250 liters, but 400 liters or 700 liters. And there are most of these houses in Russia!

The absence of a primary clarifier that traps large debris, fats and active chemistry on the one hand and a small amount of BIO bacteria on the other hand do not guarantee that these systems will give consistently good results. Naturally, the indicators for discharge standards do not correspond to reality. Therefore, it is very strange to hear when TOPAS representatives claim that treated effluents from their installations can be discharged superficially onto the landscape without additional purification in a sand and gravel filter or in a special post-treatment installation for treated effluents. Moreover, it is not clear how it is possible to advise watering not up to purified water from the system - the beds in the garden! Why should the customer figure out for himself that pouring residual sludge into a compost pit for its further use as a quality fertilizer is rich not only in processed natures. product, but also chemistry and fats? ... Our opinion, - Only dispose of with export! Anyone who has built a good house and can afford modern sewage treatment plants can afford to bring a car of good humus.

Now I would like to talk about planned tech. services.

In our opinion, the system is troublesome to maintain. No wonder, after the sale of these units, it is recommended to conclude a service agreement. After all, if not specially trained people take care of TOPAS, who, by the way, have to be paid, then the Buyer of this system will have to deal with this himself and become a specialist in this matter!

For those who have never done this, I can say that this activity does not bring much inspiration! After all, watching the waste of life, even if it is your own, is liked only by great aesthetes or those who treat it like work!

Usually, the customer is ready to pay for maintenance and does it on his own only when his budget is in great difficulty! That is why the companies serving these systems are developing so successfully now. The cost of services for 5 years usually covers the initial costs of purchasing and installing the system, in the Moscow region it is approximately 100,000.00 rubles. - 120,000.00 rubles. not counting the cost of electrical equipment and additional. Expenses that pop up for anyone.

Some readers may say that we are exaggerating that we shouldn't be talking about the Wonderful System. May be so! But before making such conclusions, it may be better to go to the official sites representing these systems and look at the maintenance section. You can read everything that we just talked about from conscientious sellers, they do not hide it, but there are others who know that this information will damage the sales image of these systems, so it is not so easy to get an answer to the question posed from them. And when you begin to understand how much this system, in fact, complicates life, because there is no effect of the central sewage system (leaked and forgotten) and unfortunately there will be no such system, then the question arises, is it not better to make a large, high-quality reservoir and drain into him sewer drains without thinking about what can be drained and what not! And then once every two weeks or once a month call a sewer truck, pay and not think about the sewage system until next time? ... But honestly! How much I filled in, so much and paid for the export.

Of course not better! You need to understand why we are cleaning drains? After all, not in order to water the tomatoes in the beds with them, but in order to then save on the constant costs of removing sewage with a sewer machine. It is necessary to clean the drain only so that when it is disposed of into the ground, it does not violate the properties of the soil in its ability to absorb water for as long as possible! It is categorically impossible to dump water on the surface after the treatment plant, even with laboratory indicators of 98%, without additional additional treatment. After all, TOPAS sellers, even with such high purification rates, as they claim, will not drink this water from their installations, and why? Wrong because this is only a publicity stunt! Today, not a single manufacturer can guarantee the purity of the effluent from the installation and the discharge indicators in the water protection zone, because discharge quality directly depends on each consumer and correct operation! And if at least 30% of the Buyers do not conscientiously operate these systems, then it is impossible to say that the drain will be safe at the exit!

So, the TOPAS system and the like, if objectively, good SBR systems give excellent results, but only where the sewer drain is simple or has undergone good preliminary preparation, when there are no overloads on drains, and most importantly, if the Consumer is Conscientious and Disciplined. From all that has been written, this system cannot be called reliable with a large margin of safety. It can only be recommended to a part of the population. For houses with a broad Russian Soul, it is unlikely that it will fit, most likely it is for a disciplined European Consumer.

By the way, we would like to draw your attention, adherents of SBR reactors, to the German SBR system by OTTO GRAF, this system is called Graf Klaro. The system can lead the SBR reactor line in quality and processing efficiency! It, like all of its competitors, should not allow too large salvo discharges, but this system does not require frequent Maintenance and OTTO GRAF recommends pumping out the accumulated sludge only ONCE A YEAR. The station is designed in such a way that the volume of the sediment chamber is sufficient for at least 12 months of full operation.

Only two cameras versus four for TOPAS, as it turned out, two cameras are quite enough, a large total tank volume, on the basis of which the system was made. The processing quality is the same as for all SBR reactors, very high, but the safety factor is much higher than the Russian counterparts.

Maintenance of these systems can also be done independently, but much easier, because fewer technical complications that interfere with the comfortable use of these systems. All electronics are removed from the station. In the tank, only disc aerator and airlift. Everything is very simple and straightforward. Another not unimportant plus of this system is that all OTTO GRAF systems are made on the basis of a high-quality Carat-S tank. It does not require additional reinforcement during installation. It is made of injection molded plastic with good stiffening ribs. The OTTO GRAF Carat-S tank has a 15-year warranty.

3. BIOREACTORS: NV, Uponor, GrafPicobell

BIOREACTORUPONOR

PROS systems UPONOR BIO CLEAN

A wonderful system that does its job in good faith.

This is a biochemical unit for batch cleaning. The system combines BIO wastewater treatment with chemical action at the final stage, for the separation of dissolved phosphorus and nitrogen from the water.

BIO processing consists of two stages:

- Mechanical is a primary settling tank in which large debris settles and runoff is averaged.

- Biological - here it is based on the SBR principle of reactors PERIODIC aeration and settling of effluents, followed by pumping of the separated sludge into the primary settler, and the sediment water flows by gravity into the secondary settler.

Chemical processing:

- In the secondary sump, chemical reagents are automatically dosed.

The system, if you do not give peak loads exceeding the permissible volley discharges, gives excellent results. The degree of purification is high.

CONS of UPONOR BIO CLEAN system

1. This system has no protection against Fats, it is necessary to install a fat separator in the kitchen;

2. A very highly intelligent system. Almost everything is provided, starting from the intensity of wastewater treatment (it tracks how much wastewater enters the installation), ending with a reminder when it is necessary to call a sewage truck! It also reminds you when you need to change the chemical canister.

Why did we bring these achievements of human thought to the MINUSES of the system? It's great when the computer thinks for us and warns in time about all the problems that we may have!

The fact is that the computerization of cleaning systems leads to dependence on the manufacturer's company! The buyer cannot do without high-quality support of this system. He will have to meet with the supervisor at least once a year to carry out routine maintenance. If the computer is out of order, then the system turns into an ordinary 3-chamber sump (septic tank) until the arrival of a specialist and the error is eliminated. Any specialized maintenance of such intelligent systems leads to additional costs and dependence on the seller.

3. The use of Chemicals is not a bad decision, but an additional burden on the Buyer's responsibility. At the very least, he will have to constantly take care of the Chemicals, which cost from 200 to 350 Euros annually.

4. Relatively short warranty period of 5 years for a fairly high technology and expensive system.

5. For a system designed for an average house. Price is prohibitive, approximately 320,000.00 rubles. RF. This is the price of only a treatment plant, without solving the entire problem of building Local Treatment Facilities (LOS). The station is responsible only for high-quality wastewater treatment.

Question, - Why do we clean the drains?

Answer, - in order to save money on pumping out sewage with sewage machines! Only for this purpose they clean the drains, so that the purified water can then be disposed of in their area into the ground, and if the soil does not allow, then it should be discharged superficially, using the landscape of the site, into a storm ditch, but for this, the drain must then undergo additional purification. Conclusion - we clean the drain in order to subsequently dispose of it into the ground! The cleaner the cleaning, the longer the PRIMER will serve us!

From all that has been said, it is clear that if we consider the organization of the VOC in full, where the treatment plant is only a link in all chains, then the cost of the project can grow to 450,000.00 - 500,000.00 rubles. RF. The second part of the task is to construct a VOC, i.e. the organization of drainage fields for water disposal is associated with earthworks and a large amount of consumables (crushed stone, sand, equipment), so these costs must be taken into account when solving the problem of building VOCs in your home.

BIOREACTOR seriesNV from the firmTraidebis

A wonderful system for a country house! Not without flaws, but they can be considered insignificant when you understand how this system works.

A wonderful system for a country house! Not without flaws, but they can be considered insignificant when you understand how this system works.

I propose to first look at how NV works, and then discuss its pros and cons.

The system is made of reinforced fiberglass, has a tapered geometry, it can be immediately distinguished from the entire range of systems presented on the Market.

The system consists of three cameras AND, IN and FROM... Zones AND and IN are inside the cone-shaped zone FROMand do not have a bottom, this is a fundamentally important feature of this system. In fact Large capacity FROMit is logically divided into three zones and the drain does not experience difficulties when moving from one zone to another; the principle of communicating vessels is used. Thanks to this division into zones, the system works without difficulty, reliably and stably.

Zone IN is a pipe with a diameter of 200 mm, into which a disk diffuser is inserted. When air is supplied to the zone IN there is a thrust, as in a huge airlift, and the drain passing through the zone AND sucked into the zone IN and carried by air bubbles moves upward in the pipe IN up, getting back into the zone AND... And everything starts all over again, the drain under the influence of gravitational forces tends downward, passing through the honeycomb, the places of fixation of the BIO bacteria, is maximally exposed to the BIO effect and at the exit from the zone AND picked up again by a giant airlift up to get back into the zone AND... Part of the PLA at the exit from zone A fills the zone FROM (Sedimentation area). The cone shape of this system plays an important role in the treatment of effluents at the settling stage, the entire IL under the action of gravitational forces settles at the bottom of the Zone cone FROM, and the closer to the exit the water becomes almost transparent.

With such a treatment solution, it is clear that the runoff in the zones AND and IN is maximally in motion, subject to deep aeration and is constantly in the zone of action of BIO bacteria, and in the zone FROM maximum rest comes, which gives a wonderful result.

The NV system, from all that has been said, is really both in appearance and in essence reactor - BIO REACTOR.

prosNV:

- simple and straightforward, like a 3-chamber septic tank, and yet it is a BIO reactor;

- nothing to break;

- all processes in the system are started by only one compressor supplying air for aeration;

- due to the fact that the capacity is divided into zones only logically (this is due to the fact that the zones AND and IN without a bottom), it can be considered as a whole. The volume is approximately equal to three daily drainage rates. In the event of a power outage, it turns into a 2-chamber septic tank.

- flow-through system, i.e. how much profit - so much left, there is nothing to break and nothing to clog.

- thanks to honeycombs, made of foamed nylon, fixed in the zone AND, a large number of microorganisms multiply in the NV system, which process the effluent. Large colonies of bacteria give the system a good margin of safety and allow the Consumer, in some cases, not to think about the quality of the discharge (household chemicals, toilet paper).

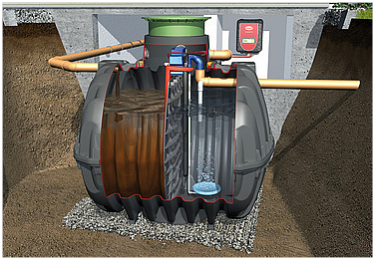

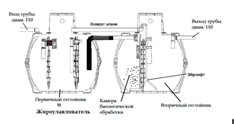

DEEP BIOLOGICAL CLEANING SYSTEMGRAFPICOBELL

![]()

The system is simple and perfect! The main principle is maintained - natural overflows from one zone to another, all overflows are organized by a pipe with a diameter of 110 mm. The overflow from the primary sump to the aeration zone is organized so as to retain all the fats in the first chamber, according to the principle of a grease catcher. The total volume of the system is approximately equal to the 3-day rate of discharge of wastewater into the sewer. In principle, this is enough to achieve clarification of water for subsequent discharge into the ground. The drawing shows that if there is no aeration zone in the second zone, then this system will be a classic 3-chamber septic tank. But thanks to a properly organized aeration zone, the septic tank turned into a BIO reactor with a large margin of safety, into a system that not only brightens the effluent, but also maximally lowers the BOD (the indicator by which determines how much the drain is biologically dangerous for humans), the lower the BOD, the higher quality of runoff. Cleaning quality 95% - 98%.

The Germans here too acted extremely honestly, not making any secrets from the proposed solution. Everything is very clear! Both in the drawing and in life. There is practically nothing to break and nothing to clog. Everything is made on the basis of a high-quality Carat-S tank, which OTTO GRAF uses in various tasks, from storm water collection to multi-level modular-type deep biological treatment systems.

Bioreactor on two tanks Carst-S System based on tanks Carat-S 18 m3 / day

Bioreactor on two tanks Carst-S System based on tanks Carat-S 18 m3 / day

Let's see how ingeniously simple a powerful BIO reactor with a large margin of safety is.

Here are the main indicators by which to judge the purity of the drain:

BOD - biological oxygen demand

BB - weighted

Surfactants - surfactants (in the domestic case - soap solution)

So, the effluent enters the primary sump.

1. Primary settling tank - a chamber for settling effluents, averaging their activity, settling large debris insoluble in water (paper, hair, sand, etc.). In this container, the strongest oxidants - chlorine, potassium permanganate, alkalis and acids - decrease their activity. Garbage, grease that does not dissolve in water, remains in this container and is pumped out once a year (or twice a year).

This tank is responsible for the first stage in sewage treatment - Anaerobic (without oxygen). In this chamber, additional fermentation, methanization ("combustion" of sludge by means of methane release) takes place. Thanks to anaerobic processes, the runoff becomes much softer in all respects.

I must say that the primary sump is a very important area in the wastewater treatment process! Firstly, all the garbage remains in it, secondly, fat is retained, which interferes with the processes at other stages of cleaning, and thirdly, the activity of Chlorine and other elements aggressive to the BIO environment decreases. Therefore Graf Picobell is resistant to detergents containing chlorine, alkali and acids! And the larger the primary clarifier, the more confidence that the quality of wastewater treatment will be high and stable!

After the sewerage runoff remains in the primary sedimentation tank (approximately a day), it enters the Aeration tank and undergoes aerobic processes!

2. Aeration zone- he is directly responsible for the active BIO wastewater treatment by means of AEROBIC bacteria, i.e. a community of bacteria that need oxygen to function.

It is important here that the runoff is pre-prepared, softened as much as possible from chemistry (as mentioned above), so that nothing interferes and does not harm the BIO-environment in the aeration zone. It is also very important that the bacteria participating in the wastewater treatment process are constantly as abundant as possible, so that they have a large number of fixing points from being washed out and destroyed by the escaping chemicals into the aeration zone!

Graf Picobell has used the so-called BIO loading to multiply bacteria in huge numbers! It makes it possible for bacteria to multiply and resist chemical processes and volley discharges.

Having got from the primary settling tank into the aeration tank (aeration zone), the effluent is actively oxidized by oxygen. Air is supplied to this zone through the aerators by the compressor, it is sprayed and enriches the softened waste with oxygen, bacteria come into play and do the most important thing, separate the sludge from the water. Rather, IL is a product of processing of household waste water by bacteria. It is done! The stock is divided into Silt and Water! Now the drain needs to settle. Therefore, the effluent enters the secondary sump!

3. Secondary settling tank - this is a zone of rest. If in the aeration tank the effluent is boiling in oxygen, we can say “BOOK”, then in the third chamber, which is called the Secondary settling tank, the processed effluent must settle. Which is actually happening. In this zone, the effluent enters the bottom of the secondary clarifier in a special way, so as to disturb the peace as little as possible! Sludge (suspended particles) is heavier than water and therefore settles to the bottom in a state of rest, and the water closer to the outlet from the secondary clarifier becomes as clarified and transparent as possible.

In the settling chamber, the elimination of nitrates and nitrites occurs due to the anoxide medium and the intensive activity of aerobic microorganisms, the nitrification-denitrification processes are launched, which ensures a good removal of nitrogen and phosphorus compounds from wastewater.

The settled sludge is pumped from the secondary sedimentation tank to the primary by means of an airlift! Due to the fact that part of the effluent is returned from the secondary clarifier every 15 minutes to the primary clarifier, the smell in the primary clarifier is significantly removed.

And since the water in the secondary sedimentation tank becomes, one might say, charged for wastewater treatment, together with the BIO-rich sludge bacteria, getting into the primary sedimentation tank, it starts the BIO processes already in it. Reliable, no cleverness system. He works out his money 100%

Pros of GrafPicobell:

- high quality wastewater treatment;

- no smell at the exit;

- it is allowed to dump toilet paper into the system and use non-BIO household chemicals in amounts that do not exceed the needs of an average home.

- the prostate in the design does not detract from its capabilities, but suggests that All ingenious - Simple!

- the risk of surface drainage of runoff into the storm sewer is minimal (but it exists, therefore the Manufacturer strongly recommends that the sewage should be cleaned after treatment in the ground or in a special post-treatment unit);

- Scheduled maintenance is carried out 1 - 2 times a year;

- Maintenance is simple and straightforward! Call the Flusher 1 TIME A YEAR, open the hatch, insert the pumping into the first chamber, pump out, fill with water, close the hatch. THAT'S ALL! The manufacturer tried to get as close as possible to the principle of CENTRAL sewerage - DRAIN AND FORGOT!

- The price of the station is acceptable, no more than 150,000.00 to 195,000.00 rubles. RF. The cost of all engineering structures with the Graf Picobell station does not exceed RUB 300,000.00.

- Due to the fact that the system is easy to operate, and the costs of its maintenance are scanty, it can be argued that the price of equipment at the start is the cost of the final costs for the entire service life. Graf Picobell has a 15 year warranty for the underground part and 2 years for the electrical part.

Cons of GrafPicobell:

- you need to remember that this is a BIOLOGICAL organism and excessive negligence in operation (discharge of aggressive chemicals, such as potassium permanganate and chlorine, in large quantities), kills the entire microflora of the system, and it becomes, at best, a 3-chamber septic tank, and in the worst of an ordinary drain pit!

| Well

Septic tank - local treatment facilities intended for private use and the organization of an autonomous country sewage system, in simple words - a sewerage system for a summer residence and a sewerage system for a home. Today, a septic tank is the most affordable treatment plant for a private house.

Septic tank for giving As a rule, it is small in size and requires from 1 to 3 square meters for its installation. meters of plot and about 10 square meters for a soil filter. Installing a septic tank is quite simple, but you must first take into account a few requirements.

Home septic tank may have slightly increased dimensions than a septic tank for a summer residence. The sizes depend on the number of people living in the house. It is also possible to install one large septic tankfor several houses. Installation of a septic tank is possible on most land plots, however there are exceptions that need to be provided.

Biological wastewater treatment plant BioPURIT - an improved biological treatment system for a private house, which includes all the positive qualities that it has SEPTICand taking into account modern developments and recommendations for improving the process of cleaning domestic wastewater and maintaining an autonomous sewage system. For those who consider the septic tank insufficient for their needs, the BioPURIT station is best suited.

SBR system is a fairly new product on the private house sewerage cleaning market. The most common SBR is in the west. The system is more complex with a high level of cleaning. Septic tank in this system it can only be used as a container for creating an SBR bioreactor. The cost of the system is much higher than other purification systems. It justifies the system - autonomy, compactness, economy and high level of cleaning.

All treatment systems are applicable in the following options:

- private house (detached or inside residential complexes)

- cottage (detached or inside residential complexes)

- cottage (installation on several houses is possible)

Domestic waste water

Domestic waste water are subdivided into two main types according to the type of contamination contained:

- First - " gray drain»- includes drains for sinks, bathtubs, shower stalls, etc.

- The second - " black drain"- fecal runoff from toilets

Domestic waste water take place both in residential premises and in production (household premises). The degree of sewage pollution directly depends on the rate of water consumption by each resident. Therefore, in the calculations, they use purely residents.

Domestic wastewater treatment plant - a relatively simple process associated with the main types of prevailing contaminants in wastewater:

- biological are biological objects such as microorganisms, fungi, bacteria, etc.

- organic - various organic compounds, physiological excretions (feces), animal waste, food waste, vegetable oils, vegetable waste.

- mineral - usually it is earth dust, sand, clay, small stones, acids, alkalis, salts, etc.

The chemical composition varies by region and season.

Discharge of untreated domestic wastewater into the ground or open water bodies extremely quickly degrades the ecological situation in a given place, significantly increases the risk of infection with various diseases of people, animals and plants, as well as the occurrence of local epidemics.

In this regard, a mandatory high-quality, multi-stage treatment of domestic waste water, preceding their discharge into the soil or water body.

Household treatment facilities are created to meet these challenges.

The process of cleaning domestic wastewater is phased:

- removal of suspended solids

- decomposition of organic particles

- cleavage of chemical compounds

- water clarification

- soil tertiary treatment

Soil post-treatment is essential if - septic tank installation... It takes place on a specially designated area of \u200b\u200bland called "filtration fields" or "stray fields". This section is made up of several drainage layers. When it is not possible to organize filtration fields on the site, a special post-treatment filter is installed. Which brings the purification of the effluent, which the septic tank provides to the level that allows the discharge of purified water into open ground or into an open reservoir.

An ultraviolet disinfection module can also be added to a domestic wastewater treatment plant. This module significantly improves the biochemical properties of the outlet water by disinfecting it without creating byproducts such as chloroform from water chlorination.

Domestic waste water treatment - one of the most important tasks in the widespread development in Russia of mass suburban construction. Requirements for individual housing construction without fail include the construction of a sewerage system and treatment facilities. Our experts will offer ready-made solutions for the treatment of domestic wastewater for individual construction ( septic tank for summer cottages, septic tank for home, biological treatment plant), and for large settlements.

Sewage treatment plants for a country house

Country sewerage

Sewerage for home and summer cottages

BioPURIT hybrid biological wastewater treatment plant

Home septic tank

Septic tank for giving

SBR - biological treatment system

|

Biological treatment system SBR this is one of the modern promising solutions in the field of biological treatment of domestic wastewater. SBR - Sequence Batch Reactor (English) - Batch bioreactor... The advantage of SBR over traditional cleaning methods, where water flows by gravity through several tanks or chambers, is that in SBR these cleaning stages are carried out cyclically within one tank - bioreactor... SBR system is a local treatment plant using the principle of activated sludge formation by the accumulation method. Domestic waste water pollution is quickly absorbed by activated sludge microorganisms in the tank and is converted by these microorganisms into biomass. |

Tornado - biological treatment system (new)

|

The "Tornado" system assumes wastewater treatment up to 98% |

Fiberglass storage tank

Biofilter

Wastewater treatment well

top of the page