Building wooden house Today is a combination of centuries-old traditions and modern technologies. There are a lot of ways to build a log cabin, but a separate place is occupied by the cutting method called "in the bowl".

What is the connection "in the bowl", how to correct such a log house, to pay attention - the topic is quite relevant at present.

Cutting the corners of the log house "in the bowl" ("in the region") is one of the most common methods.

The connection of the logs with each other is carried out by cut down or drank deepening - bowls. Such a method of cutting a church belongs to the option of laying logs "with the residue" - part of the log 20-50 centimeters long is beyond the walls. At first glance it seems that this is a waste building materialBut in fact, this method of connection provides the greatest stability of the whole structure.

In addition to the special strength, the walls of the house, cut down "into the bowl", acquire qualities that allow to exploit the structure year-round. The solid connection of the logs significantly increases the level of thermal insulation, the angles are not allowed into the placement of drafts. The cutting cut "in the bowl" preserves the structure of the wood, which positively affects its ability to remain strong for a long time. The impact on the walls of external natural factors is insignificant, since the log compound system completely eliminates moisture in the interventional space.

Credit, chopped "into the bowl", does not require additional finishing works. Externally, the house looks very colorful and originally. If desired, due to the various sizes of protore protmer logs, the structure can be given a type of fairy-tale hut.

The minuses of the cutting cut "in the bowl" can be attributed to the fact that for its construction it will take more building material - this leads to the rise in price.

In addition, the complexity of the technology deprives the developer who does not have experience, the ability to make a log house with their own hands.

If the project assumes the external cladding of the house, it is better to cut down a log house "in the paw", because the protruding ends log logs "in the bowl" will significantly complicate the work.

Connection "in the bowl"

Before chopping a bowl and groove, make marking. For this, there is a resembling school zirkul tool - a carpentry feature. Marking is done simultaneously on two logs, which provides enough high accuracy. End devices are set to the desired distance. Pencil, and then marker draws the contour of the bowl.

The tool "Carpentry" has different modifications, up to exclusive (with built-in level and focus), but in any case, skill is required to work with it. Video in which the process markup process is shown, will help to understand the principle of action etogabout device.

There are three options for the connection "in the bowl": "In the Obloman", "in Oblop" and "in the Okryp".

"IN OBLE" ("in the bowl) - The simplest type of compound, which has, in turn, is three varieties. The word "OBLOM" ("Upbean") means "round". Bowl-emitted in the top of the log has a rounded shape, so the method is called "in the region." The transverse log is placed in this bowl.

To install the next crown, the styling (or longitudinal) groove is cut down, which contributes to the best fit of the logs. Before laying the next log, it is filled with insulation of flank or other material.

Options for cutting "in the region" are varying by the direction of the longitudinal groove.

Cutting "In Polterev" - an option when the grooves swear on the same side of the log as the bowl.

In the second case, the grooves is sent down and cut down under the bowl, at the bottom of which leave a convex aged comb, having a groove form. The accuracy of the coincidence depends on the stability of the structure and the degree of its protectedness from the wind.

"In Kurdyuk" - the third way of cutting "in the edge" - in the technical plan is the most difficult. Kurdyuk is an extra protrusion located on top of the crest on the bottom of the bowl in the transverse direction, that is, along the log. Kurdyuk enters a special notch, equipped at the bottom of the log.

On K. artikka is clearly visible to the differencex options for connecting "in the region". Almost this means: the bowl in all cases is directed upward, but the longitudinal groove in the "bottom" position reliably protects the angle from getting into the connection of rain and melt water.

"In Oblop", « in oven", Siberian bowl - the name of the second type of cutting cutting by the" in the bowl "method. This is a kind of inverted bowl.

The name "in Oblop" suggests that the upper log in as if it bows and locks the lower crown. Experienced masters say that with such a connection method, if chop correctly, even the sound, similar to cotton, even hears.

The difference between this option from all described above is that the bowl is cut down in the bottom, and not at the top of the log. And the grooves, and the bowl, directed down, completely eliminate the possibility of getting into them all sorts of precipitation (rain, snow, thawed water).

Different types of this type of angular connection allow the location of the longitudinal groove on the log on top.

"B Okryp"

The log house made "in the hid" is used, as a rule, for the construction of household buildings. The reason for this is a high degree of injection of angles. Flat rectangular shapes of a quarter of a quarter of a diameter from above and from the bottom of the log without additional "locks" type of spikes, grooves or ridges cannot guarantee sufficient connection density. As a result of the admission of the slightest inaccuracy when cutting a log, a building is obtained that is unsuitable for use as a dwelling.

Conclusion

Building a log "in the bowl", as, however, and any other, is very responsible. Especially when it comes to a residential building. Before you begin to cut a log house, you need to evaluate your capabilities - both financial and physical. Without experienced masters, and just helpers can do it almost impossible. Order Ready Domocomplekt from a proven manufacturer or invite the brigade of experienced masters - the most optimal options for building such a house.

Build technology wooden houses "Riding in the paw" is withstanding time. Frams from logs were used since Rus. Thus, they were built at home both for the poor and for nobility. A wave of modern technologies taught the lesson to the population, the health level fell significantly. It caused an ecological boom in construction, more and more often at home are built with their own hands.

During the long time the existence of the technology has arisen for its options. Today, the Swedish, Canadian, Norwegian and Russian methods are most actively used. Russian equipment is divided into several subspecies:

- cutting into the bowl;

- in cooling;

- in pursuit;

- in the region;

- in the needle;

- in paw and others.

Of these, the cutting of the walls in the paw, which will be discussed below. What is the technology of cutting?

The main advantages and disadvantages of a log cabin in the paw

So, the main difference between the logging in the paw from the popular method in the bowl is the economical use of building materials, because the logs do not protrude beyond the edges of the cut. The log house in the paw implies that the logs are used for the entire length. In addition, if you stopped on a profiled timber for the construction of your building, you should use only the described method. Note that such a way of cutting has some drawbacks. From the artist will need attentiveness in the markup. A small error can skew walls. Note that the use of the "Conduct in Lap" method reduces the protection of the corners of the house from external influence.

How to start work

To simplify work, choose pinned logs. If you want to build a bathhouse from a solid log, let's start by his choice.

The best option is to be a log with a smaller diameter. This is due to the fact that it is necessary to cut irregularities while working on the damn. All logs will need such a procedure. If you provide big logs, then processing will lose smaller. Initially, the markup is required.

Processing Brene

At this stage of the workflow, it is important to make such a log processing to obtain identical sizes of boobs at its ends. Subsequent logs handle the first measurements. GOST 30974-02 will come to the rescue, in which the established numbers for a log house in the paw are clearly set.

For further calculations, we take the value of 200 mm as the smallest diameter of the log. Then act according to the scheme:

- we determine the central points at the ends, using the roulette;

- marking is made, for which we take a construction plumb and draw two vertical features on the end with small sizes so that they are symmetrical;

- the distance between the lines must correspond to GOST - in this case a \u003d 141 mm;

- then there are similar lines in the horizontal direction.

After that, start to trim the irregularities in their circumference, without affecting the line for 10-15 mm. After spinning the rush at all. It is important to know that the horizontal verge of the nerd by its length should be equal to or exceed the maximum diameter of the largest log. The vertical planes must provide optimal corner coating and a convenient assembly process. Often their length is equal to the largest diameter of the selected logs. For example, it is 250 mm. The next step: it is necessary to process a pour to get the desired dimensions, and this is 141 mm. There must be a prism in which there is a square cross section. It is subject to a subsequent processing stage, which is carried out in two ways.

Spend calculations to break the vertical faces of the log on 8 identical parts. Digid through them horizontally so that they are parallel. Then it is necessary to dry the damn to get 2 planes that pass through different horizontals. Keep the slope according to the total horizontal axis of the entire log.

Take the values \u200b\u200bfrom the table for the desired diameter, draw vertical on the shoal planes. Next, you need to cut down according to the lines and repeat the procedure for the other end.

Spend such an operation for all the decks and collect them, putting one to another. You can also make it possible to make a pattern on cardboard or plywood paws and apply it for other logs. If paws and grooves are done by carpentry, the information below will be extremely useful for you.

How to cut a longitudinal groove

The crown is called a series of logs. The lowest crown, the main one, is called "busting". The logs for it should be processed in a different way. The following scheme is used. First on the site where there will be opposing fire walls, put the log only with the upper grooves. Here the lower grooves are not required. Remove the irregularities so that a one-piece horizontal plane formed. Then, on their paws, lay the logs across with the already worked paws.

Collect the wints, alternately imposing logs on each other.

After that, divert the line to the value equal to the gap between the near pailates. Follow the outline for the lower axial groove. Now remove the log, burn the groove and re-put it in place.

The cutting of the cut is considered difficult to execute. It requires an attentive approach, careful settlement calculations, otherwise negative consequences will not make himself wait - skew the house, blowing the corner. Wall cutting should be very neat and accurate. But, nevertheless, such a method protects finances using a minimum of building materials.

More articles on this topic:

- How to execute a log house "in the bowl"?

- How chopping house or bath "in paw"?

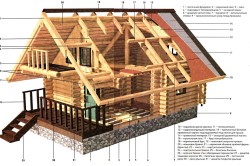

The loghouse is called the design of logs or timber, which are composed horizontally on each other.

When erecting a house, the logs for the first, busting crown are shy on one side, up to a width of at least 15 - 20 centimeters.

The log house is held due to the compounds (dressings) of the elements with each other using the grooves and additionally inserted coppins. Dressing can be angular, forming the joints of the outer walls of the house, and T-shaped, which form an inner partition.

Selection of material and necessary tools

Scheme of the main elements of the log house.

The logs in order to cut a log house with their own hands, are selected about equal diameter:

- for relatively warm regions - 22-25 cm;

- for the northern regions - at least 27 cm.

The length of the solid material should exceed the length of the future wall by 0.7-1 m. The elements of insufficient length are spliced \u200b\u200busing a "comb-groove" compound.

It is important to remember that on the lower 1-2 crown of the log cabin need only one-piece logs.

In modern markets there are many materials for a log house, which are already partially prepared for working with them:

- rounded log without bark and with the same diameter from the top to the leather;

- bar is simple, which is a material with a square cross section;

- bar profiled with a prepared longitudinal groove;

- glued materials of different profiles.

The choice of this or that type of materials is dictated only by the financial capabilities of the owner and convenience in work. For an inexperienced builder, a choice of material with a standard longitudinal groove is preferable, which will significantly reduce the cost of labor and increase the quality of the finished building.

In addition to the material, a number of instruments will be needed for a log of:

- petrol or electric saw;

- ax;

- damage (scruber) - a special tool for cutting "in the bowl";

- construction level;

- plumb;

- drill with wood nozzles;

- measuring tools.

Back to the category

How to make a log house for home or bath?

Scheme of an angular connection of logs.

Currently, 2 main types of cutting for round forest (logs are simple, glued or rounded):

- The cutting "in the bowl" is made with the residue, part of the wood from the logs are chosen by retreating about 0.5 m. The method is less economical, but has an advantage in the northern regions, since the angles of chopped "in the bowl" of the house are much smaller.

- The cut "in the paw" differs from the previous one that the connecting elements are made at the most ends of the logs. The method is more economical, but the wood-damaged wood is more exposed to moisture and frost, which makes the construction less warm.

Frams from various bars are manufactured mainly by means of a junction "in the paw".

Back to the category

How to execute a log house "in the bowl"?

Scheme of log connection in the bowl.

The logs for the lower, the busting crown is shood out from the other side that will fit to the foundation so that the resulting trees have been width of at least 15 cm. In order to slightly cut the log house, it is necessary to carefully place a place for each groove-bowl, so that the adjacent crown is placed in It is without clearance, but freely. Along the logs choose a semicircular groove, which gives additional stability of the wall and prevents the blow to its wind. The grooves and cups make on the top of the log (Russian method) or the bottom of it (Siberian method). It is believed that in the Siberian method of building moisture will not be able to get between the crowns.

Place 2 logs lower Crown Parallel to each other at the desired distance. They put the transverse log so that 40-50 cm protruding ends remained. With the help of a scraiber (features), there are a "cup" on one and the other end of the log.

The trait is a special tool resembling a large circula with vertical and horizontal levels. Working with him is as follows:

- The legs of the scruiber are set to such a position so that the distance between them is equal to ½ diameter of the log, which will be placed in a cup.

- One leg is put on the hump of the bottom log, the other coincides with the ripple of the transverse one.

- Draw, leading legs on the surface of the logs so that at the end the tool is on the back side of the logs, which will be included in the "cup".

- When working, it is necessary to ensure that the tool does not deviate from the initial position horizontally and vertical.

According to the placed lines and choose wood from the "cup". Similarly, come with a 2-meter log. Set logs by placing them in the deepening of cups and configuring one to another if necessary.

Scheme of species and cross sections of a bar.

To increase the strength of the design and decrease the drafts from the slots between the logs of the masters make complicated options for cutting "into the bowl", performing various elements inside it.

In the same way, there are and cut down bowls for laying subsequent crowns. Before laying each row along the length of the previous log, the vertical holes with a diameter of 3-4 cm with a pitch of 1.5 m, in which wooden brazed are stolen. On the upper log before laying the bottom, the holes for aging of the lower row, and on its upper part of the hole are shifted in a checker order.

When forming windows and doors, they are paved in the middle of their 1-2 whole logs. Part of it that is in the opening is removed only after the final build build.

T-shaped words for interior Wall A similar way is made, only transverse logs in this case are placed in the wall on the spot designated on the project at home.

As we already know from previous publications, log house can be made different ways. To date, two ways are widely used - "in the edge" (or "in the bowl") and "in the paw".

Each of these compounds is quite reliably and is used in the construction of log cabins.

In this article we find out how the log house is performed in.

The cutting into the oiled (in the bowl) is distinguished by the fact that the ends of the logs protrude beyond the perimeter of the cut by 25-30 cm.

On the one hand, this leads to some overexposition of wood and reducing the inner area of \u200b\u200bthe room of the bath, but this connection is very reliable.

Srub, made "in the oiled", the angles are well protected from the wind, and the log house is very stable.

Cutting into the edge can be performed in a difficult wayWhat is shown in the figure.

Cutting into the edge can be performed in a difficult wayWhat is shown in the figure.

At the same time, the protrusion is arranged in a bowl of one log, and in the lower log, the groove is chosen under it.

Such a connection is also called "in the size with a gym".

For marking logs, a carpentine zirkul (line) is used to mark the logs, which are scheduled for the necessary grooves and bowls for later sample.

After cutting down the logs, the logs are combined and looking at how tightly they fit to each other.

After cutting down the logs, the logs are combined and looking at how tightly they fit to each other.

More precisely, the depressions of the bowl will be performed, the more heat it will turn out to be a fire, it will require a smaller amount of insulation and in general the log house will be more durable.

So it will be very responsible for the fit of the cup, as well as the longitudinal grooves in the logs.

The longitudinal grooves in the logs can be performed both in the form of a semicircle and in the form of a triangle. It is more complicated by the semicircle, but the seal is much better at the same time. The figure shows the correct and incorrect fit of the logs.

The longitudinal grooves in the logs can be performed both in the form of a semicircle and in the form of a triangle. It is more complicated by the semicircle, but the seal is much better at the same time. The figure shows the correct and incorrect fit of the logs.

When building a log house, all the places of compounds are definitely laid by the insulation of moss, pacles or other material.

After laying each log, it is necessary to prettenly catch it all over the entire length and in the scene to the maximum compact all the connections. Also, do not forget to control the verticality of the resulting walls.

After the logberies dry carefully and messengers it will be possible to move to its pant.

In the video below, you can see how the longitudinal groove and bowls are marked with a carpentry feature, as well as how they are guided for a longitudinal groove and bowls (for playback, press the triangle):

The strength and heat engineering of the wooden structure in a large extent depend on the type of angular wrist. The builders of the old Slavic settlements did not hold the options for its manufacture in the secret. Thanks to their oral master classes, proven folk technologies were able to preserve. Carpentry traditions have been significantly enriched at the expense of foreign experience and the introduction of useful improvements. Knowledge baggage accumulated weighty. Now B. wooden construction A variety of ways are applied by varnish bar and logs, one of which is to be used to build their own baths.

Two "indigenous" families of louds

The fundamental criterion for dividing the methods of writing into two large classes - the presence of either the absence of bypass. So the folk masters called the remains of the log, and then the bars leaving on the ends beyond the limits of the circuit of the wooden structure. Relying on this indicatorIn the technologies of the construction of log cabins, I highlight two main fees:

- "In the bowl", according to which the angles are cut down with the residue. This is the most common way that has a mass of variations of domestic and foreign origin. Minus nodal bowls in a tangible consumption at all are not cheap material, plus in excellent thermal insulation of the angle. Yes, and looks on the bowl of the structure quite effectively.

- "In the paw" or in a simple "no residue". According to it, the contour of the structure is styled precisely according to plan. With an equivalent material consumption equivalent, the internal dimensions of the structure are larger. The corners chose in the paw in the paw require mandatory cladding, otherwise they will be bludging and mocking. Frams, built without reversal, can be seen by clapboard, block house, plastering, lining with brick or sandwich panels. Unlike options with the bowls, they are applicable here, and sometimes it is recommended all the directions of the finish.

One of the fundamental rules states that all angular compounds must be performed according to a single scheme. Since the wrist of a bar and log walls was carried out according to the scheme "in the bowl", then it will be necessary to cut down the partitions in the same way. Immediately pay attention to that for corner connections All existing ways are applicable in the log wedges. But the bath from a bar is cut primarily in the paw, but the occasion is also used and a number of cup-shaped types.

Both classes of corner wrist "covered" by an impressive number of subsidiary subspecies that differ in the complexity of manufacture and heat engineering qualities. Choice the best way Determine:

- performer's experience;

- climate specificity of the terrain;

- the period preferred to take bunny procedures.

For the assembly of the crowns of the countryside, operated only in the summer hours, the simplest ways of writhing are suitable. Especially if the owner is going to build a bath on cottage plot Alone. The customer of the brigade of masters in need of a warm structure for year-round use should not be denied in choosing a challenging technological scheme. Information about the differences and features of the wrist will help both the independent performer, and the excitement of builders, who wants to spend money not in vain, make a reasonable choice.

Options for cutting with the residue

The most accessible for a novice carpenter by making an angular node recognize the cut into the bowl, i.e. With the residue of the log on the end. In the "cup" class there are simple and ultra-empty technologies. In wooden construction, it is important to understand: what is easier to chop, will heal less and serve. However, without carpentry skills and knowledge in this art for the manufacture of complex structural recesses, it is better not to take.

Simple Bowl Making Algorithm

For the production of cutting into a simple cup in the log, two grooves in the shape of half-cylinders and a longitudinal interventored furrow, called a lunar groove, are selected in the log. All deepening in the log is made from above, which is very convenient for the wizard, but not good for the walls. In the hole deployed to the sky easily, moisture is easily selected and dust falls through the pairs of density due to drying. Therefore, simple bowls need constant renewal of cacopa.

The owner of the cylindered material does not need to suffer with preliminary preparation. Calibrated logs have a single size, the installation grooves are already selected in them. Even the manufacture of angular recesses. Cylindrid manufacturers can be done if an order and intelligible design documentation goes to them. The buyer of the sawn forest is to be processed: to make, dry, choose a longitudinal moon-shaped furrow for reliable bumps of the crowns, and then start to wheelhouse into the bowl.

Sequence of work on the manufacture of simple bowls:

- The squeezed log on the sister-in-making place for marking.

- If the longitudinal interventovaya groove has not yet been made, on the thin end of the lower log, in the upper part of which removing is to be made, draw a line equal to the width of the future groove.

- Slide the legs of the factory or homemade feature to the width of the placed mounting groove.

- Stinn the line with legs to the humps laid in the log cabin and trying to it the upper fellow, then we scratch the sharp legs on the lower log, the exact profile of the upper element, "ocked" the log from all sides.

- Having completed the marking of the groove, spread the legs of the line to the distance equal to half of the average radius of the log layered above.

- Strip again the legs of the drawing carpentry tool to the approximate and to the lower log lying across the side to describe the half-cylinders of future angular recesses.

- We will remove the approximate upper element of the cut, and on the lower log, we will make a pressure that do not reach the depth of the drawn recesses 7-10mm.

- We choose an ax that marked withdrawns and finalize the surface of the shinebel.

The method of manufacturing an angular connection based on a log cabin in a spike bowl is presented to the video:

There is no special difference in the sequence of actions. You can chop first a groove, then angular notches or in reverse order. The main thing is that all three constructive components are accurately extruded. You have to get caught by anyone: it will be necessary to try on and put the surplus if the top log is "sees" into the log cabin. Therefore, with the final sample to the protruding lines is not in a hurry. It is desirable to gradually bring it to mind to the mind, so that it is too big samples not to spoil the material. In the old time, the first time the crane mounting recesses smeared tar and put the top element on it. The lavety marks indicated where they still need to pose.

Subsidiaries Bowl

The cutting of a church in the bowl attracts inexperienced performers simplicity and relatively small labor costs. However, without additional castle elements, it is very hard for heat. For the construction of a summer bathhouse, this is quite acceptable. For the construction of a warmer building, the lock knot is better to supplement the selection. The way of cutting is to complicate, but heat engineering will improve.

In the list of the nearest "relatives" technologies for shutters in the bowl:

- Cutting into the overojen (she is in the chop), which is a mirror reflection of the bowl. This method is also called Siberian cabbage. It is distinguished by the fact that the angular locks and the lunar groove are simply turned down. The lower orientation of the excavation eliminates the penetration of moisture and dust into the nodal conjugation, so that the insulation does not deteriorate and does not mock the log house.

- Bowl with a protrusion. It appeared as a result of the popular improvement of methods in the chille and in the region, according to which the deforestations are made either from above, or the bodies from the bottom. The cutting of the bowl with the protrusion allows you to arrange a longitudinal groove from below, and the angular notes at the top or proceed on the contrary. Because It will be necessary to lay a log with interventic furrows in the bowl, the excipher configuration cannot be still half a cylindrical. Therefore, a rounded protrusion appeared in the bowl, repeating the radius of the longitudinal mounting groove.

- Cutting in the hid. It is to form two equivalent rectangular cuttings on the upper and lower side. The option is simpler, but suitable only for the construction of economic buildings.

- Ublop with a gym. In order to optimize the strength and thermal insulation of the angle in the bowl, leavens are left - this is a unwanted quarter in a bowl from the inside of the angle. For dosilets, there will still be a response with a mating log.

- Cutting into Kurdyuk. It differs from the simple bowl of the presence in the extrusion of an additional spike that increases the strength of the angular node. Schip is called Kurdyuk or Potomok. He gave the name method and raised heat engineering qualities breed Wall. Oriented the cutting into Kurdyuk in both traditional parties. The bowl is originally chopped by half of its height, then spikes are turned out. The sizes of the formed spike are transferred to the mating log without special tricks: rolling into a log house and marked the serfs where the response groove should be chopped.

Pretty demanding in relation to the skill and experience of the performer, two ways to cut a log cabin in the hook are considered. The first of them predetermines the cutting of half of the bowl, and the remaining, not disheveled half must be clearly docked with the semicircular cutting of the mating log. The second technology resembles a bowl with a gaze, but the logs are rejected by one Kant, and the opposite side turns inside the building. When cutting into the hook, the maximum log power is maintained, thanks to which the angles are warm and reliable.

This is how the cutting into a simple hook:

Overseas technologies of louds with the residue

The fundamentally Canadian and Swedish schemes of logging are similar to the Siberian technique "in OHLUP". Only the angular grooves and grooves to them have no rounded in the section, but a trapezoidal configuration. This is a good plus, because When shrinking, the Slavic bowls are expanding, because of what they need a periodic subaccination. Canadian and Swedish recess after shrinkage tightly "sit down" on the log died to her. There are no gaps at all, and over the years, dusting is also sprinkling spontaneously.

The technique of execution is different. External distinguish can be partially opposed in the castle area of \u200b\u200bthe "Canadian" log cabin and sharpened by six faces with a pretty "Swedish" crossing. W. canadian technology There is a good simplified follower - cutting into the saddle.

The extremely demanding point of all the shuttle schemes with the residue is precisely the length of the log part of the log, serving beyond the limits of the structure of the structure. It is impossible to do without a short crossing, otherwise it will fall. For a desire to save not led to the emergency state of a log, GOST for the number 30974-2002 clearly regulated the limit distances: from the end of the log to the center of the breakdown of the bowl should be at least 1.4 diameters of the log processed.

Video demonstration of Norwegian cuts:

Methods of cutting without a residue

Options for cutting cutters in the paw are significantly less than methods with a bowl. The reason for their appearance was not economic considerations, but the desire to remove the wooden Terem in the luxury palace by finishing. The angles in the paw are significantly colder. The capillaries on the ends are open, so the outer side of the angular connections in the paw strongly advise to sew at least boards.

For the construction of a church with the use of the technique "in the paw", a bar is suitable, the yokes - dried into two vertical Cant from the opposite sides of the log. Suitable otlindering and ordinary rounder with vertical left and right-wing trees - "DOOLS". Bolk length, i.e. The length of the side cut is equal to the largest diameter of the material used. Bolk width, i.e. The distance between the trees is 2/3 or 3/4 diameters of the vertex of the finest in the acquired batch of the log. Its and it is necessary to first identify and "fool" as a reference for other logs, so that in the process it is not found that part of the material does not fit under the size of the planned paw. By the way, the nerds can be outset immediately on all the logs, and then go to the manufacture of paws of the selected type.

General Lape Manufacturing Instructions

The straight paw is the simplest scheme in the "laptom" class, so you can try to make it my own. She has all the lines of the upcoming tester strictly vertical and horizontal. So that the angle is blocked less, the paw can be supplemented with a gaze, deposit this constructive addition from the inside of the angle. The most reliable connection in the class is oblique paw, because the inclined planes are not allowed to turn out the elements of the log cabin and carefully retain heat.

It turns out all the variations in the equivalent sequence:

- Prepared for processing the damn again we take away from above and below. The depth of the treasure should be equal to the width of the nerd. As a result, we get a parallelogram with one imaginary side and deployed to our square cross section;

- The end of the parallelogram is drawn into 8 equivalent horizontal parts.

- According to the selected paw type and table sizes on the preceded plane, we note and connect points;

- There are lines of future treasures with requiring planes and squads, if it is decided that they should be;

- Carefully remove the surplus on the markings and on the first finished paw we make a template for transferring the size of the following logs.

There is no need to independently calculate the sizes of oblique paws, they are in the tables. The masters of them are bothering slowly, scrupulously. The lunar groove is scratched along the logs laid into the log cabin, push the legs of the line to the value of the detected gap.

Corner Wildlings in Brous

Forming a rounded connection in a timber is difficult, and it is not necessary, because for the bruise of the crusted crowns, their techniques have been developed. On the basis of the paws were created identical options with very similar names: Okhenap, Polterev, Kurdyuk.

However, the bar has its own, specific methods and types of angular compounds using plug-in or chipped materials. The walls according to the tradition of wooden architecture are "penetrated" with bellows - vertical wooden nails of 25-30 cm in diameter and height equal to 0.8 from the height of the cut.

![]()

However, the bar has its own, specific methods and types of angular compounds using plug-in or chipped materials. The walls according to the tradition of wooden architecture are "penetrated" with bellows - vertical wooden nails of 25-30 cm in diameter and height equal to 0.8 from the height of the cut. It should be remembered that between the elements of any connection in the blocking and log cabin, it is necessary to leave a vertical clearance to compensate for the standard shrinkage, followed by construction. In the bowls and paws, the limit value of the gap 0.5 cm, in the mounting longitudinal grooves of 1.0 cm.

We described the common, but not all existing logistics schemes. The difference in the methods of their implementation and in the heat engineer will tell you that it is better to prefer good luck!