Concrete construction device - the process integrated and the quality of the result depends on a number of factors - the correct selection of materials, compliance with the proportions of the components of the mixture, compliance with its cooking and laying technology. A special place in obtaining high-quality concrete is the organization of measures to care for the hardening mixture.

The need to care for fresh concrete

The main purpose of working to care for the hardening concrete mixture is the creation of optimal thermal and humidity modes, which depends on the normal increase in the strength of the material.

Concrete hardness is a long-term physicochemical process and for its complete completion requires a certain time interval. Especially at the beginning of the simulation period of the mixture for the flow of hydration reaction - compounds of cement grains with water - it is necessary to ensure a sufficient amount of moisture in concrete. Premature removal or freezing of water in a concrete mixture leads to a deterioration in its structure and strength characteristics.

In many respects, the increase in the strength of the concrete depends on the temperature at which the hardening process proceeds. Normal is the temperature of + 18- + 22 o C and relative humidity within 80%. With low plus temperatures, the mixture is slowed down, when dropping below zero, if not adopting appropriate measures, stop completely.

The most careful care requires freshly added concrete in the first days - during the rapid rise in strength. When creating normal conditions, concrete on Portland cement in the first two weeks of drying is gaining about 70% of the planned strength, which is inherent in 28-day age.

Concrete care rules in the summer

In the warm period of the year, the main purpose of concrete care measures is to protect the surface from drying out.

The basic rules for creating an optimal humidity regime are simple, but, the main thing is to comply with the regularity of their implementation:

- All open surfaces must be carefully protected from wind and direct sunlight. To this end, concrete construction is covered with moisture coatings - burlap or tarpaulin. The role of protection against drying can perform polyethylene film.

If there are no such materials, then after 2-4 hours after concreting, the surface can be sprinkled with sawdust or sand and pour water. The irrigation frequency is determined by climatic conditions and should be such that the coating is constantly in a wet state. The duration of moisturizing is to reach 70% of the projected strength concrete. Concrete watered with a sleeve with a spray tip.

- At very high ambient temperatures, the formwork itself is moisturized in front of concreting. If the formwork is removed until the end of the care of concrete, then vertical rafts are poured. In dry heat climatic conditions, the system of tubes with small holes is arranged for irrigation of the circular and vertical surfaces.

- Freshled concrete needs to be protected not only from heat, but also from the effects of groundwater, especially aggressive. This can be achieved by drainage and the device of the insulating layer. For clay cements, these activities are relevant for three days, and for all other species - for two weeks.

Watering of freshly chosen concrete can be difficult to preserve large amounts of salts in water. Salts after evaporation of the fluid remain on concrete and can cause some deterioration in the strength properties of the surface layer. In this case, the observed materials are located a few inches above the surface of the concrete, water only the coating. The mixture is moistened with pairs without falling on her salts.

Shelter and watering freshly found concrete - events requiring significant labor costs. Therefore, for the sites of significant sizes, which are not intended for contact with concrete, instead of watering, special painting formulations are used, protective polymer films, tar or bitumen emulsions.

Constructions made of lung concrete with porous fillers require a special moisture mode. To care for such concrete, special paint and varnish coatings are used, protecting the surface from moisture.

Freshled concrete need to be protected from mechanical influences - shocks and concussions.

Caring for concrete under reduced temperatures

In the presence of the selection of concreting time, definitely, it is better to prefer the warm season. If it is necessary to carry out concrete work in the winter, then this will help special measures to protect the mixture from freezing to a set of design strength.

If you independently prepare a solution without the use of antiorrose modifiers - use heated water. The laying of the mixture should be carried out continuously. If the upper layer managed to frozen - it must be treated with steam and remove the simply plot, immediately continuing concreting.

Winter concreting technologies:

- The use of concrete with antiorrotic components that are supplied already in the finished form.

- Heating frozen concrete with powerful transformers.

- When concreting, under the conditions of border temperature, it is possible to warm the design using insulating materials.

- One of the options for creating a normal thermal regime is the device "low tent" in combination with heating using a heat gun.

- In concreting, thin-walled electrical heating structures are undesirable, since it can cause a cut. In this case, the rational output is the use of infrared heaters or steam heated.

When using steam-heating in the first eight hours after laying the mixture, the temperature of the pair should be monitored every two hours. In the next 16 hours - once every 4 hours, then it is enough once in shift. When using infrared heaters, you need to observe the distance between them and the concrete structure - at least 1.2 meters. It is possible to warm up and the concrete element itself, and the formwork, which is outside for better heat-absorption is covered with black matte paints. Before heating infrared radiation, the concrete surface must be protected from drying with the film.

When concreting, in terms of temperatures, -20 o C is used thermoactive formwork, which is a design consisting of steel plates with heating elements mounted on them and a layer of outer thermal insulation. At the end of the warm-up, the formwork is removed, and then concrete cools under the shelter. The shelter is arranged from stycloth blankets, tarp tissue and plastic film. The cooling of the concrete structure should be carried out under constant control.

Concrete care products after fill

The modern chemical industry offers a lot of funds that are able to effectively help in care of concrete during the recruitment period of the project strength.

- NovaPor - serves to care for the unprotected surface of the concrete structure. Protects the hardening mixture from low air humidity, intensive effects of direct sunlight, high temperatures and strong winds. The use of this tool helps to eliminate the appearance of shrinking cracks, showering cement that has not passed the process of hydration and aggregate. The tool is a water emulsion of paraffins.

- Ecofob - means used for impregnation (impregnation) mixtures. Increases the resistance of the concrete mixture by frost, as well as the defrosting substances of chemical action. This substance is used mainly in order to care for concrete pavements on motorways, runways, industrial, economic and storage facilities. Ecofob is used when erecting bridge structures, garages and concrete supports.

- Antisol E20 is a white liquid that does not contain components provoking corrosion processes, fireproof and does not contain chlorine. Applying a thin layer of this means allows you to protect the concrete from too much drying and prevent a decrease in the strength characteristics of the hardening solution. This composition is used to care for hardened concrete. Antisol E20 fills the pores, increasing the frost resistance and waterproof material. The tool retains its positive qualities even in conditions of intensive operation of concrete coatings.

Determining the procedure for concrete care measures and control of their implementation

In the context of capital construction, the care of the hardening concrete mixture is established by the laboratory and are approved by the technical leaders of the facility structure.

With the erection of massive hydraulic structures, all methods for regulating thermal and humidity modes are determined by projects of the object and work. Such events are governed by SNiP.

For continuous monitoring of accuracy of work on concrete care, all events are entered into a special "magazine concrete work" Filling the concrete care magazine must be carried out daily.

Sample concrete care log can download (opens in a new tab).

Regular performance of fresh-fledged concrete care measures will avoid losses of concrete strength characteristics and create a solid construction that can serve for many years.

GD Star Rating

a WordPress Rating System

Number of pages:48

Weight, g:150

and under the order in solid (book) binding - 350 rubles.

When you need concrete work

The construction of almost any object in which the maintenance of the work of work is the necessary norm is not without concreting. Concrete work magazine SNiP 3.03.01-87, GOST 10181.0 It is the form of a document that is used on objects where concrete works are underway.

This magazine is an important primary production document, which reflects:

- Technological sequence;

- Accepted deadlines;

- Curing;

- Performance of execution;

- Conditions for the production of all concrete works;

- The results of the quality control of the concrete mix,

- The result confirms the distribution of responsibility between various construction participants.

Indications of the journal of concrete work

Concretion, as well as monitoring the quality of concrete, is carried out in accordance with all the requirements of SNiP "carrier and enclosing structures".

The title page of the magazine must be filling out before the start of concrete work, the General Contractor with the participation of subcontract organizations and the customer. The title list and information about various changes in the records in it fills the representative of the general contractor, on behalf of the general contractor. In case the person responsible for the safety of the journal is changing directly in the process of performing work, then copies of all sheets of magazine with the necessary changes can direct any interested persons to the state building supervision authority any interested parties. In the case of the loss of the magazine and the absence of information in the construction supervision authority on the change of responsible person, the person who was indicated in the magazine of concrete work during its registration.

The journal is conducted by an organization directly performing work. On behalf of the organization of the Count 1-10 magazine and Count 20, the elimination of all comments fill authorized representatives. As for graph 11-18, they are filled with laboratory technicians of a building laboratory, which monitors the quality of the used concrete mix, as well as all samples of concrete. As for records in the 19th column, only persons listed on the title page can be made there, as well as representatives of the author's supervision, special state building surveillance. It is forbidden to conduct a log of records to persons who are not listed on the title page, as well as it is forbidden to correct the recording "to theooting". If necessary, recording can fix the authorized person, then assuring the recording of a personal signature recording.

The completed magazine is transferred directly to the General Contracting Construction Organization, in order to monitor work control, as well as documentation. At the end of the log, to continue the work the next volume is drawn up, and then registered according to certain rules. After acceptance, the general contractor leaves a signed and completed magazine at storage until the object is sent directly to the customer. In the process of preparing for the delivery of the object, the Journal must be conveyed to the authorized representative of the Customer, up to the moment the authority of the State Construction Supervision of the final verification.

Guidelines for filling the log:

- The magazine issues a production and technical construction department with a title-sheet previously completed;

- It is conducted for all construction objects;

- During the construction of small artificial structures, journal is allowed to the group of structures, but necessarily allocating each of these structures;

- When accepting concrete from a concrete plant, information in graphs 3 and 7 must be added according to the invoice with the numbers indicating the numbers;

- Graphs 8 - 9 are filled exclusively when performing work in winter conditions;

- Concrete temperature measurement information When withstanding it is entered into a special magazine, designed to control the temperature.

The log needs to make information about:

- Concreting date;

- The name of the concrete part of the structure, as well as structural elements;

- Concrete brand;

- Composition of concrete mix and water-cement relation;

- Selection card;

- The form and activity of cement;

- Sediment cone (medium) at the place of laying;

- The temperature of the concrete mixture to exit the concise mixer;

- The temperature of the concrete mix when laying;

- The volume of concrete laid in the case (per shift);

- Method of sealing concrete mix (vibrator type);

- Air temperature;

- Air duct;

- No. Act on the manufacture of control samples of concrete;

- Sketch of the concrete part of the structure with mandatory marks at the beginning, as well as at the end of the shift;

- Signatures of replaceable masters and laboratory technicians;

- The form and activity of cement;

- Results of testing control specimens when palable;

- Results of testing of control samples in 28 days;

- The date of the palace of a certain part of the structure;

- Notes.

But besides him, there is still a whole bunch of special journals that the responsible manner of work should know as its five fingers. About one of these magazines and will be discussed in this article.

And so, let's talk today about the magazine of concrete works. The sample is given in Appendix "F" SP 70.13330.2012 "Bearing and enclosing structures. Actualized editorial board 3.03.01 - 87. Electronic version of the magazine can free download at the end of the article.

What it is

This magazine is not large, the design also does not occupy a lot of time, but it is necessary to fill out if concrete works are underway at the facility installed it in paragraph 3.5 of the SP 70.13330.2012. Fills his responsible manner of work in those days when concrete work is performed.

This joint venture is given. new form The magazine, the old form you must already write off. Have it in mind.

I used to read somewhere that if the volume of concrete works does not exceed 50 m3, then the log of concrete works is not necessarily and can be recorded directly in the general journal of work. But I can't remember where I read it. If anyone knows write, please, in the comments.

Below I will give a sample of filling the magazine concrete work. Press on the pictures to enlarge the image.

How to fill?

Many are asked by this question, but I think here everything is intuitively understandable and familiar with the example of the completed magazine you have disappeared with many questions, but still I will try to explain some moments.

The magazine from the title leaf and table of 14 columns. The first 8 columns fills the responsible manner of work, and from 9 to 13 it draws the one who is experiencing concrete structures for strength. The strength is experiencing in an intermediate and design (28 days.) Aged.

When you fill out 4 columns, try to indicate all concrete symbols. For example, if a B20F100W6 concrete is applied in the project, then specify all these data in the log. If you are in a magazine of concrete work only the Class of Concrete B20, then when checking, the State Construction Supervision Inspector may be doubtful in the applied concrete and require proof of compliance with the requirements of frost resistance and waterproof.

And you will have to prove it by presenting a quality document on concrete mixAnd there, too, can also miss and not write data on frost resistance and waterproof. And you have to make an additional technical inspection of concrete structures. Do you need it?

Concrete Journal Like All other magazines need to be numbered, to miss and fasten the organization's seal. Also, it does not allow corrections and blots. It enters the list of executive documentation and upon completion of construction is transmitted to the developer, and then the operating organization.

In the case of concrete work at an outdoor temperature less than + 5 ° C, especially in winter timethen it will be necessary to keep a magazine to care for concrete. We will talk about him.

P.S If you have any questions, then feel free to ask them in the comments, and I will try to answer them. Subscribe to the blog and get new articles among the first.

Support a blog - download the electronic version of the concrete work magazine for the symbolic price!

In the payment window after successful payment click on Go to the store's website and the file will go to download.

Free download:

P.S. Friends I want to recommend program "Executive Documentation" from Altius Soft. If you want to automate and speed up the process of conducting executive documentation, then you cannot do without this program. Thank!

On each construction facility should be the magazine for concrete. In the journal, it is necessary to regularly register the date and time of laying concrete, the method of care for concrete, the flow rate and time of application of the pavement and thermal insulation materials, the weather and the duration of the care of concrete, as well as the opening time of the coating movement.

In concreting of responsible structures, the composition of concrete care measures, the order and timing of the work is established in or given in the instructions of building laboratories approved by the chief construction engineer. All concrete care events are entering concrete care.

Graphs concrete magazine:

1. Name of concreted part of the construction

2. Volume of concrete

3. Module surface m2 / m3

4. Method of maintaining concrete

5-6. The date and time of the end of laying concrete - month and number - clock

7-8. Start holding concrete - month, number and hour - concrete temperature

9. Duration of maintenance per hour

10. Outdoor temperature

11. Estressive temperature

12. Date of measuring temperature: month, number, hour

13. Temperature wells. Concrete temperature

14. Signature of a laboratory manner when monitoring and measuring

15. Note

To obtain the concrete of the required strength and density, surface quality, as well as to achieve all these indicators, it is necessary to organize correct care Before concrete: maintain it in a wet state, to protect in the initial time of setting and hardening from concussions, blows and vibrations, prevent sudden temperature drops. The lack of concrete care even with high-quality source materials and compliance with the cooking technology and mixing the mixture may not be reduced to no effort and lead to a defective, unsuitable for the operation of a concrete product or design.

The most favorable conditions for set by concrete strength or resistance of concrete is humidity close to 100%, and temperature ambient - 18 ... 20 ° C.

To protect the concrete from drying out at low ambient air temperatures in the case of manufacture in wooden formwork of walls, runs, riggers or other structures with a small area of \u200b\u200ban open surface, it is possible to not apply any additional measures, since concrete in the process of its formation will suck water absorbed by wood.

The open surfaces of freshly lined concrete into hot and dry weather after 1 ... 4 h after laying are covered with moisture-intensive material (burlap, sand, sawdust, mineral wool slabs, etc.) and watered with water.

Depending on the conditions of hardening concrete, watering is produced with such a calculation so that the surface is always in a wet state.

In hot weather, they also watered wooden formwork. When removing the formwork in the early time, watering must continue, especially abundantly watering the vertical vertical surfaces. Approximate deadlines, during which it is necessary to maintain a concrete in a wet state, depend on the type of cement, the design features of the manufactured product and are 3 ... 14 days.

Shelter and watering concrete require significant material and labor costs. Therefore, in cases where the surface of the concrete is not intended to be further for contact with the solution, it can be used to protect it from drying. Protective films or special painting formulations (Ethinol varnish, tar and bitumen emulsions, liquefied bitumen, etc.).

In winter, a whole range of events is used to care for concrete and is conducted.

Greetings, friends! Today there will be an article that has already probably wait for many long ago, but now it will not be forgiven. Friends, in the article about I promised you to write about the magazine to care for concrete. Here, by the way, this promise.

And here are friends, we will talk about this topic today.

Preface

Recently, Ivan addressed me in the comments. He asked about the promised article about concrete care magazine.

Before his comment, I practically did not understand and did not learn this magazine. I promised him that during the day I would give a sample of the magazine. When I began to study this question deeper, I realized that everything was not so simple here. That's what I answered him in the end.

About the journal

In general, paragraph 5.11.17 SP 70.133330.2012 It is indicated that "under the average temperature of the outside air below 5 degrees Celsius should be conducted by the Concrete Temperature Control Journal. This is not a magazine to care concrete, and the magazine control the temperature of concrete. And the form of F-55 magazine to care for concrete is not entirely that.

And now the most interesting thing - the sample of concrete temperature control magazine is not in any regulatory document And even on the Internet you will not find anything. This is a fact of friends. True, from today, a sample magazine will appear on this site.

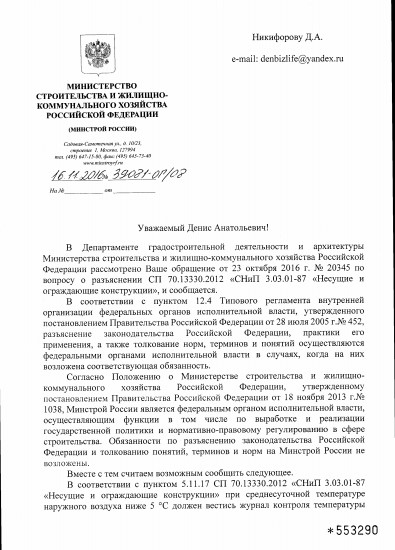

As Ivan Ivan, I write this article because I received an answer to my request from the Ministry of Travel of Russia. They answered me quite understandable and even presented a sample magazine of concrete temperature control. But not a completely mounted sample (since it is not), and more recommended option.

Here is the letter itself:

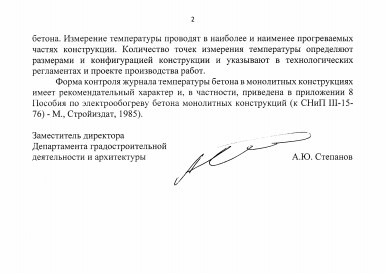

It follows from the letter that the form of concrete temperature control in monolithic structures has a recommendatory nature and, in particular, is given in Appendix 8 of concrete electrical heaters. monolithic structures (SNIP III-15-76).

And here are friends, I suggest you familiarize yourself with this form. This is not a magazine of concrete temperature control, but some temperature sheet. I will give you the opportunity to download not only a sample of the temperature sheet, but also the answers of the Ministry of Construction of Russia and AO NIC "Construction". They may need you if when checking the temperature sheet, which you will lead, do not like the construction control or construction supervision.

Download and use, but do not forget to share an article on social networks. And Many thanks to Ivan for the comment and perseverance.