The main problem accompanying work on concreting in winter timeis low temperature. As an output can be considered the use of material of special brands, the use of antiorrosal additives, electric heating and other modern tricks.

Each of the options is good in its own way. But only correctly chosen technology will help concrete work when low temperatures Without loss of quality.

Insofar as chemical reaction Water cement is an exothermic process, low temperatures ambient Slow down the deposition time of concrete, as well as its solidification and the development of their resistance. Cold weathered usually provides higher finite concrete resistance, since the lower the initial temperature, the better the cement hydration is, which ensures the maximum efficiency of the cementing material. However, this will lead to a slower development of concrete strength and delays in the process of finishing and stripping.

Temperature conditions

The slaining surface is seized and hardens the faster than warmer and land around.

What hinds cold

In winter, it hinders not only cold, but also excessive moisture, contributing to the slowdown in the frost process.

Here are the main factors negatively affecting the process.

Similarly, the materials and equipment necessary to protect concrete should be used from the first moments of concrete placement and, thus create the necessary conditions For adequate development of resistance. One of the most frequently used methods for accelerating the hardening of concrete is the placement of heat generating lamps.

These situations justify the adoption of special precautions when the processes of placement, curing and protection of concrete are produced from cold weather exposure. Good practices for the use of concrete at low temperatures lead to the appropriate approach, as they are crucial for the durability of concrete.

- Cement hydration slows down, Up to the complete stops of frozen and set.

- Water necessarily present in the mixture, freezes, destroying the structure of the material.

- Moisture contained in the ambient air in high concentration, slows down the frost. The time of durability in this case increases significantly.

Optimal conditions

With the onset of the winter season construction works Do not stop.

Concrete casting events

Concrete can be placed, finish and cured in cold weather conditions when the care plans are sufficient and measures are taken to ensure successful placement of concrete during the cold season. List proper equipment and personnel to enter into force long before time. Climate Protection Plan provides for the preservation of the working environment and concrete at a sufficient temperature for placing and finishing concrete. Think about the use of low grasp concrete, which helps reduce the time of setting and sewing water, since the cold air is delayed by the evaporation rate and a specific time of setting. Consider the use of concrete mixes containing accelerating additives, or the use of cement with high initial strengths, which requires less time to protect against freezing.

Activities during concreting

Do not start the final finish operations while there is a concrete exudation. Activities after casting.- Think about heating to the formal.

- Provide sufficient concrete finish without excess water.

- Use good quality curable compounds.

Depending on the conditions, the temperature in concrete work can contribute, not to prevent or interfere with the process.

- With mode from 0⁰ to + 10⁰, hydration is noticeably braked. On average, the process of a set of strength up to 70% is up to 4 weeks.

- Temperature above + 11⁰ slightly accelerates solidification, but to the norms and in this case far.

- The temperature in + 20⁰ is favorable, then you can not perform additional operations to accelerate the durability.

Note!

Standard installed regulatory documentsIt is customary to consider complete hydration of material for 28 days.

To achieve 70 percent stories with favorable factors, 10-12 days are enough.Concrete Mass Heating Methods

Curing is a process in which in a particular period is supported by monitored conditions in a specific period in order to ensure sufficient cement hydration and proper hardening of concrete. Cost, simplicity and time - factors that should be considered when choosing a treatment procedure for a given case.

To get high-quality concrete in any structure, a good advanced defense techniques must follow, regardless of the environment, which is present. An important parameter when casting concrete in cold weather is the concern for concrete cylinders used for the adoption or rejection of the product.

Water as a need

Cement hydration without water presence is impossible. It acts as a necessary component that helps the formation of cement stone. Throughout the ripening time, water contact with cement is required.

Temperature mark below 0⁰ is considered critical.

At this time, the liquid begins to freeze, expanding and destroying the structure of the material. Especially unwanted several cycles of freezing and thawing. In this case, structural bonds are intensive, ultimately completely destroying the finished design.

After these days of the cold weather, we suffer, it seems that we had to dust specific notes in some places to know what steps need to be taken for concrete in cold weather. Of course, if you are in areas, coolest than me, you will get used to both to you and to groups of structures that work, but here usually no need to ensure that the thermometer takes into account these conditions of concreting in cold weather.

Consequences of concreting in cold weather?

But you'd better understand, isn't it? As you know well, in order for concrete to become stable, a chemical process must be produced, in which the cement is hydrated in combination with water in the mixture, but, of course, water should be in a liquid state that does not serve us frozen.

Features of the work in winter

Consider all the nuances and possible problems arising under negative ambient temperature. The main task is not to give water in the solution to freeze. Especially relevant the problem, if you work with your own hands, drawing up life.

Summer wait long, you have to adapt to not the most comfortable conditions.

Cement needs a certain amount of water to obtain full hydration and harden, but if part of the water is frozen, it does not interfere in the process, and cement hydration remains incomplete, so the predicted resistance is not achieved.

There is no need to achieve water freezing points to obtain concrete damage, since below 5 ° has been delayed in the installation rate, since the chemical process slows down due to temperature. When you need to set the time, water that remains free, can evaporate before reacting with concrete, especially in the dry wind, which directly affects the hardening of the mixture.

- You can apply anti-corrosion additives (PMD) for concrete.

- IN some cases Helps the shelting of the flooded surface of PVC film or rolled insulation.

- The electric heating of concrete structures works well.

- The temporary structures are reinforced over concrended areas and provide heating with a thermal cannon.

- Often the cement mixture is prepared on heated water. Supported when kneading positive temperatures will give a good result. Especially if laid concrete isolate from frost in one of the above methods.

Note!

When fixing the work of a large volume, expensive techniques are not always used due to high cost.

Often the instruction prohibits the use of electric heating devices.

So you have to choose the optimal option for your case.Concrete Test when accepting structures

Obviously, this is more pronounced in the outer layers of a piece, which increases the external porosity, which directly affects the durability of concrete and the possibility that in the future these pores can cause damage in freezing processes when they fill the water.

On the other hand, in case the temperature drops when the mixture is already freezing, water that has not yet moisturized to cement, free, it will increase its volume and can damage the concrete inside. This is especially important in the first few hours after the fill, since there are still a lot of free water, subject to freezing and increasing its volume in the pores of the test.

Basic Rules and Standards

- With a well-chosen heat balance finished mixesDry fillers not containing frills are loaded into the concrete mixer in not heated.

- The temperature of the mixture at the exit of the mixer for Portland cement (including Pozzolanova), the slagoportland cement marks below 600 should be + 35⁰.

- For grades above 600 and fast-hardening analogs, the temperature plan + 30⁰, for the alumina cement + 25⁰.

- The time of transportation and laying a heated cement mixture should not exceed the time before the concrete begins to be captured.

- The temperature of the mixture to the beginning of heating or withstand should not be lower than + 5⁰ (when using concrete with contamination components). With thermal processing, the mode is not lower than + 2⁰.

- Concrete Pouring is continuously underway, with forced interruptions, it is covered with a film or heated.

Note!

Conditions are considered normative when concrete works and air temperature around are not lower than +5 ⁰.

Raise it to the desired level Temporary warmlights will help.It is also possible that solid water remains inside the concrete mass, but if it returns to a liquid state, when part of the hardening, it will be clamped inside the concrete and, even worse, it will prevent the volume that it will freeze occupy a mass of concrete, thereby creating cavity inside masses.

When is concreting in cold weather?

It is clear that it is very convenient, right? This item that is fully defined in the instruction in which it says that the temperature at the time of the pouring of concrete in the mold will not be less than 5º. Does this mean that in these cases we need to go home and wait when the weather is more favorable?

- Concrete without contamination additives by the time of freezing should acquire strength of 50%, 40% and 30% for brands B-12.5; B-15 / B-22.5 and B-30 / B-40, respectively. For periodical freezing and thawing after the construction of structures, the border of strength, regardless of the brand of concrete - 80%.

- A solution with antiorrosal additives by the time of freezing should achieve strength of 30%, 25% and 20% for brands B-15, B-22.5 and B-30, respectively.

- When the temperatures of the laid concrete and the ambient air are more than 25⁰, the design with the filled formwork is covered.

Conducting work on the soils with the eternal Merzlot

It should be especially noted that manipulation with concrete mixtures on the soils in the regions with permafrost is recommended to produce in strict accordance with the norms.

Concrete Mixed Temperature Mode

Well, theoretically, yes, but in real life no one believes. Of course, we must take into account certain measures to avoid the consequences of concrete in the cold weather, which we have said earlier. So let's see what we can do to be able to concrete in cold weather without negative consequences for a particular concrete.

Measures that need to be considered when concreting in cold weather

We have seen that the main problem of concreting in cold weather is the presence of water in the equation that is the most affected temperature, therefore it seems logical that the main actions that we need to do should be aimed at influencing this material in several ways.

The effect on the cooling of the fill of the harsh effects of wind and temperature is also taken into account.

- When selecting the composition of the mixture, you will have to take into account the effect of related components on the behavior of cement. The season of delivery, the shelf life in warehouses also has an important meaning.

- Installation of concrete structures in specific regions is produced when the soil conditions correspond to the project.

- Cooked for filling base protect against thawing in summer period And from freezing in winter.

- When laying directly on the maritime, temperature concrete solution should not be higher + 10⁰. This is calculated by heat engineering calculations that do not allow soil exhaustion.

- If it is necessary to lay a mixture with a temperature greater than + 10⁰ with withstanding the thermosa or electric heating, a pillow is made.

It is a thermal insulating sand layer with a positive temperature. Sand trambet and wait for circulation.

The main problem of concreting in cold weather is the presence of water, which is most susceptible to low temperatures. One of the first actions that we can do is reduce the amount of water in the test. Temperature conditions can affect smaller water water, so the low water ratio to cement during concrete dosing can improve concrete behavior at low temperatures.

For this purpose, the use of fluidizers may be of interest, so, despite the receipt of dry paste due to the low amount of water, it can support the performance of the test. As soon as we reducing the amount of water in the mass as much as possible, there is still a possibility that the temperature will depend on the temperature, so we should disappear as soon as possible, i.e. Accelerate the setting and hardening so that messenger water, free and freezing, becomes water combined with cement.

Then another sand layer is poured on it, the waterproofing is filling and poured with concrete. The thickness of the insulating pillow depends on the production project.

- To accelerate the solidification of the solution, anti-corrosive components and accelerators of hardening are often used. Their number should not provoke the defrosting of the primer base.

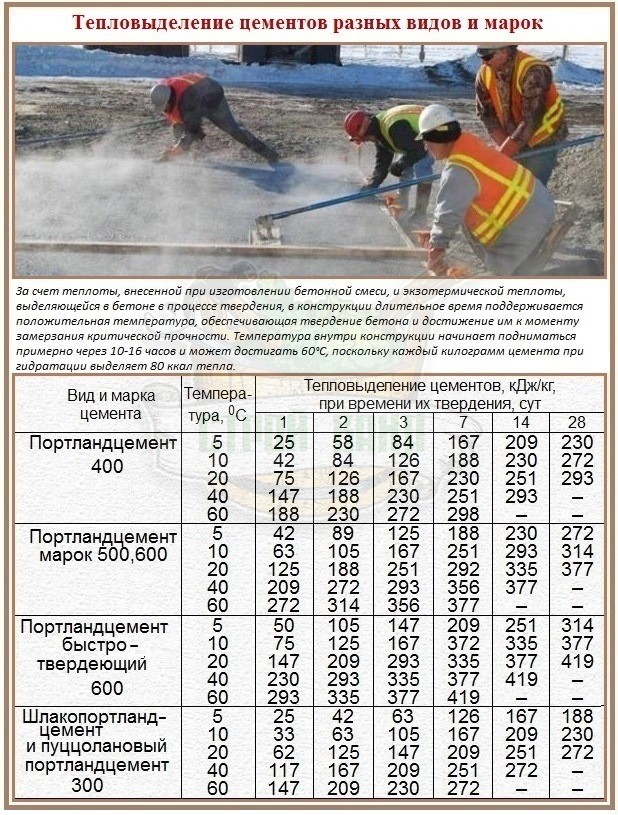

- Fresh concrete mixture is the isothermal process. That is, the stages of the reaction of the interaction of water with cement and other components. Due to this, heat is highlighted, warming most of the design.

- The presence of formwork also plays an important, insulating role. The surface layer, although it is modeled, protects everything else.

- Of all the components of the concrete mass, water is the most lightweight. Therefore, it rushes into the upper bed of the block, concentrating there in excess. As a result, crystallization, expansion and destruction of the foundation shell, plates and other things.

- Buy in the construction store PVC film. For material affordable priceBut please get a lot. Cover the concrete elements by it, pressed along the edges of the stones. If there is no hope for a thaw, leave the design until spring. So you will save everything, sacrificing only a thin top layer.

- Not covered concrete collapsed by the spring is stronger. The snow, accumulating on it, will accelerate the process of crystallization of water that destroys material. Several cycles of thawing and freezing will adversely affect the fruits of your work.

- If in the spring you found detached fragments, carefully eliminate them with a broom or brush. For the main part, do not worry, it is in order. But the surface is simply renovated by plastered them. Concrete will reach the mind, the faster, the warmer will be on the street.

- Calcium chloride reduces the timing of the composition of the composition, and the other components are plasticized by a mixture, facilitating its laying.

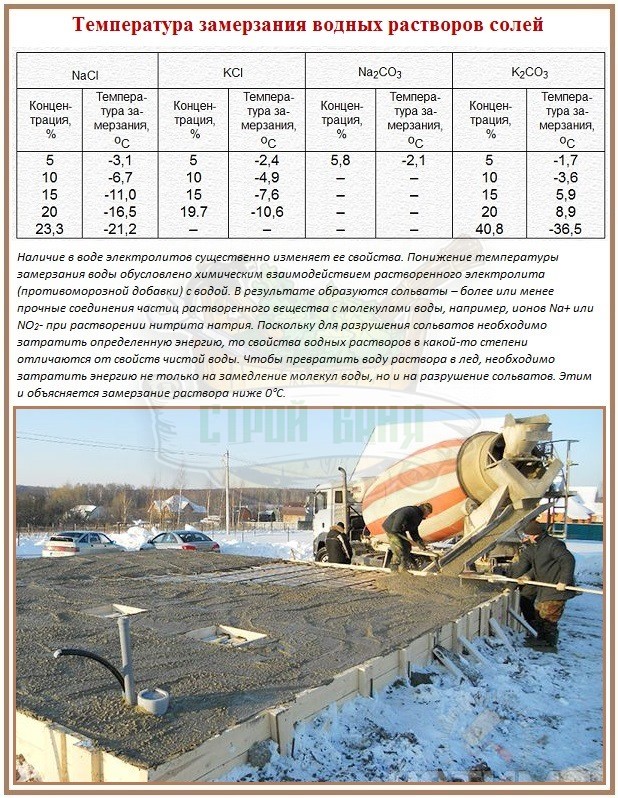

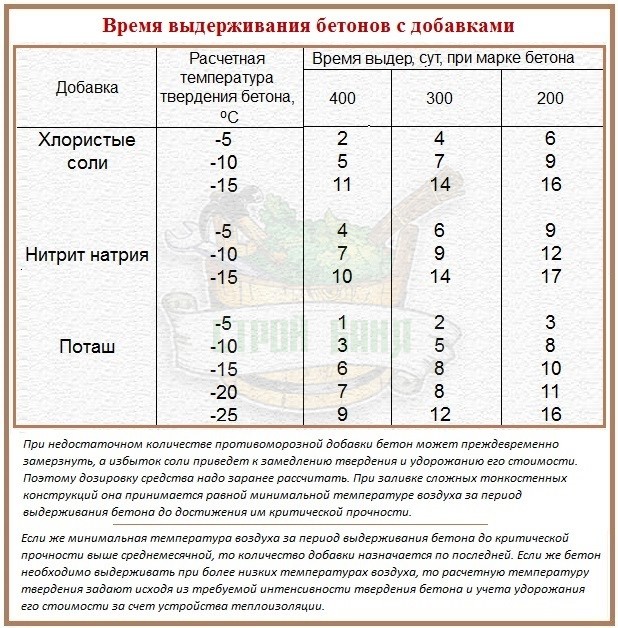

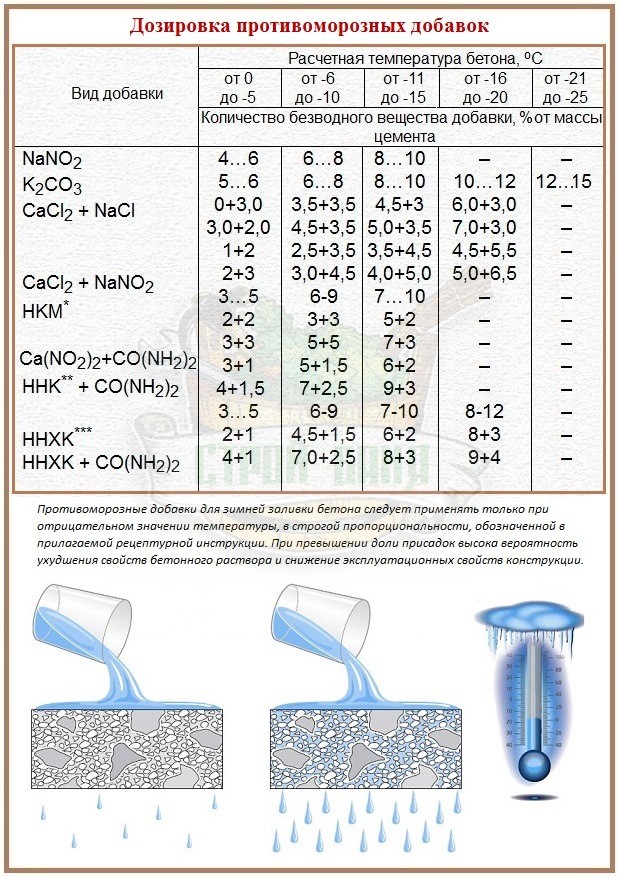

- Salts are mixed to concrete mass in the form of aqueous solutions. Their concentration is calculated on the tables.

- The design is gaining the necessary strength per month by 50%, for three months - by 100%.

- With positive temperatures, it is not recommended to work with such a mixture due to too fast frozen. The material is advisable to use in winter, but it is undesirable to work with frosts below -20⁰.

- In contrast to ordinary compositions, this type is less durable and durable, specifications A little inferior, but satisfactory.

The upper layer of not hardened concrete during freezes can collapse.

Pouring concrete at low temperatures

This can be achieved using the installation of accelerating additives, which will reduce the time during which water will be free, and the cold can affect it. We can also combine water faster using more fine-grained cements that have a higher initial impedance, because they are combined faster, which leads to the disappearance of free water.

Bringing water in combination with cement as soon as possible is a good measure for accounting in concrete in cold weather. Even when it comes to cement, we can use those that have a high hydration temperature, so that they help that the temperature is not so low to influence the mass.

It happens that the developer has started work in early autumn, in the hope of completing them to frosts. But the cold came earlier than planned, and concrete structures are already flooded, but did not reach the completed strength.

The owner who carefully studied the information at what temperature can be working with concrete, experiencing light shock and confusion. But it is not worth worrying, as the set of strength will only suspend. At the occurrence of thaw, the frost process will resume in the standard mode.

We can also affect the temperature using antifreeze additives, so that water reduces the freezing temperature and, therefore, does not affect the operation of the cold at the temperature significantly below, but is sufficient for confidence that it is not the final characteristics of a particular element will be changed.

What hinds cold

All this is very good, but we can not only influence the mass of fresh concrete, which we are going to pour, changing its dosage or chemical characteristics, but we can also act directly at the temperature to which the product was once concrete.

Experts explain that with a temporary decrease in air temperature, only a thin surface layer of concrete is frozen. The powerful stove of the foundation or overlap is not affected, the design will not increte irreversible damage. The worst thing is waiting for the builder - showering the fine top layer, at any time to be recovered.

Heat the concrete mix

A good measure for concreting in cold weather is to place concrete to limit the temperature with which it faces in the process of solidification. Yes, yes, this is one of the opportunities that work best. If the cold does not reach concrete, it will not be affected, and we can be calm, we will follow its normal process and avoid that there is a big difference in the temperature gradient between the surface of the concrete element and its inner part, which can cause cracking.

Why only the outer sheath suffers

If frozen concrete

It happened, and your creation was still underwent inadvertently stunned early frosts, did not have time to find it properly.

But how can we cover concrete? There are several ways to do this, depending on the element, because it will not be the same to cover the columns plant than the new cast concrete. In the case of special elements, such as pillars can be used wooden opalwhich significantly limits the passage of the cold in inner space or polystyrene formwork. Of course, the use of metal formwork is not good practice.

In addition to using the formwork, which supports the temperature better, it is recommended to increase the molding time, at least during the first 48 critical hours, until the water free from the mass is almost completely reduced, so these forms are responsible for maintaining a constant suitable mass temperature .

Cold concrete method

This method today is widely used in the construction of large areas, airfields, roads. The principle consists in adding to a mixture of antiorrotic additives - sodium chloride and calcium chloride.

Additives strongly lower the threshold of water freezing.

Output

Stern climate or forced construction work at low temperatures should not be alarmed. Competent calculation, correctly selected additives and technologies will help cope with the task. More topic will reveal the video in this article.

The foundation is a fundamental design, on the quality of which depends geometric, technical and operational characteristics of the erected structures. Due to the specifics of the process of hardening the fill of concrete and reinforced concrete foundations It is undesirable to engage in winter to avoid their deformation and premature destruction. Minus thermometer readings significantly limit the construction in our latitudes. However, if necessary, the fill of concrete at negative temperatures can still be successfully carried out if the correct method is selected and the technology is accurate.

Features of the winter "national" fill

Nature whiskers often make adjustments to development plans in the domestic territory. That pouring rain interferes with the ruin of the pit, then the squall wind is interrupted, then he is constraining the offensive of the country's season.

The first frosts at all in the root change the course of work, especially if the fill of the concrete monolithic base was planned.

Concrete foundation design is obtained as a result of a mixture filled with a formwork. It features three practically equal in the value of the component: aggregate and cement with water. Each of them contributes a significant contribution to the formation of durable railway facilities.

By volume and mass in the body of the artificial stone created, the aggregator prevails: sand, gravel, dressing, crushed stone, broken brick, etc. According to functional criteria, the binder is leading a binder - cement, whose share in the composition is less than the fraction of the aggregate of 4 -7 times. However, it is he who binds bulk components together, but acts only in a pair of water. In essence, the water is as important component concrete mix, like cement powder.

Water in a concrete mix is \u200b\u200benveloping fine particles of cement, involving it in the hydration process, followed by a crystallization stage. Concrete mass does not pour out how to say. It hardens through the gradual loss of water molecules originating from the periphery to the center. True, in the "transition" of concrete mass to the artificial stone not only the components of the solution are involved.

On the right course of processes, the environment has a considerable effect:

- With the values \u200b\u200bof the average daily temperature from +15 to + 25 ° C, the concrete mass hardness and a set of strength takes place at a normal pace. In the specified mode, concrete turns into stone through 28 days specified in standards.

- With the average daily readings of the thermometer + 5ºС, the hardening slows down. Concrete relevant strength will reach approximately 56 days, if there is no tangible temperature fluctuations.

- Upon reaching 0 ° C, the hardening process is suspended.

- At negative temperatures, the mixture is flooded with a formwork. If the monolith has already managed to gain critical strength, then after thawing in the spring, it concrete will again enter the hardening phase and continues it until a complete set of strength.

Critical strength is closely related to the cement brand. What it is higher, the less day it is necessary to the concrete mix before it is set.

In the event of an insufficient set of strength before freezing, the quality of concrete monolith will be very dubious. The water freezing in concrete mass will crystallize and increase in volume.

As a result, an internal pressure of destructive communication within the body of concrete will occur. The porosity will increase, due to which the monolith will make more moisture into itself and is weaker to resist frosts. As a result, it will be reduced operational time or at all will have to work with zero.

Minus temperature and foundation device

It is pointless to argue with weather phenomena, it is necessary to correctly adapt to them. Therefore, there was a thought on the development of the methods of the installation of foundations in our difficult climatic conditions, possible for implementation during the cold period.

It should be noted that the application will increase their construction budget, because in most situations it is recommended to resort to more rational options for the foundations. For example, use a boronobic way or carry out factory production.

At the disposal of those who are not satisfied with alternative methods, there are several techniques proven by successful practices. Their appointment is to bring concrete to the condition of critical strength before freezing.

By type of exposure, they can be divided into three groups:

- Ensuring the external care of the concrete mass filled into the formwork until the set of critical strength.

- Increase the temperature inside the concrete mass until the moment of sufficient hardening. Performed by electrical heating.

- Introduction to a concrete solution of modifiers that reduce water freezing point or activating processes.

The choice of the method of winter concreting is affected by an impressive number of factors, such as power sources on the site, forecast of weather forecasters for a period of hardening, the ability to give a preheated solution. Based on local specifics, selected best option. The most economical of the listed position is the third, i.e. Pouring concrete at a minus temperature without warm-up, predetermining the introduction of modifiers to the composition.

How to pour concrete foundation in winter

To know what method is better to take advantage of concrete to critical strength indicators, you need to know their characteristic features, familiarize yourself with the minuses and advantages.

Note that a number of methods are used in a complex with any analogue, most often with a preliminary mechanical or electric heating Components of concrete mix.

External conditions "for ripening"

Favorable for hardening External conditions are created outside the object. It is to maintain the temperature of the environment surrounding concrete at the standard level.

Caring for the flooded "in minus" concrete is carried out in the following ways:

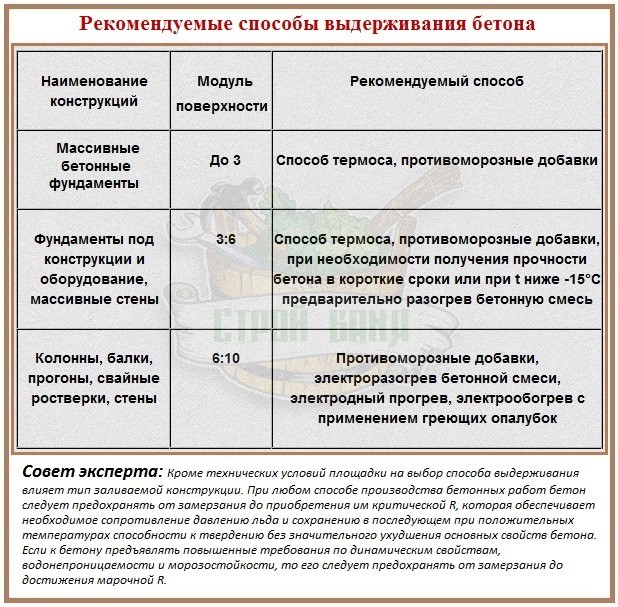

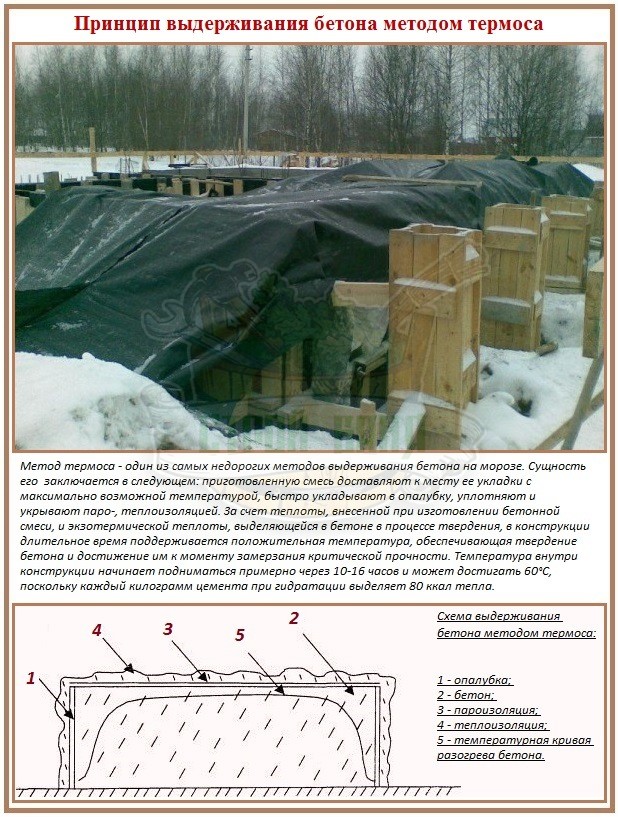

- Thermos method. The most common and not too expensive version consisting in protecting the future foundation from external influences and heat loss. The formwork is extremely promptly filled with a concrete mixture heated above standard indicators, quickly covered with vapor insulation and thermal insulation materials. Isolation does not give the concrete mass to cool. In addition, in the process of hardening, the concrete itself allocates about 80 kcal of thermal energy.

- Withstanding a flooded object in warm-up - artificial shelters that protect against the external environment and allow you to conduct activities on additional air warming. Around the formwork, tubular frames are erected, covered with tarpaulo or trimmed plywood. If warmer or heat guns for supplying heated air are installed to increase the temperature inside, then the method goes to the following category.

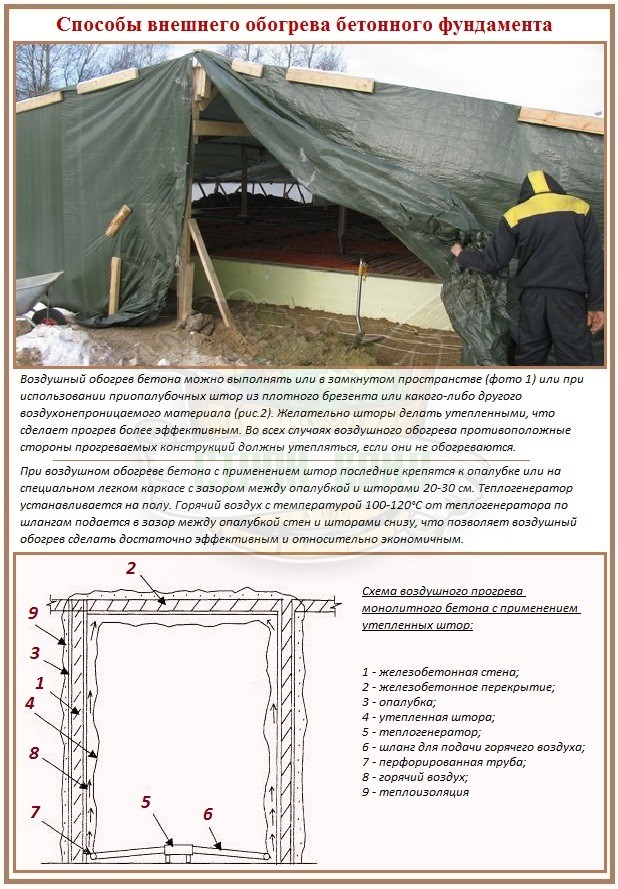

- Air heating. Ensures the construction around the object of the closed space. At a minimum, formwork is closed with curtains from tarpaulin or similar material. It is desirable that the curtains are with thermal insulation to increase the effect and reduce costs. In the case of the use of curtain pairs or air flow from the heat gun is supplied to the gap between them and formwork.

It should be noticed that the implementation of these methods will increase the construction budget. The most rational "thermos" to force the covering material. The warm-up structure is even more expensive, and if it is also a heating system to rent, then it is worth thinking about the number of expenses. Their application is appropriate if there is no type alternative and pour monolithic slab Under freezing and spring defrosting.

It should be remembered that multiple defrosting is devastably for concrete, therefore, the external heating must necessarily bring to the hardening parameter.

Concrete Mass Heating Methods

The second group of methods is used mainly in industrial construction, because needs an energy source, in accurate calculations and in the fate of a professional electrician. True, the folk craftsmen are in search of an answer to the question whether it is possible to flood the usual concrete into the formwork at a minus temperature, found a very witty output with the supply of energy with a welding machine. But for this we need at least the initial skills and knowledge in difficult building disciplines.

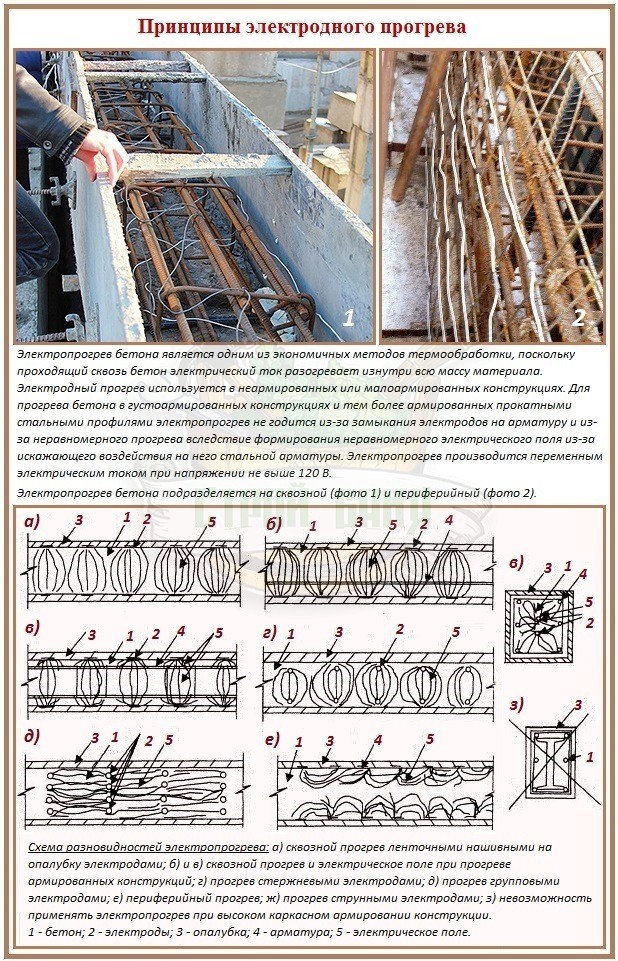

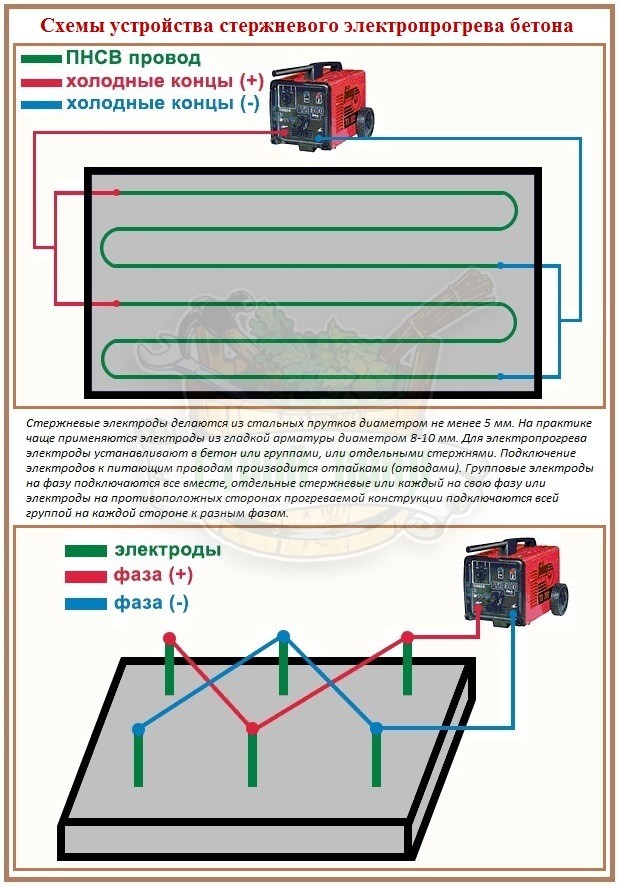

In technical documentation, the methods of electrical heating concrete are divided into:

- Through. According to which concrete warms up electric currentswhich are supplied with electrodes that are laid inside the formwork that can be rod or string. Concrete in this case plays the role of resistance. The distance between the electrodes and the supplied load must be accurately calculated, and the expediency of their use is unconditionally proven.

- Peripherals. The principle consists in heating the surface zones of the future foundation. Thermal energy It is supplied by heating devices through the ribbon electrodes attached to the formwork. It may be strip or sheet steel. Inside the massif, heat is distributed due to the thermal conductivity of the mixture. Effectively, the thick of the concrete is heated to a depth of 20 cm. Further less, but the voltages are formed, significantly improving the criteria for strength.

Methods of end-to-end and peripheral electrical heating are used in unarmed and little reinforced structures, because Armature affects the warming effect. With a thick installation of reinforcement rods, currents will close the electrodes, and the formable field will be uneven.

The electrodes at the end of the warm-up forever remain in the design. In the list of peripheral techniques, the most famous is the use of heating formwork and infrared mats stacked over the constructed base.

The most rational way to warm up the concrete is recognized with an electrical cable. Heating wire can be paved in the structures of any complexity and volume, regardless of the frequency of reinforcement.

The minus of heating technologies is to be able to cut concrete, because calculations and regular monitoring of the temperature state of the structure are required.

Introduction of additives in concrete solution

The introduction of additives is the easiest and cheapest method of concreting at minus temperatures. According to it, the fill of concrete in winter can be performed without the use of warming up. However, the method may well complement the thermal processing of an internal or outdoor type. Even when using it, with heating the hardening foundation, the ferry, air, electricity is felt.

Ideally, the enrichment of the solution additives is best combined with the construction of the simplest "thermos" with the thickening of the heat insulating shell on areas with a smaller thickness, at the corners and other protruding parts.

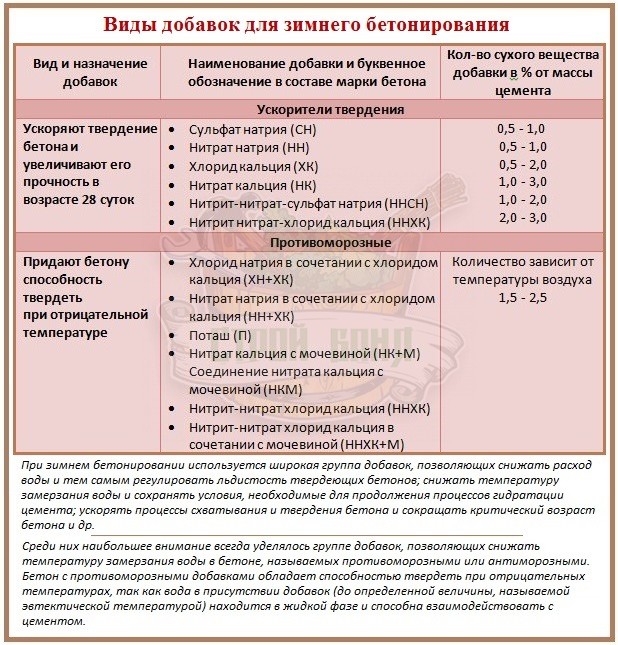

Additives used in the "Winter" concrete solutions are divided into two classes:

- Substances and chemical compounds that reduce the freezing point of fluid in the solution. Provide normal hardening at minus temperatures. These include sweat, calcium chloride, sodium chloride, sodium nitrite, their combinations and similar substances. The type of additives is determined based on the requirements for the solution of solutions.

- Substances and chemical compounds accelerating the hardening process. These include sweat, modifiers with the basis of a mixture of calcium chloride with urea or nitrite-nitrate calcium, its own sodium chloride, one nitrite-nitrate calcium, etc.

Chemical compounds are introduced in a volume of 2 to 10% of the mass of cement powder. The number of additives are selected, focusing on the expected impact temperature of artificial stone.

In principle, the use of antiorrosal additives allows concreting and at -25ºС. But such experiments are not recommended to builders of private sector facilities. In fact, they are resorted to late autumn with isolated first frosts or early spring, if the concrete stone must be able to operate to a certain period, and alternative options there is none.

Common anti-corrosion additives for pouring concrete:

- Potash or otherwise carbon dioxide (K 2 CO 3). The most popular and easy-to-use modifier "winter" concrete. Its use in priority due to the lack of corrosion of reinforcement. For potash, the appearance of salt divorces on the surface of concrete is not characteristic. It is Potash that guarantees the hardening of concrete when the thermometer readings up to -25 ° C. The lack of its introduction is to accelerate the setting rates, because of which it will be necessary to manage the mixture with the fill in the mixture in 50 minutes. In order to preserve the plasticity for the convenience of pouring into a solution with Potash, a soylonaf or sulphite-alcohol bard is added in a volume of 3% of the mass of cement powder.

- Sodium nitrite, otherwise nitrous acid salt (Nano 2). Provides concrete a stable set of strength at temperatures up to -18.5 ° C. The compound has anticorrosive properties, increases the intensity of hardening. Minus in the appearance of oction on the surface of the concrete structure.

- Calcium chloride (CaCl 2), which allows concreting at temperatures up to -20 ° C and accelerating concrete grasp. If it is necessary to introduce a substance in a concrete in an amount of more than 3%, it is necessary to increase the brand of cement powder. The lack of use is the appearance of heights on the surface of the concrete structure.

Preparation of contamination mixtures is made by special order. First, the aggregate with the main part of the water is mixed. Then, after light mixing, cement and water with chemical compounds in it are added. Stirring time is 1.5 times compared with the standard period.

Potash in a volume of 3-4% of the mass of the dry composition is added to concrete solutions, if the ratio of the binder to the aggregator 1: 3, nitrite nitrate in the amount of 5-10%. Both antiorrosal funds are not recommended to use in the fill of structures operated in a water-water or very humid environment, because They contribute to the formation of alkalis in concrete.

In the pouring of responsible structures, it is better to use cold concrete cooked by mechanical way in the factory. Their proportions are accurately calculated with a substrate target and air humidity during the fill.

Prepare cold mixes on hot waterThe share of additives is introduced in a clear accordance with weather conditions and with the type of constructed structure.

Concrete fill methods in winter:

Winter concreting with warm-old device:

Antiorious agent for winter concreting:

Before filling solutions with antiorrosal additives, it is not necessary to warm up the bottom of the pit or trench, died under the foundation. Before the fill of the heated compositions, warming up the bottom is obligatory to avoid irregularities that may be possible due to the ice mounted in the soil. Pouring should be performed on one day, ideally in one app.

If the interruptions cannot be avoided, the intervals between the fills of the concrete solution must be minimized. In compliance with the technological sublictions, the concrete monolith will type the necessary margin of safety, it is powered by winter and will continue to harden with the arrival of warm times. In the spring it will be possible to start the construction of walls on the finished reliable basis.

2016-04-13 21:53:09

The wife lives in the same city, and I work in another. Bought a recently large country area. So my plan was formed that concreting and decor would have to do in the winter period (now cases are not terrib.). Solved on cottage plot Make a big gazebo with the tracks suitable for it. True, the brains had enough ... I can't even imagine how I would do. Began to worm the Internet in search of information on the fill of the foundation in winter and concrete in particular.