No matter how convincingly not promoted manufacturers of wooden entrance doors their products, it is out of doubt about strength and reliability significantly inferior to steel counterparts. However, among the metal fellow, there is a gradation that shares them into categories in the degrees of protection, in terms of impeccable service and for aesthetic qualities. Steel entrance block - the acquisition is not discharge of cheap purchases. Therefore, before going to the store, you need to find out how to choose an inlet metal door, for which you need to pay, and what is not worth spending.

In priority choice reliability

We will not deceive yourself and others, proving that the "iron" defense we like in the aesthetic indicators. Although the latest Italian, and domestic models can be called attractive without reservations. We are solved on the installation of a steel "barrier", first of all, due to ultrahigh physico-mechanical characteristics of the material and due to the possibility to equip the design with the maximum number of protective devices.

First you need to pay attention to:

- on the specifications Products specified in the manufacturer's documentation;

- on the structural features of the frame and the canvas entrance door;

- by the number of mounted devices capable of complicating the solution to the problem of unauthorized penetration.

Moreover, for myself, you personally need to determine the necessary and sufficient limit of reliability in advance, since the bust in these indicators entails not only the increase in the price. Often, super reliable metal doors create absolutely unnecessary problems to the owners. Permanently breaking too complex crab locks with the junction of the upper riglel, after which it has to be trite new door. Too serious canvas is difficult to open / close the children and elderly family members. In addition, the mechanisms are rapidly wear out, the frame is deformed, the canvas sails on the exterior loops.

Required and sufficient technical specifications

Let's start with the quality and thickness of the metal, on which the weight of the structure is dependent and the price. In the production of iron entrance doors does not use "Iron". It is not used in pure form anywhere, only alloys. Make sheet steel doors obtained during hot or cold rolling. Once we find out how to choose metal door, It is necessary to compare the properties of the material:

- The hot-rolled metal is suicide and dark on the color, but under the decorative coating of its blacks is not visible. He is more susceptible to the appearance of rust foci on its surface, quickly eats corrosion. If the manufacturer used exactly this type of material, the document will include GOST for the 19903 number.

- Cold rolled alloy is more expensive than the previous version. Without processing pleases with standard color galvanized steel. The doors made from it are not affected by direct contact with atmospheric troubles. GOST with a number of 19904 will tell about its use in the manufacture of the door.

If the alloy is oversaturated with carbon, it loses plasticity. High content of alloying elements is also nothing. Optimal for the production of doors and their further operation are sub-associated (up to 11%) and medium-carbon (up to 0.6%) steel alloys.

Next, we estimate the prospects and choose the iron door, designed to protect our property on the thickness of the steel sheet. This indicator will also find in technical documents. Its values \u200b\u200bmay vary from 0.8 mm to 4.0 mm, according to:

- the doors made of sheet steel with a thickness of 0.8-1.0 mm do not belong to the clan of the input structures. Suitable for the arrangement of economic buildings intended for storing low-value things, gardening inventory;

- the canvas of two sheets with a metal thickness of 1.0-2.0 mm is a suitable solution for equipping office space in a multi-storey business center with security;

- 2.0-2.5 mm - the norm for the door leading from the apartment in the entrance;

- 4.0 mm is the optimal option for a country mansion, especially if it does not live in it.

The thicker sheet steel, the harder and more expensive the door. It will be more expensive not only due to the cost of the material, but also due to the special installation scheme, additional powerful loops and the enhanced frame. The optimal weight of the iron door for residential facilities is considered to be 70 kg. 90-100 kg and more weighing doors for banks and bulletproof options.

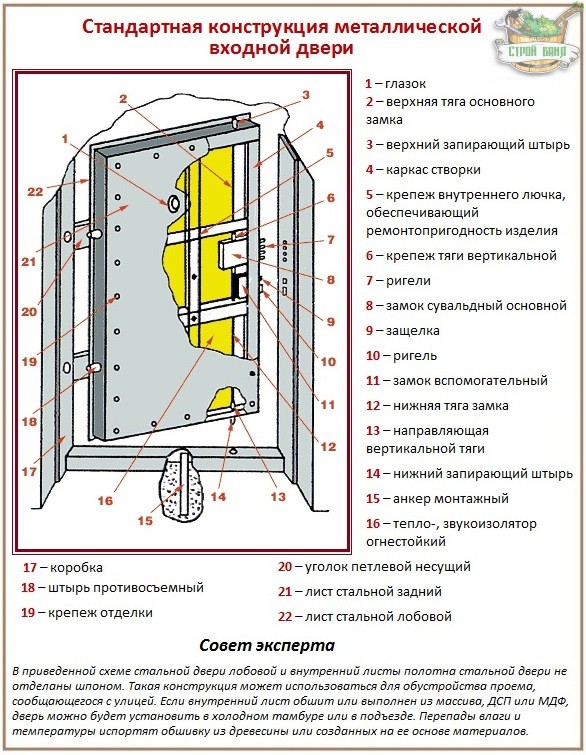

Structural features of the steel door

Two main components of any door Block - The canvas and box, it is a frame, which corresponds more to the product from steel blanks. The most reliable is recognized as a monolithic frame with one welded stitch, a less reliable frame, welded from four segments of the hot-rolled co-rolled pipe rod. The most "hip" type is welded from four segments, each of which in turn is welded from two equal to the length of the corners.

If shorter: the more welding seams, the worse, according to the statement of engineers. In their opinion, welding changes the initial settlement geometry. The consequences of the violation of the estimated geometric parameters can not appear at all immediately after installation, among them:

- dry and accompanying the need for application effort;

- right opposite drafts and gaps that allow you to cut the inner loop, open the door scrap or mount;

- enclosure of the canvas, the bolts of the lock system.

On the front side of the canvas should not be welded seams. The outer part must be made of the monolithic sheet, otherwise it will not withstand a strong impact of a pitchflower.

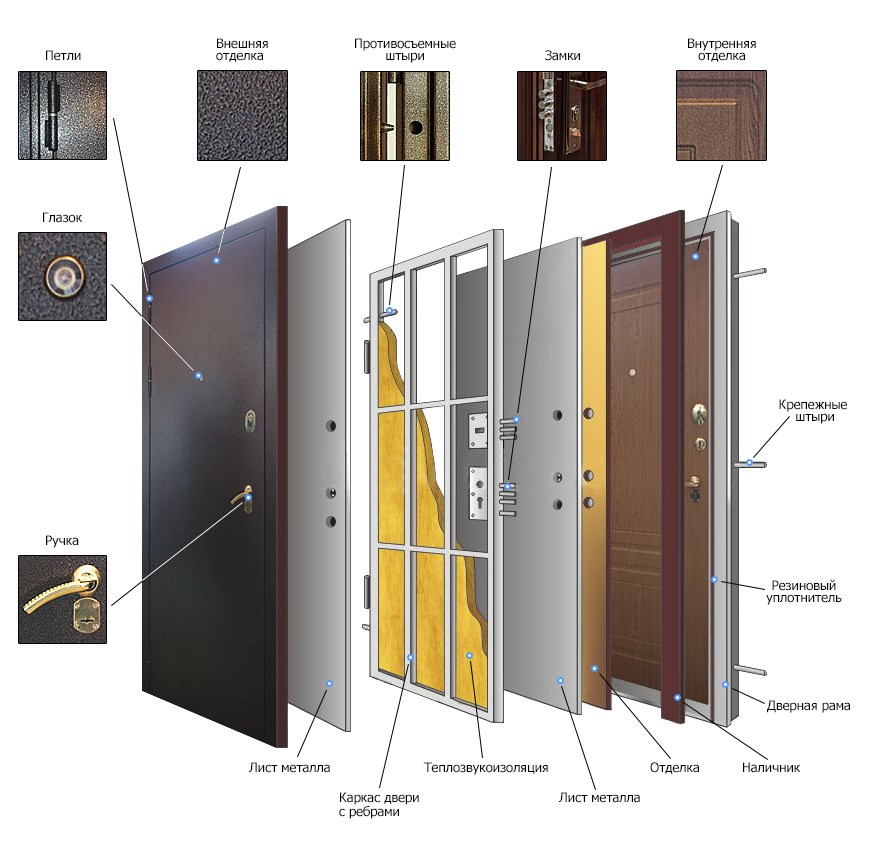

Canvas as a landmark

The canvas itself is a rectangular frame, which is attached to two metal sheets. There may be one steel outer leaf and an inner panel of array, MDF or a chipboard coated with laminated film, veneer, cheap vinyl. This feature distinguishes the entrance blocks to the capable of withstanding the attacks of the atmosphere and are not able to resist the solar rays and moisturizing.

If the owner decides which of metal doors to choose to install in the opening, communicating with the street, the answer is unequivocal - completely iron, since the temperature differences and fluctuations in the level of moisture will lead wood and materials created from its fibers. Shut up blocks with tandem metal-MDF apartments or additional entrance to vacation homeLeading from a closed tambour in housing.

Note. The condition of full protection against hacking with infertility thieves - lomik and vague is steel cash and focus. They will close all unreliable sections and stop access to responsible details.

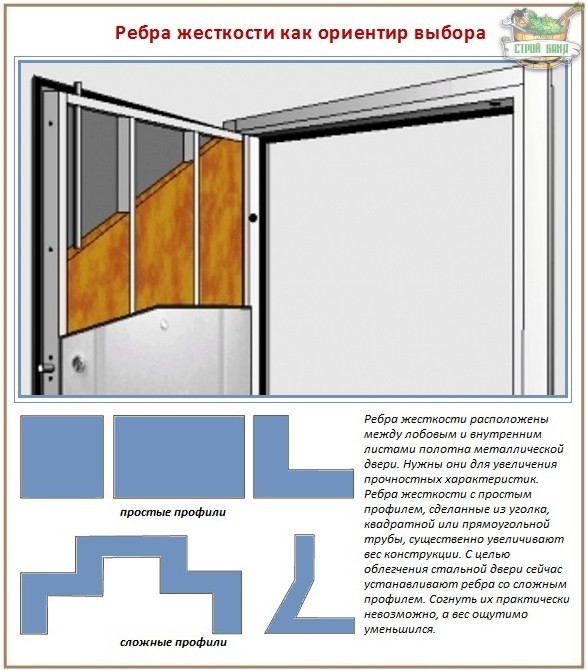

Recalculate the ribs of stiffness

Between the outer steel sheet and the inner panel, it does not matter from what material it is made, the ribs of cruelty are located. At a minimum there should be two vertical and one horizontal. Best of all, if the ribs are larger than the specified limit, because their number increases reliability. But simultaneously with reliability they will increase weight.

In order to reduce the weight of the ribs, not from a conventional corner or rectangular steel pipe, and from long rental with a complex profile. Bend complicated-profile ribs is almost impossible, and they are driving the door slightly.

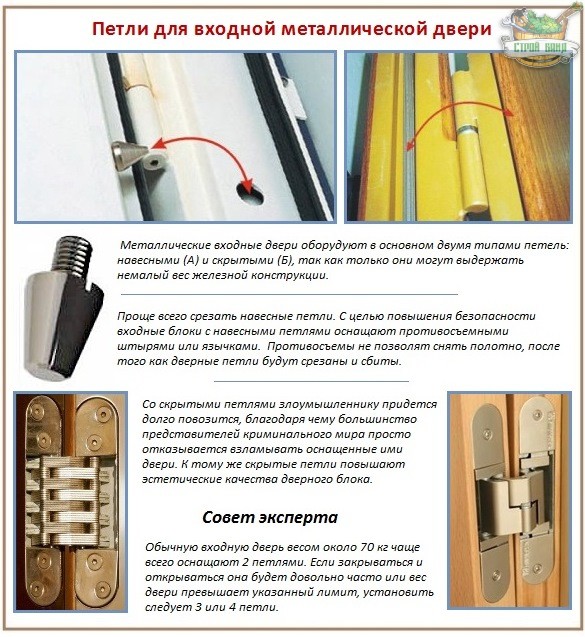

Reliable door hinges

Those who wish to find out how to choose the right door to choose, attention should also be paid on loop. Steel door blocks equip two varieties:

- hidden loops, unconditionally eliminating the desire to cut off;

- common outdoor, cut which in principle can, but remove the canvas will not allow anti-mounted devices - small steel pins, "recessed" into special holes of the frame with a closed door.

For inexplicable reasons, the last type is most often used. Apparently because the degree of protection provide anti-conversations.

The amount of loops determines the weight of the canvas. For a standard in 70 kg, there are enough two loops if the door is not operated with increased intensity with a closing 50 times a day. Those who are going to actively move back and forth, and those who decided to install a bullet-proof door, loops will need 3-4 pieces. The loops must have a reference bearing, which will extend the term of impeccable devices and facilitates operation.

About warm and ways to save it

The metal door does not contribute to the preservation of heat, as the material perfectly conducts heat waves. The thermal insulation is placed between the outer and inner sheet of the web, for which the mineral wool insulation or foamed polystyrene is used because of the resistance of the combustion and environmental priorities. You should not hope for insulation, cold bridges are still formed in the zone of the ribs of rigidity and the perimeter of the frame. But with isolation is still warmer than quite without it.

From drafts and foreign smells will save the rubber seal. Most manufacturers equip the canvas with two rows, but experts believe that one is enough.

Castle - friend and faithful watchdog

"Invertible guard dogs", that is, not opened locks does not exist. The difference between the unreliable and reliable lock is only in a segment of the time that the attacker needs to be spent on an opening. True, too complex stopping systems are sometimes summoned by the owners themselves, because neither manufacturers nor the sellers of iron doors are not advised to get involved in constructive delights.

The most efficient shut-off option, both consumers and manufacturers recognize the presence of two castle systems of different types. It is desirable that the main one is equipped with bars for locking in several directions for a long time, and the auxiliary satisfied the owners often closing the door to the short period.

To talk about what entrance doors are beautiful and what it is better to choose to arrange a house or apartment with a prevailing interior and exterior, no washed. Opinions in all individual, there is no need to bring them to the general denominator. You can only advise to buy door blocks with an external anti-vandal coating that protects the appearance of the input group from fans to spoil beautiful things. Its, by the way, can be applied independently after installation. So, on the top of the search cliffs, we will strengthen the checkbox with the inscription "Reliability", measure the discharge according to the rules that can be found in the appropriate article, and rust to conquer sellers awareness, not forgetting that we came to buy a super durable iron barrier.

Choosing a reliable and functional entrance door, we are guided by many principles. A pleasant design is, of course, it is good, but for the demanding developers usually dominated the issues of solidity and foundation of structures. It is difficult to resist if in some salon we offer a metal door of the high thickness, which is "better and stronger than any competitors." In fact, not everything is so unequivocal. For example, the doors produced by comrades from the Middle Kingdom were always famous for normal and increased thickness, but irreparable problems with durability and vomotability remain. So, not everything depends on the thickness of the canvas, here it seems that it is important which materials are used in production, and how the assembly / welding of the door block itself occurs, as far as the design is thought out. Let's deal with what the thickness of the canvas is generally folded from the steel door, and how it affects the working and consumer qualities of the products you are interested in.

If you are not yet determined with the choice, see our offers.

Free challenge measureer

The "Your Phone" field is required to fill.

The first thing is the most effect on the thickness is the cross section of the rigidness, which forms the power frame of the canvas. It uses various rental options: corners or chawliers, but the profile tube with dimensions is most often used: 40x25, 40x40, 40x50. In this case, you need to pay attention to the wall thickness of the ribbon. Naturally, there will be a significant difference in the strength of the door, if the wall thickness is one millimeter, either two or three, and in itself the cross section of the roiber affects the strength and lobustness indirectly. Unfortunately for the buyer, find out what exactly the metal is used by the manufacturer in the frame, you can only be in its workshops.

Sheets of sheaturing

The second factor of the thickness of the web is characteristics sheet metalwhich is used to cover the steel door. The Chinese are actively used for these purposes to use a thick tin with a thickness (along with painting) about 0.5-1 mm. Such a door is easy, convenient for installation and even beautiful, but opened in two minutes by any prickly tools. Using 1-1.5 mm thick sheets, many (especially foreign) firms with special equipment make pretty reliable and practical doors that meet current regulatory requirements for doors as a fencing building construction. In fact, in order not to injure the consumer's psyche and remain competitive, the declared metal thickness is usually overestimated by a producer on a pair of "millime". Check and reveal it is also quite difficult. For the sake of justice, we note that the doors with a thin or even one-sided trim in some circumstances will be quite suitable, for example, as technical, interroom.

In our country (this shows statistics and practice) the most optimal thickness of the sheets is about 1.5-2 mm. They are relatively easy to weld with publicly available equipment and provide sufficient strength at a moderate mass of the finished product. Sometimes, in the manufacture of the door, metal is used with a thickness of 3-4 mm or an additional 2 mm sheet (usually from the outside). Obviously, such a design will have a higher resistance to power influence. But that this truly rose in the class of intolerance, it is also necessary to apply all other measures - high-quality locks of increased secrecy, special bron alphabets, reinforced loops, functional crab mechanism, special installation ... Otherwise, we only have a useless increase in the mass of the door design with all the consequences Operating consequences, and tangible increase in value.

Unfortunately, very often people confuse the concepts of the "sheet thickness" and "thickness of the steel door canvas." So that the people did not know much, the sellers are intentionally (or without understanding) they impose such delusions, and meanwhile, as you notice, the dependence between the sheet thickness and the thickness thickness is insignificant. But if you see a thick and relatively inexpensive door, then you should ask the thickness of the metal of the sheath and the thickness of the walls of the ride rigidity.

The third point affecting the thickness of the metal of the inlet door from the metal is the type of finishing. Naturally, the thickness of the painting of soluble paints affects the thickness. A little more layer will give a powder spraying, especially if it is made with the creation of texture. And another thing is different facing panels. For example, MDF thickness and similar materials can average from 8 to 14 millimeters. As for the decoration of the door with an array of wood, then the panels can reach 25 mm thickness and more. As for the "dodged" finishes, such as "Leather + Sinytec", then the thickness is more dependent on the fancy of the wizard. Note that the facing of the doors outside and from the inside of the room can be performed various materials.

In any case, the door thickening due to these layers performs quite utilitarian functions, in particular, insulating. Facing panels and soft volumetric finishes significantly increase the thermal insulation characteristics of the steel canvas and the input group as a whole, which is especially important if the door is operated on the street. Also, additional layers help stop sound waves - noise will not pass through the door.

We make the right conclusions

So, the thickness of the cake of the input door on average there are their following indicators: 40 mm (ribbing) + 2x2 mm (shears of the trim) + 12x2 (MDF panels) \u003d 68 mm. This indicator It is enough to implement the entrance to most residential premises. The maximum is usually about 100 mm. Let's immediately confirm your assumptions: in a wider web you can install a larger number of insulation - indeed, it is so. But this does not mean that the insulating properties of the door will grow proportionally. Much depends on the quality of the assembly and installation, as well as from other structural features of the steel door: the presence of cold bridges, type and quality of seals, shape and density of the gunner, the type of slopes ... for the entrance door, in order to exclude condensate fallout, it is still better to organize buffer thermal insulation mode - With the help of a cold tambour or an additional domestic door.

It should be understood that if the thickness of the web in terms of indicators is significantly falling out of the average values \u200b\u200bof 50-90 mm, then difficulties arise with other elements of the system. First of all, it concerns mortise parts - shut-off mechanisms and fittings. In particular, in a thin web (less than 45 mm), it is technically impossible to establish a reliable suvalid castle normally to establish a crab mechanism rue. Too fine canvas are extremely difficult to make a suitable form suitable for adjustment to the acclacent form and set several seal contours. Such a door is the outlet of the outlook, to which special requirements in terms of decor and thermal insulation are presented.

The increased thickness of the door will require a troublesome and expensive selection of long larvae for cylinder locks, handles, eyes. Such doors in any case weigh more, so it is necessary to strengthen the loop group, including an increase in the number of loops. Do not forget that there will be more materials for the massive canvase, and, therefore, the price of the product will also increase. Constructions, thickening approaching to ten centimeters, it makes sense to install in the most responsible places, especially if the steel front door is operated on the street - entrance to the office or, let's say, in a private cottage.

The thickness of the railway canvas depends on several indicators:

- the parameters of the rigidity;

- sheet metal thickness used to create a canvas and door box;

- type of decoration.

Stiffness ribs are included in the package of doors with high resistance to mechanical hacking. For the manufacture of these elements, experts use several options for metal rolling: profile pipe, Corner, Schwell. The value of the stiffness edge wall thickness, which varies from 1 to 3 mm on average.

The thickness of the steel for the entrance door, as considered above, varies in a wide range. It should be remembered that the strength of the entrance block to the power influence also provides high-quality accessories: locks with a complex mechanism of secrecy, protective armored panelands, reliable loops, etc.

Today, a variety of materials are used to finish the woven. Paints and nitroemali do not affect the thickening of the entrance block, unlike the facing panels and the "douched" finishes. The MDF entrance doors often have a cloth thickness of 70 mm and above. MDF plates are able to increase the thickness of the product by 10-16 mm or more. The thickness of wooden linings is often over 25 mm.

Standard door thickness

What thickness should the entrance door be to maximize the room from the thieves?

Some manufacturers of metal structures provide customers with the opportunity to choose the thickness of the entrance door to the apartment or other rooms. Determined by the thickness of the input unit, it is important to take into account the following nuances:

On the russian market The door is widespread 50-90 mm thick. This indicator is enough for structures intended for the input zone of residential premises.

The thickness of the fire doors depends on the design features of the product and the fire resistance limit of the input unit. The average thickness of the refractory doors can be varied from 50 to 70 mm. Fire doors most often made from cold rolled steel and equipped with accessories, resistant to extremely high temperatures. Fire doors have a small sheet thickness thickness: from 1.2 to 1.5 mm.

At the production of "Stroystalinvest" use a metal with a thickness of 2.2 mm for the doors of the standard configuration. This is the optimal value to ensure the stability of the door to opening without weighting of the input unit. The structural features of a particular model affect the thickness of the canvas of the corporate door. For example, the MDF thickness of the panels is from 10 to 16 mm.