03.09.2016 8276

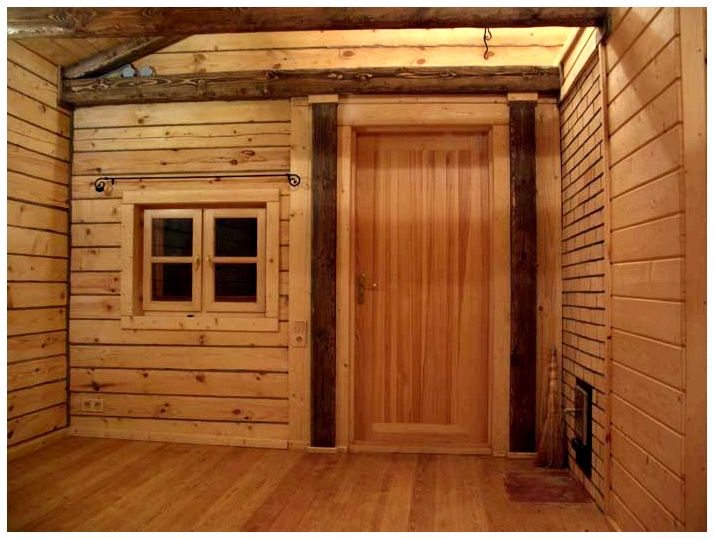

To make your own hands, you need to purchase material, prepare the tools, remember the joinery skills. Usually there are at least two doors in it - the inlet and the steam room is the main room, for which the bathhouse is built. It creates temperature conditions, useful for people, but extreme for materials, so in the manufacture of doors, these features take into account.

What to do? We choose the material

The input designs of the pre-banker or the wax room can be from any material,door to the steam room do it yourself should be made of wood.Natural material will be able to endure all the temperature drops, not highlighting harmful substances (like plastic), without heating to an unbearable degree (like iron). Deciduous rocks (oak, aspen, alder, linden) are recommended by masters for the manufacture of bath items and accessories - they contain less resin evaporated with heating, which have to breathe. Coniferous wood (pine, spruce, cedar) is also used, but we will have to come down with a sharp smell and resinous "tears" on the surface. Despite the rigidity and difficulty of processing, a plurality of bath log cabins are made from coniferous rocks.

Oil, alder - soft materials With a beautiful texture. Linden feature - isolation when heating phytoncides with possessing healing properties. Oak has all the excellent advantages of high-quality wood, including high cost. The door to the pair can be made from any kind of tree:

- oak - solid tree of valuable rock, but prone to cracking;

- larch - has a natural antiseptic, is not subject to rotting and attacks of bugs;

- lipa - highlights phytoncides, pleasantly smells, but he dares during operation and rotates quite quickly;

- aspen - the cheapest material, costs 40% less linden, does not crack when dried;

- pine - durable breed, separating odorous resins;

- spruce is less resinous, but absorbs a lot of moisture, requires drying. Long retains its original color.

From pine and aspen, considering these breeds suitable for such purposes. Now there are exotic species of wood - Abashi (African oak), Canadian cedar.

Council. From whatever breed of wood, the door for the steam room was made, it is important to provide for the absence of bitch. The effects of high temperatures, water and steam will lead to their lifting and formation of holes.

Forest tools and materials

To make a door for a bath with your own hands, use a standard carpentry set of tools:

- saw (jigsaw, hacksaw);

- mill;

- a hammer;

- chisel;

- plane;

- screwdriver, screwdriver, drill;

- self-tapping screw;

- wooden seasons.

The bath will require the following materials:

- bar 50 * 50 mm - for stacks;

- bar of the selected tree of wood 60 * 80 mm of sufficient pattern - for the manufacture of the box;

- 50 * 30 mm board - for the door leaf, a 5-mm thick strapping bar is larger than that of the board;

- loops.

The amount and nature of the material depends on the design of the door. It is usually deaf single-door doors one - or two-frame, standard size which:

- width - 0.7-0.8 m;

- height - 1.7 m;

- the height of the threshold is 0.15-0.3 m.

Accessories and fasteners are selected from stainless steel, the handle is made of wood, since the metal is strongly heated, and the plastic highlights harmful pairs when heated. Shut-off elements must easily open from the inside, without jamming - for example, latches.

Important. The threshold to the bath (and the steam room) provide for a height of at least 15 cm to avoid speaking - heat leaving in the slot under the door.

Getting processed

The door design consists of two parts - boxes and canvas. First you need to make the door frame yourself, then the canvas and connect them with the help of loops. The door leaf is a single or two-layer connection of boards framed by or without it. Box - frame made up of bars and placed in the opening of the door. The whole process of manufacturing and installing the door implies four stages:

- preparation of the opening, the creation of the souls;

- making box;

- door leaf (in frame or without it);

- installation of construction.

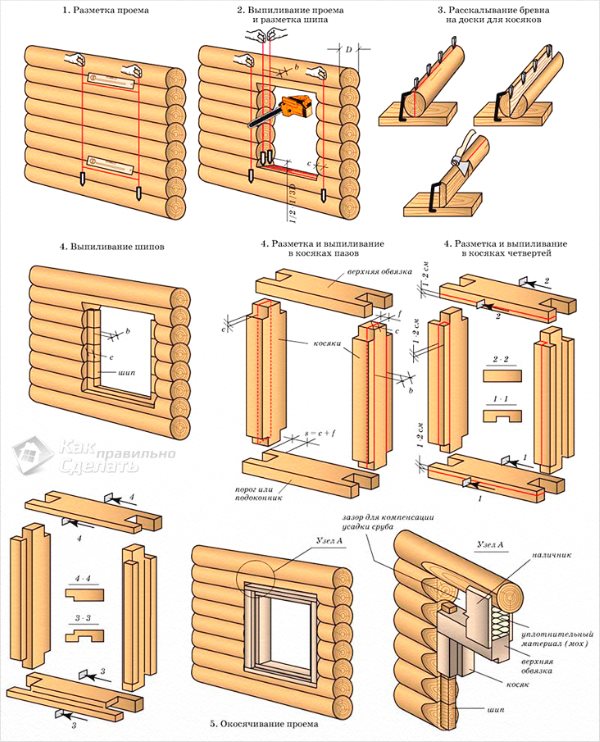

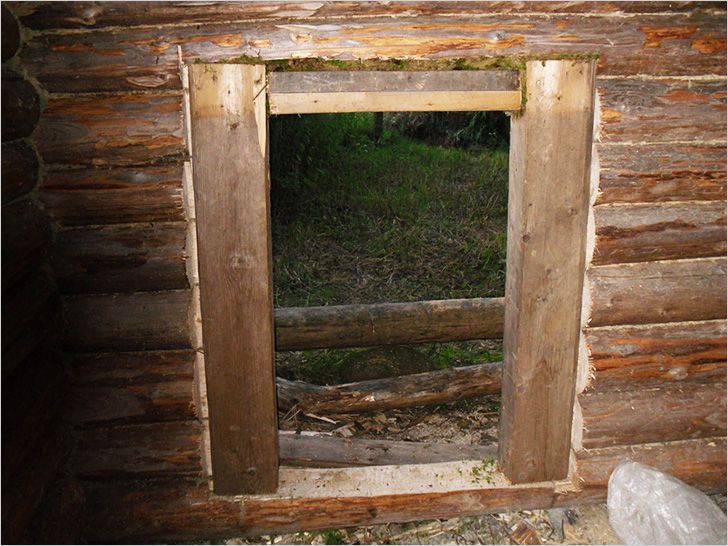

Stage 1. Preparation of the opening. Adjust the size of the opening in width and height of the door. In the middle of the log logs vertically, 50 * 50 mm grooves are selected vertically on both sides - under the sample bars with the same dimensions to which the box are then attached.

Stage 2. Creating a box. Make a box for 50 mm thick bars - two vertical racks and two horizontal crossing. At the ends of the crossbreak, the spikes are cut out, and the grooves are made in the racks - the connection "in the joint" is not applied, as it is not strong enough. Collected box It is installed in the opening, fixed to the scene by wooden wedges, the vertical structure is controlled by the level. From the outside of the box around the perimeter, a quarter is selected - the landing place for the door canvas. For loops, the gap is selected 2-3 mm.

Stage 3. Production of the door leaf. Appearance Doors in the bath largely depends on the canvas. It can be:

- from boards;

- from boards with strapping;

- pilencated.

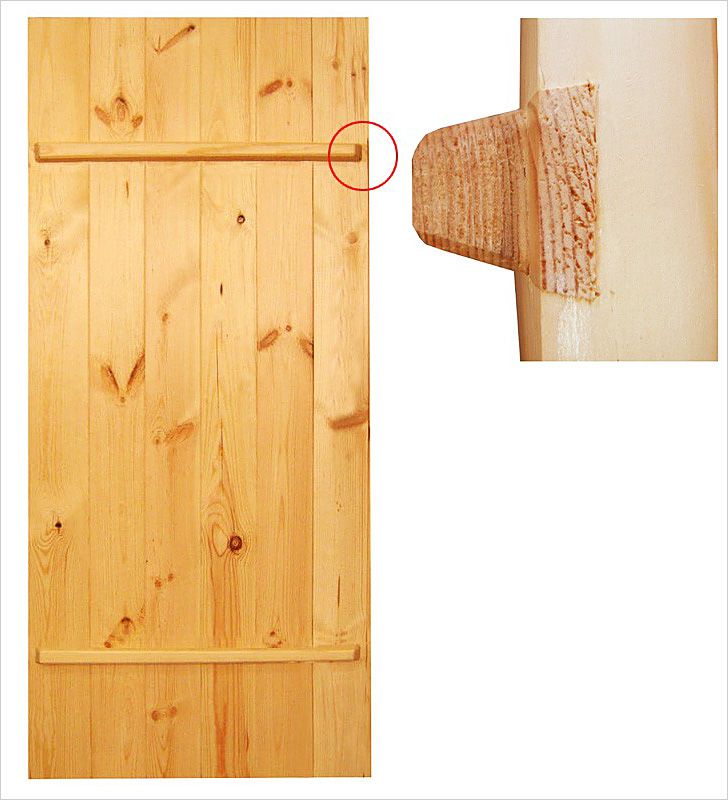

The steam room can be the most simple - from the boards without a frame, "under ancient":

- Place and measured on the size of the board (better sex), the planer smoothed the surface.

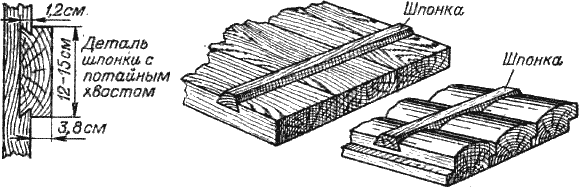

- By any of the three ways: smooth ends on the glue or without it, the spanning ("spike-groove") or the quarters selected along the edge one on top of another. Select grooves, spikes or a quarter from the edge yourself, using a milling mill, or purchase ready-made headboards.

- Connect the connection with transverse and diagonal bars (donas) from the outside. The obvious way is to screw the transverse crossbars with self-draws. The masters make a sample-deepening on the surface under the transverse and diagonal bars using a mill or hacksaw with a chisel. Experienced joiners make this deepening of a special type of "Lastochka Tail".

- Issuate loops (in such a structure, glowing samples are appropriate), housing, it is customized that the sash fits tightly, there was no distortion.

The door to the steam room can be with a strapping - a timber that is attached around the perimeter of the canvas. Pre-in the strapping choose the grooves for the canvas. Additionally, the groove compound is strengthened with self-draws. The dimensions of the canvas of such a model are reduced by the value of the strapping bar, given that the entire door should go into a box without large gaps. Step by step proceed as follows:

- Placed and cut off the length of the box vertical bars of the strapping frame.

- Grooves are made from their inner side - the canvas and spikes of horizontal upper and lower strapping bars will enter here.

- The finished canvas is adjusted in size - its length in the amount of the width of the upper and lower strapping bars should be equal to the length of the vertical boards.

- In the transverse bars at the ends, spikes are made with the calculation of their entry into the grooves of vertical parts.

- The whole design is assembled, the corners are aligned (strictly 90 ̊). Reinfect connections are fixed with wooden wrenches or self-drawing.

Experienced masters forces to make the door to the bath with their own hands of a complicated design - a panel, with numerous fililene inserts in a frame consisting of several transverse and longitudinal boards. The principles of the connection are the same - "Schip-groove", inserts are included in the grooves, without the use of glue or self-tapping. This door is simultaneously durable and ensures the mobility of the elements to avoid timber cracking when the design is expanding the compression.

Stage 3. Installation. After the box and the door leaf are ready, it remains to install the door in the bath, observing several conditions:

- The door box is mounted to the stack or in a specially made groove of the opening, which should be 1-1.5 cm wide - first, for free manipulations to equalize the design, secondly, taking into account the further shrinkage and movement of the bar and the door.

- need, observing the rules fire safety: The door should open out. For this, the sample of a quarter is made from the outside.

- When hanging the canvas to avoid breaks, it is recommended to use three pairs of loops: from above, below and in the middle. The distance from the corner point of the sash to the loops -20-25 cm.

Entrance doors for metal bath: installation features

To put the door to the bath, it is not necessary to make the entire input design with your own hands. It is enough to limit the search for a suitable option on the market and install yourself. Choose, plastic or metal.

It is advisable to put the iron door to the bath, the owner decides: such a model is more reliable than others protect the room, but it is harder, rust under the influence of moisture. Therefore, it is preferable steel door A bath with an anti-corrosion powder coating, although its price is higher.

In addition, the rigid metal design does not give a shrinkage as the living around it. When a label, the log house can hang on the door, whose skew to one millimeter leads to its locking. Installation of the iron door in the bath is carried out with regard to this fact - necessarily make a dock-eyed:

- In the opening on both sides, grooves are made, which are equipped with a special wooden chain.

- The cluster bars are tightly attached only to the lower logs, serving a kind of guide for navigating the upper logs.

- A wooden box is fastened to the opposite, and it is, in turn, the rail door is mounted in a bath.

- From above, the box is left with 2-4 cm for a possible shrink shrink. Seam is woven, insulating, hiding under the platbands.

Given the high weight of the door, the barbs for the souls and boxes should be quite thick.

Installing the door to the bath, built of brick or foam blocks, does not differ from such work in residential premises. Metal design It is recommended to insulate, insulating accessories - in winter, a handle with a lock can be caught.

Make and put the door to the bath with your own hands - not a simple, but the sink type of work that brings satisfaction that allows you to reasonably save and buy useful carpentry skills.

For the Russian soul, the bath has always been a place for a special, cleansing and body and soul, folk craftsmen independently performed all the difficult work in the construction of a bath. A real wooden steam room - isn't it joy for everyone who has a private house? Of course, now there is an opportunity to order a house with a stove and steps, but wouldn't it be better to understand your own in business and build your best Banke?

It is impossible to say that the occupation is simple, there are many nuances, important aspectsYou need to understand and remember when working constantly: both materials and types of wood, and assembly, and sizes - everything is important! But what is most important, so this door! It is unpleasant when suddenly in the middle of swimming suddenly stretch a cold draft or suddenly the output will open, or suddenly the door swings, which is even worse, if everything is already at the limit of his forces - there is no time at all before the war with a naughty doorway from the trimmed tree.

In this article we will talk about how to step by step to make a wooden door to a bath with your own hands and you will see that all of the above can be avoided if you take the case with the mind and all accuracy.

How to make the door to the steam room?

The main requirement for the doorway in the bath is excellent thermal insulation - it is necessary that the heat remains inside and did not succeed out, that is, the door should fit tightly to the door frame, and that in turn does not have slots along the wall. Therefore, everything will be extremely important for us: making, insulation, installation and result, of course.

To date, there are many firms that will offer you the door to the bath, perhaps it will even be good in all respects, except for one price. Unfortunately, all goods that relate to the steam room have an exorbitantly high cost, which is completely unreasonable. In fact, make a wooden door to himself much cheaper.

How to make a door for a bath with your own hands: Preparing for work (with photos)

Sizes and nuances

So, for a start, we will define the parameters. The input itself should not be higher than 170 cm, otherwise the leakage of precious heat into the street risks. Between the jambs, it is best to leave a distance of 60-70 cm, despite the fact that such dimensions may seem uncomfortable to someone and are too small, it is also necessary that there is a sufficient obstacle to hot temperature air.

Single or confused, bivalves? We choose a less royal version - the door with one sash will be more profitable - when someone will go or go out, while others remain inside, even the smallest door will run a lot of coolness, not to mention the one that swallows on both sides. In addition, it should open.

Typically, the bath involves the installation of two doors - one leads to the pre-banner, and the other directly into the steam room. Sometimes the front room also serves as the washer, so they do in particular when the budget is limited and the box of miniature sizes itself.

Materials

- Wood. It is considered an ideal version of the time of time, it is from ancient times from ancient times the doors for Older Russian baths. The thing is that the tree perfectly withstands moisture drops in the air and temperature regime. By the way, the accessories on the door can also be done only from the tree - otherwise you can get a burn.

- Glass. This option appeared in everyday life recently and acquired even some popularity - it looks quite exquisite and stylish, although unusual Russian eye. It may seem that it is indefinitely, and temperatures are high, nevertheless you have to dissuade you. Indeed, the glass is not too durable, but it is possible to quickly run out of their room in the event of an unforeseen situation. And about the degrees Celsius, one can say one thing - heat-resistant glass withstands extremely high grades.

But plastic is not best ideaIt is indeed very subject to the effect of temperature and can simply change its outlines beyond recognition.

What tree to choose and how to process it? For centuries, a proven option is tightly choped boards from the linden. This tree is ideal for all parameters for use in a wet space. In addition, it is said that it has some esoteric properties and can fill a person with positive emotions, energy. If you are skeptical about these believers, you will be killed by the facts: this wood contributes to the abundant release of sweat, which is perfect for the wage, where slags and toxins are removed, and the structure of the material is soft, it will be comfortable in operation and beautifully as a result.

You can use conifers - they smell perfectly, give a persistent unsurpassed fragrance of forests throughout for long years And only one minus - resin. Before choosing a larch, think over several times how you will process from constant liquid release.

Aspen is also good, although it does not possess many qualities of linden and needles. The structure is hardworth and when heated will be distinguished by a pleasant bitter aroma.

Of course, the inner surface will need to be impregnated with an antiseptic solution, the same as all walls in the room.

You can not use olif or varnish, these substances are becoming poisonous with increasing temperature and will poison those who want to improve.

Insulation

When the basis is ready, go to an equally important part of the program - insulation. Here you can use everything: wool, foam, felt, pass. If you do not have enough finance or do not want to acquire something in the store once again, but after repairing unnecessary plywood, as it often happens, it is quite possible to put it in this stage. The main thing is to allow the deformation of the door canvase.

How to make a bath door with your own hands: Step-by-step instructions

So, we have decided on the most important parameters - material, insulation, sizes. We will produce from wood, and for example, will take a standard size of 1.8 mx 0.7 m.

- The first thing we take the board, remember that the quality is above all, the thickness is at least 5 cm. You can use store sheets or home, but take into account the selected punch.

- Further put on a plank in a row and equal to each other. Here you can use the simple and well-known PVA glue - we sample the hiring and all keeps on the ground.

- When our canvas smears, sketch marked on the samples of the grooves. And we will make them in the form of a cone with a truncated top, the recess should be half the board, and the base is 5 cm, and top 35 mm.

- Let us give out the deepening on our notes with the help of award-award saw and we make two identical inscribed, an angle of 45 degrees, and in depth - a quarter or half of the board. Little trick - for coincidence of the corners, fasten the timber, shared according to the same parameters.

- Now use the chisel - we remove the remaining wood and put the swords. It is possible and larger than 5 cm.

- Then we all collect and check how dense it came out, after which the bars can be removed and checked for shortcomings.

- If everything is in order to insert them back, only now we are already planted with a lot - dry and for strength with glue, this is a final chord - from how well you put them will depend on the reliability and duration of the service life of the entire door.

Installation of the door leaf to the log house: Bath door do it yourself

Now part of the work is really behind, but still ahead there is still a lot - you need to put the resulting door to your rightful place. If at this stage, make mistakes, each time the door will sweat the door from moisture and expand - and this leads to a deplorable results - either to suffer and every time it is with difficulty open-to close it, or constantly keep it. Further fungus and disruption will be followed. Therefore, the fililene frames are so firmly entered into use - because the door canvas will only swell on two vertical beams, and the sealers themselves are put in increments of 4 millimeters, so they do not depend on concomitant circumstances.

It is important to know that it is possible to engage in the installation of the doorway only when the log house itself has already been fully established, which means no less than 6, and better than 8 months from the date of construction. Otherwise, you are hard to risk getting large cracks and twisted input.

We put the entrance wooden door for a bath, with a photo

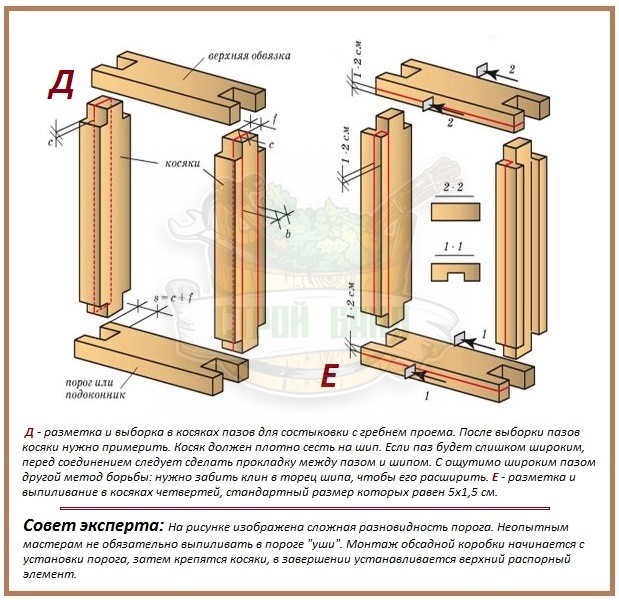

- Determine the dimensions. For example, the door canvas we have 80 millimeters in thickness, which means the box of the box to be equal to 120, and in a thickness of 50 mm. That is, we make two vertical racks - the one that will be with hinges and the opposite, as well as two horizontal with a cross section of 5 to 8 cm.

- Now we make two vehicles 1.80 m two 5 cm. In these billets, chosen a quarter for the door itself. If this tool is not available, you can take a simple milling mill and manually work. We do it in the same plane - relatively longitudinal faces in parallel. It is necessary to avoid the appearance of the gaps.

- On the side where the loops will be located, supply the outline for the sash and with the help of a milling ager we create a remission for them, exactly what is needed under this thickness - do not need to drag them hard in the wood - the door will be badly discovered. Now we decide on the table long, and from above quaternary blanks.

- With the loop side by the wedges we make a small gap, just a couple of millimeters, and the other - more - here you need about 5 mm., Only then your door will move freely.

- We combine longitudinal strips with transverse and measure their length, cut them with a hacksaw.

- In the corners, we make a quarter and all parts of the door in between themselves. The box should be in a disassembled state to put the cloth and insert the loops on it. At the same stage, the angles are checked - they must be straight.

- Now that everything is ready, fully assemble and fix the loops with the help of screws 2 on all joints. For greater strength to avoid the appearance of cracks over time, you need to do a half-millimeter.

Now check the performance of the structure and if everything went successfully, it must freely open and close, while tightly leaned towards the box.

How to make a bath door do it yourself, video

Making doors for baths do it yourself, video

The manufacture of the door to the bath is no less important than the installation of waterproofing and insulation of walls and ceilings. This is due to the fact that even the presence of a small gap in doorway It will be significantly reduced by the level of heat in the premises, especially in winter. To ensure high-quality thermal insulation, you need to make doors and frames without gaps, as well as use dense wood. In addition, the presence of increased moisture in the premises, which adversely affects the materials.

Special load goes to the outer door, because it, on the one hand, is subject to low temperaturesand on the other - high. As a result, the dew point may be on the inner surface and the door rotes from the inside. These main factors are taken into account when designing.

From this article you will learn how to make the door to a bath with your own hands, as well as watch the photo and video instructions.

Specificity of material selection

These basic requirements are presented to the doors:

- Must withstand temperatures up to 100 ° C, do not crack from heating and not swell from moisture.

- Have minimal dimensions in order to reduce heat loss when opening / closing.

- The surface of the doors should not be processed by the compositions that are evaporated when heated.

- Made from wood breeds with minimal resins.

Therefore, if the choice is made in favor of the tree, then deciduous breeds, such as aspen, linden, oak are chosen. You can also use coniferous, but they will have trouble, and then apply protective covering. When building a modern bath bath, you can choose glass or heat-resistant plastic doors. Glass is the most favorable materialSince it is not exposed to moisture and heat, has a long service life. It is enough to choose shockproof thick glass for this purpose.

Note! Plastic doors to put in the bath you need only qualitative, as otherwise, the material from which they are made can lose their decorative properties and shifted literally for several years.

In the manufacture of wooden doors, the following lumber will be needed:

- Bar from which the door frame will be made. When choosing sizes, you need to focus on the thickness of the walls in the bath, so that the box does not drank, and harmoniously fit into the opening. It is usually enough timber with a cross section of 50x100 mm.

- Bar designed for door strapping, with a cross section of 50x50 mm.

- Edged board for flooring of the door leaf. The thickness of the boards is chosen thinner of a 5 mm timber.

All purchased material should be inspecting for such defects as non-compliance with the stated size, overcasts after processing, the presence of rot and holes from the knots. If any, then you need to give up from shopping. In addition, the material must be dried by a natural way. If you take boards dried for short term Or on the wrong technology, then when operating, they may be blocked, and as a result, not only the door, but the whole box is deformed.

Not any material is also suitable as fittings. It should have not only elevated properties of resistance to moisture and high temperatures, but also not heated to a large extent. Especially this concerns the door handle, clicks and grazing. Consequently, you need to stop your choice on a tree or plastic.

Note! The loops need to take powerful, with anti-corrosion protection.

Dimensions of doors

The size of the door should be as minimal, but sufficient for the person to go to the bath. This is due to the fact that it is required to reduce the yield of heat from the premises. For example, if there is a temperature of -30 ° C on the street, and indoors for recreation + 25 ° C, then the door accounts for a load with a difference between 55 ° C, with a thickness of much less than at the walls. For the steam room, the temperature difference even more, as it is not possible to make it from a thick bar, because it will be too heavy. Therefore, the doors for the baths and saunas should have the following dimensions:

- Height not more than 1.7 m.

- The width does not exceed 0.7 m.

- Threshold to reduce drafts on the floor, must be at an altitude of at least 15 cm.

The entrance door to the bath from the street can be made standard sizes.

Manufacture of door web

For the manufacture of the door leaf, you will need smooth with small roughness boards. If there is no possibility to purchase them, they can be made independently on the milling machine or with a hand cutter. In the absence of inspection of joinery work, contact a specialized workshop. The boards are cut according to the necessary dimensions that should take into account the fact that the bottom of the bottom will be formed from above, and the part of the spike boards will be hidden. With a horizontal version, you will have to consider the size of the strapping and the size of the grooves in which the canvas is inserted. Then proceed to the creation of a smooth surface of the canvas with a roughness of not more than 0.1 mm. This will require the removal of a small layer with each side of no more than 2 mm.

The web is assembled initially in rough form in order to create a tight connection and get the minimum connecting seams. If there are significant irregularities on the rubber or spikes, they will have to be carefully removed. With loose connections, you need to try to collect various combinations of boards. When the cloth is ready, the upper and lower board are removed, and then the rest is aligned clearly in size by dipping on the circular. After that, the grooves are lubricated with a uniform layer of wood glue and are connected by means of dense pressed. For a high-quality connection, each connected board must be carefully meditated with a wooden hammer without damaging the spikes. The finished canvas leave to dry for a few days, after which it is inspected for the presence of slots and irregularities that should be eliminated.

Manufacturing door strapping

The strapping is made in this way:

- bars are taken and cut down the length of the canvas with a reserve on half of its thickness to form a compound with horizontal strapping;

- then there are two more bars across the door width;

- with the help of hand cutters, the grooves in two bars are formed, to fix the web, and in the rest - the spikes of suitable sizes are cut;

- the strapping is assembled without canvas and is checked for the presence of irregularities and gaps.

When the binding is ready, it is built with a cloth. At the same time, adherence to direct corners is checked. If this fails to do this, the grooves are dotted to the desired size.

Testing door clapboard

Note! Before covering the door, the door is processed by an antiseptic, and then covered with a layer of vaporizolation.

In the width of the opening, the blanks of the lining. The board is manufactured, which will be located diagonally the canvas from the inside, after which it is fixed on the self-tapping screw. In the formed space between the blade and lining, the insulation is laid. Further stacking is performed. The first is sticking to the strapping and leveled with the end part of the door in order to prevent the distortion. Next, the remaining elements of the casing are stacked.

Box manufacture

For assembly door box Bar is taken and cut to the desired length. Then, with the help of a cutter in a vertical rack, two recesses in one-quarter width and a length equal to the thickness of the timber with a slight nasha in 5 mm are done at the ends of the bar. I need to be needed so that the tree can climb moisture and did not believe the design. Similarly, another box for the box is manufactured. After that, make two transverse timber with response grooves at the ends. The bar should pick up with a minimum number of bitch.

Note! The lower part of the door frame will be used as a threshold, and perform over the floor surface by 15 cm.

Then the finished parts of the box are laid out on a flat surface, and the correctness of the connections is checked. Corners must be straight. Then the box should be finally copped with glue, as well as check the fit of the door to it. If all actions are configured correctly, and the result is satisfactory, then then mark the places of fastening for the loops, which are then screwed up with self-draws to the door and to the box. In the middle of the doors screw the third loop, which will prevent the deformation.

Note! Distances from the top and bottom to the loops should be at least 25 cm.

Installation

Installing the door frame requires the preparation of grooves in the wall. They are convenient to cut through with a grinder, and the remnants hollow over the chisel. The width of the opening should be more than 5 mm than the box, for the possibility of accurate installation in a vertical position. Then carefully the box is inserted into the grooves and immediately aligns. Rama is finally attached to the dowel. Then hang the door on the loop and close the gaps closely, which it forms with a box with the help of felt. The gap between the frame and the wall should also be hampered by felt, and from above to fill the platbands.

Note! Doors should open out.

At the final stage of installation, door handles are screwed, and is installed on the inside of the casuals or a junk.

The manufacture of doors for the bath process is quite complicated because it requires experience in carpentry work. In addition, you should choose the right to choose the appropriate materials and to handle them.

Video

This video shows the installation wooden doors in wooden Siruba Baths: